Energy - Allianz Global Corporate & Specialty

Energy - Allianz Global Corporate & Specialty

Energy - Allianz Global Corporate & Specialty

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

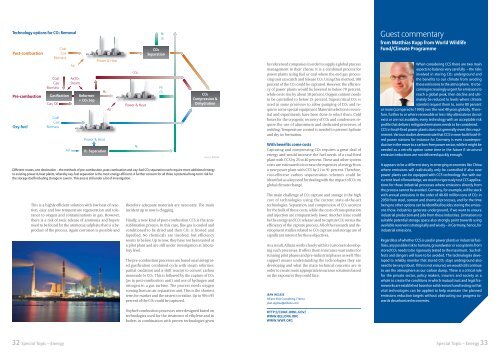

Technology options for CO2 Removal<br />

Post-combustion<br />

Pre-combustion<br />

Oxy-fuel<br />

Coal<br />

Gas<br />

Biomass<br />

Gasification<br />

Gas, Oil<br />

Coal<br />

Gas<br />

Biomass<br />

Coal<br />

Gas<br />

Biomass<br />

32 Special Topic – <strong>Energy</strong><br />

Air<br />

Air<br />

Air/O2<br />

Steam<br />

Reformer<br />

+ CO2 Sep<br />

Power & Heat<br />

O2 Separation<br />

Power & Heat<br />

This is a highly efficient solution with low heat of reaction,<br />

easy and low temperature regeneration and tolerance<br />

to oxygen and contaminations in gas. However,<br />

there is a risk of toxic release of ammonia and buyers<br />

need to be found for the ammonia sulphate that is a byproduct<br />

of the process. Again corrosion is possible and<br />

H2<br />

Air<br />

CO2<br />

Power & Heat<br />

N2<br />

N2<br />

O2<br />

CO2<br />

Separation<br />

N2<br />

O2<br />

CO2<br />

Compression &<br />

Dehydration<br />

Source: Bellona<br />

Different routes, one destination – the methods of pre-combustion, post-combustion and oxy-fuel CO ² separation each require more additional energy<br />

to existing power & heat plants, whereby oxy-fuel separation is the most energy-efficient. A further concern for all three is potential long-term risk for<br />

the storage itself including storage in cavern. This area is still under a lot of investigation.<br />

therefore adequate materials are necessary. The main<br />

incident up to now is clogging.<br />

Finally, a new kind of post-combustion CCS is the antisublimation<br />

process. In this case, flue gas is cooled and<br />

conditioned to be dried and then CO2 is frosted and<br />

liquefied. No chemicals are involved, but efficiency<br />

seems to be low. Up to now, they have not been tested at<br />

a pilot plant and are still under investigation at laboratory<br />

level.<br />

The pre-combustion processes are based on an integrated<br />

gasification combined cycle with steam reformer,<br />

partial oxidation and a shift reactor to convert carbon<br />

monoxide to CO2. This is followed by the capture of CO2<br />

(as in post-combustion unit) and use of hydrogen and<br />

nitrogen in a gas turbine. The process needs oxygen<br />

coming from an air separation unit. This is the shortest<br />

term for market and the easiest to realize. Up to 90 to 95<br />

percent of the CO2 could be captured.<br />

Oxyfuel-combustion processes were designed based on<br />

technologies used for the treatment of ethylene and in<br />

boilers in combination with proven technologies given<br />

by referenced companies in order to supply a global process<br />

management to their clients. It is a combined process for<br />

power plants using fuel or coal where the end gas processing<br />

unit can catch and release CO2. Using this method, 100<br />

percent of the CO2 could be captured. However, the efficiency<br />

of power plants would be lowered to below 70 percent,<br />

while costs rise by about 30 percent. Oxygen content needs<br />

to be controlled to below 25 percent. Supercritical CO2 is<br />

used in some processes to allow pumping of CO2 and requires<br />

some special equipment. Material selection is essential<br />

and experiments have been done to select them. Cold<br />

boxes for the cryogenic recovery of CO2 and condensers require<br />

the use of aluminium and dedicated processes of<br />

welding. Temperature control is needed to prevent hydrate<br />

and dry ice formation.<br />

With benefits come costs<br />

Capturing and compressing CO2 requires a great deal of<br />

energy and would increase the fuel needs of a coal-fired<br />

plant with CCS by 25 to 40 percent. These and other system<br />

costs are estimated to increase the expenses of energy from<br />

a new power plant with CCS by 21 to 91 percent. Therefore,<br />

cost-effective carbon sequestration schemes could be<br />

identified as a key need for dealing with the impact of CO2 on<br />

global climate change.<br />

The main challenge of CO2 capture and storage is the high<br />

cost of technologies using the current state-of-the-art<br />

technologies. Separation and compression of CO2 account<br />

for the bulk of these costs, while the costs of transportation<br />

and injection are comparatively lower. Another issue could<br />

be the energy and CO2 release used to capture CO2 versus the<br />

efficiency of the capture process. All of the research and development<br />

studies related to CO2 capture and storage are of<br />

significant interest for these objectives.<br />

As a result, <strong>Allianz</strong> works closely with its customers develop -<br />

ing such processes. It offers them insurance warranties for<br />

running pilot phases and pre-industrial phases as well. This<br />

support means understanding the technologies they are<br />

developing and what the main technical concerns are in<br />

order to create more appropriate insurance solutions based<br />

on the exposures they could face.<br />

JEAN INGLESE<br />

<strong>Allianz</strong> Risk Consulting, France<br />

jean.inglese@allianz.com<br />

HTTP://CDIAC.ORNL.GOV/<br />

WWW.BELLONA.ORG<br />

WWW.WWF.ORG<br />

Guest commentary<br />

from Matthias Kopp from World Wildlife<br />

Fund/Climate Programme<br />

When considering CCS there are two main<br />

aspects to balance very carefully – the risks<br />

involved in storing CO2 underground and<br />

the benefits to our climate from avoding<br />

these emissions to the atmosphere. It is becoming<br />

increasingly urgent for emissions to<br />

reach a global peak, then decline and ultimately<br />

be reduced to levels where climate<br />

scientist request them to, some 80 percent<br />

or more (compared to 1990) over the next 40 years globally. Therefore,<br />

further to or where renewable or less risky alternatives do not<br />

exist or are not available, every technology with an acceptable risk<br />

profile that delivers mitigated emissions needs to be considered.<br />

CCS in fossil-fired power plants does not generally meet this requirement.<br />

Various studies demonstrate that CCS in new-built fossil-fired<br />

power stations for instance for Germany is even counterproductive<br />

in the move to a carbon-free power sector, while it might be<br />

needed as a retrofit option some time in the future if structural<br />

emission reductions are not delivered quickly enough.<br />

It appears to be a different story in emerging economies like China<br />

where emissions will realistically only be controlled if also new<br />

power plants can be equipped with CCS technology. But with our<br />

current level of knowledge, we need to rigorously test CCS applications<br />

for those industrial processes where emissions directly from<br />

the process cannot be avoided. Germany, for example, will be stuck<br />

with annual emissions in the order of 40-60 million tons of CO2 in<br />

2050 from steel, cement and chemical processes, and for the time<br />

being no other options can be identified besides storing the emissions<br />

those industries generate underground, if we want to ensure<br />

industrial production and jobs from those industries. Limitations to<br />

suitable potential storage space also strongly point towards using<br />

available reservoirs strategically and wisely – in Germany, hence, for<br />

industrial emissions.<br />

Regardless of whether CCS is used in power plants or industrial facilities,<br />

any possible risk to humans, groundwater or ecosystems from<br />

stored CO2 needs to be rigorously tested to the maximum. Such effects<br />

and dangers will have to be avoided. The technologies developed<br />

to reliably monitor that stored CO2 stays underground also<br />

need to be very robust. If this is not ensured, we would still continue<br />

to use the atmosphere as our carbon dump. There is a critical role<br />

for the private sector, policy makers, insurers and society as a<br />

whole to create the conditions in which mutual trust and legal frameworks<br />

are established based on solid research and testing so that<br />

vital technologies can be applied to help maintain the planned<br />

emissions reduction targets without obstructing our progress towards<br />

decarbonized economies.<br />

Special Topic – <strong>Energy</strong> 33