March 3 - 5,1999, Karlsruhe, Germany - FZK

March 3 - 5,1999, Karlsruhe, Germany - FZK

March 3 - 5,1999, Karlsruhe, Germany - FZK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

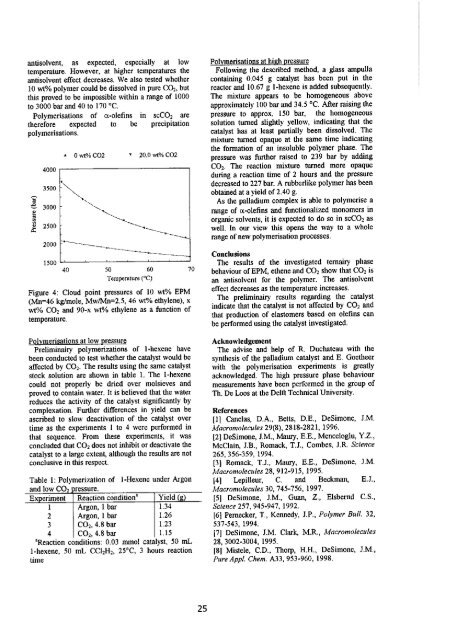

antisolvent, as expected, especially at low<br />

temperature. However, at higher temperatures the<br />

antisolvent effect decreases. We also tested whether<br />

10 wt% polymer could be dissolved in pure CQ2, but<br />

this proved to be impossible within a range of 1000<br />

to 3000 bar and 40 to 170 °C.<br />

Polymerisations of a-olefins in scC0 2 are<br />

therefore expected to be precipitation<br />

polymerisations.<br />

Pressure (bar)<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

* 0 wt% C02 ' 20.0 wt% C02<br />

- \<br />

. \ .<br />

-1<br />

\<br />

i 1 1— 1 J 1<br />

40 50 60 70<br />

Temperature (°C)<br />

Figure 4: Cloud point pressures of 10 wt% EPM<br />

(Mn=46 kg/mole, Mw/Mn=2.5, 46 wt% ethylene), x<br />

wt% C0 2 and 90-x wt% ethylene as a function of<br />

temperature.<br />

Polymerisations at low pressure<br />

Preliminairy polymerizations of 1-hexene have<br />

been conducted to test whether the catalyst would be<br />

affected by C0 2. The results using the same catalyst<br />

stock solution are shown in table 1. The 1-hexene<br />

could not properly be dried over molsieves and<br />

proved to contain water. It is believed that the water<br />

reduces the activity of the catalyst significantly by<br />

complexation. Further differences in yield can be<br />

ascribed to slow deactivation of the catalyst over<br />

time as the experiments 1 to 4 were performed in<br />

that sequence. From these experiments, it was<br />

concluded that C0 2 does not inhibit or deactivate the<br />

catalyst to a large extent, although the results are not<br />

conclusive in this respect.<br />

Table 1: Polymerization of 1-Hexene under Argon<br />

and low C0 2 pressure.<br />

Experiment Reaction condition Yield (g)<br />

1 Argon, 1 bar 1.34<br />

2 Argon, 1 bar 1.26<br />

3 C02,4.8bar 1.23<br />

4 C02,4.8bar 1.15<br />

"Reaction conditions: 0.03 mmol catalyst, 50 mL<br />

1-hexene, 50 mL CC12H2, 25°C, 3 hours reaction<br />

time<br />

25<br />

Polymerisations at high pressure<br />

Following the described method, a glass ampulla<br />

containing 0.045 g catalyst has been put in the<br />

reactor and 10.67 g 1-hexene is added subsequently.<br />

The mixture appears to be homogeneous above<br />

approximately 100 bar and 34.5 °C. After raising the<br />

pressure to approx. 150 bar, the homogeneous<br />

solution turned slightly yellow, indicating that the<br />

catalyst has at least partially been dissolved. The<br />

mixture turned opaque at the same time indicating<br />

the formation of an insoluble polymer phase. The<br />

pressure was further raised to 239 bar by adding<br />

C0 2. The reaction mixture turned more opaque<br />

during a reaction time of 2 hours and the pressure<br />

decreased to 227 bar. A rubberlike polymer has been<br />

obtained at a yield of 2.40 g.<br />

As the palladium complex is able to polymerise a<br />

range of a-olefins and functionalized monomers in<br />

organic solvents, it is expected to do so in scC0 2 as<br />

well. In our view this opens the way to a whole<br />

range of new polymerisation processes.<br />

Conclusions<br />

The results of the investigated ternairy phase<br />

behaviour of EPM, ethene and C0 2 show that C0 2 is<br />

an antisolvent for the polymer. The antisolvent<br />

effect decreases as the temperature increases.<br />

The preliminairy results regarding the catalyst<br />

indicate that the catalyst is not affected by C0 2 and<br />

that production of elastomers based on olefins can<br />

be performed using the catalyst investigated.<br />

Acknowledgement<br />

The advise and help of R. Duchateau with the<br />

synthesis of the palladium catalyst and E. Goetheer<br />

with the polymerisation experiments is greatly<br />

acknowledged. The high pressure phase behaviour<br />

measurements have been performed in the group of<br />

Th. De Loos at the Delft Technical University.<br />

References<br />

[1] Canelas, D.A., Betts, D.E., DeSimone, J.M.<br />

Macromolecules 29(8), 2818-2821, 1996.<br />

[2] DeSimone, J.M., Maury, E.E., Menceloglu, Y.Z.,<br />

McClain, J.B., Romack, T.J., Combes, J.R. Science<br />

265, 356-359, 1994.<br />

[3] Romack, T.J., Maury, E.E., DeSimone, J.M.<br />

Macromolecules 28, 912-915, 1995.<br />

[4] Lepilleur, C. and Beckman, E.J.,<br />

Macromolecules 30, 745-756, 1997.<br />

[5] DeSimone, J.M., Guan, Z., Eisbernd C.S.,<br />

Science 257, 945-947, 1992.<br />

[6] Pernecker, T., Kennedy, J.P., Polymer Bull, 32,<br />

537-543, 1994.<br />

[7] DeSimone, J.M. Clark, M.R., Macromolecules<br />

28, 3002-3004, 1995.<br />

[8] Mistele, CD., Thorp, H.H., DeSimone, J.M.,<br />

Pure Appl. Chem. A33, 953-960, 1998.

![{A1[]Sp - Bibliothek](https://img.yumpu.com/21908054/1/184x260/a1sp-bibliothek.jpg?quality=85)