Success Story The 100th CX for the SHL Plant in ... - Krauss Maffei

Success Story The 100th CX for the SHL Plant in ... - Krauss Maffei

Success Story The 100th CX for the SHL Plant in ... - Krauss Maffei

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

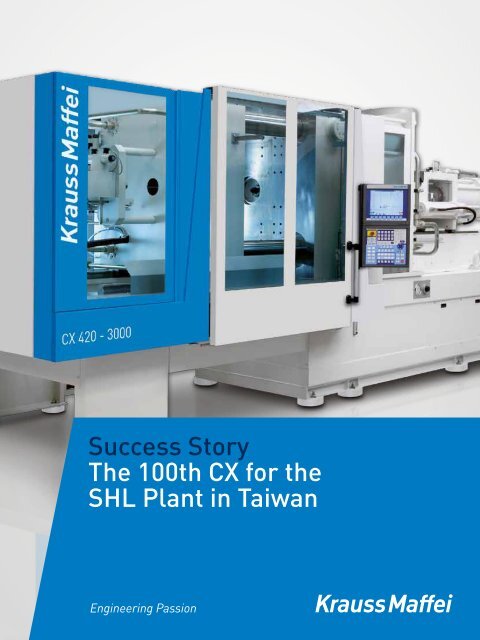

<strong>Success</strong> <strong>Story</strong><br />

<strong>The</strong> <strong>100th</strong> <strong>CX</strong> <strong>for</strong> <strong>the</strong><br />

<strong>SHL</strong> <strong>Plant</strong> <strong>in</strong> Taiwan<br />

Eng<strong>in</strong>eer<strong>in</strong>g Passion

Special Pr<strong>in</strong>t, Ahead <strong>Krauss</strong><strong>Maffei</strong>, Ausgabe 01/12<br />

Roger Samuelsson<br />

CEO and founder of <strong>SHL</strong> Group<br />

Modern & synchronized assembly <strong>for</strong>ms <strong>the</strong> basis<br />

<strong>for</strong> production <strong>in</strong>volv<strong>in</strong>g tight tolerances<br />

<strong>SHL</strong> (Scand<strong>in</strong>avian Health Ltd.),<br />

with over 1,800 employees<br />

globally, is <strong>the</strong> world’s largest<br />

privatelyowned designer,<br />

developer and manufacturer of<br />

advanced drug delivery devices<br />

<strong>for</strong> <strong>the</strong> biopharmaceutical <strong>in</strong>dustry,<br />

such as auto <strong>in</strong>jectors,<br />

pen <strong>in</strong>jectors and <strong>in</strong>halers.<br />

<strong>The</strong> company was established <strong>in</strong> 1989<br />

with <strong>the</strong> goal of comb<strong>in</strong><strong>in</strong>g worldclass<br />

manufactur<strong>in</strong>g <strong>in</strong> Asia with <strong>in</strong>ter national<br />

management practices. <strong>The</strong>re are more<br />

than 100 <strong>in</strong>jection mold<strong>in</strong>g mach<strong>in</strong>es at<br />

<strong>SHL</strong>’s facilities <strong>in</strong> Asia, with a clamp<strong>in</strong>g<br />

<strong>for</strong>ce range of 50 to 420 tons. All mach<strong>in</strong>es<br />

are equipped with ei<strong>the</strong>r 6axis or l<strong>in</strong>ear<br />

robots. Mach<strong>in</strong>e types range from hydraulic<br />

to hybrid and fully electrical mach<strong>in</strong>es,<br />

as well as multicomponent mach<strong>in</strong>es<br />

with turntable and <strong>in</strong>dex<strong>in</strong>g technology.<br />

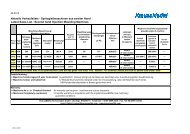

High precision, high capacity<br />

When manufactur<strong>in</strong>g s<strong>in</strong>gleuse disposable<br />

<strong>in</strong>jection systems, such as auto <strong>in</strong>jectors,<br />

<strong>the</strong> quality of all components must be<br />

absolutely identical. Thus, verifiable compliance<br />

with <strong>the</strong> most str<strong>in</strong>gent quality<br />

standards must be guaranteed when<br />

runn<strong>in</strong>g production 24/7. <strong>Krauss</strong><strong>Maffei</strong>’s<br />

<strong>CX</strong> mach<strong>in</strong>es, with different clamp<strong>in</strong>g<br />

<strong>for</strong>ces, have been certified <strong>for</strong> <strong>the</strong>ir designated<br />

scope of delivery and per<strong>for</strong>mance<br />

characteristics. <strong>The</strong> quality requirements<br />

were configured accord<strong>in</strong>g to <strong>the</strong> types of<br />

components <strong>in</strong>stalled and set with<strong>in</strong> <strong>the</strong><br />

maximum permissible noise emissions<br />

and maximum tolerances of <strong>the</strong> shot<br />

weight. “With <strong>the</strong> <strong>CX</strong> series of mach<strong>in</strong>es,<br />

we have fur<strong>the</strong>r enhanced reliability<br />

and cont<strong>in</strong>ue to produce consistent high<br />

quality components”, emphasizes Roger<br />

Samuelsson, CEO and Founder of <strong>the</strong> <strong>SHL</strong><br />

Group, “this has always been a hallmark<br />

of <strong>SHL</strong>”.<br />

High degree of transparency<br />

With one of <strong>the</strong> most modern & synchronized<br />

assemblies with comprehensive documentation,<br />

<strong>Krauss</strong><strong>Maffei</strong> has established<br />

a transparent basis <strong>for</strong> manufactur<strong>in</strong>g<br />

with<strong>in</strong> tight tolerances. This allows us to<br />

build a mach<strong>in</strong>e optimized <strong>for</strong> produc<strong>in</strong>g<br />

molded parts. Where necessary, <strong>the</strong> mach<strong>in</strong>es<br />

can also be designed and qualified<br />

accord<strong>in</strong>g to Good Manufactur<strong>in</strong>g Practice<br />

guidel<strong>in</strong>es which <strong>in</strong>clude required documentation.<br />

When it comes to produ c<strong>in</strong>g<br />

molded parts, quality can be dist<strong>in</strong>g uished<br />

by process reliability and <strong>the</strong> exact<br />

“ As a global manufacturer of drug delivery<br />

devices <strong>for</strong> <strong>the</strong> biopharmaceutical <strong>in</strong>dustry,<br />

<strong>the</strong> key to our company’s success<br />

has been <strong>the</strong> high quality of our products.<br />

We utilize precise manufactur<strong>in</strong>g that is<br />

proven and reproducible. And our goal is<br />

zero error tolerance, a goal that our partners<br />

must share with us. <strong>Krauss</strong><strong>Maffei</strong> is<br />

a good example of such a partner.”<br />

repeatability of <strong>the</strong> s<strong>in</strong>gle components,<br />

and this is where synchronized assembly<br />

plays a crucial role. <strong>The</strong> synchronized<br />

assembly of <strong>in</strong>jection mold<strong>in</strong>g mach<strong>in</strong>es<br />

with clamp<strong>in</strong>g <strong>for</strong>ces of 35 to 350 tons<br />

means both <strong>the</strong> assembly and commission<strong>in</strong>g<br />

of each mach<strong>in</strong>e are synchronized<br />

<strong>in</strong> twelve cycle steps. Introduced <strong>in</strong> 2005,<br />

synchronized assembly has cont<strong>in</strong>uously<br />

improved thanks to employees’ flexibility<br />

and will<strong>in</strong>gness to work toge<strong>the</strong>r. This<br />

can be seen, <strong>in</strong> particular, <strong>in</strong> <strong>the</strong> high<br />

quality of deliveries and <strong>the</strong> short throughput<br />

times. We now use KAIZEN, a well<br />

established system, as a general concept<br />

<strong>for</strong> cont<strong>in</strong>uous improvement processes.<br />

“Our goal is to achieve <strong>the</strong> highest possible<br />

customer satisfaction”, expla<strong>in</strong>s Michael<br />

Müller, Vice President of <strong>Krauss</strong><strong>Maffei</strong> <strong>in</strong><br />

Ch<strong>in</strong>a, “and an example of our success <strong>in</strong><br />

achiev<strong>in</strong>g such a goal can be demonstrated<br />

by look<strong>in</strong>g at our relationship with one of<br />

our longstand<strong>in</strong>g customers, <strong>SHL</strong>, where<br />

we just delivered <strong>the</strong> <strong>100th</strong> <strong>Krauss</strong><strong>Maffei</strong><br />

mach<strong>in</strong>e last December, to <strong>the</strong>ir facilities<br />

<strong>in</strong> Taoyuan, Taiwan”.