Catalogue

Catalogue

Catalogue

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

24<br />

2. c)<br />

Wiring and connection diagrams (IEC 34-8)<br />

Standard CEG motors are equipped with 6 studs terminal blocks made of phenolic resin. Brass terminal marking<br />

comply with IEC 34-8.<br />

Leads coming from the winding coils through motor frame hole terminate with closed loop connectors at terminal<br />

block. Nuts and bridges for motor connection are fitted in a plastic bag inside the terminal box.<br />

See following paragraphs for connection diagrams:<br />

• Single-speed THREE-PHASE motor connection diagrams section 3. a1 page 32<br />

• Two-speed THREE-PHASE motor connection diagrams section 3. b1 page 36<br />

• SINGLE-PHASE motor connection diagrams section 3. d1 page 44<br />

• SINGLE- and THREE-PHASE motor connection diagrams section 3. g1 page 58<br />

Different terminal blocks are available on demand: 8 studs for separate brake connection, 9 studs for star/delta starting<br />

and 12 studs for double speed motors with separate windings.<br />

External switches, commutators and leads longer than standard are also available.<br />

Terminal boxes<br />

Standard construction for CEG terminal box consists of compartment and cover made of aluminium alloy or thermoplastic<br />

material. Two rubber gaskets are fitted between cover and compartment and between compartment and motor frame.<br />

Single component terminal box type can be fitted as an option.<br />

Special boxes are available to contain single-phase motor capacitors, switch devices or commutators for customized<br />

version.<br />

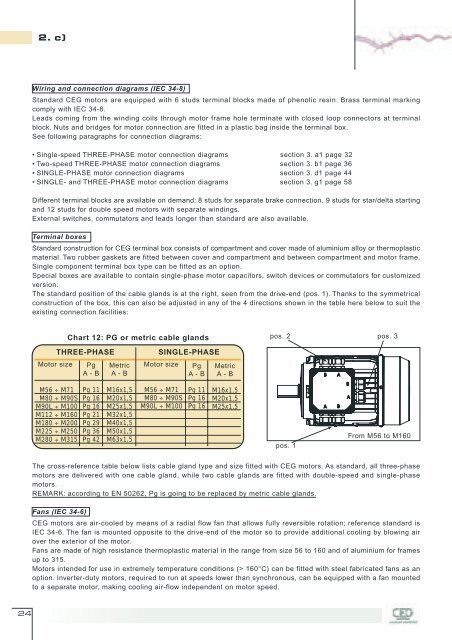

The standard position of the cable glands is at the right, seen from the drive-end (pos. 1). Thanks to the symmetrical<br />

construction of the box, this can also be adjusted in any of the 4 directions shown in the table here below to suit the<br />

existing connection facilities:<br />

M56 ÷ M71<br />

M80 ÷ M90S<br />

M90L ÷ M100<br />

M112 ÷ M160<br />

M180 ÷ M200<br />

M225 ÷ M250<br />

M280 ÷ M315<br />

Chart 12: PG or metric cable glands pos. 2 pos. 3<br />

THREE-PHASE<br />

Motor size Pg Metric<br />

A - B A - B<br />

Pg 11<br />

Pg 16<br />

Pg 16<br />

Pg 21<br />

Pg 29<br />

Pg 36<br />

Pg 42<br />

M16x1,5<br />

M20x1,5<br />

M25x1,5<br />

M32x1,5<br />

M40x1,5<br />

M50x1,5<br />

M63x1,5<br />

SINGLE-PHASE<br />

Motor size<br />

M56 ÷ M71<br />

M80 ÷ M90S<br />

M90L ÷ M100<br />

Pg<br />

A - B<br />

Pg 11<br />

Pg 16<br />

Pg 16<br />

Metric<br />

A - B<br />

M16x1,5<br />

M20x1,5<br />

M25x1,5<br />

pos. 1<br />

From M56 to M160<br />

The cross-reference table below lists cable gland type and size fitted with CEG motors. As standard, all three-phase<br />

motors are delivered with one cable gland, while two cable glands are fitted with double-speed and single-phase<br />

motors.<br />

REMARK: according to EN 50262, Pg is going to be replaced by metric cable glands.<br />

Fans (IEC 34-6)<br />

CEG motors are air-cooled by means of a radial flow fan that allows fully reversible rotation; reference standard is<br />

IEC 34-6. The fan is mounted opposite to the drive-end of the motor so to provide additional cooling by blowing air<br />

over the exterior of the motor.<br />

Fans are made of high resistance thermoplastic material in the range from size 56 to 160 and of aluminium for frames<br />

up to 315.<br />

Motors intended for use in extremely temperature conditions (> 160°C) can be fitted with steel fabricated fans as an<br />

option. Inverter-duty motors, required to run at speeds lower than synchronous, can be equipped with a fan mounted<br />

to a separate motor, making cooling air-flow independent on motor speed.