You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

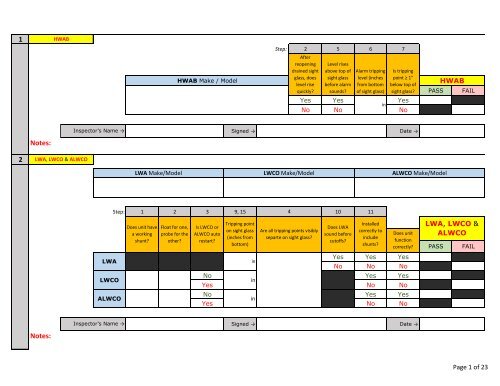

1<br />

HWAB<br />

HWAB Make / Model<br />

Step: 2 5 6 7<br />

After<br />

reopening<br />

drained sight<br />

glass, does<br />

level rise<br />

quickly?<br />

Level rises<br />

above top of<br />

sight glass<br />

before alarm<br />

sounds?<br />

Alarm tripping<br />

level (inches<br />

from bottom<br />

of sight glass)<br />

Is tripping<br />

point ≥ 1"<br />

below top of<br />

sight glass?<br />

Yes Yes Yes<br />

in<br />

No No No<br />

PASS<br />

HWAB<br />

FAIL<br />

Notes:<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

2<br />

LWA, LWCO & ALWCO<br />

LWA Make/Model LWCO Make/Model ALWCO Make/Model<br />

LWA<br />

LWCO<br />

ALWCO<br />

Step: 1 2 3 9, 15 4<br />

10 11<br />

Does unit have<br />

a working<br />

shunt?<br />

Float for one,<br />

probe for the<br />

other?<br />

Is LWCO or<br />

ALWCO auto<br />

restart?<br />

Tripping point<br />

on sight glass<br />

(inches from<br />

bottom)<br />

in<br />

Are all tripping points visibly<br />

separte on sight glass?<br />

Does LWA<br />

sound before<br />

cutoffs?<br />

Installed<br />

correctly to<br />

include<br />

shunts?<br />

Does unit<br />

function<br />

correctly?<br />

Yes Yes Yes<br />

No No No<br />

No Yes Yes<br />

in<br />

Yes No No<br />

No Yes Yes<br />

in<br />

Yes No No<br />

LWA, LWCO &<br />

ALWCO<br />

PASS<br />

FAIL<br />

Notes:<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Page 1 of 23

3<br />

RBSPLS & NRBSPLS<br />

Normal operating steam psi:<br />

Step 2 Step 7<br />

Lowest SVB set point psi: →<br />

RBSPLS Make/Model<br />

NRBSPLS Make/Model<br />

Step:<br />

RBSPLS<br />

NRBSPLS<br />

3<br />

5, 8<br />

12, 16 17<br />

Is setpoint ≥<br />

10 psi above Is NRBPLSsetpoint ≥ 5 psi of<br />

Did switch<br />

RBSPLS setpoint & ≥ 5 psi or<br />

1<br />

normal steam<br />

Trip point work<br />

psi? more less than lowest SVB<br />

correctly?<br />

psi Range Set point setpoint?<br />

PASS FAIL<br />

psi<br />

psi<br />

Yes<br />

No<br />

Yes<br />

No<br />

psi<br />

psi<br />

Yes<br />

No<br />

Yes<br />

No<br />

BSPL Switches<br />

Notes:<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Page 2 of 23

4<br />

SVB<br />

SVB 1 Make/Model<br />

SVB 2 Make/Model<br />

Step 2:<br />

Boiler MAWP →<br />

Boiler capacity (lbs./hr) →<br />

Normal boiler psi →<br />

Step: 9 18 19 1<br />

3, 4, 6, 7 13 17 21, 22, 23<br />

SVB's pass<br />

Water flows Is SVB vent Heated vent<br />

Is lift and<br />

Capacity<br />

Are set points<br />

Psi<br />

reseat psi accumulation SVBs<br />

freely down directed line touches<br />

Range Set Point<br />

lbs./hr<br />

adequate?<br />

vent drains? outside? drip pan?<br />

Lift Reseat correct? test? PASS FAIL<br />

SVB1<br />

SVB2<br />

SVB3<br />

Yes Yes Yes Yes Yes Yes<br />

psi<br />

psi<br />

psi<br />

No No No No No No<br />

Yes Yes Yes Yes Yes Yes<br />

psi<br />

psi<br />

psi<br />

No No No No No No<br />

Yes Yes Yes Yes Yes Yes<br />

psi<br />

psi<br />

psi<br />

No No No No No No<br />

15, 21<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

5<br />

FSMFO<br />

Step:<br />

1<br />

4 5<br />

Flame Scanner: Make/Model<br />

Is scanner UV-Self Checking<br />

and not rebuilt?<br />

Time lapse for<br />

fuel valves to<br />

close.<br />

Lapse for fuel<br />

valves to close<br />

≤ 4 seconds?<br />

PASS<br />

FSMFO<br />

FAIL<br />

Yes<br />

No<br />

secs<br />

Yes<br />

No<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

Page 3 of 23

6<br />

FSNSIS & IT<br />

Programmer: Make/Model<br />

Step: 1 6 7 6 8 9<br />

Scanner UV-<br />

Self checking<br />

and not<br />

rebuilt?<br />

Duration<br />

voltage tic<br />

illuminated<br />

Did tic<br />

illuminate for<br />

10 seconds?<br />

Spark duration<br />

(in seconds)<br />

Was spark<br />

duration > 10<br />

seconds?<br />

Did scanner<br />

show flame?<br />

Yes Yes Yes Yes<br />

secs<br />

secs<br />

No No No No<br />

FSNSIS & IT<br />

PASS<br />

FAIL<br />

Notes:<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

7<br />

MFIT<br />

Programmer: Make / Model<br />

Step: 4 5<br />

Time from<br />

#4 ≤ 14<br />

opening to<br />

seconds?<br />

closed<br />

Yes<br />

secs<br />

No<br />

PASS<br />

MFIT<br />

FAIL<br />

Notes:<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Page 4 of 23

8<br />

LFPS<br />

LFPS on<br />

NG<br />

LFPS on<br />

FO<br />

LFPS on<br />

FD<br />

Damper<br />

Make/Model<br />

Step 3<br />

Correct switch<br />

Step 5<br />

set up? (see Did switch<br />

Trip Point below) work<br />

correctly?<br />

Yes<br />

No<br />

Yes<br />

No<br />

Yes<br />

No<br />

Yes<br />

No<br />

Yes<br />

No<br />

Yes<br />

No<br />

PASS<br />

LFPS<br />

FAIL<br />

For single point positioning control systems (via drilled and pinned linkage), only one LFPS is required.<br />

For parallel positioning systems (with no mechanical linkage) a LFPS is required on the gas flow control valve, the oil flow control valve, and the inlet air<br />

damper (three switches in all, directly activated by the actuator that is monitored by the LFPS).<br />

In cases of VFD fan control: this test is valid only if damper controls air flow at low fire. For all other cases where a VFD controls air flow at low fire, an<br />

appropriate alternate procedure must be developed and reviewed by CFM/OCAMES prior to operation.<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

9<br />

OBPS<br />

Step 3<br />

OBPS Make/Model<br />

Switch worked<br />

correctly?<br />

Yes<br />

No<br />

PASS<br />

OBPS<br />

FAIL<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

Page 5 of 23

10 CAPS<br />

This SOP is only applicable when using a constant speed forced draft fan (no VFD's).<br />

CAPS Make/Model<br />

Step 5<br />

Step 8<br />

= 80% of<br />

lowest<br />

Combustion Air Pressure (inwc)<br />

combustion air<br />

Boiler tripping Does boiler trip at or above CAPS<br />

pressure calculated value?<br />

Low Fire Mid Fire High Fire pressure<br />

PASS FAIL<br />

inwc<br />

Step 4<br />

inwc<br />

inwc<br />

inwc<br />

inwc<br />

Step 9<br />

Yes<br />

No<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

11<br />

FDMIS<br />

Step: 3 6 9<br />

Leg 1 worked<br />

correctly?<br />

Leg 2 worked<br />

correctly?<br />

Leg 3 worked<br />

correctly?<br />

PASS<br />

FDMIS<br />

FAIL<br />

Yes Yes Yes<br />

No No No<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

12<br />

FPI<br />

Step: 4 5 9 10<br />

FPI Make/Model<br />

Highest<br />

furnace<br />

pressure in<br />

firing range<br />

Break/Set<br />

Point = #4 x<br />

1.2 (120%)<br />

Does switch<br />

work<br />

normaly?<br />

Yes<br />

No<br />

Actual Furnace<br />

Trip Point<br />

PASS<br />

FPI<br />

FAIL<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

Page 6 of 23

13<br />

PPT<br />

Boiler type<br />

and required<br />

AC<br />

AC V fireside m<br />

Required Air<br />

Changes<br />

Step 1<br />

Boiler Fireside<br />

Volume<br />

Maximum<br />

Boiler Capacity<br />

Step 2<br />

Required Minimum Purge =<br />

RMP<br />

V fireside = boiler Volume in ft 3 (see manufacturer)<br />

m = maximum boiler capacity in lb/hr of steam<br />

AC = required Air Changes (water tube = 4, fire tube = 8)<br />

Water Tube:4<br />

Fire Tube: 8<br />

ft 3<br />

lb/hr<br />

secs<br />

Step: 6 8 9 10 12 14 15 Step 16<br />

Low Fire to<br />

High Fire<br />

secs<br />

Time lapse at<br />

"Purge<br />

Complete"<br />

secs<br />

Time in High<br />

Fire = Time in<br />

Purge =<br />

#6 minus #4<br />

secs<br />

Did Time in<br />

Purge (#7) last<br />

at least 60<br />

seconds?<br />

Yes<br />

No<br />

Time lapse at<br />

"Moving to<br />

Ignition"<br />

secs<br />

Time lapse at<br />

PTFI<br />

secs<br />

Time in<br />

"Moving to<br />

Ignition" to<br />

PTFI<br />

secs<br />

( ( #4 + #13 ) / 2 ) + #7 = EHFP (#14)<br />

Equivalent<br />

High Fire<br />

Purge = EHFP<br />

secs<br />

Step: 17 20 21<br />

Is EHFP ≥<br />

RMP?<br />

Yes<br />

No<br />

Time in Post<br />

Purge<br />

secs<br />

Is Post Purge ≥<br />

15 seconds?<br />

Yes<br />

No<br />

PASS<br />

PPT<br />

FAIL<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

Page 7 of 23

14<br />

PAPS<br />

PAPS Make/Model<br />

Step: 3<br />

4 11 10, 15, 17<br />

Highest differential pressure<br />

between "low" and "full open"<br />

#3 x 0.8 = 80%<br />

PAPS set<br />

point<br />

Actual PAPS<br />

make point<br />

Switch worked<br />

correctly?<br />

Yes<br />

No<br />

PASS<br />

PAPS<br />

FAIL<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

15<br />

FDDWOPS<br />

Step: 2 4 5 7 8 9<br />

11<br />

FDDWOPS Make/Model<br />

Meter showed<br />

switch open<br />

when boiler<br />

off?<br />

Make points during purge<br />

% load when<br />

switch opens<br />

% load when<br />

switch closes<br />

Incoming air<br />

Damper vanes<br />

at wide open<br />

reading<br />

90% of #7 =<br />

Minimum<br />

switch set<br />

point<br />

Are make<br />

points ><br />

minimum set<br />

point<br />

Did purge stay on "high<br />

air" with switch disconnected<br />

(no start of countdown)?<br />

FDDWOPS<br />

PASS<br />

FAIL<br />

Yes<br />

No<br />

Yes<br />

No<br />

Yes<br />

No<br />

If switch is not directly activated by damper, then all linkages to switch must be drilled and pinned.<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

Page 8 of 23

16<br />

OSDPI<br />

If normal boiler operation does not require a non-modulating damper, no<br />

OSDPI is required if stack damper is welded in "open" position.<br />

OSDPI Make/Model<br />

Step: 1, 2 3 6 10 11 12 14<br />

16, 18<br />

Is OSDPI<br />

installed<br />

correctly?<br />

When boiler is<br />

off, does<br />

meter show<br />

switch is<br />

open?<br />

% load when<br />

switch opens<br />

at high air flow<br />

= make pt.<br />

Exhaust air<br />

Damper vanes<br />

at wide open<br />

reading<br />

80% of #10 =<br />

Minimum set<br />

point<br />

Is make point<br />

(#6) ><br />

minimum set<br />

pt. (#8)<br />

Did purge stay on "high<br />

air" with switch disconnected<br />

(no start of countdown)?<br />

Does switch<br />

work correctly<br />

via toggles?<br />

Yes Yes Yes Yes<br />

Yes<br />

No No No No<br />

No<br />

PASS<br />

OSDPI<br />

FAIL<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

17<br />

LFGOLI<br />

Step: 1 3, 9 4, 10 11<br />

LFGOLI Make/Model<br />

Minimum<br />

O 2 % at 200 ppm<br />

CO /<br />

combustibles.<br />

O 2 % at trip<br />

point<br />

LFGOLI<br />

activated at <<br />

#1?<br />

Is device both<br />

an interlock<br />

and alarm?<br />

PASS<br />

LFGOLI<br />

FAIL<br />

Natural Gas<br />

Fuel Oil<br />

% %<br />

%<br />

%<br />

Yes<br />

No<br />

Yes<br />

No<br />

Yes<br />

No<br />

Yes<br />

No<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

Page 9 of 23

18<br />

FGRDRI<br />

FGRDRI Make/Model<br />

Step: 1, 2 4, 5 8 9, 10 11 12 14 16<br />

Is FGRDRI<br />

installed<br />

correctly?<br />

Is more purge<br />

time needed<br />

for open<br />

damper?<br />

Damper<br />

position<br />

required for<br />

purge<br />

Is damper at<br />

least 80%<br />

opened or<br />

closed as<br />

required?<br />

Make point on<br />

firing start<br />

Multimeter<br />

shows open<br />

during firing<br />

(voltage)?<br />

"Un-make"<br />

point on shut<br />

down<br />

Does prepurge<br />

hold<br />

with switch<br />

removed?<br />

Yes Yes Yes Yes Yes<br />

No No No No No<br />

PASS<br />

FGRDRI<br />

FAIL<br />

Notes:<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

19<br />

LFGPCS<br />

LFGPCS Make/Model<br />

Step: 1 2 3 4 5 13 14<br />

Is switch<br />

installed in<br />

correct<br />

location?<br />

Are there<br />

snubbers or<br />

dampeners on<br />

gas line?<br />

LFGPSC range<br />

Regulated<br />

pressure on<br />

main line after<br />

PRV<br />

#4 x 0.8 (80%)<br />

= LFGPCS set<br />

point<br />

LFGPCS<br />

tripping point<br />

Did LFGPCS<br />

trip at or<br />

above set<br />

point?<br />

Yes No Yes<br />

No Yes No<br />

PASS<br />

LFGPCS<br />

FAIL<br />

Notes:<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Page 10 of 23

20<br />

HFGPCS<br />

HFGPCS Make/Model<br />

Step: 1 2 3 4 5 13 14<br />

Is switch<br />

installed in<br />

correct<br />

location?<br />

Regulated<br />

pressure on<br />

main line after<br />

PRV<br />

#3 x 1.2<br />

(120%) = HFGPCS device<br />

HFGPCS make set point<br />

point<br />

Is #4 ≤ make<br />

point?<br />

HFGPCS<br />

tripping point<br />

Did HFGPCS<br />

trip at or<br />

below make<br />

point?<br />

Yes Yes Yes<br />

No No No<br />

PASS<br />

HFGPCS<br />

FAIL<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

21<br />

AFGSOV & AFGSVV<br />

Step: 8 3, 18, 22<br />

AFGSVV<br />

Upstream<br />

AFGSOV<br />

Downstream<br />

AFGSOV<br />

Make/Model<br />

Does valve<br />

open on boiler<br />

shut down?<br />

Yes<br />

No<br />

Zero bubbles<br />

in 2 minutes?<br />

Yes<br />

No<br />

Yes<br />

No<br />

Yes<br />

No<br />

AFGSOV &<br />

AFGSVV<br />

PASS<br />

FAIL<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

Page 11 of 23

22<br />

LRVOPS<br />

LRVOPS-A<br />

LRVOPS-B<br />

Make/Model<br />

Installed with<br />

Step: 2 3 view port and<br />

4<br />

5 9, 16 10, 17 12, 19<br />

back pressure<br />

MAPP regulator?<br />

Lift pressure<br />

LRVOPS-A<br />

LRVOPS-B<br />

Regulated oil<br />

supply psi<br />

Capacity in<br />

gal/hr<br />

Psi<br />

Range<br />

SRVOPS set<br />

point<br />

Is set point <<br />

(#1+10psi) and<br />

< MAPP<br />

Is lift psi < (#1<br />

+ 10psi)?<br />

Yes Yes Yes<br />

psi<br />

psi<br />

psi<br />

No No No<br />

Yes Yes Yes<br />

psi<br />

psi<br />

psi<br />

No No No<br />

Reseat<br />

pressure<br />

psi<br />

psi<br />

PASS<br />

LRVOPS<br />

FAIL<br />

Notes:<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

23<br />

LFOPCS<br />

LFOPCS Make/Model<br />

Step: 1 2 3 4 8 7<br />

Is a snubber or<br />

dampener is<br />

use?<br />

No<br />

Yes<br />

LFOPCS<br />

pressure range<br />

Lowest oil<br />

pressure<br />

during<br />

run-up<br />

#3 x 0.8 (80%)<br />

= LFOPCS set<br />

point<br />

Oil tripping<br />

pressure<br />

Is #8 ≥ #4?<br />

Yes<br />

No<br />

PASS<br />

LFOPCS<br />

FAIL<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Page 12 of 23

24<br />

HFOPCS<br />

HFOPCS Make/Model<br />

Step: 1 2 3 7 6<br />

HFOPCS<br />

pressure range<br />

Oil psi during<br />

pre-fire<br />

#2 x 1.2<br />

(120%) =<br />

HFOPCS set<br />

point<br />

Oil tripping<br />

pressure<br />

psi psi psi<br />

Is #7 ≤ #3?<br />

Yes<br />

No<br />

PASS<br />

HFOPCS<br />

FAIL<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

25<br />

LAMPS<br />

Step: 1<br />

2 3 6 5<br />

LAMPS Make/Model<br />

LAMPS psi<br />

range<br />

LAMPS set<br />

point<br />

Atomizing<br />

media<br />

pressure at<br />

low fire<br />

#2 x 0.8 (80%)<br />

= MTP<br />

LAMPS<br />

tripping<br />

pressure<br />

Did boiler<br />

LAMPS trip at<br />

or above<br />

MTP?<br />

Yes<br />

No<br />

PASS<br />

LAMPS<br />

FAIL<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

26<br />

27<br />

LAMDPS<br />

LAMFS<br />

Only required if oil pressure is higher than atomizing media pressure (prevents possible flow of oil into atomizing media lines)<br />

Page 13 of 23

28<br />

AFOSV-LT<br />

Step 5, 10<br />

Upstream<br />

AFOSV<br />

Downstream<br />

AFOSV<br />

Make/Model<br />

Is constant<br />

drip rate < 1<br />

drop in 10<br />

seconds?<br />

Yes<br />

No<br />

Yes<br />

No<br />

AFOSV-LT<br />

PASS<br />

FAIL<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

29<br />

POC-AFOSV<br />

Step:<br />

10, 17 13, 20<br />

Upstream<br />

AFOSV<br />

Downstream<br />

AFOSV<br />

Make/Model<br />

Did POC switch "open" before<br />

AFOSOV opens enough to<br />

allow flow?<br />

Yes<br />

No<br />

Yes<br />

No<br />

Did AFSOV, in "open" status,<br />

allow boiler to fire?<br />

No<br />

Yes<br />

No<br />

Yes<br />

POC-AFOSV<br />

PASS<br />

FAIL<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

Page 14 of 23

30<br />

PPBS<br />

Did boiler start on propane<br />

pilot?<br />

Yes<br />

No<br />

PASS<br />

PPBS<br />

FAIL<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

31<br />

APFGSOV & APFGSVV<br />

Step: 8 3, 18,22<br />

Upstream<br />

APFGSOV<br />

Downstream<br />

APFGSOV<br />

APFGSVV<br />

Make/Model<br />

Does valve<br />

open when<br />

boiler shuts<br />

down?<br />

Yes<br />

No<br />

Did valve leak<br />

after closing?<br />

No<br />

Yes<br />

No<br />

Yes<br />

No<br />

Yes<br />

APFGSOV &<br />

APFGSVV<br />

PASS<br />

FAIL<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

Page 15 of 23

32<br />

LPFGPCS<br />

LPFGPCS Make/Model<br />

Step: 1 2 3<br />

5 6 11 16<br />

LPFGPCS<br />

located in<br />

correct<br />

position?<br />

Are snubbers<br />

or dampeners<br />

involved?<br />

LPFGPCS<br />

Range<br />

LPFGPCS Set<br />

Point<br />

Regulated<br />

Pilot Pressure<br />

Is #3<br />

80%<br />

of #5?<br />

LPFGPCS Trip<br />

Pressure<br />

Main flame lit<br />

instantly and<br />

smoothly?<br />

Yes Yes Yes Yes<br />

No No No No<br />

LPFGPCS<br />

PASS<br />

FAIL<br />

Notes:<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

33<br />

HWADT, LWACT & DAODS<br />

HWADT Make/Model<br />

LWACT Make/Model<br />

DAODS level sensor Make/Model<br />

HWADT<br />

LWACT<br />

DAODS<br />

Step: 1 3, 9, 16 2<br />

4, 10, 17 12 13 20, 25, 28 21, 26, 29<br />

Set Point<br />

Is set point<br />

located at<br />

acceptable<br />

level?<br />

Level sensor type<br />

Is sensor<br />

correct type?<br />

Is drain<br />

controlled via<br />

electric valve?<br />

Does DAODS<br />

have a flow<br />

sight on drain<br />

line?<br />

Tripping level<br />

Is tripping<br />

point at<br />

acceptable<br />

level?<br />

Did device<br />

function<br />

correctly?<br />

Yes Yes Yes Yes<br />

No No No No<br />

Yes Yes Yes Yes<br />

No No No No<br />

Yes Yes Yes Yes Yes Yes<br />

No No No No No No<br />

HWADT, LWACT<br />

& DAODS<br />

PASS<br />

FAIL<br />

Notes:<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Page 16 of 23

34<br />

LWADT & HWACT<br />

LWADT Make/Model<br />

HWACT Make/Model<br />

HWACT<br />

LWADT<br />

Step: 1 3, 8 2<br />

4, 9 12, 14 13, 15<br />

Set Point<br />

Is set point<br />

located at<br />

acceptable<br />

level?<br />

Level sensor type<br />

Is sensor<br />

correct type?<br />

Tripping level<br />

Is tripping<br />

point at<br />

acceptable<br />

level?<br />

Did device<br />

function<br />

correctly?<br />

Yes Yes Yes Yes<br />

No No No No<br />

Yes Yes Yes Yes<br />

No No No No<br />

LWADT &<br />

HWACT<br />

PASS<br />

FAIL<br />

Notes:<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Page 17 of 23

35<br />

DASV<br />

DA Tank Make/Model<br />

Step 1<br />

Date of most recent passing DA-WMPT<br />

DA MAWP<br />

psi<br />

Step: 2 3 5 19 20<br />

DA Tank<br />

passed DA-<br />

WMPT < 6<br />

yrs?<br />

Does DA Tank<br />

have a vacuum<br />

breaker?<br />

Water flows<br />

freely down<br />

vent drains?<br />

Vent<br />

Is DASV vent<br />

directed<br />

outside?<br />

Heated vent<br />

line touches<br />

drip pan?<br />

Yes Yes Yes Yes Yes<br />

No No No No No<br />

Step: 7<br />

8 9 14 17 15, 18<br />

DASV<br />

Capacity DASV<br />

lbs./hr<br />

Range<br />

Set Point<br />

psi<br />

Is #8 = 5 psi<br />

above DA Tank<br />

psi?<br />

DASV capacity<br />

1000<br />

lbs/hour?<br />

Lift<br />

Reseat<br />

Is lift and<br />

reseat psi in<br />

correct range?<br />

Did DASV<br />

function<br />

correctly?<br />

Yes Yes Yes Yes<br />

psi<br />

psi<br />

No No No No<br />

PASS<br />

DASV<br />

FAIL<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Notes:<br />

Page 18 of 23

36 SVFPRV<br />

This test is applicable to any safety pressure relief valve following any PRV in the boiler plant.<br />

SVFPRV Make/Model<br />

Step: 2 27 28 4<br />

6 7<br />

SVFPRV Vent<br />

If SVFPRV serves DA:<br />

Capacity<br />

Range Set Point<br />

SVFPRV lbs./hr<br />

DASV set point<br />

Water flows<br />

freely down<br />

vent drain?<br />

Is vent<br />

directed<br />

outside?<br />

Heated vent<br />

line touches<br />

drip pan?<br />

Is SVFPRV<br />

about<br />

5 psi > #5<br />

Yes Yes Yes Yes<br />

psi<br />

psi<br />

No No No No<br />

Step: 8<br />

9 10 11 12 18 21 19, 21 24<br />

Upstream psi<br />

before SVFPRV<br />

psi<br />

psi on steam<br />

line following<br />

SVFPRV<br />

psi<br />

PRV bypass<br />

valve size<br />

in.<br />

Bypass valve<br />

wide open<br />

capacity<br />

lbs/hr<br />

PRV wide<br />

open capacity<br />

lbs/hr<br />

Is SVFPRV<br />

capacity > #9<br />

and #10<br />

SVFPRV Lift<br />

SPFPRV Reseat<br />

Is lift and<br />

reseat psi in<br />

correct range?<br />

During acc.<br />

test, is psi ><br />

6% above #4<br />

set point?<br />

Did SVFPRV<br />

function<br />

correctly?<br />

Yes Yes Yes Yes<br />

psi<br />

psi<br />

No No No No<br />

PASS<br />

SVFPRV<br />

FAIL<br />

Notes:<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

37<br />

38<br />

39<br />

40<br />

LWCOHW & ALWCOHW<br />

LRVHW<br />

HWTS<br />

FS<br />

For systems with hot water only boilers<br />

Page 19 of 23

41<br />

CMA & CGA<br />

CMA Make/Model<br />

CGA Make/Model<br />

CMA<br />

CGA<br />

Step: 1 2 3 4 5 6 7 8 10<br />

Number of<br />

alarms<br />

Are number<br />

and locations<br />

adequate?<br />

Alarm set<br />

point<br />

Test gas<br />

concentration<br />

Carbon Monoxide (CO)<br />

Is set point<br />

≤ 50 ppm?<br />

Is test gas at<br />

≤ 50 ppm?<br />

Combustible Gas<br />

Is set point ≤<br />

10% of LEL?<br />

Is test gas at ≤<br />

10% of LEL?<br />

Did units pass<br />

mfr.'s testing<br />

SOP's?<br />

Yes Yes Yes Yes<br />

ppm<br />

ppm<br />

No No No No<br />

Yes Yes Yes Yes<br />

% %<br />

No No No No<br />

CMA & CGA<br />

PASS<br />

FAIL<br />

Notes:<br />

Inspector's Name →<br />

Signed →<br />

Date →<br />

Page 20 of 23