Cooling Towers 9.30.20

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.b-ct.net<br />

Sight-Specific Customized to<br />

Your Equipment and Facility<br />

<strong>Cooling</strong> Tower/<br />

Chiller<br />

General<br />

Operations<br />

Illustrations and Notes arranged by<br />

Sedley Parkinson, Instructor<br />

B & CT Training LLC<br />

www.b-ct.net<br />

Sep 2020

Contents<br />

Fluid Dynamics ........................................................................................................................................................................ 3<br />

Valves .................................................................................................................................................................................. 3<br />

Water Hammer: Valve Induced....................................................................................................................................... 5<br />

Backflow Prevention ....................................................................................................................................................... 6<br />

Pumps.............................................................................................................................................................................. 7<br />

Water Flow Dynamics and Electricity Correlation .......................................................................................................... 9<br />

Psi ...................................................................................................................................................................................... 10<br />

Vapor Pressure .............................................................................................................................................................. 10<br />

Pressure Measurement ................................................................................................................................................. 12<br />

Ideal Gas Law ................................................................................................................................................................ 13<br />

Heat Pumps ................................................................................................................................................................... 14<br />

Water ................................................................................................................................................................................ 17<br />

°F vs. Btu ........................................................................................................................................................................ 17<br />

Steam Table................................................................................................................................................................... 22<br />

Water to Ice Expansion ................................................................................................................................................. 23<br />

pH .................................................................................................................................................................................. 24<br />

Aquastat ........................................................................................................................................................................ 25<br />

Antifreeze ...................................................................................................................................................................... 26<br />

Pressure Reducing Valve (PRV) ..................................................................................................................................... 28<br />

Heat Exchangers ............................................................................................................................................................ 31<br />

Electricity ............................................................................................................................................................................... 32<br />

DC vs AC ............................................................................................................................................................................ 32<br />

VFD: Affinity Law ............................................................................................................................................................... 33<br />

LEED Program .................................................................................................................................................................... 34<br />

Thermocouples ................................................................................................................................................................. 35<br />

The Grid ............................................................................................................................................................................. 36<br />

<strong>Cooling</strong> <strong>Towers</strong>: Dynamics .................................................................................................................................................... 37<br />

Saturation Curve ........................................................................................................................................................... 37<br />

Evaporative <strong>Cooling</strong> ...................................................................................................................................................... 40<br />

Relative Humidity .......................................................................................................................................................... 41<br />

Psychrometric Chart ...................................................................................................................................................... 42<br />

Size: Tonnage ................................................................................................................................................................ 44<br />

<strong>Cooling</strong> Tower Types ..................................................................................................................................................... 45<br />

<strong>Cooling</strong> Tower Components .............................................................................................................................................. 50<br />

pg. 1

Fill .................................................................................................................................................................................. 50<br />

Water Level Controllers ................................................................................................................................................ 53<br />

Immersion Heaters ........................................................................................................................................................ 54<br />

<strong>Cooling</strong> Tower Scale .......................................................................................................................................................... 55<br />

Source: CaCO 3 and Silica ............................................................................................................................................... 55<br />

Prevention ..................................................................................................................................................................... 56<br />

Scale Removal ............................................................................................................................................................... 58<br />

Corrosion ........................................................................................................................................................................... 59<br />

Galvanic Corrosion ........................................................................................................................................................ 59<br />

Rust ............................................................................................................................................................................... 60<br />

Biological Growth ............................................................................................................................................................ 62<br />

Algae, Yeast, Molds ...................................................................................................................................................... 62<br />

Legionella ..................................................................................................................................................................... 63<br />

Chillers ................................................................................................................................................................................. 69<br />

History .............................................................................................................................................................................. 69<br />

Basic Composition ........................................................................................................................................................... 70<br />

Refrigerants ....................................................................................................................................................................... 75<br />

Corrosion ........................................................................................................................................................................... 78<br />

MIC ................................................................................................................................................................................ 78<br />

Eddie Current Testing ................................................................................................................................................. 80<br />

Chiller Compressor Types ................................................................................................................................................. 81<br />

Absorption <strong>Cooling</strong> ........................................................................................................................................................... 89<br />

Ammonia/Hydrogen Refrigeration ............................................................................................................................... 89<br />

Lithium Bromide (LiBr) Absorption Chillers .................................................................................................................. 90<br />

Free <strong>Cooling</strong> ...................................................................................................................................................................... 91<br />

Chiller Surge ...................................................................................................................................................................... 92<br />

pg. 2

Fluid Dynamics<br />

Valves<br />

Ball<br />

Gate<br />

Butterfly<br />

Globe<br />

Pressure Regulators<br />

are usually globe<br />

valves<br />

Diaphragm<br />

Stem pushes down on<br />

rubber gasket<br />

Spring Check<br />

Swing<br />

Check<br />

Lift<br />

Check<br />

pg. 3

Actuators remotely open and close valves<br />

Manual override<br />

Motorized actuators close slowly,<br />

avoiding water hammer<br />

A Solenoid is an electric actuator: electricity creates a<br />

temporary magnet pushing the permanent magnet down.<br />

pg. 4

Water Hammer: Valve Induced<br />

pg. 5

Backflow Prevention<br />

Symbol<br />

Backflow means the undesirable reversal of flow of a<br />

liquid, gas or solid into the potable water supply.<br />

Back-siphonage occurs when higher pressure fluids, gases,<br />

or suspended solids move to an area of lower pressure<br />

fluids.<br />

Q.: How often does the backflow prevention assembly<br />

need to be tested?<br />

A.: On installation and at least once a year thereafter by<br />

a licensed backflow tester.<br />

pg. 6

Chemical Feed Pumps<br />

Pumps<br />

Speed:<br />

How often<br />

Chemical<br />

injection<br />

quill<br />

Stroke:<br />

How deep<br />

Check<br />

valve<br />

Peristaltic Chemical Feed Pumps<br />

Pinch process does not lose prime, but<br />

tube needs to be replaced periodically<br />

pg. 7

Feed Water Pumps<br />

Horizontal Screw Feed Water Pumps<br />

Vertical Multistage<br />

(multiple impellers)<br />

Feed Water Pumps<br />

Also called a “can pump”<br />

(like a tin can)<br />

Parallel Connection:<br />

flow increase constant pressure<br />

Series Connection:<br />

pressure increase constant flow<br />

pg. 8

Water Flow Dynamics and Electricity Correlation<br />

Parallel:<br />

Amps increase, volts stay the same<br />

Series:<br />

Volts increase, amps stay the same<br />

Volts measure how hard the electricity is pushing (Electrical Force)<br />

Amps measure current, or how much electricity is flowing [Ah = Amp-hours]<br />

Watts measure how much electricity is going through the circuit (Power)<br />

Ohms (Ω) measures Resistance<br />

Note correlation<br />

Pressure: psi → Volts<br />

Flow: gpm → Amps<br />

Hydraulic HP → Watts<br />

252 calories = 1 Btu<br />

1 ft 3 of natural gas ≈ 1020 Btu<br />

1 kilowatt·hr (kwh) of electricity = 3413 Btu<br />

1 pound of Coal ≈ 9,200 Btu<br />

1 pound of gasoline ≈ 14,300 Btu<br />

1 pound of diesel or fuel oil ≈ 16,000 Btu<br />

1 Therm = 100,000 Btu<br />

1 Dekatherm (DTH) = 1,000,000 Btu<br />

0.293 Watts = 1 Btu/hr<br />

pg. 9

Psi<br />

Absolute Zero = Perfect Vacuum<br />

Vapor Pressure<br />

0<br />

Vacuum<br />

Maximum water<br />

content in air =<br />

saturation point<br />

Evaporation or<br />

Vaporization<br />

Vaporization ><br />

Condensation<br />

Vaporization =<br />

Condensation<br />

Equilibrium<br />

Pressure changes with Temperature (molecules<br />

move around more when heated)<br />

Saturation Point<br />

(Equilibrium) changes with<br />

Temperature and Pressure<br />

and becomes the<br />

Saturation Curve<br />

pg. 10

Atmospheric vs Gauge<br />

psig<br />

(gauge)<br />

psia<br />

(absolute)<br />

H 2O<br />

boiling pt<br />

Perfect Vacuum -14.7 0 °F<br />

Near Vacuum -14.5 0.2 53°<br />

Mt. Everest -5.6 9.1 157°<br />

Lake Tahoe -3.0 11.7 200.7°<br />

Sea Level 0 14.7 212°<br />

Dead Sea 0.8 15.5 215°<br />

Space = a vacuum<br />

psia = 0<br />

psig = -14.7<br />

Sea Level =<br />

1 atmosphere<br />

= 14.7 psia<br />

= 0 psig<br />

Mt. Everest = 29,029 ft<br />

LakeTahoe= 6224 ft<br />

Dead Sea = -1378 ft<br />

High altitude cooking instructions: 3500 to 6500 ft<br />

Increase simmer time to 19 min (with lower boiling<br />

temperature, it takes longer to cook food.)<br />

Vacuum<br />

pump<br />

Vacuum<br />

jar<br />

pg. 11

Pressure Measurement<br />

Bourdon Tube Gauges: flattened<br />

hollow tubes that s-t-r-e-t-c-h out<br />

when introduced to pressure.<br />

Digital pressure<br />

gauges do not<br />

need a pig tail<br />

and can<br />

automatically log<br />

measurements<br />

into a computer.<br />

Compound gauges measure both pressure<br />

and vacuum. Note: inches of mercury<br />

(a perfect vacuum = 30” Hg)<br />

0 psia = -1 bar (metric) = -100 kPa (metric)<br />

1 atm = 100 kPa = 1013 mbars = 760 mmHg = 30 inHg = 14.7 psia = 0 psig<br />

Vacuum gauge<br />

pg. 12

Ideal Gas Law<br />

When Temperature↑ and Volume stays the same, then Pressure↑<br />

= BOILER<br />

When Pressure↑ and Volume stays the same, then Temperature↑ = AIR COMPRESSOR<br />

The INTERCOOLER uses water or<br />

outside air to cool compressed<br />

air in-between stages.<br />

2 nd Stage<br />

1 st Stage<br />

When Pressure↓ and Volume stays the same, then Temperature↓ = Propane Tank<br />

ICE !<br />

P↓ × V c = T↓ : Refrigeration<br />

(Restricting Orifice)<br />

Hot<br />

Cold<br />

Various types of expansion valves<br />

Air Conditioning<br />

* Simplified for training purposes. Actual:<br />

pg. 13

Heat Pumps<br />

Around 37°F many heat pumps reach what is<br />

called the balance point where the heat pump<br />

needs to run constantly to maintain a<br />

comfortable indoor temperature. Efficiency<br />

drops as you approach this point.<br />

Reversing Valve<br />

pg. 14

Dehumidifier<br />

DEHUMIDIFIER<br />

Wood Dehumidification Kiln<br />

HVAC Dehumidification Air Handler<br />

pg. 15

Temperature<br />

: through nonmoving or solid parts<br />

: through moving substances, such<br />

as water, steam, or air<br />

: through energy waves, even<br />

travels through a vacuum (such as the sun<br />

transfers heat to Earth through space)<br />

Latent heat of<br />

liquefaction<br />

Latent heat of<br />

vaporization<br />

vaporizing →<br />

BTUs<br />

Latent Heat:<br />

BTUs<br />

← condensing<br />

pg. 16

Temperature<br />

Water<br />

°F vs. Btu<br />

@ 0 psig = 1 Atm = sea level<br />

Saturated Steam = steam at the boiling pt.<br />

Superheated<br />

(above the<br />

boiling pt.)<br />

32°F 212°F<br />

0°C 100°C<br />

970.3 BTUs to boil 1 # of H 2O<br />

Water at 32°F<br />

contains 0 BTUs<br />

(beginning point for<br />

BTU measurement)<br />

-144BTU 0BTU 180BTU 1150.3BTU<br />

Heat Content<br />

1 BTU = heat needed to change 1 lb. of water 1º F<br />

To change 1 lb of:<br />

Ice 1º F, add 0.5 Btu<br />

Steam 1º F, add 0.45 Btu<br />

How many BTUs does one pound of steam contain at 212°F at Sea Level?<br />

32 ºF water to 212 ºF water takes 180BTU/lb. 180<br />

212 ºF water to 212 ºF steam takes 970.3BTU/lb. +970.3<br />

1150.3 BTUs<br />

pg. 17

Sea Level<br />

Pressure<br />

Phases of Water<br />

°F vs psi<br />

Pressure vs. Temperature<br />

Freeze Point<br />

Curve<br />

Evaporation<br />

Curve<br />

14.7 psia<br />

= 0 psig<br />

= 1 atm<br />

= 1 bar<br />

Solid<br />

Sea Level<br />

Vapor<br />

Triple<br />

Point<br />

(not to scale)<br />

Absolute Zero<br />

(Theoretical)<br />

Temperature<br />

32°F<br />

0°C<br />

212°F<br />

100°C<br />

Solid<br />

Triple<br />

Point<br />

Vapor<br />

Where Freeze Point Curve, Evaporation Curve and Sublimation Curves Meet<br />

= 0.09psia and 32.02°F<br />

pg. 18

Freeze Dryers<br />

Home Unit<br />

Freeze Dryer<br />

Sublimation<br />

= Freeze Dryers<br />

Low temperature and pressure<br />

Vacuum<br />

Chamber<br />

2. About 90% of the food’s<br />

moisture is drawn off by<br />

sublimating the ice at<br />

temperature as low as -60º F<br />

pg. 19

Water to Vapor Expansion<br />

When Temperature ↑ and Pressure stays the same, then Volume must ↑<br />

v = 0.01672 ft 3<br />

Now imagine a 500 gallon boiler rupturing and instantly filling the<br />

building with 111,700 ft 3 (100 hot air balloons) of flash steam<br />

1865 Sultana<br />

2000 returning Union<br />

POW’s died from boiler<br />

explosion<br />

Denver: 500 gallon boiler explosion<br />

Today, the most common reasons<br />

for boiler explosions are improper<br />

purge cycle and low water cut-off<br />

failure.<br />

pg. 20

Cavitation:<br />

Implosion of low pressure steam bubbles back to water<br />

causing miniature shock waves, damaging metal surface.<br />

Propeller Cavitation<br />

Valve Cavitation:<br />

sounds like gravel<br />

moving through pipe<br />

pg. 21

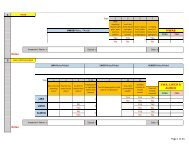

Psig<br />

Inches of Hg (Vacuum)<br />

Steam Table<br />

Gauge<br />

Pressure<br />

Psia<br />

Boiling<br />

Point<br />

ºF<br />

Btu content of<br />

1 lb. of water<br />

at B.P.<br />

Btu needed to<br />

turn 1 lb. of water<br />

at B.P. into steam<br />

Btu content<br />

of saturated<br />

steam<br />

Volume<br />

of water<br />

ft 3 /lb<br />

Volume<br />

of steam<br />

ft 3 /lb<br />

29.7 0.09 32 0 1075.8 1075.8 0.01602 3306<br />

29.5 0.2 53 21 1063.8 1085.0 0.01603 1526<br />

27.9 1.0 102 70 1036.3 1106.0 0.01614 334<br />

19.7 5.0 162 130 1001.0 1131.0 0.01641 73.5<br />

9.6 10.0 193 161 982.1 1143.3 0.01659 38.4<br />

7.5 11.0 198 166 979.3 1145.0 0.01665 35.1<br />

5.5 12.0 202 170 976.6 1146.6 0.01667 32.4<br />

3.5 13.0 206 174 974.2 1148.1 0.01667 30.1<br />

1.4 14.0 210 178 971.9 1149.5 0.01670 28.0<br />

0 14.7 212 180 970.3 1150.3 0.01672 26.8<br />

1 15.7 216 184 967 1152 0.01675 24.8<br />

2 16.7 219 187 965 1153 0.01677 23.4<br />

5 19.7 227 196 960 1156 0.01683 20.1<br />

10 24.7 240 208 952 1160 0.01692 16.3<br />

15 29.7 250 219 945 1164 0.01700 13.8<br />

20 34.7 259 228 939 1167 0.01708 11.9<br />

25 39.7 267 236 933 1170 0.01714 10.5<br />

30 44.7 274 243 928 1172 0.01721 9.4<br />

40 54.7 287 256 919 1176 0.01732 7.8<br />

50 64.7 298 267 911 1179 0.01743 6.7<br />

60 74.7 307 277 904 1182 0.01752 5.8<br />

70 84.7 316 286 898 1184 0.01761 5.2<br />

80 94.7 324 295 891 1186 0.01769 4.7<br />

90 104.7 331 302 886 1188 0.01777 4.2<br />

100 114.7 337 309 880 1189 0.01785 3.9<br />

110 124.7 344 316 875 1191 0.01792 3.6<br />

120 134.7 350 322 870 1192 0.01799 3.3<br />

130 144.7 355 328 866 1193 0.01806 3.1<br />

140 154.7 360 333 861 1195 0.01812 2.9<br />

150 164.7 366 339 857 1196 0.01818 2.7<br />

200 214.7 388 362 837 1199 0.01847 2.1<br />

250 264.7 406 382 820 1202 0.01873 1.7<br />

etc.↓ 300 417 394 809 1203 0.01890 1.54<br />

400 446 424 781 1205 0.01934 1.16<br />

450 456 437 767 1205 0.01955 1.03<br />

500 467 449 755 1204 0.01975 0.93<br />

600 486 472 732 1203 0.02013 0.77<br />

900 532 527 669 1195 0.02123 0.50<br />

1200 567 572 612 1183 0.02232 0.36<br />

1500 596 612 556 1167 0.02346 0.28<br />

2000 636 672 463 1135 0.02565 0.19<br />

2500 668 731 361 1191 0.02860 0.13<br />

2700 680 756 312 1068 0.03027 0.11<br />

3206.2 705 903 0 903 0.05053 0.05053<br />

Sea Level<br />

Supercritical Steam refers to conditions<br />

above 3206.2 psia and 705 °F where steam<br />

and water reach a new phase.<br />

pg. 22

Water to Ice to Expansion Ice<br />

Expansion<br />

slightly<br />

negative<br />

9 %<br />

slightly<br />

positive<br />

slightly<br />

positive<br />

Water to Ice Volume Expands 10%<br />

Which is about the same as:<br />

10 ft 3 water making 11 ft 3 of ice<br />

Hexagonal shape<br />

60°<br />

…, and Ice Floats<br />

(less dense)<br />

60°<br />

Breweries have high steam demand<br />

…, and breaks lines<br />

pg. 23

pH<br />

Hydrochloric Acid<br />

(HCl)<br />

H + OH -<br />

10 0 = 1 = 100%<br />

10 -14 = .00000000000001<br />

Stomach Acid<br />

(weak HCl)<br />

10 -1 = .1 = 10%<br />

10 -13 = .0000000000001<br />

Vinegar<br />

Lemon Juice<br />

10 -2 = .01 = 1%<br />

10 -12 = .000000000001<br />

The concept of pH was<br />

first introduced in 1909<br />

by Danish chemist<br />

Soda Pop<br />

Orange Juice<br />

10 -3 = .001 = .1%<br />

10 -11 = .00000000001<br />

Tomato Juice<br />

Acid Rain<br />

10 -4 = .0001 = .01%<br />

10 -10 = .0000000001<br />

Eye Drops<br />

Normal Rain<br />

10 -5 = .00001<br />

10 -9 = .000000001<br />

Saliva<br />

Urine<br />

10 -6 = .000001<br />

10 -8 = .00000001<br />

Pure Water<br />

10 -7 = .0000001 =<br />

10 -7 = .0000001<br />

Sea Water<br />

Swimming Pools<br />

10 -8 = .00000001<br />

10 -6 = .000001<br />

Baking Soda<br />

10 -9 = .000000001<br />

10 -5 = .00001<br />

Great Salt Lake<br />

10 -10 = .0000000001<br />

10 -4 = .0001<br />

Ammonia (NH4OH)<br />

Soaps<br />

10 -11 = .00000000001<br />

10 -12 = .000000000001<br />

10 -3 = .001<br />

10 -2 = .01<br />

At pH > 7, OH -<br />

(hydroxide) becomes<br />

the active ion.<br />

Bleach<br />

Oven Cleaner<br />

10 -13 = .0000000000001<br />

10 -1 = .1<br />

OH -<br />

Drain Cleaner<br />

Caustic (NaOH)<br />

10 -14 = .00000000000001<br />

H +<br />

10 0 = 1<br />

HCl (acid) + NaOH (base) → H 2O (pH 7) + NaCl<br />

(salt water)<br />

pg. 24

Aquastat<br />

Aquastat sets hot water<br />

boiler temperature ranges<br />

STRAP-ON SURFACE<br />

TEMPERATURE PROBE<br />

Temperature probe bulb<br />

fits into thermowell.<br />

Low Limit:<br />

Turns on the burner<br />

view from inside vessel<br />

Differential:<br />

Normal operating range<br />

above low limit (turns off burner)<br />

Triple Aquastat<br />

High Limit:<br />

Safety Cutoff<br />

Manual reset indicates this is a high<br />

temperature limit safety cutoff<br />

pg. 25

Temperature °F<br />

Antifreeze<br />

Prevents freezing in Closed Loops<br />

during shut downs.<br />

Refractometers use light to<br />

measure glycol’s freeze point<br />

PG<br />

C₃H₈O₂<br />

Composition<br />

EG<br />

C2H6O2<br />

Food Grade<br />

(You can drink it)<br />

Safety<br />

Toxic<br />

(Follow proper use and<br />

disposal guidelines)<br />

Nitrites are added to prevent<br />

corrosion.<br />

Cost (as of 2014)<br />

Inhibitor = Nitrites<br />

= corrosion prevention<br />

Because of safety, food-processing closed loop<br />

boilers generally are charged with Propylene<br />

Glycol.<br />

Use<br />

Because of cost, nonfood-processing closed loop<br />

boilers generally are charged with Ethylene Glycol.<br />

Glycols<br />

@

Steam Trap Trouble Shooting<br />

Pyrometer<br />

A significant drop in temperature<br />

indicates that a steam trap is<br />

functioning properly.<br />

Thermal Imager<br />

pg. 27

P↓ × Pressure V c = T↓ (Ideal Reducing Gas Law) Valve (PRV) Restricting Orifice<br />

Manual-Bolt<br />

adjust<br />

Auto-Pressurestatic adjust<br />

Auto-Thermostatic<br />

adjust<br />

Hollow Capillary<br />

Tubes<br />

Steam Pressure/Temperature Reducers<br />

operate on the exact same principles as<br />

Chiller/AC TXVs<br />

Wood drying kiln<br />

Internally Equalized<br />

pg. 28<br />

Externally Equalized

Demineralizer (DeMin Water)<br />

Not only softens the water by removing positive ions such as Ca +2 and Mg +2 but<br />

also removes undesired negative ions such as SO 4<br />

-2<br />

, Cl - , CO 3<br />

-2<br />

, HCO -3 .<br />

Single Bed Demineralizer<br />

Regeneration<br />

Mixed Bed Demineralizer<br />

pg. 29

Reverse Osmosis (Membrane Filtration)<br />

No salt or other chemicals are needed, however,<br />

the costs of replacement membranes, the<br />

electricity needed to pump the water through the<br />

membranes, and the excess higher concentration<br />

waste water all need to be calculated in when<br />

considering this form of water treatment.<br />

pg. 30

Heat Exchangers<br />

U-Tube<br />

= Two pass<br />

Shell and Tube<br />

Straight Tube =<br />

One pass<br />

Plate and Frame<br />

BPHE: Brazed Plate Heat Exchanger<br />

No gaskets<br />

Higher efficiency means<br />

equivalent heat transfer can be<br />

achieved with smaller units<br />

pg. 31

Electricity<br />

DC vs AC<br />

Error! Bookmark not defined.<br />

Tesla vs. Edison<br />

Direct Current:<br />

One Way Flow<br />

Single Phase AC<br />

Alternating Current: Switches Back and<br />

Forth from Positive to Negative<br />

Hertz = rotations per second<br />

Three Phase AC<br />

pg. 32

VFD: Affinity Law<br />

Variable Frequency Drive<br />

The Affinity Law<br />

Law 1a) Air flow is directly proportional to fan speed.<br />

Example: When fan speed doubles, air flow doubles.<br />

1a) Fan Speed ↑ = Air Flow ↑<br />

Law 1b) Torque increase is proportional to the square of the fan speed increase.<br />

Example: When fan speed doubles, torque increases four times<br />

When fan speed triples, torque increases nine times 1b) (Fan Speed ↑ ) 2 = Torque ↑<br />

Law 1c) Power required is proportional to the cube of fan speed increase.<br />

Example: When fan speed doubles, power required is six times<br />

1c) (Fan Speed ↑ )<br />

When fan speed triples, power required is 27 times<br />

3 = Power ↑<br />

Significant Energy Savings<br />

Use only the fan speed your system is calling for.<br />

A 100 HP fan running at half speed uses the<br />

same energy as a 13 HP motor!<br />

(½) 3 x 100HP = (1/8) x 100HP = 13HP<br />

Equipment Savings<br />

Single-speed motors start abruptly:<br />

High starting torque<br />

High starting current surges (up to 8 times)<br />

Variable speed drives gradually ramp up the motor.<br />

pg. 33

LEED Program<br />

In the United States and in a number of<br />

other countries around the world, LEED<br />

certification is the recognized standard for<br />

measuring building sustainability.<br />

Four Certification Levels<br />

pts possible)<br />

The LEED green building rating system -- developed<br />

and administered by the U.S. Green Building<br />

Council, a Washington D.C.-based, nonprofit<br />

coalition of building industry leaders -- is designed<br />

to promote design and construction practices that<br />

increase profitability while reducing the negative<br />

environmental impacts of buildings and improving<br />

occupant health and well-being.<br />

Out of 110 possible points<br />

LEED certification is helping to steer the HVAC industry towards higher efficient<br />

boilers and chillers. In the long run, these systems pay for themselves.<br />

<br />

☺<br />

Out <br />

In ☺<br />

pg. 34

Thermocouples<br />

A small electric current is<br />

created when heated.<br />

Thermopile:<br />

End bulb has multiple wire “twistings”,<br />

produces larger electron flow.<br />

Thermocouple:<br />

Single twisted wire sensor<br />

Temperature probe<br />

Thermopile<br />

Pilot<br />

Copper capillary tube protects the inner<br />

insulated wire and also conducts electricity<br />

back to the head where voltage can be<br />

measured (usually in millivolts).<br />

Spark Ignitor<br />

Common in<br />

atmospheric burners<br />

pg. 35

The Grid<br />

the Grid<br />

Base Load Power Plants run<br />

continuously while Intermediate and<br />

Peak Plants meet local load demands<br />

Transmission<br />

Energy Losses<br />

pg. 36

<strong>Cooling</strong> <strong>Towers</strong>: Dynamics<br />

Saturation Curve<br />

Saturation Curve<br />

1000gH20 / Kg Air<br />

all air is water vapor<br />

Equilibrium = Saturation Curve = Dew Point<br />

Water vapor in air<br />

400g<br />

300g<br />

200g<br />

100g<br />

0 K= -273°C= -460°F<br />

No water vapor in air<br />

No molecular movement<br />

Absolute zero temperature<br />

temperature increase →<br />

373 K=100°C=212°F<br />

All water vaporized<br />

(@0psig)<br />

0g<br />

Water droplets, suspended in the air,<br />

form as humid air temperature drops<br />

past the saturation curve.<br />

←temperature drop<br />

H 2O falls out as dew and frost,<br />

OR rain and snow.<br />

f<br />

r<br />

o<br />

s<br />

t<br />

d<br />

e<br />

w<br />

Freeze Point<br />

pg. 37

Air Moisture Content →<br />

Adiabatic Process<br />

Moist air rises over mountains: lower air pressure,<br />

vapor condenses on dust particles forming<br />

suspended droplets or ice crystals (clouds).<br />

Descending clouds increase in<br />

air pressure, clouds evaporate<br />

back into vapor = Rain Shadow.<br />

Rain/Snow →<br />

Temperature Increase →<br />

Same principle applies<br />

to large air masses<br />

pg. 38

Extreme<br />

Precipitation<br />

A combination of the adiabatic process and<br />

the inability of cold air to hold moisture, the<br />

Dry Valleys of Antarctica is said not to have<br />

any measurable precipitation for over<br />

2,000,000 years.<br />

The Brahmaputra Mountains in Eastern<br />

India reports the highest average rainfall of<br />

467 inches per year.<br />

pg. 39

Evaporative <strong>Cooling</strong><br />

Rapid expansion of volume during phase change (liquid to gas) =<br />

temperature drop, the lost energy is carried away by vapor molecules.<br />

Evaporation<br />

Saturation Point,<br />

the air can’t hold<br />

any more water.<br />

(Wet Bulb)<br />

New Higher<br />

Air Moisture<br />

Content<br />

Original Air<br />

Moisture<br />

Content<br />

New Lower Air<br />

Temperature<br />

Original Air<br />

Temperature<br />

Direct Evaporative <strong>Cooling</strong><br />

(effectiveness reduced in high humidity)<br />

pg. 40

Relative Humidity<br />

Relative Humidity<br />

100% 1 Kg H2O/Kg air<br />

= pure steam<br />

80% 800g/Kg air<br />

% Relative Humidity = Water<br />

content of air compared to<br />

how much water the air could<br />

hold at that temperature.<br />

50%<br />

40%<br />

30%<br />

20%<br />

10%<br />

500g/Kg air<br />

400g/Kg air<br />

300g/Kg air<br />

200g/Kg air<br />

100g/Kg air<br />

Absolute zero<br />

The higher the<br />

temperature, the<br />

more water the air<br />

can hold.<br />

100ºC<br />

Boiling Point at sea level<br />

< 100% RH: evaporation can still take place and temperature drops.<br />

Wet Bulb represents maximum possible<br />

evaporation temperature drop.<br />

100% Relative Humidity =<br />

Saturation Curve<br />

pg. 41

Psychrometric Chart<br />

Psychrometry<br />

Sling Psychrometer<br />

Digital Psychrometer<br />

(accuracy may vary, depending on model)<br />

Incoming Air<br />

Dry Bulb = 90°F<br />

@10% RH<br />

Outgoing Air<br />

Wet Bulb = 60°F<br />

@100% RH<br />

pg. 42

pg. 43

AC Size: Tonnage<br />

- 144 BTU / lb.<br />

The unit of measure used in air conditioning<br />

to describe the cooling capacity of a system.<br />

One ton of cooling is based on the amount<br />

of heat needed to melt (or freeze) one ton<br />

(2000 lbs.) of ice in a 24 hour period.<br />

1 ton cooling = 2000 lbs. x 144 BTU/lb.<br />

= 288,000 BTU/day<br />

= 12,000 BTU/hr.<br />

1000 to 5000 ton water cooled<br />

(capacity depends on RH)<br />

1 ton window AC<br />

50 ton rooftop air cooled<br />

Dry <strong>Cooling</strong><br />

No water evaporation<br />

Dry cooling can only reach<br />

down to dry bulb temperature.<br />

pg. 44

<strong>Cooling</strong> Tower Types<br />

Natural Draft <strong>Cooling</strong> <strong>Towers</strong><br />

(no electric fans)<br />

Hyperboloid Natural Draft <strong>Cooling</strong> <strong>Towers</strong>:<br />

patented in 1918<br />

hot moist air ↑<br />

Natural Draft <br />

cool air →<br />

pg. 45

Forced Draft <strong>Cooling</strong> <strong>Towers</strong><br />

pg. 46

Induced Draft <strong>Cooling</strong> <strong>Towers</strong><br />

FRP<br />

FRP = Fiber Reinforced Plastic (Fiberglass)<br />

PVC = Polyvinylchloride<br />

Wood Frame<br />

HDPE = High Density Polyethylene Plastic (Recycled)<br />

pg. 47

Cross Flow<br />

Fill Basin<br />

Splash<br />

Guards<br />

Counter Flow<br />

Drift<br />

Eliminator<br />

pg. 48

Open Recirculating<br />

<strong>Cooling</strong> Tower<br />

Fill<br />

Drift Eliminator<br />

Closed Recirculating<br />

<strong>Cooling</strong> Tower<br />

Radiator Insert<br />

Galvanized steel<br />

Closed system:<br />

Notice pipe locations<br />

pg. 49

<strong>Cooling</strong> Tower Components<br />

Fill<br />

Drift Eliminators<br />

Blade<br />

Cellular<br />

Packaged Film Fill<br />

hot water in↓<br />

hot water in↓<br />

moist air out↑<br />

hot water in↓<br />

moist air out↑<br />

moist air<br />

out<br />

cold water out↓<br />

dry air in↑<br />

cold water out↓<br />

dry air in↑<br />

cold water out↓<br />

dry air in↑<br />

pg. 50

Stackable Sheet Film Fill<br />

pg. 51

Splash Fill<br />

Horizontal<br />

V Bars<br />

Ladder<br />

Looking from the bottom up<br />

Looking from the top down<br />

pg. 52

Water Level<br />

Water Level Controllers<br />

Controllers<br />

Electric Sensor<br />

Controller<br />

Hi<br />

Alarm<br />

Hi<br />

Lo<br />

Ground<br />

Pumps &<br />

valves<br />

Conductive Liquid<br />

Ball Float<br />

Slide<br />

Diaphragm<br />

Equilibrium<br />

pg. 53

Immersion<br />

Heaters<br />

Immersion Heaters<br />

Prevents winter freezing<br />

Thermowells protect thermometers<br />

hollow<br />

pg. 54

<strong>Cooling</strong> Tower SCALE<br />

<strong>Cooling</strong> Tower Scale<br />

Source: CaCO3 and Silica<br />

CaCO3<br />

Calcium Carbonate<br />

Mg(OH) 2<br />

Magnesium Hydroxide<br />

CaSO 4<br />

Calcium Sulfate<br />

SiO 2<br />

Silica<br />

Side stream Filter<br />

pg. 55

Hardness →<br />

SCALE Prevention CONTROL #1<br />

Bleed Off<br />

Stay under the saturation point. Keep the cycles<br />

of concentration in check by using bleedoff<br />

controls.<br />

Scale<br />

forms<br />

Saturation<br />

maximum<br />

Supersaturated<br />

Conductivity<br />

set point.<br />

1 cycle<br />

= raw water<br />

2 cycles<br />

= twice as concentrated<br />

due to evaporation<br />

3 cycles<br />

= three times<br />

4 cycles<br />

Electric Motor Actuator slowly opens<br />

(helps prevent water hammer)<br />

Signals actuator to bleed off<br />

system until conductivity drops<br />

Inline probe measures<br />

how well electricity flows<br />

between electrodes in<br />

water then converts<br />

reading to Conductivity.<br />

Electromagnetic<br />

Solenoid<br />

pg. 56

Hardness→<br />

OH¯ Concentration→<br />

SCALE CONTROL #2<br />

Phosphates and pH<br />

Use scale control chemicals.<br />

Polymers/HEDP keep crystals in suspension.<br />

Phosphonates disrupt formation of crystal lattices.<br />

Nalco solid chemical dissolver/dispenser<br />

New maximum<br />

Proper use of chemicals<br />

raises the saturation line,<br />

enabling higher cycles and<br />

water conservation.<br />

Supersaturated<br />

New conductivity<br />

set point.<br />

Old saturation<br />

maximum<br />

From 2.5<br />

to 3.4 cycles<br />

1 cycle 2 cycles<br />

3 cycles<br />

4 cycles<br />

SCALE CONTROL #3<br />

IF pH is high, add acid.<br />

High concentration of<br />

OH¯ ions (high pH)<br />

lowers the solubility of<br />

calcium carbonate, it<br />

precipitates out and scale<br />

forms.<br />

Scale<br />

forms<br />

7 pH → 9 10 11 12 13 14<br />

pg. 57

Scale Removal<br />

Pressure Spray & Vacuum<br />

CaCO 3 + 2HCl (acid) CaCl 2 + H 2 O + CO 2 (gas)<br />

Dilute HCl<br />

Scale Chips<br />

Acid<br />

(Inhibited with Nitrites)<br />

Municipalities generally do not accept pH

Cathode<br />

Corrosion<br />

Galvanic Galvanic<br />

Corrosion<br />

Corrosion<br />

mild steel vs stainless steel<br />

brass vs steel<br />

Metal<br />

Oxides↓<br />

Cathode<br />

(zero corrosion)<br />

Anode<br />

e -<br />

Cathode<br />

(zero corrosion)<br />

Metal<br />

Oxides→<br />

Anode<br />

e -<br />

Anode<br />

Tubercles<br />

←(zero corrosion)<br />

Cathodic ←<br />

→Anodic<br />

Plastic/Nylon<br />

sleeves/gaskets<br />

More anodic→ corrodes first<br />

←Further apart, stronger galvanic effect→<br />

Coated bolts/screws<br />

Dielectric Union<br />

pg. 59

Rust<br />

Dissolved oxygen “steels” (oxidizes) electrons<br />

from Iron. A weak but significant electrical<br />

current forms creating Anode (+) and<br />

Cathode (-) areas.<br />

O 2 + 4e¯+ 2H 2O → 4OH¯<br />

Fe +2<br />

Anode<br />

2e¯<br />

Cathode<br />

Fe +2 ions are released into the water along with<br />

the newly formed OH¯ ions.<br />

Fe +2<br />

Fe<br />

Anode<br />

Cathode<br />

Fe +2 combines with 2OH¯ and precipitates out as rust.<br />

Fe +2 + 2OH¯ → Fe(OH) 2<br />

rust<br />

rust<br />

Cathode<br />

Fe<br />

Fe<br />

Cathode<br />

Anode<br />

Iron Rust<br />

White Rust = Zinc rust on<br />

galvanized metal<br />

(selective leeching).<br />

pg. 60

H + Concentration→<br />

.<br />

Acidic waters have high H + ion concentrations which react with electrons at<br />

the cathode releasing hydrogen gas: 2H + + 2e¯ → H 2 (g).<br />

Corrosion is accelerated.<br />

0 ← pH 3 5 7<br />

Group VII<br />

Halogens<br />

Like Oxygen, the halides Bromine, Chlorine and Iodine are<br />

also “looking” for electrons which are readily available at the<br />

cathode. At high levels, these oxidizing biocides have a<br />

tendency to cause corrosion.<br />

Oxidizing<br />

Biocides<br />

Road Salt (NaCl) Corrosion<br />

pg. 61

Biological Growth<br />

Algae, Yeast, Molds<br />

Unchecked mold and algae growth restricts air<br />

flow plugs lines and ultimately reduces efficiency.<br />

pg. 62

Legionella Bacteria<br />

History<br />

The first recognized outbreak occurred at the Bellevue Stratford during an American<br />

Legion conference in 1976 in Philadelphia. As many as 221 people were given<br />

medical treatment, and 34 died from extreme pneumonia symptoms. The U.S.<br />

Centers for Disease Control and Prevention mounted an unprecedented investigation<br />

and, by September, the focus had shifted from outside causes, such as a disease<br />

carrier, to the hotel itself. After 5 months of research, the Legionellosis bacterium<br />

was finally identified; it was in the cooling tower. Normally, the bacterium dies<br />

when the water droplets in the mist spray leaving the cooling tower dries up in the air.<br />

However, at the Stratford, the mist spray from the cooling tower exhaust fans was<br />

being sucked back in by the building’s fresh air intake!<br />

Major Legionella Outbreaks<br />

Non-communicable<br />

(cannot be transferred<br />

between humans)<br />

Year Location Cases Died Bacteria Source<br />

1976 Philadelphia 221 34 <strong>Cooling</strong> Tower<br />

1985 Stafford, UK 175 28 <strong>Cooling</strong> Tower<br />

1999 Bovenkarspel, Netherlands 200 32 Humidifier & Whirlpool<br />

2000 Melbourne, Australia 125 4 <strong>Cooling</strong> Tower<br />

2001 Murcia, Spain 449 6 <strong>Cooling</strong> Tower<br />

2002 Barrow, UK 172 7 <strong>Cooling</strong> Tower<br />

2003 Pas-de-Calais, France 86 18 <strong>Cooling</strong> Tower<br />

2005 Fredrikstad, Norway 56 10 Air Scrubber<br />

2011 Playboy Mansion, Los Angeles 123 0 Hot Tub<br />

Due to early<br />

intervention<br />

Legionella are more<br />

difficult to kill in areas<br />

with high slime build up.<br />

Between 1995 and 2005, over 32,000<br />

worldwide cases of Legionnaires'<br />

disease and more than 600 outbreaks<br />

were reported to the European Working<br />

Group for Legionella Infections (EWGLI).<br />

pg. 63

Infected lung<br />

Water test<br />

Urine test<br />

pg. 64

BIOCIDES<br />

Oxidizing antimicrobials kill by “stealing” electrons from critical atoms<br />

disrupting internal functions or damaging cell walls.<br />

Nonoxidizing kill by replacing critical molecules with “poison” molecules.<br />

Oxidizing<br />

Biocides<br />

Chlorine, Bromine, and Iodine “steel” (oxidize)<br />

electrons from molecules of living cells and<br />

they die or fail to reproduce.<br />

Note: No. 53 Iodine (I)<br />

is also a medicinal<br />

disinfectant.<br />

Hypochlorite Ion<br />

Hypochlorous Acid<br />

Chlorine Gas/ Tablets /Bleach + H 2 O → OCl ¯ + HOCl + OH¯<br />

Ions attack<br />

cell walls.<br />

Acids attack<br />

internal cell<br />

functions.<br />

Bromine Tablets + H 2 O →<br />

OBr ¯ + HOBr + OH¯<br />

Chlorine<br />

Hypobromite Ion<br />

Hypobromous Acid<br />

Bromine<br />

Nalco OxySlugger dispenser<br />

pg. 65

Oxidizing Biocides<br />

Ozone (O3)<br />

e¯<br />

1) 1) Generated on site and does not<br />

require storage.<br />

2)<br />

2)You cannot over-dose as unused<br />

ozone escapes out of the water and<br />

reverts to oxygen.<br />

3) Disinfection qualities are not<br />

dependent on pH, nor does the<br />

addition affect the pH of water.<br />

4) Effectiveness can be measured with<br />

an ORP (Oxidation/Reduction<br />

Potential) meter.<br />

5) Less corrosive than chlorine and<br />

bromine in water.<br />

6) Works well for areas with naturally<br />

soft water.<br />

Ozone is a strong oxidizing<br />

biocide that attacks cell walls<br />

pg. 66

Oxidizing Biocides<br />

Sodium Hypochlorite =<br />

NaClO<br />

Bleach: Inexpensive but decomposes<br />

with heat and light.<br />

Solution: On site bleach generator. MIOX ®<br />

Salt (NaCl) + Electricity (via electrolysis) = Bleach<br />

pg. 67

Nonoxidizing<br />

Biocides<br />

Surface Acting<br />

Quaternary ammonium<br />

compounds (quats) are<br />

cationic surface-active<br />

molecules. They damage<br />

the cell walls of bacteria,<br />

fungi, and algae. The cell<br />

“bleeds” and dies.<br />

Metabolism (internal) Acting<br />

Many antimicrobials interfere with energy metabolism inside the cell. The cell gets “sick”<br />

and cannot reproduce. The following are examples of these types of biocides:<br />

organotins<br />

bis(trichloromethyl) sulfone<br />

methylenebis(thiocyanate) (MBT)<br />

Beta-bromo-Beta-nitrostyrene (BNS)<br />

dodecylguanidine salts<br />

bromonitropropanediol (BNPD)<br />

pg. 68

Chillers<br />

History<br />

By using a mixture of alcohol and ether,<br />

Benjamin Franklin, along with John Hadley<br />

of Cambridge, dropped room temperature<br />

down to 7℉.<br />

“From this experiment, one may see the<br />

possibility of freezing a man to death on<br />

a warm summer day.” B.F.<br />

History<br />

Oliver Evans designed the first<br />

vapor air-conditioning machine,<br />

but never made one.<br />

1834<br />

Jacob Perkins, using Evans design, was first to<br />

patented the air conditioner, but never made one.<br />

In 1902, Willis Carrier built<br />

the first working chiller.<br />

1920’s<br />

< 1920’s:<br />

Simple Ice Box<br />

Monitor Top<br />

(compressor on top)<br />

pg. 69

Basic Composition<br />

pg. 70

Psi →<br />

Btus/pound →<br />

pg. 71

Expansion Valve<br />

Thermostatic<br />

Expansion Valve<br />

( = TEV = TXV )<br />

Electric<br />

Expansion<br />

Valve<br />

Orifice Plate<br />

Expansion<br />

Valve<br />

Low Load<br />

High Load<br />

Float<br />

Expansion<br />

Valve<br />

pg. 72

Liquid Line Filter Drier<br />

Refrigerant Oil Filter<br />

pg. 73

Chiller<br />

Economizer<br />

pg. 74

Refrigerants<br />

Refrigerants<br />

It is suspected that a variety of biological<br />

consequences such as increases in sunburn, skin<br />

cancer, cataracts, damage to plants, and reduction of<br />

certain plankton in the ocean may result from the<br />

increased UV-B exposure due to ozone depletion.<br />

Image of the largest Antarctic<br />

ozone hole recorded (September<br />

2006), over the Southern pole.<br />

1920’s Sulfur Dioxide . . . . . . . Corrosive, Toxic<br />

Methyl Formate . . . . . Flammable, Toxic<br />

Ammonia . . . . . . . . . . . Toxic<br />

1930’s Chlorofluorocarbons Ozone Depletion<br />

CFC’s<br />

1960’s Hydrochloroflourocarbons Ozone Depletion<br />

HCFC’s<br />

1990’s Hydrofluorocarbons Safe<br />

HFC’s<br />

CFCs: Banned in US and Canada HCFCs: Being phased out HFCs: OK<br />

pg. 75

Refrigerants (continued)<br />

>>>>CFC refrigerants<br />

CARBON, FLORINE, CHLORINE.<br />

Banned from use or production within all<br />

countries covered by the Montreal<br />

Protocol.<br />

>>>>HCFC refrigerants<br />

HYDROGEN, CARBON, FLORINE, CHLORINE.<br />

Being phased out.<br />

>>>>HFC refrigerants<br />

HYDROGEN, FLORINE, CARBON.<br />

HFC’s contain no chlorine:<br />

NO OZONE DEPLETION.<br />

It is estimated that the Ozone layer will<br />

revert back to its original level by 2050!<br />

pg. 76

ANHYDROUS<br />

= Contains no water<br />

Being Phased Out<br />

Acceptable<br />

Natural Refrigerants:<br />

R717 Ammonia NH 3 BP -28°F<br />

R290 Propane C 3H 8 BP -44°F<br />

R600a Iso-butane C 4H 10 BP 11°F<br />

R600 Butane C 4H 10 BP 31°F<br />

R744 Carbon Dioxide CO 2 BP -109°F<br />

Azeotrope<br />

- A mixture made up of two or more refrigerants<br />

with similar boiling points that act as a single fluid.<br />

The components of azeotropic mixtures will not<br />

separate under normal operating conditions and<br />

can be charged as a vapor or liquid.<br />

Zeotrope<br />

- A mixture made up of two or more refrigerants<br />

with different boiling points which creates a<br />

boiling point “glide”. Therefore: Zeotropic<br />

mixtures should be charged in the liquid state.<br />

pg. 77

Corrosion<br />

MIC<br />

MIC<br />

Microbiologically Induced Corrosion<br />

Biofilm = Slime<br />

Under the slime is an<br />

area where Anerobic<br />

bacteria thrive.<br />

Cathode<br />

←e¯<br />

M +<br />

Anode<br />

e¯→ Cathode<br />

Anaerobic bacteria “eat” metal by means<br />

of reduction reaction.<br />

Its waste is food for the aerobic bacteria in the<br />

slime. These colonies form tubercles.<br />

Aerobic = breaths 0xygen<br />

Anaerobic = does not breath O2<br />

Tubercle grows,<br />

penetrating completely<br />

through metal.<br />

←e¯<br />

↑<br />

M +<br />

e¯→<br />

Upon removing Tubercles,<br />

shiny, raw metal is exposed.<br />

pg. 78

MIC Prevention and control<br />

Water Treatment Biocides + Non-penetrable, Non-metallic Coatings<br />

Fouling prevention and control<br />

Manually “punching ” tubes<br />

Automatically punching tubes<br />

pg. 79

Eddie Current Testing<br />

Cracks, corrosion, or other imperfections<br />

create out of specification signals.<br />

pg. 80

Chiller Compressor Types<br />

Positive Displacement<br />

Reciprocating<br />

Single Acting<br />

Double Acting<br />

pg. 81

Rotary<br />

Single Screw<br />

Double Screw<br />

pg. 82

TXV<br />

Oil separator<br />

Economizer<br />

pg. 83<br />

Auto shut valves

Scroll<br />

Vane<br />

pg. 84

Dynamic<br />

Centrifugal<br />

pg. 85

Because of the high boiling point, lowpressure<br />

chillers evaporate the refrigerant<br />

in vacuum conditions<br />

Beacause of the nature of a vacuum, sometimes non-refrigerant<br />

gas (air) leaks in (is sucked in).<br />

Low Pressure Centrifugal Chiller Purge Unit<br />

Removes and vents non-condensable gases and at the same<br />

time, returns refrigerant as a liquid to chiller condenser.<br />

Compressor<br />

Filter drier<br />

Safety Burst Disc<br />

Pneumatically controlled shutoff valves<br />

pg. 86

Centrifugal:<br />

Magnetic Bearing<br />

Computer controlled lead lag<br />

alternates operating compressor for<br />

even, on-demand use<br />

When the chiller is operated in cooling mode, the<br />

condensed liquid refrigerant exits the electronic<br />

expansion valve (4), and enters the<br />

bottom of the flooded evaporator, where it is<br />

evenly dispersed along the length of the<br />

evaporator by the use of a distributor plate (3).<br />

Liquid refrigerant inside the evaporator at low<br />

pressure then makes contact with the copper<br />

tubes that the building’s water runs through,<br />

exchanges heat to the refrigerant, and vaporizes<br />

it (2) at the suction pressure of the compressor<br />

(1). As a result of the lower density of the vapor<br />

and the suction of the compressor, the vaporized<br />

refrigerant gas is then drawn to the top of the<br />

evaporator through the mist eliminators (5). (Mist<br />

eliminators inhibit minute liquid particles<br />

entrained in the vaporized refrigerant, from<br />

entering the compressor). Passing through the<br />

(pre-rotation) inlet guide vanes (6), the vaporized<br />

refrigerant then enters the compressor inlet (7),<br />

where the angle of incidence of the refrigerant<br />

hitting the first stage impeller, is altered, thereby<br />

allowing a higher compression efficiency for a<br />

given compressor rotor speed.<br />

No lubricating oil needed.<br />

Electronically Controlled TXV<br />

pg. 87

Hermetic and<br />

Semi Hermetic<br />

Hermetic<br />

piston<br />

scroll<br />

Hermetic = air tight, not designed to be opened. Design<br />

helps prevent contamination of edibles.<br />

Semi Hermetic = air tight, but designed to enable access<br />

to inside components.<br />

Semi Hermetic<br />

pg. 88

Absorption <strong>Cooling</strong><br />

Ammonia/Hydrogen Refrigeration<br />

Evaporating ammonia cools off,<br />

travels along tube and is reabsorbed<br />

by the water.<br />

COLD<br />

COLD<br />

Hydrogen<br />

Electric Heater Driven<br />

RV Propane Driven<br />

pg. 89

Lithium Bromide (LiBr) Absorption Chillers<br />

Water is used as a<br />

refrigerant. At very low<br />

psi, it will not freeze.<br />

Evaporation chamber is<br />

maintained @<br />

0.24 in. Hg = 0.12 psia.<br />

At this pressure (closely<br />

above the triple point),<br />

water boils at 39°F<br />

producing chilled process<br />

water in the coil.<br />

pg. 90

Free <strong>Cooling</strong><br />

When conditions are favorable, significant ∆T can be achieved<br />

and energy is saved by simply bypassing the chiller.<br />

pg. 91

Chiller Chiller Surge Surge<br />

If heat is not removed sufficiently from the condenser, then the<br />

refrigerant will build up pressure resisting the compressor and, in<br />

some extreme cases, flow backwards against the compressor!<br />

Normal flow<br />

Compressor<br />

SURGE: Too high of pressure in condenser,<br />

forces backflow, damaging chiller.<br />

Evaporator<br />

Condenser<br />

high psi<br />

Possible Causes:<br />

Poor water circulation to cooling tower: plugged filters, pump failure<br />

<strong>Cooling</strong> tower fan failure<br />

Scale and or biological growth build-up in condenser (no heat transfer)<br />

Heavy fouling in cooling tower media (cooled water not being produced)<br />

In some extreme cases, the evaporator has gotten too cold and forms a vacuum<br />

(example: chilled water demand drops suddenly)<br />

Monitor Approach Temperatures<br />

Evaporator Approach is the difference between the evaporating refrigerant temperature, measured at the<br />

well in the evaporator, and leaving chilled water temperature.<br />

Condenser Approach is the difference between the liquid refrigerant temperature, as measured on the<br />

liquid line, and leaving condenser water temperature.<br />

Take all readings with the water cooled chiller at full load.<br />

pg. 92

4 Funtion Valve, 7<br />

4<br />

A<br />

Absolute Zero, 10, 18, 37, 41<br />

Absorption Chiller, 90<br />

Absorption <strong>Cooling</strong>, 89<br />

AC, 32<br />

Acid, 24<br />

Actuator, 4, 56<br />

Adiabatic Process, 38<br />

Aerobic, 78<br />

Affinity Law, 33<br />

Air Conditioner, 13, 14<br />

Algae, 62<br />

Alkaline, 24<br />

Alternating Current, 32<br />

American Legion, 63<br />

Ammonia, 24<br />

Ammonia/Hydrogen Refrigeration, 89<br />

Amps, 9<br />

Anerobic, 78<br />

Anion, 29<br />

Anode, 59, 60<br />

Antarctica, 39<br />

Antifreeze, 26<br />

Aquastat, 23, 25<br />

Atm, 17<br />

Azeotrope, 77<br />

Back Siphonage, 6<br />

Backflow, 6<br />

Bacteria, 26, 78<br />

Balance Point, 14<br />

Ball Valve, 3<br />

Bar, 12<br />

Barometer, 12<br />

Base, 24<br />

Base Load, 36<br />

Bellevue Stratford Hotel, 63<br />

Benjamin Franklin, 69<br />

BHP, 9<br />

Biocide, 65<br />

Bleach, 65, 67<br />

Boiling Point, 11, 17, 22<br />

Bourdon-Tube, 12<br />

BPHE, 31<br />

Brahmaputra Mountains, 39<br />

Braized Plate, 31<br />

Bromine, 61, 65<br />

BTU, 17, 22<br />

BTU Content, 22<br />

CaCO3, 55<br />

Calcium Carbonate, 55<br />

B<br />

C<br />

Calcium Sulfate, 55<br />

Cambridge, 69<br />

Can pump, 8<br />

Cathode, 59, 60, 61<br />

Cation, 29<br />

Cavitation, 21<br />

Centrifugal Compressor, 85<br />

CFCs, 75, 77<br />

Cherrapunjee, 39<br />

Chiller Surge, 92<br />

Chillers, 69<br />

Chlorine, 61, 65, 76<br />

Closed Recirculating <strong>Cooling</strong> Tower, 49<br />

Coal, 9<br />

Compound Guage, 12<br />

Compressor, 13<br />

Condensate, 12<br />

Condensation, 10, 18<br />

Conduction, 16<br />

Controllers, 25<br />

Convection, 16<br />

Critical Pressure and Temperature, 22<br />

Cross corrugated, 50<br />

Cross flow, 48<br />

DC, 32<br />

Dead Sea, 11<br />

Dehumidifier, 15<br />

Delta T, 91<br />

Demineralize, 29<br />

Deposition, 18<br />

Dew, 37<br />

Diaphragm feed pump, 7<br />

Dielectric Union, 59<br />

Direct Current, 32<br />

Direct Evaporative <strong>Cooling</strong>, 40<br />

Double Acting Compressor, 81<br />

Double Screw Compressor, 82<br />

Drift eliminator, 50<br />

Dry bulb, 41, 42<br />

Dry Valleys, 39<br />

Dynamic Compressor, 85<br />

Economizer, 74<br />

Eddie Current, 80<br />

Edison, Thomas, 32<br />

Electrodes, 56<br />

Electrolysis, 67<br />

Electromagnet, 56<br />

Equilibrium, 10, 37<br />

Ethylene Glycol, 26<br />

Evaporation, 10, 18<br />

exothermic, 41<br />

Expansion Valve, 13<br />

Expansion, water to ice, 23<br />

Explosion, 20<br />

D<br />

E

Feed Water Pumps, 8<br />

Fiber reinforced plastic, 47<br />

Film Fill, 51<br />

Filter Drier, 73<br />

Flash Steam, 20<br />

Float Expansion Valve, 72<br />

Food Grade Antifreeze, 26<br />

Foot Valve, 7<br />

Forced draft, 46<br />

Fouling, 50<br />

Free cooling, 91<br />

Freeze Drier, 19<br />

Freeze Point, 26<br />

Fridgidair, 69<br />

Frost, 37<br />

FRP, 47<br />

Fuel Oil, 9<br />

Galvanic corrosion, 59<br />

Galvanized Steel, 49<br />

General Electric, 69<br />

Glide, 77<br />

Glycol, 26<br />

gravel, 21<br />

Grid, 36<br />

Halides, 61<br />

Hamburger Helper, 11<br />

HCFCs, 75, 77<br />

HDPE, 47<br />

Heat Exchanger, 31<br />

Heat Pump, 14<br />

HEDP, 57<br />

Hermetic, 88<br />

Hexagonal, 23<br />

HFCs, 75, 77<br />

High density polyethylene, 47<br />

Hot Air Balloon, 20<br />

Hydrofluorocarbons, 75<br />

Hydrogen, 24<br />

Hydroxide, 24<br />

Hyperbolic, 45<br />

Hypobromous Acid, 65<br />

Hypochlorous Acid, 65<br />

Ideal Gas Law, 13, 20, 28<br />

Immersion heater, 54<br />

Impeller, 21, 85<br />

Induced draft, 47<br />

F<br />

G<br />

H<br />

I<br />

Induction Coil, 80<br />

Intercooler, 13<br />

Iodine, 65<br />

Jacob Perkins, 69<br />

John Hadley, 69<br />

Kiln, 15<br />

Ladder, 52<br />

Lake Tahoe, 11<br />

Latent heat, 44<br />

LEED, 34<br />

Legionella, 63, 64<br />

LiBr, 90<br />

Lithium Bromide Chiller, 90<br />

Low Water Cutoff, 20<br />

Magnetic Bearing Chiller, 87<br />

Melting, 18<br />

Membrane, 30<br />

Mercury Switch, 25<br />

Metabolism, 68<br />

MIC, 78, 79<br />

Mold, 62<br />

Monitor Top, 69<br />

Mono Lake, 57<br />

Mt. Everest, 11<br />

Multistage Pump, 8<br />

Myox, 67<br />

Neutral Water, 24<br />

Nitrites, 26<br />

Non-metallic Coating, 79<br />

J<br />

K<br />

L<br />

M<br />

N<br />

O<br />

Ohms, 9<br />

Oil Filter, 73<br />

Old Faithful, 17<br />

Oliver Evans, 69<br />

Open Recirculating <strong>Cooling</strong> Tower, 49<br />

Oriface Plate Expansion Valve, 72<br />

ORP, 66<br />

Oxides, 59<br />

Oxidizing, 65<br />

Ozone, 66<br />

pg. 94

Ozone Layer, 75<br />

Parrallel pumps, 8<br />

Pascal, 12<br />

Peristaltic Feed Pump, 7<br />

pH, 24<br />

Phases of Water, 17<br />

Philadelphia, 63<br />

Phosphates, 57<br />

Pickup Coil, 80<br />

Pigtale Loop, 12<br />

Pilot, 35<br />

Plate and Frame, 31<br />

Polyvinylchloride, 47<br />

Precipitation, 39<br />

Pressure vs. Heat Content Chart, 71<br />

Pressure/Temperature Reducing Valve, 28<br />

Pressurestat, 25<br />

Pressuretrol, 25<br />

Priming Valve, 7<br />

Propane Tank, 13<br />

Propeller, 21<br />

Propylene Glycol, 26<br />

psia, 11, 12<br />

psig, 11, 12, 17<br />

Psychrometer, 42<br />

Psychrometric Chart, 41, 43<br />

Punching Tubes, 79<br />

Purge Cycle, 20<br />

PV=nRT, 13<br />

PV=T, 13, 20<br />

PVC, 47<br />

Pyrometer, 27<br />

Quaternary ammonia, 68<br />

Quill, 7<br />

Radiant Heat, 16<br />

Radiation, 16<br />

Reduced Pressure Zone, 6<br />

Refractometer, 26<br />

Refrigeration, 13<br />

Regeneration, 29<br />

Relative Humidity, 41, 42<br />

Resin Beads, 29<br />

Resistance, 9<br />

Restricting Orifice, 28<br />

Reverse Osmosis, 30<br />

Reversing Valve, 14<br />

RH, 42<br />

RO, 30<br />

P<br />

Q<br />

R<br />

Rotary Compressor, 82<br />

Rust, 60, 61<br />

Sand Filter, 55<br />

Saturated Steam, 17<br />

Saturation Curve, 10, 37<br />

Saturation Point, 10, 40, 56<br />

Scale, 57<br />

Scroll Compressor, 84<br />

Sea level, 19<br />

Sea Level, 11, 17, 18, 22<br />

Semi hermetic, 88<br />

Sensible Heat, 16<br />

Series Connection, 9<br />

Series Pumps, 8<br />

Shell and Tube, 31<br />

Side Stream Filter, 55<br />

Silica, 55<br />

sine wave, 32<br />

Single acting compressor, 81<br />

Single phase, 32<br />

Single Screw Compressor, 82<br />

Siphon Loop, 12<br />

Slime, 78<br />

Snap Switch, 25<br />

Sodium Hypochlorite, 67<br />

Solenoid, 4, 56<br />

Sørensen, Søren, 24<br />

Spark Ignitor, 35<br />

Splash fill, 52<br />

Splash guards, 48<br />

Steam Table, 22<br />

Step Down Transformer, 36<br />

Step Up Transformer, 36<br />

Stethoscope, 27<br />

Stroke, 7<br />

Sublimation, 18, 19<br />

Sultana, 20<br />

Supercritical Steam, 22<br />

Superheated Steam, 17<br />

Surge, 92<br />

Termperature Glide, 77<br />

Tesla, Nickola, 32<br />

TEX Valve, 72<br />

Thermal Imager, 27<br />

Thermocouple, 35<br />

Thermopile, 35<br />

Thermowell, 25, 54<br />

Three phase, 32<br />

Tom Thumb, 9<br />

Tonnage, 44<br />

Torque, 33<br />

S<br />

T<br />

pg. 95

Transformer, 36<br />

Transmission, 36<br />

Triple Point, 18, 90<br />

Tubercle, 78<br />

TXV, 72<br />

VFD, 33<br />

Volts, 9<br />

Volute, 85<br />

W<br />

Vacuum, 10, 11, 12, 19<br />

Vacuum Gauge, 12<br />

Vane Compressor, 84<br />

Vanes, 84<br />

Vapor Pressure, 10<br />

Vaporization, 10<br />

Variable Frequency Drive, 33<br />

V-bars, 52<br />

Vertical offset, 50<br />

V<br />

Water hammer, 5<br />

Water level indicator, 53<br />

Watts, 9<br />

Wet bulb, 41, 42<br />

White rust, 60<br />

Willis Carrier, 69<br />

Zeotrope, 77<br />

Z<br />

pg. 96