Enterprise Design Guide - Public - CommScope

Enterprise Design Guide - Public - CommScope

Enterprise Design Guide - Public - CommScope

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

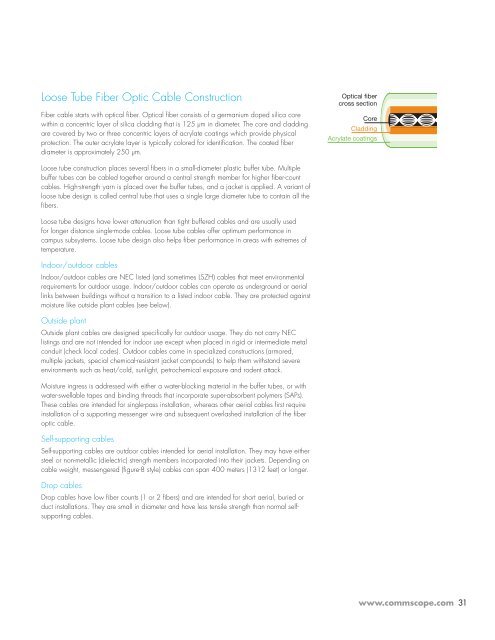

Loose Tube Fiber Optic Cable Construction<br />

Fiber cable starts with optical fiber. Optical fiber consists of a germanium doped silica core<br />

within a concentric layer of silica cladding that is 125 µm in diameter. The core and cladding<br />

are covered by two or three concentric layers of acrylate coatings which provide physical<br />

protection. The outer acrylate layer is typically colored for identification. The coated fiber<br />

diameter is approximately 250 µm.<br />

Loose tube construction places several fibers in a small-diameter plastic buffer tube. Multiple<br />

buffer tubes can be cabled together around a central strength member for higher fiber-count<br />

cables. High-strength yarn is placed over the buffer tubes, and a jacket is applied. A variant of<br />

loose tube design is called central tube that uses a single large diameter tube to contain all the<br />

fibers.<br />

Loose tube designs have lower attenuation than tight buffered cables and are usually used<br />

for longer distance single-mode cables. Loose tube cables offer optimum performance in<br />

campus subsystems. Loose tube design also helps fiber performance in areas with extremes of<br />

temperature.<br />

Indoor/outdoor cables<br />

Indoor/outdoor cables are NEC listed (and sometimes LSZH) cables that meet environmental<br />

requirements for outdoor usage. Indoor/outdoor cables can operate as underground or aerial<br />

links between buildings without a transition to a listed indoor cable. They are protected against<br />

moisture like outside plant cables (see below).<br />

Outside plant<br />

Outside plant cables are designed specifically for outdoor usage. They do not carry NEC<br />

listings and are not intended for indoor use except when placed in rigid or intermediate metal<br />

conduit (check local codes). Outdoor cables come in specialized constructions (armored,<br />

multiple jackets, special chemical-resistant jacket compounds) to help them withstand severe<br />

environments such as heat/cold, sunlight, petrochemical exposure and rodent attack.<br />

Moisture ingress is addressed with either a water-blocking material in the buffer tubes, or with<br />

water-swellable tapes and binding threads that incorporate super-absorbent polymers (SAPs).<br />

These cables are intended for single-pass installation, whereas other aerial cables first require<br />

installation of a supporting messenger wire and subsequent overlashed installation of the fiber<br />

optic cable.<br />

Self-supporting cables<br />

Self-supporting cables are outdoor cables intended for aerial installation. They may have either<br />

steel or non-metallic (dielectric) strength members incorporated into their jackets. Depending on<br />

cable weight, messengered (figure-8 style) cables can span 400 meters (1312 feet) or longer.<br />

Drop cables<br />

Drop cables have low fiber counts (1 or 2 fibers) and are intended for short aerial, buried or<br />

duct installations. They are small in diameter and have less tensile strength than normal selfsupporting<br />

cables.<br />

Optical fiber<br />

cross section<br />

Core<br />

Cladding<br />

Acrylate coatings<br />

www.commscope.com 31