Structure material - Engineering Class Home Pages

Structure material - Engineering Class Home Pages

Structure material - Engineering Class Home Pages

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Structure</strong><br />

<strong>material</strong><br />

Wood<br />

Steel<br />

Concrete<br />

Masonry<br />

Fabric<br />

Material Copyright Prof Schierle 2011 1<br />

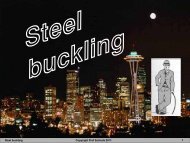

Rupture Length<br />

Rupture length is the maximum length a bar of<br />

constant cross section can be suspended without<br />

rupture under it’s weight in tension (compression<br />

for concrete & masonry)<br />

Rapture length defines the efficiency of <strong>material</strong> as<br />

ratio strength / weight:<br />

R = F / �<br />

where<br />

R = rupture length<br />

F = breaking strength<br />

� = specific gravity (self weight)<br />

The graph is partly based on a study of the<br />

Light weight <strong>Structure</strong>s Institute Stuttgart University<br />

Material Copyright Prof Schierle 2011 2<br />

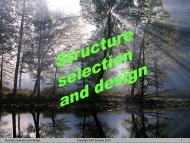

Wood<br />

Energy use<br />

For simple beam of<br />

• Aluminum [Aluminium]<br />

• Concrete [Béton]<br />

• Steel [Acier]<br />

• Wood [Bois]<br />

demonstrates wood requires<br />

much less energy ! ���<br />

Study of EPFL<br />

(Ecole Polytechnique Federale de Lausanne)<br />

Material Copyright Prof Schierle 2011 3<br />

1

Wood<br />

Types:<br />

• Balloon framing (rare)<br />

• Platform framing<br />

• Heavy timber framing<br />

Advantages:<br />

• The only renewable <strong>material</strong><br />

• Warm, natural appearance<br />

• Low energy required<br />

• Easy to work<br />

• Low cost<br />

Challenges:<br />

• Combustible<br />

• Termite attacks<br />

• Decays in variable humidity<br />

• Limited height and floor area<br />

Material Copyright Prof Schierle 2011 4<br />

Platform framing<br />

Platform framing is used for low-rise residential<br />

structures, due to economy & flexibility. 2x4 studs<br />

@ 16” reach from platform to platform. Double<br />

top plates overlap at corners and splices. Plywood<br />

sheathing, nailed to studs, resists lateral wind and<br />

seismic loads. Joists, usually 2x12 @ 16” support<br />

plywood floor and roof (platforms). Blocking<br />

resists joist buckling and supports plywood panel<br />

edges to transfer shear. Standard plywood and<br />

gypsum board panels 48” (4’) wide match 2, 3, or 4<br />

joist/stud spaces of 24”, 16” or 12”, respectively.<br />

A Joists, 2x12 or 2x10 @ 16", 24“, or 12” o.c..<br />

B Blocking<br />

C Double top plates overlap at corners and splices<br />

D Studs, 2x4, 2x6, or 3x4 @ 16“ or 24” o. c.<br />

E Bottom plates<br />

F Double plates supporting joists<br />

G Anchor bolt, 1/2“ @ 4‘ o. c.<br />

H Sole plate, min. 6" above soil<br />

I Concrete foundation<br />

Maximum height: 3 stories (4 with fire sprinklers)<br />

Material Copyright Prof Schierle 2011 5<br />

Wall erection<br />

Plywood shear wall resists<br />

lateral wind and seismic loads<br />

Woodframe house<br />

Material Copyright Prof Schierle 2011 6<br />

2

Clifton Condos, Beverly Hills<br />

Architect: Schierle<br />

Material Copyright Prof Schierle 2011 7<br />

Terrace <strong>Home</strong>s, Hermosa Beach<br />

Architect: Schierle<br />

Material Copyright Prof Schierle 2011 8<br />

Terrace <strong>Home</strong>s<br />

Hermosa Beach<br />

Material Copyright Prof Schierle 2011 9<br />

3

Heavy timber framing<br />

Material Copyright Prof Schierle 2011 10<br />

Timber house<br />

Architect: Thomas Herzog<br />

(rods resist lateral load)<br />

Gamble house Pasadena<br />

Architects: Green and Green<br />

Material Copyright Prof Schierle 2011 11<br />

Compression � �Tension<br />

- � Strain � +<br />

Hysteresis loop<br />

(test stress-strain curve)<br />

E = Energy absorbed by<br />

ductility<br />

Steel<br />

Types:<br />

• Heavy steel<br />

• Light gauge steel<br />

Advantages:<br />

• Can be recycled<br />

• Ductile (absorbs seismic energy)<br />

• Lighter than concrete and masonry<br />

(small seismic forces)<br />

• No limitation of height or floor area<br />

Challenges:<br />

• Requires much energy to produce<br />

• Higher cost than other <strong>material</strong><br />

• Requires fire proofing<br />

• Requires accurate workmanship<br />

• Limited availability in some countries<br />

Material Copyright Prof Schierle 2011 12<br />

4

Heavy steel shapes<br />

Profiles: typical labels<br />

1. W-shape, light (W14x22)<br />

2. W-shape, heavy (W14x730)<br />

3. S-shape, Standard (S12x50)<br />

4. W-shape, wide flange (W16x40)<br />

5. C-shape, Channel (C10x30)<br />

6. T-shape<br />

Cut from S-shape (ST6x25)<br />

Cut from W-shape (WT8x20)<br />

7. Angle, unequal legs (L6x4x½)<br />

Double angle (DL6x4x½)<br />

8. Angle, equal legs (L4x4x½)<br />

Double angle (DL3x3x½)<br />

9. Pipe<br />

Standard (P4)<br />

Extra strong (XP4)<br />

Double extra strong (DXP4)<br />

10. Structural Tubing<br />

Square (ST6x6x½)<br />

Rectangular (ST8x4x½)<br />

Material Copyright Prof Schierle 2011 13<br />

Floor / roof framing<br />

Material Copyright Prof Schierle 2011 14<br />

Steel joints<br />

1 Pin joint, transfers only beam shear to column<br />

2 <strong>Class</strong>ic moment joint, transfers shear and bending moment<br />

3 Dog-bone moment joint, reduces stress for seismic safety<br />

4 Joist to beam joint with top flange cut back<br />

5 Beam to beam joint with both flanges cut back<br />

A Column<br />

B Beam<br />

C Connector angles, welded in shop, bolted in field<br />

D Machine bolts, usually installed in field to connect beam<br />

E Welded connection of beam flanges to column<br />

F Stiffener plates resist bending stress from beam flanges<br />

G Secondary beam / joist supported by primary beam / girder<br />

Material Copyright Prof Schierle 2011 15<br />

5

Steel moment frames<br />

Beam / column moment joint<br />

provides lateral resistance<br />

Material Copyright Prof Schierle 2011 16<br />

Truss floors<br />

Joist and beam roof<br />

Material Copyright Prof Schierle 2011 17<br />

Expressed steel<br />

Hillside house<br />

Architect: Helmut Schulitz<br />

Braced frame<br />

Imos factory<br />

Architect: Richard Rogers<br />

Cable stayed roof<br />

Material Copyright Prof Schierle 2011 18<br />

6

Light-gauge steel<br />

(cold-rolled)<br />

1. Channel stud (2 ½ – 6“)<br />

2. C-stud (2 ½ – 6“)<br />

3. I-stud (3 5/8 –8“)<br />

4. C-joist (6 – 12”)<br />

5. I-joist (6 – 12”)<br />

Material Copyright Prof Schierle 2011 19<br />

Light-gauge steel<br />

Material Copyright Prof Schierle 2011 20<br />

Concrete<br />

Types:<br />

• Site cast<br />

• Precast<br />

• Prestressed<br />

Advantages:<br />

• Widely available<br />

• Can be recycled<br />

• Many finishes<br />

• Takes any form<br />

• Fire resistant<br />

• Durable<br />

Challenges:<br />

• Heavy weight<br />

(large seismic forces)<br />

• Requires rebars<br />

to resist tension<br />

• Possible cracks<br />

without prestress<br />

Material Copyright Prof Schierle 2011 21<br />

7

Concrete properties:<br />

• strong in compression<br />

• weak in tension<br />

• steel re-bars resist tension<br />

Material Copyright Prof Schierle 2011 22<br />

Site cast concrete<br />

facilitates free forms but<br />

formwork may be costly<br />

Material Copyright Prof Schierle 2011 23<br />

Precast Concrete<br />

Advantages:<br />

• repetitive use of formwork<br />

• factory quality control<br />

Challenges:<br />

• element joints<br />

• transportation cost<br />

Material Copyright Prof Schierle 2011 24<br />

8

Precast Concrete<br />

Material Copyright Prof Schierle 2011 25<br />

Masonry<br />

Types:<br />

• Brick masonry<br />

• Concrete masonry<br />

• Stone masonry<br />

Historic stone masonry:<br />

Roman aqueduct Segovia, Spain<br />

Roman aqueduct Pont du Gard France<br />

Advantages:<br />

• Widely available<br />

• Can be recycled<br />

• Earthy appearance<br />

• Fire rated<br />

• Durable<br />

Challenges:<br />

• Heavy weight<br />

(large seismic forces)<br />

• Requires rebars to<br />

resist seismic forces<br />

• Limited height<br />

Material Copyright Prof Schierle 2011 26<br />

Brick Masonry<br />

CMU (Concrete Masonry Units)<br />

Material Copyright Prof Schierle 2011 27<br />

9

Modular coordination<br />

Based on unit size<br />

A Inside dimensions: # of units + 1 joint<br />

3 units+4 joints<br />

B Outside dimensions: # of units – 1 joint<br />

5 units+4 joints<br />

C System dimensions: # of units<br />

4 units+4 joints<br />

Material Copyright Prof Schierle 2011 28<br />

Concrete masonry<br />

CMU: Concrete Masonry Units<br />

Minimum reinforcement<br />

Rebars around openings<br />

In severe seismic areas:<br />

Horizontal & vertical rebars @ 4 feet<br />

In moderate seismic areas:<br />

Horizontal rebars @ 10 feet<br />

Vertical rebars @ 4 feet<br />

Material Copyright Prof Schierle 2011 29<br />

Brick masonry<br />

Minimum reinforcement<br />

Rerbars around openings<br />

In severe seismic areas:<br />

Horizontal & vertical rebars @ 4 feet<br />

In moderate seismic areas:<br />

Horizontal rebars @ 10 feet<br />

Vertical rebars @ 4 feet<br />

Material Copyright Prof Schierle 2011 30<br />

10

CMU wall with rebars<br />

Grouting<br />

(bonds rebars with masonry)<br />

Material Copyright Prof Schierle 2011 31<br />

San Diego Convention Center (anticlastic)<br />

Architect: Arthur Erickson; Engineer: Horst Berger<br />

Fabric<br />

Types:<br />

• Anticlastic (saddle shape)<br />

• Air supported<br />

• Air inflated<br />

Advantages:<br />

• Light-weight<br />

(less seismic load)<br />

• Translucent<br />

(daylight saves energy)<br />

Challenges:<br />

• Fire rating<br />

(Teflon coated fiber glass is<br />

fire rated; polyester is not)<br />

• Durability (about 30 years)<br />

Material Copyright Prof Schierle 2011 32<br />

Air supported<br />

Inside air pressure<br />

greater than outside<br />

• Require revolving doors<br />

to keep air pressure<br />

Air inflated<br />

Air pressure between<br />

double membrane or tubes<br />

Material Copyright Prof Schierle 2011 33<br />

11

Anticlastic Membranes<br />

Stadium roof Oldenburg, Germany<br />

Engineer: Schlaich / Bergermann<br />

Material Copyright Prof Schierle 2011 34<br />

Material Copyright Prof Schierle 2011 35<br />

Architect: Saugey / Schierle<br />

Engineer: Froadveaux / Weber<br />

Swiss Expo 64<br />

Stuttgart<br />

Architect: Schierle<br />

Engineer: ASI<br />

Sea World Vallejo<br />

Stadium roofs<br />

Engineer: Schlaich / Bergermann<br />

Kuala Lumpur<br />

Material Copyright Prof Schierle 2011 36<br />

12

<strong>Structure</strong><br />

<strong>material</strong><br />

Use intrinsic beauty<br />

Wood<br />

Steel<br />

Concrete<br />

Masonry<br />

Fabric<br />

Material Copyright Prof Schierle 2011 37<br />

13