ASPHALTopics | Fall 2015 | VOL 28 | NO 3

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

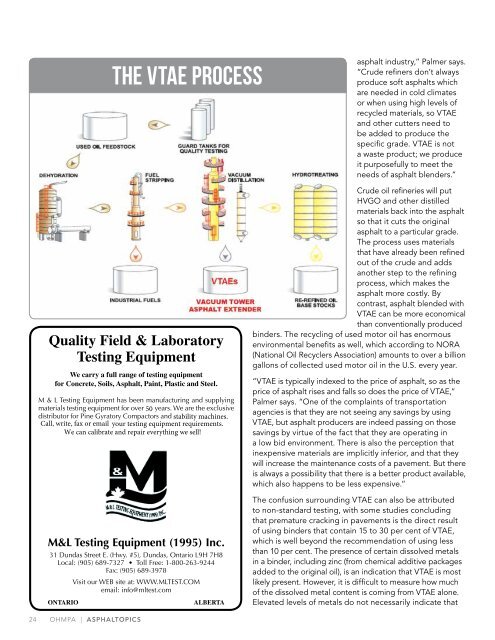

The VTAE Process<br />

asphalt industry,” Palmer says.<br />

“Crude refiners don’t always<br />

produce soft asphalts which<br />

are needed in cold climates<br />

or when using high levels of<br />

recycled materials, so VTAE<br />

and other cutters need to<br />

be added to produce the<br />

specific grade. VTAE is not<br />

a waste product; we produce<br />

it purposefully to meet the<br />

needs of asphalt blenders.”<br />

Crude oil refineries will put<br />

HVGO and other distilled<br />

materials back into the asphalt<br />

so that it cuts the original<br />

asphalt to a particular grade.<br />

The process uses materials<br />

that have already been refined<br />

out of the crude and adds<br />

another step to the refining<br />

process, which makes the<br />

asphalt more costly. By<br />

contrast, asphalt blended with<br />

VTAE can be more economical<br />

than conventionally produced<br />

binders. The recycling of used motor oil has enormous<br />

environmental benefits as well, which according to <strong>NO</strong>RA<br />

(National Oil Recyclers Association) amounts to over a billion<br />

gallons of collected used motor oil in the U.S. every year.<br />

50<br />

stability machines.<br />

Call, write, fax or email your testing equipment requirements.<br />

We can calibrate and repair everything we sell!<br />

“VTAE is typically indexed to the price of asphalt, so as the<br />

price of asphalt rises and falls so does the price of VTAE,”<br />

Palmer says. “One of the complaints of transportation<br />

agencies is that they are not seeing any savings by using<br />

VTAE, but asphalt producers are indeed passing on those<br />

savings by virtue of the fact that they are operating in<br />

a low bid environment. There is also the perception that<br />

inexpensive materials are implicitly inferior, and that they<br />

will increase the maintenance costs of a pavement. But there<br />

is always a possibility that there is a better product available,<br />

which also happens to be less expensive.”<br />

The confusion surrounding VTAE can also be attributed<br />

to non-standard testing, with some studies concluding<br />

that premature cracking in pavements is the direct result<br />

of using binders that contain 15 to 30 per cent of VTAE,<br />

which is well beyond the recommendation of using less<br />

than 10 per cent. The presence of certain dissolved metals<br />

in a binder, including zinc (from chemical additive packages<br />

added to the original oil), is an indication that VTAE is most<br />

likely present. However, it is difficult to measure how much<br />

of the dissolved metal content is coming from VTAE alone.<br />

Elevated levels of metals do not necessarily indicate that<br />

24 OHMPA | ASPHALTOPICS