KSL-279 | Installation Manual for RHPC Systems on Hydraulic Presses

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

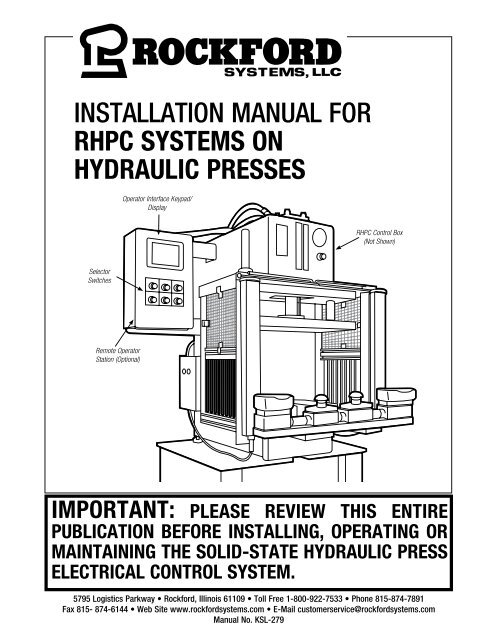

INSTALLATION MANUAL FOR<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> SYSTEMS ON<br />

HYDRAULIC PRESSES<br />

Operator Interface Keypad/<br />

Display<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> C<strong>on</strong>trol Box<br />

(Not Shown)<br />

Selector<br />

Switches<br />

Remote Operator<br />

Stati<strong>on</strong> (Opti<strong>on</strong>al)<br />

IMPORTANT: PLEASE REVIEW THIS ENTIRE<br />

PUBLICATION BEFORE INSTALLING, OPERATING OR<br />

MAINTAINING THE SOLID-STATE HYDRAULIC PRESS<br />

ELECTRICAL CONTROL SYSTEM.<br />

5795 Logistics Parkway • Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d, Illinois 61109 • Toll Free 1-800-922-7533 • Ph<strong>on</strong>e 815-874-7891<br />

Fax 815- 874-6144 • Web Site www.rock<str<strong>on</strong>g>for</str<strong>on</strong>g>dsystems.com • E-Mail customerservice@rock<str<strong>on</strong>g>for</str<strong>on</strong>g>dsystems.com<br />

<str<strong>on</strong>g>Manual</str<strong>on</strong>g> No. <str<strong>on</strong>g>KSL</str<strong>on</strong>g>-<str<strong>on</strong>g>279</str<strong>on</strong>g>

TABLE OF CONTENTS<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

SECTION 1—IN GENERAL..............................................................................................................................................................3 - 9<br />

SECTION 2—INTRODUCTION.....................................................................................................................................................10 - 14<br />

SECTION 3—INSTALLATION OF <str<strong>on</strong>g>RHPC</str<strong>on</strong>g> CONTROL SYSTEM COMPONENTS...............................................................................14 - 24<br />

SECTION 4—SETUP AND PROGRAMMING................................................................................................................................25 - 42<br />

SECTION 5—TROUBLESHOOTING..............................................................................................................................................43 - 45<br />

SECTION 6—MAINTENANCE AND INSPECTION.................................................................................................................................46<br />

SECTION 7—METHODS OF SAFEGUARDING MACHINES............................................................................................................. 47-48<br />

SECTION 8—RETURN MATERIALS AUTHORIZATION FORM..............................................................................................................49<br />

SECTION 9—ORDER FORM................................................................................................................................................................50<br />

© 2019 Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC. All rights reserved. Not to be reproduced in whole or in part without written permissi<strong>on</strong>. Litho in U.S.A.<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

2 Call: 1-800-922-7533

SECTION 1—IN GENERAL<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

Safety Precauti<strong>on</strong>s<br />

“ ”<br />

“ ”<br />

Danger is used to indicate the presence of a hazard which WILL cause SEVERE<br />

pers<strong>on</strong>al injury if the warning is ignored.<br />

THIS SAFETY ALERT SYMBOL IDENTIFIES IMPORTANT SAFETY MESSAGES IN THIS MANUAL.<br />

WHEN YOU SEE THIS SYMBOL , BE ALERT TO THE POSSIBILITY OF PERSONAL INJURY, AND<br />

CAREFULLY READ THE MESSAGE THAT FOLLOWS.<br />

Efficient and safe machine operati<strong>on</strong> depends <strong>on</strong> the development, implementati<strong>on</strong> and en<str<strong>on</strong>g>for</str<strong>on</strong>g>cement of a safety program. This program requires,<br />

am<strong>on</strong>g other things, the proper selecti<strong>on</strong> of point-of-operati<strong>on</strong> guards and safety devices <str<strong>on</strong>g>for</str<strong>on</strong>g> each particular job or operati<strong>on</strong> and a thorough<br />

safety training program <str<strong>on</strong>g>for</str<strong>on</strong>g> all machine pers<strong>on</strong>nel. This program should include instructi<strong>on</strong> <strong>on</strong> the proper operati<strong>on</strong> of the machine, instructi<strong>on</strong><br />

<strong>on</strong> the point-of-operati<strong>on</strong> guards and safety devices <strong>on</strong> the machine, and a regularly scheduled inspecti<strong>on</strong> and maintenance program.<br />

Rules and procedures covering each aspect of your safety program should be developed and published both in an operator’s safety manual, as<br />

well as in prominent places throughout the plant and <strong>on</strong> each machine. Some rules or instructi<strong>on</strong>s which must be c<strong>on</strong>veyed to your pers<strong>on</strong>nel and<br />

incorporated into your program include:<br />

Never place your hands or any part of your body in this machine.<br />

Never operate this machine without proper eye, face and body protecti<strong>on</strong>.<br />

Never operate this machine unless you are fully trained, instructed, and you have read the instructi<strong>on</strong> manual.<br />

Never operate this machine if it is not working properly—stop operating and advise your supervisor immediately.<br />

Never use a foot switch to operate this machine unless a point-of-operati<strong>on</strong> guard or device is provided and<br />

properly maintained.<br />

Never operate this machine unless two-hand trip, two-hand c<strong>on</strong>trol or presence sensing device is installed<br />

at the proper safety distance. C<strong>on</strong>sult your supervisor should you have any questi<strong>on</strong>s regarding the proper<br />

safety distance.<br />

Never tamper with, rewire or bypass any c<strong>on</strong>trol or comp<strong>on</strong>ent <strong>on</strong> this machine.<br />

A company’s safety program must involve every<strong>on</strong>e in the company, from top management to operators, since <strong>on</strong>ly as a group can any operati<strong>on</strong>al<br />

problems be identified and resolved. It is every<strong>on</strong>e’s resp<strong>on</strong>sibility to implement and communicate the in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> and material c<strong>on</strong>tained in catalogs<br />

and instructi<strong>on</strong> manuals to all pers<strong>on</strong>s involved in machine operati<strong>on</strong>. If a language barrier or insufficient educati<strong>on</strong> would prevent a pers<strong>on</strong> from<br />

reading and understanding various literature available, it should be translated, read or interpreted to the pers<strong>on</strong>, with assurance that it is understood.<br />

FOR MAINTENANCE AND INSPECTION ALWAYS REFER TO THE OEM’s (ORIGINAL EQUIPMENT<br />

MANUFACTURER’S) MAINTENANCE MANUAL OR OWNER’S MANUAL. If you do not have an owner’s<br />

manual, please c<strong>on</strong>tact the original equipment manufacturer.<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

Call: 1-800-922-7533 3

SECTION 1—IN GENERAL<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

Safety References<br />

OSHA’S ACT AND FEDERAL REGULATIONS<br />

Since the enclosed equipment can never overcome a mechanical<br />

deficiency, defect or malfuncti<strong>on</strong> in the machine itself, OSHA<br />

(Occupati<strong>on</strong>al Safety and Health Administrati<strong>on</strong>) has established certain<br />

safety regulati<strong>on</strong>s that the employers (users) must comply with so that<br />

the machines used in their plants, factories or facilities are thoroughly<br />

inspected and are in first-class operating c<strong>on</strong>diti<strong>on</strong> be<str<strong>on</strong>g>for</str<strong>on</strong>g>e any of the<br />

enclosed equipment is installed.<br />

1. An Act – Public Law 91 - 596, 91st C<strong>on</strong>gress, S. 2193,<br />

December 29, 1970<br />

Duties:<br />

Sec. 5. (a) Each employer —<br />

(1) shall furnish to each of his employees employment and a place<br />

of employment which are free from recognized hazards that<br />

are causing or are likely to cause death or serious physical<br />

harm to his employees;<br />

(2) shall comply with occupati<strong>on</strong>al safety and health standards<br />

promulgated under this Act.<br />

(b) Each employee shall comply with occupati<strong>on</strong>al safety and<br />

health standards and all rules, regulati<strong>on</strong>s, and orders issued<br />

pursuant to this Act which are applicable to his own acti<strong>on</strong>s<br />

and c<strong>on</strong>duct.<br />

2. OSHA’s Code of Federal Regulati<strong>on</strong>s, Subpart O, that an<br />

employer (user) must comply with include:<br />

Secti<strong>on</strong> 1910.211 Definiti<strong>on</strong>s<br />

Secti<strong>on</strong> 1910.212 (a) General Requirements <str<strong>on</strong>g>for</str<strong>on</strong>g> all Machines<br />

Secti<strong>on</strong> 1910.217 Mechanical Power <strong>Presses</strong><br />

Secti<strong>on</strong> 1910.219 (b)(1) Mechanical Power-Transmissi<strong>on</strong> Apparatus<br />

(Flywheel and Gear Covers)<br />

3. OSHA’s 29 Code of Federal Regulati<strong>on</strong>s, Subpart J 1910.147<br />

The C<strong>on</strong>trol of Hazardous Energy (Lockout / Tagout)<br />

4. OSHA’s Publicati<strong>on</strong>s<br />

“General Industry Safety and Health Regulati<strong>on</strong>s Part 1910,” Code<br />

of Federal Regulati<strong>on</strong>s, Subpart O<br />

“C<strong>on</strong>cepts and Techniques of Machine Safeguarding,” OSHA 3067,<br />

Revised 1992<br />

These publicati<strong>on</strong>s can be obtained by c<strong>on</strong>tacting:<br />

Superintendent of Documents<br />

US Government Printing Office<br />

P.O. Box 371954<br />

Pittsburgh, PA 15250-7954<br />

Ph<strong>on</strong>e: (202) 512-1800<br />

Fax: (202) 512-2250<br />

www.gpo.gov<br />

ANSI SAFETY STANDARDS FOR MACHINES<br />

The most complete safety standards <str<strong>on</strong>g>for</str<strong>on</strong>g> machine tools are published<br />

in the ANSI (American Nati<strong>on</strong>al Standards Institute) B11 series. The<br />

following is a list of each ANSI B11 Standard available at the printing<br />

of this publicati<strong>on</strong>.<br />

B11.1 Mechanical Power <strong>Presses</strong><br />

B11.2 <strong>Hydraulic</strong> <strong>Presses</strong><br />

B11.3 Power Press Brakes<br />

B11.4 Shears<br />

B11.5 Ir<strong>on</strong> Workers<br />

B11.6 Lathes<br />

B11.7 Cold Headers and Cold Formers<br />

B11.8 Drilling, Milling and Boring<br />

B11.9 Grinding Machines<br />

B11.10 Sawing Machines<br />

B11.11 Gear Cutting Machines<br />

B11.12 Roll Forming and Roll Bending<br />

B11.13 Automatic Screw/Bar and Chucking<br />

B11.14 Coil Slitting Machines<br />

B11.15 Pipe, Tube and Shape Bending<br />

B11.16 Metal Powder Compacting <strong>Presses</strong><br />

B11.17 Horiz<strong>on</strong>tal <strong>Hydraulic</strong> Extrusi<strong>on</strong> <strong>Presses</strong><br />

B11.18 Coil Processing <str<strong>on</strong>g>Systems</str<strong>on</strong>g><br />

B11.19 Per<str<strong>on</strong>g>for</str<strong>on</strong>g>mance Criteria <str<strong>on</strong>g>for</str<strong>on</strong>g> the Design, C<strong>on</strong>struc-ti<strong>on</strong>, Care<br />

and Operati<strong>on</strong> of Safeguards as Referenced in the Other<br />

B11 Machine Tool Safety Standards<br />

B11.20 Safety Requirements <str<strong>on</strong>g>for</str<strong>on</strong>g> Manufacturing Sys-tems/Cells<br />

B11.21 Lasers<br />

B11.22 CNC Turning Machines<br />

B11.23 Machining Centers<br />

B11/TR1 Erg<strong>on</strong>omic C<strong>on</strong>siderati<strong>on</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> the Design, <str<strong>on</strong>g>Installati<strong>on</strong></str<strong>on</strong>g> and<br />

Use of Machine Tools<br />

B11/TR2 Mist C<strong>on</strong>trol<br />

B11/TR3 Hazard ID and C<strong>on</strong>trol<br />

B11/TR4 C<strong>on</strong>trol Reliability<br />

R15.06 Robotic Safeguarding<br />

These standards can be purchased by c<strong>on</strong>tacting:<br />

American Nati<strong>on</strong>al Standards Institute, Inc.<br />

11 West 42nd Street<br />

New York, New York 10036<br />

Ph<strong>on</strong>e: (212) 642-4900<br />

Fax: (212) 302-1286<br />

www.ansi.org<br />

OR<br />

Associati<strong>on</strong> of Manufacturing Technology (AMT)<br />

7901 Westpark Drive<br />

McLean, Virginia 22102<br />

Ph<strong>on</strong>e: (703) 827-5211<br />

Fax: (703) 893-1151<br />

www.mfgtech.org<br />

(C<strong>on</strong>tinued <strong>on</strong> next page.)<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

4 Call: 1-800-922-7533

SECTION 1—IN GENERAL<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

NATIONAL SAFETY COUNCIL SAFETY MANUALS AND DATA SHEETS<br />

Other good references <str<strong>on</strong>g>for</str<strong>on</strong>g> safety <strong>on</strong> machine tools are the Nati<strong>on</strong>al<br />

Safety Council’s Safety <str<strong>on</strong>g>Manual</str<strong>on</strong>g>s and Data Sheets. These manuals and<br />

data sheets are written by various committees including the Power<br />

Press, Forging and Fabricating Executive Committee. Copies of the<br />

following publicati<strong>on</strong>s are available from their library:<br />

<str<strong>on</strong>g>Manual</str<strong>on</strong>g>s<br />

Power Press Safety <str<strong>on</strong>g>Manual</str<strong>on</strong>g> - 4th Editi<strong>on</strong><br />

Safeguarding C<strong>on</strong>cept Illustrati<strong>on</strong>s - 6th Editi<strong>on</strong><br />

Forging Safety <str<strong>on</strong>g>Manual</str<strong>on</strong>g><br />

Data Sheets<br />

Bench and Pedestal Grinding Wheel Operati<strong>on</strong>s 12304-0705<br />

Boring Mills, Horiz<strong>on</strong>tal Metal 12304-0269<br />

Boring Mills, Vertical 12304-0347<br />

Coated Abrasives 12304-0452<br />

Cold Shearing Billets and Bars in the Forging Industry.............................<br />

12304-0739<br />

Degreasing (Liquid), Small Metal Parts 12304-0537<br />

Dies, Setup and Removal of Forging Hammer 12304-0716<br />

Drill <strong>Presses</strong>, Metalworking 12304-0335<br />

Drills, Portable Reamer 12304-0497<br />

Drop Hammers, Steam 12304-0720<br />

Electrical C<strong>on</strong>trols <str<strong>on</strong>g>for</str<strong>on</strong>g> Mechanical Power <strong>Presses</strong> 12304-0624<br />

Forging Hammer Dies, Setup and Removal of 12304-0716<br />

Forging <strong>Presses</strong>, Mechanical 12304-0728<br />

Gear-Hobbing Machines 12304-0362<br />

Handling Materials in the Forging Industry 12304-0551<br />

Kick (Foot) <strong>Presses</strong> 12304-0363<br />

Lathes, Engine 12304-0264<br />

Milling Machines, Metalworking 12304-0364<br />

Planers, Metal 12304-0383<br />

Power Press (Mechanical) Point-of-Operati<strong>on</strong><br />

................................................ Safeguarding, C<strong>on</strong>cepts of 12304-0710<br />

Power Press Point-of-Operati<strong>on</strong> Safeguarding: Two-Hand .......................<br />

C<strong>on</strong>trol and Two-Hand Tripping Devices 12304-0714<br />

Power Press Point-of-Operati<strong>on</strong> Safeguarding: Type A<br />

..........................................and B Movable Barrier Devices 12304-0712<br />

Power Press Point-of-Operati<strong>on</strong> Safeguarding:<br />

.................................................Point-of-Operati<strong>on</strong> Guards 12304-0715<br />

Power Press Point-of-Operati<strong>on</strong> Safeguarding:<br />

................................................ Presence Sensing Devices 12304-0711<br />

Power Press Point-of-Operati<strong>on</strong> Safeguarding:<br />

........................................ Pullbacks and Restraint Devices 12304-0713<br />

Power <strong>Presses</strong> (Mechanical), Inspecti<strong>on</strong> and<br />

.................................................................Maintenance of 12304-0603<br />

Power <strong>Presses</strong> (Mechanical), Removing Pieceparts<br />

..................................................................... from Dies in 12304-0534<br />

Power Press, Setting Up and Removing Dies 12304-0211<br />

Press Brakes 12304-0419<br />

Robots 12304-0717<br />

Saws, Metal (Cold Working) 12304-0584<br />

Shapers, Metal 12304-0216<br />

Shears, Alligator 12304-0213<br />

Shears, Squaring, Metal 12304-0328<br />

Upsetters, 12304-0721<br />

Copies of these manuals and data sheets can be obtained by<br />

c<strong>on</strong>tacting:<br />

Nati<strong>on</strong>al Safety Council<br />

1121 Spring Lake Drive<br />

Itasca, IL 60143-3201<br />

1-800-621-7619 ext. 2199<br />

Fax: (630) 285-0797<br />

www.nsc.org<br />

OTHER SAFETY SOURCES<br />

Nati<strong>on</strong>al Institute of Occupati<strong>on</strong>al Safety and Health (NIOSH)<br />

4676 Columbia Parkway<br />

Cincinnati, OH 45226<br />

Ph<strong>on</strong>e: (513) 533-8236<br />

Robotic Industries Associati<strong>on</strong> (RIA)<br />

P.O. Box 3724<br />

Ann Arbor, MI 48106<br />

Ph<strong>on</strong>e: (734) 994-6088<br />

www.robotics.org<br />

For additi<strong>on</strong>al safety in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> and assistance in devising,<br />

implementing or revising your safety program, please c<strong>on</strong>tact the<br />

machine manufacturer, your state and local safety councils, insurance<br />

carriers, nati<strong>on</strong>al trade associati<strong>on</strong>s and your state’s occupati<strong>on</strong>al<br />

safety and health administrati<strong>on</strong>.<br />

Warranty, Disclaimer and Limitati<strong>on</strong> of Liability<br />

WARRANTY<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC. warrants that this product will be free from defects in material and workmanship <str<strong>on</strong>g>for</str<strong>on</strong>g> a period of 12 m<strong>on</strong>ths from the date of shipment<br />

thereof. ROCKFORD SYSTEMS LLC’S OBLIGATION UNDER THIS WARRANTY IS EXPRESSLY AND EXCLUSIVELY LIMITED to repairing or replacing such products<br />

which are returned to it within the warranty period with shipping charges prepaid and which will be disclosed as defective up<strong>on</strong> examinati<strong>on</strong> by Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d<br />

<str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC. This warranty will not apply to any product which will have been subject to misuse, negligence, accident, restricti<strong>on</strong> and use not in accordance<br />

with Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC.’s instructi<strong>on</strong>s or which will have been altered or repaired by pers<strong>on</strong>s other than the authorized agent or employees of Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d<br />

<str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC. Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC.’s warranties as to any comp<strong>on</strong>ent part is expressly limited to that of the manufacturer of the comp<strong>on</strong>ent part.<br />

DISCLAIMER<br />

The <str<strong>on</strong>g>for</str<strong>on</strong>g>egoing Warranty is made in lieu of all other warranties, expressed or<br />

implied, and of all other liabilities and obligati<strong>on</strong>s <strong>on</strong> the part of Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d<br />

<str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC., including any liability <str<strong>on</strong>g>for</str<strong>on</strong>g> negligence, strict liability, or<br />

otherwise, and any implied warranty of merchantability or fitness <str<strong>on</strong>g>for</str<strong>on</strong>g> a<br />

particular purpose is expressly disclaimed.<br />

LIMITATION OF LIABILITY<br />

Under no circumstances, including any claim of negligence, strict liability, or otherwise,<br />

shall Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC. be liable <str<strong>on</strong>g>for</str<strong>on</strong>g> any incidental or c<strong>on</strong>sequential damages, or<br />

any loss or damage resulting from a defect in the product of Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC.<br />

(C<strong>on</strong>tinued <strong>on</strong> next page.)<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

Call: 1-800-922-7533 5

SECTION 1—IN GENERAL<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

Operator Safety Precauti<strong>on</strong>s Sign—(Attachment <str<strong>on</strong>g>for</str<strong>on</strong>g> machine operators)<br />

Accompanying this equipment is an<br />

8 1 ⁄2” x 11” operator safety precauti<strong>on</strong> sign,<br />

Part No. KSC-000, <str<strong>on</strong>g>for</str<strong>on</strong>g> any<strong>on</strong>e operating<br />

the machine where this equipment will be<br />

installed. These precauti<strong>on</strong>s are to be given<br />

to all operators, including setup people,<br />

maintenance pers<strong>on</strong>nel and supervisors.<br />

This sign should also be attached to the<br />

machine, readily accessible and visible to the<br />

operator. (A hole in the corner of this sign is<br />

provided <str<strong>on</strong>g>for</str<strong>on</strong>g> attaching purposes.) Additi<strong>on</strong>al<br />

copies of these precauti<strong>on</strong>s are available.<br />

Please call, e-mail, write, fax, or use the order<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g>m found <strong>on</strong> a later page in this manual.<br />

Fr<strong>on</strong>t<br />

When a language barrier or insufficient<br />

educati<strong>on</strong> prevents a pers<strong>on</strong> from reading or<br />

understanding the c<strong>on</strong>tents of these operator<br />

safety precauti<strong>on</strong>s, you should either translate<br />

this in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> or have it read or interpreted<br />

to the pers<strong>on</strong>. Make sure that the pers<strong>on</strong><br />

understands the in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong>. To order this<br />

pamphlet in Spanish, use Part No. KSC-000S;<br />

in French, use Part No. KSC-000F.<br />

These precauti<strong>on</strong>s must be reviewed daily.<br />

Back<br />

(C<strong>on</strong>tinued <strong>on</strong> next page.)<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

6 Call: 1-800-922-7533

PART NO. KSC 046<br />

DO NOT REMOVE OR COVER THIS SIGN - SEE BACK FOR MOUNTING<br />

Part No. KSC-054<br />

SECTION 1—IN GENERAL<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

Danger Sign(s) to be Mounted <strong>on</strong> Machine<br />

Accompanying this equipment is a 5” x 6” polyethylene danger sign, Part No. KSC-054. This sign MUST BE PERMANENTLY<br />

MOUNTED IN A PROMINENT LOCATION <strong>on</strong> the machine where this equipment is installed. This sign must be in a LOCATION<br />

THAT IS EASILY VISIBLE to the operator, setup pers<strong>on</strong>, or other pers<strong>on</strong>nel who work <strong>on</strong> or around this machine. ALWAYS<br />

mount this sign with screws or rivets when installing the enclosed equipment. If a foot switch is ordered, a 5” x 6”<br />

polyethylene danger sign, Part No. KSC-055 is provided. This sign must also be mounted according to the above instructi<strong>on</strong>s.<br />

If any danger sign becomes destroyed or unreadable, the sign must be replaced immediately. C<strong>on</strong>tact factory <str<strong>on</strong>g>for</str<strong>on</strong>g> replacement danger sign(s).<br />

Never operate this machine unless the danger sign(s) is in place.<br />

Part No. KSC-054 Danger Sign - Standard<br />

Part No. KSC-054S - Spanish<br />

Part No. KSC-055 Danger Sign<br />

(Foot) - Standard<br />

Part No. KSC-055S - Spanish<br />

Part No. KSC-055F - French<br />

CLOSING RAM AND DIE<br />

You are exposed to moving<br />

machine parts that can crush,<br />

dismember and cause death.<br />

DO NOT operate this machine without<br />

safeguards in place.<br />

NEVER<br />

place your hands or any<br />

part of your body in this<br />

machine.<br />

ER<br />

TS<br />

eye and bodily<br />

machine without<br />

nd body protecti<strong>on</strong>.<br />

K FOR MOUNTING<br />

Do not remove or cover this sign–see back <str<strong>on</strong>g>for</str<strong>on</strong>g> mounting instructi<strong>on</strong>s<br />

Part No. KSC-054<br />

Fr<strong>on</strong>t Side<br />

FAILURE to obey will result in loss<br />

of fingers or limbs, or<br />

could cause death.<br />

This sign does not cover all dangers that<br />

could happen while operating this machine.<br />

SUGGESTED PROCEDURE FOR<br />

MOUNTING THIS SIGN<br />

THE PURPOSE OF THIS SIGN IS TO<br />

ADEQUATELY WARN ALL PERSONNEL OF THE DANGER<br />

OF BODILY INJURY.<br />

To accomplish this purpose - ALWAYS mount this<br />

sign to insure the following:<br />

(1) In a c<strong>on</strong>spicuous locati<strong>on</strong><br />

(2) At or near eye level<br />

(3) Clearly visible to operator<br />

(4) PERMANENTLY affixed with<br />

bolts or rivets<br />

NEVER OPERATE MACHINE WITHOUT THIS<br />

DANGER SIGN VISIBLE TO ALL PERSONNEL.<br />

Reverse Side<br />

See page 6 <str<strong>on</strong>g>for</str<strong>on</strong>g><br />

details <strong>on</strong> this<br />

sign.<br />

Fr<strong>on</strong>t Side<br />

“Mechanical Power Press Safety” Booklet<br />

A copy of Booklet No. MPPS Mechanical Power Press Safety is available up<strong>on</strong> request. This booklet is copied verbatim from the CFR (Code of Federal<br />

Regulati<strong>on</strong>s) and c<strong>on</strong>tains all relevant secti<strong>on</strong>s of the OSHA Regulati<strong>on</strong>s c<strong>on</strong>cerning power presses with which an employer (user) must comply. The<br />

enclosed equipment must be installed, used and maintained to meet these regulati<strong>on</strong>s. Specifically, any time a foot switch is used, a suitable<br />

point-of-operati<strong>on</strong> safeguard or device must be used to prevent bodily injury. In additi<strong>on</strong>, every press must be provided with a point-ofoperati<strong>on</strong><br />

safeguard! Please review this booklet and the appropriate ANSI (American Nati<strong>on</strong>al Standards Institute) Safety Standard be<str<strong>on</strong>g>for</str<strong>on</strong>g>e installing<br />

the enclosed equipment. If you are unfamiliar with these detailed safety regulati<strong>on</strong>s, which include regulati<strong>on</strong>s <strong>on</strong> safeguarding the point of operati<strong>on</strong><br />

properly, you may want to attend our regularly scheduled machine safeguarding seminar. To obtain detailed in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> about this training seminar,<br />

please call, fax, write, or check our web site. Our address, teleph<strong>on</strong>e, fax number, and web site address are <strong>on</strong> the fr<strong>on</strong>t cover of this manual.<br />

(C<strong>on</strong>tinued <strong>on</strong> next page.)<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

Call: 1-800-922-7533 7

SECTION 1—IN GENERAL<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

Danger and Warning Labels Provided <strong>on</strong> C<strong>on</strong>trol Box<br />

The illustrated danger and warning labels are affixed to all c<strong>on</strong>trol boxes provided. All pers<strong>on</strong>nel operating or<br />

working around the machine, where this c<strong>on</strong>trol box is installed, must be required to read, understand and<br />

adhere to all dangers and warnings. If any of these labels become destroyed or unreadable, labels MUST be<br />

replaced. C<strong>on</strong>tact factory immediately <str<strong>on</strong>g>for</str<strong>on</strong>g> replacement labels and do not operate the machine until the danger<br />

and warning labels are all in place.<br />

KSS - 027<br />

Photo 1.1<br />

Inside View of <str<strong>on</strong>g>RHPC</str<strong>on</strong>g><br />

C<strong>on</strong>trol Box<br />

(C<strong>on</strong>tinued <strong>on</strong> next page.)<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

8 Call: 1-800-922-7533

SECTION 1—IN GENERAL<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

FOR REPLACEMENT SIGNS<br />

CALL, FAX, E-MAIL, OR USE THE<br />

ORDER FORM ON A LATER PAGE OF THIS MANUAL.<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC.<br />

5795 Logistics Parkway<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d, Illinois 61109<br />

Toll-Free 1-800-922-7533<br />

Ph<strong>on</strong>e 815-874-7891<br />

Fax 815-874-6144<br />

customerservice@rock<str<strong>on</strong>g>for</str<strong>on</strong>g>dsystems.com<br />

www.rock<str<strong>on</strong>g>for</str<strong>on</strong>g>dsystems.com<br />

Photo 1.2<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> C<strong>on</strong>trol Box<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

Call: 1-800-922-7533 9

SECTION 2—INTRODUCTION<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

General Descripti<strong>on</strong> of Comp<strong>on</strong>ents in the System<br />

A complete c<strong>on</strong>trol package <str<strong>on</strong>g>for</str<strong>on</strong>g> hydraulic machines includes the following:<br />

1. Literature folder c<strong>on</strong>taining installati<strong>on</strong> manuals, Operator Safety Precauti<strong>on</strong>s, danger sign(s), electrical c<strong>on</strong>trol schematics, and our latest catalog<br />

2. C<strong>on</strong>trol box—standard (custom or special includes motor c<strong>on</strong>trols and/or disc<strong>on</strong>nect switch) with danger and warning signs<br />

3. Palm butt<strong>on</strong> assembly (Includes two black palm butt<strong>on</strong>s, two palm butt<strong>on</strong> guards, <strong>on</strong>e red emergency-stop butt<strong>on</strong>, and mounting boxes. When<br />

the “automatic” mode of operati<strong>on</strong> is included, <strong>on</strong>e yellow return/inch-up butt<strong>on</strong> with mounting box is furnished.) If multiple operator stati<strong>on</strong>s<br />

are <strong>on</strong> a machine, more than <strong>on</strong>e assembly is furnished.<br />

4. Foot switch (opti<strong>on</strong>al)—If multiple operator stati<strong>on</strong>s are <strong>on</strong> a machine, more than <strong>on</strong>e foot switch is furnished<br />

5. Supervisory c<strong>on</strong>trol stati<strong>on</strong> (Required when multiple operator stati<strong>on</strong>s are used <strong>on</strong> the machine; <strong>on</strong>e stati<strong>on</strong> is required <str<strong>on</strong>g>for</str<strong>on</strong>g> each operator.)<br />

6. Other required comp<strong>on</strong>ents and safeguarding that may be necessary <str<strong>on</strong>g>for</str<strong>on</strong>g> machine (See packing list <str<strong>on</strong>g>for</str<strong>on</strong>g> details)<br />

Individual packages may vary in c<strong>on</strong>tents. However, a packing list is always enclosed showing exactly what material was shipped <strong>on</strong> this order.<br />

Please check the comp<strong>on</strong>ents actually received against this packing list immediately. In most cases, this c<strong>on</strong>trol package system includes two-hand<br />

c<strong>on</strong>trol which can be used as a point-of-operati<strong>on</strong> safeguarding device provided the palm butt<strong>on</strong>s are mounted correctly and at the proper safety<br />

distance (see <str<strong>on</strong>g>for</str<strong>on</strong>g>mula <strong>on</strong> page 18 of this manual). If the opti<strong>on</strong>al foot switch is provided, a safeguard must always be used. Examples of safeguards<br />

include barrier guards, presence sensing devices, pullbacks, restraints, gates, or two-hand c<strong>on</strong>trol. The hands or any other part of the body of an<br />

operator, maintenance pers<strong>on</strong>, setup pers<strong>on</strong>, etc., must never be put into the point-of-operati<strong>on</strong> hazard <str<strong>on</strong>g>for</str<strong>on</strong>g> any reas<strong>on</strong>, at any time.<br />

These c<strong>on</strong>trols can neither cure nor overcome a malfuncti<strong>on</strong>ing machine. They cannot compensate <str<strong>on</strong>g>for</str<strong>on</strong>g> or prevent<br />

a mechanical defect or failure of a machine part. These c<strong>on</strong>trols cannot prevent a repeat or unintended stroke<br />

(cycle) resulting from a mechanical or hydraulic comp<strong>on</strong>ent malfuncti<strong>on</strong>, defect or failure of the machine itself.<br />

Preliminary Steps Be<str<strong>on</strong>g>for</str<strong>on</strong>g>e <str<strong>on</strong>g>Installati<strong>on</strong></str<strong>on</strong>g><br />

Be<str<strong>on</strong>g>for</str<strong>on</strong>g>e proceeding with the installati<strong>on</strong> of the enclosed equipment, you should undertake the following preliminary steps.<br />

1. Read and make sure you understand this entire <str<strong>on</strong>g>Installati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Manual</str<strong>on</strong>g>.<br />

2. Refer to the fr<strong>on</strong>t cover, other line drawings and photos, then make a rough sketch of your installati<strong>on</strong> to plan the locati<strong>on</strong> of the enclosed<br />

equipment <strong>on</strong> the machine.<br />

3. This may be an opportunity to strip down the entire machine by removing all comp<strong>on</strong>ents, piping, wire, etc. Clean, paint and check the entire<br />

electrical, hydraulic, and mechanical systems of the machine <str<strong>on</strong>g>for</str<strong>on</strong>g> proper adjustment and required replacement parts be<str<strong>on</strong>g>for</str<strong>on</strong>g>e proceeding with the<br />

installati<strong>on</strong> of the furnished equipment.<br />

4. Please make sure the machine is in first-class c<strong>on</strong>diti<strong>on</strong>. Be<str<strong>on</strong>g>for</str<strong>on</strong>g>e starting any installati<strong>on</strong>, it is essential that the machine is thoroughly<br />

inspected. Be sure that all mechanical comp<strong>on</strong>ents and all collateral equipment are in first-class operating c<strong>on</strong>diti<strong>on</strong>. Your inspecti<strong>on</strong> should<br />

be d<strong>on</strong>e according to the machine manufacturer’s installati<strong>on</strong> and maintenance instructi<strong>on</strong> manual. If you have any doubts or questi<strong>on</strong>s<br />

c<strong>on</strong>cerning the c<strong>on</strong>diti<strong>on</strong> of the machine, c<strong>on</strong>tact the machine manufacturer <str<strong>on</strong>g>for</str<strong>on</strong>g> assistance. Repair or replace all parts not operating<br />

properly be<str<strong>on</strong>g>for</str<strong>on</strong>g>e proceeding.<br />

Inspecti<strong>on</strong> and maintenance programs must be established and implemented to keep machines in first-class<br />

c<strong>on</strong>diti<strong>on</strong>. Programs must include thorough inspecti<strong>on</strong>s of each machine <strong>on</strong> a weekly basis and records kept of<br />

these inspecti<strong>on</strong>s. Any part of the machine that is worn, damaged or is not operating properly must be replaced<br />

immediately or repaired be<str<strong>on</strong>g>for</str<strong>on</strong>g>e the machine is used.<br />

5. Verify that the machine is in first-class c<strong>on</strong>diti<strong>on</strong> and operating properly; shut off all power to the machine. All trapped hydraulic pressure must be<br />

released in areas of the systems that are being updated or retrofitted be<str<strong>on</strong>g>for</str<strong>on</strong>g>e proceeding. Padlock the disc<strong>on</strong>necting means in the “off” positi<strong>on</strong><br />

and do not actuate the machine again until the installati<strong>on</strong> of all package comp<strong>on</strong>ents has been completed. Lockout/tagout energy isolati<strong>on</strong><br />

procedures must always be practiced and en<str<strong>on</strong>g>for</str<strong>on</strong>g>ced.<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

10 Call: 1-800-922-7533

Safeguard Interlocks and Other Types Of Interlocks<br />

Safeguard Interlocks<br />

SECTION 2—INTRODUCTION<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

The machine will not operate or must not be operated until you either: (1) Electrically interlock or (2) Mechanically guard the machine’s point of<br />

operati<strong>on</strong> with a safeguarding system or device.<br />

When an electrically interlocked method of safeguarding the point of operati<strong>on</strong> is chosen, c<strong>on</strong>nect the interlock to the safeguard interlock terminals<br />

(P7-5 and P7-6) in the c<strong>on</strong>trol box (see page 15), and as shown <strong>on</strong> the c<strong>on</strong>trol wiring schematic (wire numbers 82 and 83).<br />

Point-of-operati<strong>on</strong> electrically interlocked safeguards, when opened, prevent or stop normal machine operati<strong>on</strong> during operator cycling modes.<br />

Examples of these types of interlocks are barrier guard interlocks and gate device interlocks.<br />

When a mechanical guard or device (n<strong>on</strong>electrically interlocked) is chosen, the safeguard interlock terminals (P7-5 and P7-6) are not used. In order<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> the machine to operate with the use of a mechanical guard or device, the safeguard interlock terminals must be c<strong>on</strong>nected.<br />

The mechanical guard or device must be properly installed, used and maintained and must always prevent all<br />

pers<strong>on</strong>nel from bodily injury.<br />

If the mechanical guard or device is not used, is removed, or is defeated, an electrically interlocked method of<br />

safeguarding must be used and c<strong>on</strong>nected to the safeguard interlock terminals (P7-5 and P7-6).<br />

Never operate this machine without point-of-operati<strong>on</strong> safeguarding.<br />

OTHER ELECTRICAL INTERLOCKS<br />

There are basically two types of electrical interlocks as applied to machine c<strong>on</strong>trol circuitry:<br />

• Interlocks <str<strong>on</strong>g>for</str<strong>on</strong>g> the purpose of pers<strong>on</strong>nel protecti<strong>on</strong>, as explained previously.<br />

• Interlocks intended <str<strong>on</strong>g>for</str<strong>on</strong>g> the purpose of protecting the machine and its c<strong>on</strong>trol comp<strong>on</strong>ents.<br />

There are other locati<strong>on</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> interlocks that, when opened, prevent all machine functi<strong>on</strong>s. Examples of these types of interlocks are safety block<br />

electrical cut-off systems, lubricating systems, die protecti<strong>on</strong> equipment, and t<strong>on</strong>nage m<strong>on</strong>itoring systems.<br />

Be sure to c<strong>on</strong>nect the various electrical interlocks to the proper terminals (in the c<strong>on</strong>trol box) according to the machine wiring schematics. If your<br />

schematics do not include these electrical interlocks, please send this in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> to the factory and they can be added to your drawings. There is<br />

an additi<strong>on</strong>al charge <str<strong>on</strong>g>for</str<strong>on</strong>g> this service.<br />

Features of the <str<strong>on</strong>g>RHPC</str<strong>on</strong>g> C<strong>on</strong>trol—<strong>Hydraulic</strong> Press<br />

• Redundant and cross-checking microprocessors<br />

• Redundant switching style DC power supplies<br />

• Press c<strong>on</strong>trol operates <strong>on</strong> 85-135 V AC<br />

• Provisi<strong>on</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> opti<strong>on</strong>al light curtain interface with<br />

Off/On supervised keyed selector switch<br />

• Easy to read blacklit liquid crystal operator interface<br />

display having 4 lines x 20 characters<br />

• Four (4) 24-V DC digital user inputs, programmable,<br />

selectable canned messages<br />

• Two (2) ram advance (down or up) outputs, standard 120 V AC<br />

• One (1) Ram speed change (fast-slow) output, standard 120 V AC<br />

• One (1) ram return (up or down) output,<br />

standard 120 V AC<br />

• Seven-digit stroke counter<br />

• Seven-digitbatch counter with preset<br />

• Automatic mode of operati<strong>on</strong><br />

• Automatic single stroke mode of operati<strong>on</strong><br />

• Operator interface keypad and display,<br />

text in English or Spanish<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

Call: 1-800-922-7533 11

SECTION 2—INTRODUCTION<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

Sequence of Operati<strong>on</strong><br />

RUN MODE—INCH/SINGLE/AUTO<br />

Inch—The inch mode is intended <str<strong>on</strong>g>for</str<strong>on</strong>g> machine setup <strong>on</strong>ly. In this mode of operati<strong>on</strong>, pressing both palm butt<strong>on</strong>s causes the ram to move<br />

in small increments—inch. The ram stops at the bottom of the stroke. Auto up (return) is not active in the inch mode. Press the<br />

yellow return palm butt<strong>on</strong> to inch the ram back to home. Hold the yellow palm butt<strong>on</strong> down to return the ram to the home positi<strong>on</strong><br />

n<strong>on</strong>stop. NOTE: Never attempt to use the inch mode during a producti<strong>on</strong> mode.<br />

Single—Pressing both palm butt<strong>on</strong>s or pressing the foot switch causes ram movement to the bottom of the stroke and stops. The ram does<br />

not stop at sequence stop positi<strong>on</strong>. Auto up (return) of ram is active. After the ram reaches the bottom of the stroke, it automatically<br />

returns to home and stops—single stroke.<br />

Auto—Pressing a prior acti<strong>on</strong> butt<strong>on</strong> and then both palm butt<strong>on</strong>s causes ram movement to the bottom of the stroke and then back to top<br />

automatically. This will c<strong>on</strong>tinue until a top stop butt<strong>on</strong> or E-stop butt<strong>on</strong> has been pressed.<br />

SPEED CHANGE—HIGH-HIGH/LOW-LOW<br />

High—The ram ignores the speed change positi<strong>on</strong> and moves to the bottom of the stroke at high speed.<br />

High/Low—The ram moves to the speed change positi<strong>on</strong> at high speed, and then changes from high to low speed at the speed change<br />

positi<strong>on</strong>.<br />

Low—The ram ignores the speed change positi<strong>on</strong> and moves to the bottom of the stroke at low speed.<br />

RETURN—PRESS-PRESS/DIST-DIST (PRESSURE-PRESSURE/DISTANCE-DISTANCE)<br />

OFF/PROG/RUN<br />

Press—The ram is returned to home positi<strong>on</strong> when the hydraulic pressing pressure (press) reaches the preset value and closes an internal<br />

normally open c<strong>on</strong>tact. The setting of the preset pressing pressure is set by the customer.<br />

Press/Dist—The ram is returned to home positi<strong>on</strong> when the normally open c<strong>on</strong>tact of the pressure switch or the bottom of stroke limit switch<br />

closes.<br />

Dist—The ram is returned to home positi<strong>on</strong> when the normally open c<strong>on</strong>tact in the bottom of stroke limit switch closes.<br />

NOTE: Pressing pressure may be relieved (dumped) prior to returning the ram to home positi<strong>on</strong>. The <str<strong>on</strong>g>RHPC</str<strong>on</strong>g> c<strong>on</strong>trol module has a user<br />

programmable bottom of stroke dwell functi<strong>on</strong>. By enabling this functi<strong>on</strong> and setting the dwell time, pressing pressure is dumped prior<br />

to the ram returning to the home positi<strong>on</strong>. This dwell functi<strong>on</strong> helps in reducing hydraulic shock produced when hydraulic fluids are<br />

reversed under pressure.<br />

Off—The off selecti<strong>on</strong> prevents the machine from running producti<strong>on</strong>. This mode is intended <strong>on</strong>ly <str<strong>on</strong>g>for</str<strong>on</strong>g> temporary shutdown. Do not use this<br />

mode <str<strong>on</strong>g>for</str<strong>on</strong>g> machine servicing or per<str<strong>on</strong>g>for</str<strong>on</strong>g>ming repairs. Always use lockout/tagout procedures when servicing the hydraulic press.<br />

Prog—The prog (program) selecti<strong>on</strong> enables changing user defined parameters withing the c<strong>on</strong>trol module.<br />

Run—When run is selected, the hydraulic press is in the normal process run mode.<br />

ACTUATING MEANS—HAND-FOOT<br />

Hand—With the mode selector set to inch and both palm butt<strong>on</strong>s are pressed, the ram inches down (each time the palm butt<strong>on</strong>s are pressed)<br />

and stops at the bottom of the stroke. With the mode slector set to single and both palm butt<strong>on</strong>s are pressed, the ram moves to the<br />

end of the stroke in <strong>on</strong>e c<strong>on</strong>tinuous moti<strong>on</strong> and stops at the bottom of the stroke. After reaching the bottom of the stroke, release<br />

both palm butt<strong>on</strong>s and the ram will automatically return to the home positi<strong>on</strong>. This operati<strong>on</strong> is comm<strong>on</strong>ly referred to as hand down,<br />

hand through.<br />

Foot—With the mode selector set to single, press the foot switch. The ram moves to the bottom of the stroke and then stops. After reaching<br />

the bottom of the stroke, release the foot switch and the ram will automatically return to the home positi<strong>on</strong>. This is comm<strong>on</strong>ly referred<br />

to as foot down, foot through.<br />

A point-of-operati<strong>on</strong> safeguard must be used when slecting foot, single-stroke operati<strong>on</strong>.<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

12 Call: 1-800-922-7533

SECTION 2—INTRODUCTION<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

C<strong>on</strong>trol Box<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g> <str<strong>on</strong>g>RHPC</str<strong>on</strong>g> hydraulic power punch press c<strong>on</strong>trol is an ec<strong>on</strong>omically, full-featured, dual microprocessor-based punch press c<strong>on</strong>trol.<br />

This c<strong>on</strong>trol system is designed to comply with OSHA 29 CFR 1910.212 and ANSI B11.2. It is an ec<strong>on</strong>omical replacement <str<strong>on</strong>g>for</str<strong>on</strong>g> existing older style<br />

“relay-based” c<strong>on</strong>trol systems found in many older machines today. Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g> hydraulic press c<strong>on</strong>trol is an excellent choice <str<strong>on</strong>g>for</str<strong>on</strong>g> new OEM<br />

machines, or rebuilt units.<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g> c<strong>on</strong>trols can be supplied in a custom enclosure with motor c<strong>on</strong>trols and fused disc<strong>on</strong>nect or as a standard enclosure. The<br />

standard c<strong>on</strong>trol is designed to interface directly into an existing motor c<strong>on</strong>trol circuit. The standard hydraulic punch press c<strong>on</strong>trol package is made<br />

up of the following: a punch press c<strong>on</strong>trol module, a 20” x 20” x 8” NEMA 12 enclosure, a keypad/display operator interface, a light curtain Off/<br />

On keyed selector switch (light curtain opti<strong>on</strong>al), an Off/Prog/Run keyed selector switch, a hand/foot ACTUATING MEANS keyed selector switch,<br />

a Pressure/Pressure-Distance/Distance RETURN MODE keyed selector switch, a High/High-Low/Low SPEED CHANGE keyed selector switch, an<br />

Inch/Single/Auto MODE keyed selector switch, a 250 VA trans<str<strong>on</strong>g>for</str<strong>on</strong>g>mer (230/460 PRI, 120 V SEC) with fusing <str<strong>on</strong>g>for</str<strong>on</strong>g> the primary and sec<strong>on</strong>dary side of<br />

the trans<str<strong>on</strong>g>for</str<strong>on</strong>g>mer, a 4-pole (3 NO/1 NC <str<strong>on</strong>g>for</str<strong>on</strong>g>ce-guided c<strong>on</strong>tacts) master c<strong>on</strong>trol relay that operates <strong>on</strong> 120 V AC, a 4-pole (3 NO/1 NC <str<strong>on</strong>g>for</str<strong>on</strong>g>ce-guided<br />

c<strong>on</strong>tacts) top-stop relay that operates <strong>on</strong> 120 V AC, and 98 wire terminals. Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g> standard c<strong>on</strong>trol may also be ordered in a plain door<br />

enclosure. The keypad/display interface and all operators may be mounted in a remote stati<strong>on</strong> enclosure.<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g> hydraulic punch press c<strong>on</strong>trol module uses complimentary inputs <str<strong>on</strong>g>for</str<strong>on</strong>g> the foot switch, palm butt<strong>on</strong>s, and light curtain inputs. All<br />

inputs are 24 V DC and are optically isolated <str<strong>on</strong>g>for</str<strong>on</strong>g> noise immunity. Each output from the c<strong>on</strong>trol module is accomplished through <strong>on</strong>e <str<strong>on</strong>g>for</str<strong>on</strong>g>ce-guided<br />

relay that has <strong>on</strong>e NO dry c<strong>on</strong>tact. Each output is fused <str<strong>on</strong>g>for</str<strong>on</strong>g> a maximum of four amps (4 A). All outputs come standard at 120 V AC. All 120 V AC<br />

c<strong>on</strong>trolled devices (relays and solenoids) must be suppressed across their coils. Each c<strong>on</strong>trol is shipped with three suppressors. If c<strong>on</strong>trolled devices<br />

are other than standard voltage, outputs may be rec<strong>on</strong>figured <str<strong>on</strong>g>for</str<strong>on</strong>g> desired voltages. The <str<strong>on</strong>g>RHPC</str<strong>on</strong>g> hydraulic press c<strong>on</strong>trol comes with redundant crosschecking<br />

microprocessors and redundant DC power supplies. This provides c<strong>on</strong>trol reliable operati<strong>on</strong> of all outputs in the event <strong>on</strong>e microprocessor<br />

or <strong>on</strong>e DC power supply fails.<br />

Keypad/Display<br />

Photo 3.1<br />

Standard C<strong>on</strong>trol Box with Keypad/Display<br />

(C<strong>on</strong>tinued <strong>on</strong> next page.)<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

Call: 1-800-922-7533 13

SECTION 2—INTRODUCTION<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

REMOTE OPERATOR-STYLE CONTROLS<br />

Remote operator-style c<strong>on</strong>trols include the same features and modes of operati<strong>on</strong> as the standard c<strong>on</strong>trol boxes, however, they do not have a<br />

c<strong>on</strong>trol trans<str<strong>on</strong>g>for</str<strong>on</strong>g>mer. These c<strong>on</strong>trols are intended <str<strong>on</strong>g>for</str<strong>on</strong>g> use where a machine’s existing magnetic motor starter, fused disc<strong>on</strong>nect switch, and c<strong>on</strong>trol<br />

trans<str<strong>on</strong>g>for</str<strong>on</strong>g>mer meet all safety requirements and will remain in use. If an existing c<strong>on</strong>trol trans<str<strong>on</strong>g>for</str<strong>on</strong>g>mer cannot be reused, c<strong>on</strong>tact Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>.<br />

The three remote operator-style c<strong>on</strong>trol boxes available have the keypad/display and all operators <strong>on</strong> the door of the enclosure. The remote operatorstyle<br />

c<strong>on</strong>trol boxes available are:<br />

Style X—Standard <str<strong>on</strong>g>RHPC</str<strong>on</strong>g> c<strong>on</strong>trol box without the c<strong>on</strong>trol trans<str<strong>on</strong>g>for</str<strong>on</strong>g>mer<br />

Style Y—Standard <str<strong>on</strong>g>RHPC</str<strong>on</strong>g> c<strong>on</strong>trol box without the c<strong>on</strong>trol trans<str<strong>on</strong>g>for</str<strong>on</strong>g>mer, but with an E-stop palm butt<strong>on</strong>,<br />

return palm butt<strong>on</strong>, and prior-acti<strong>on</strong> push butt<strong>on</strong> in the enclosure<br />

Style Z—Standard <str<strong>on</strong>g>RHPC</str<strong>on</strong>g> c<strong>on</strong>trol box without the c<strong>on</strong>trol trans<str<strong>on</strong>g>for</str<strong>on</strong>g>mer, but with an E-stop palm butt<strong>on</strong>,<br />

return palm butt<strong>on</strong>, prior-acti<strong>on</strong> push butt<strong>on</strong>, and two (2) guarded run/inch butt<strong>on</strong>s <strong>on</strong> the<br />

sides of the enclosure<br />

CONTROL MODULE KIT<br />

The <str<strong>on</strong>g>RHPC</str<strong>on</strong>g> c<strong>on</strong>trol module kit includes the c<strong>on</strong>trol module, two (2) <str<strong>on</strong>g>for</str<strong>on</strong>g>ceguided relays, c<strong>on</strong>trol<br />

module shock mounts, fasteners, suppressors, extra fuses, ferrules, danger and warning<br />

labels, and electrical schematics. The minimum area required to install this kit <strong>on</strong> an existing<br />

c<strong>on</strong>trol panel is 18” high x 18” wide x 8” deep.<br />

NOTE: This c<strong>on</strong>trol module kit is not furrnished with an enclosure, enclosure panel, c<strong>on</strong>trol<br />

trans<str<strong>on</strong>g>for</str<strong>on</strong>g>mer, c<strong>on</strong>trol fuses, terminals, or wiring.<br />

KEYPAD/DISPLAY KIT<br />

The <str<strong>on</strong>g>RHPC</str<strong>on</strong>g> keypad/display kit includes the Off/Run/Prog keyed slector switch, light curtain Off/On keyed slector switch, actuating means Hand/Foot<br />

keyed slector switch, Inch/Single/Auto mode keyed selector switch, High/High-Low/Low speed change keyed selector switch, Pressure/Pressure-<br />

Distance/Distance return keyed selector switch, all nameplates, and 25’ of shielded cable. Additi<strong>on</strong>al operators may have been furnished. The<br />

minimum area required to install this keypad/display kit is 11” high x 10” wide x 2” deep.<br />

(C<strong>on</strong>tinued <strong>on</strong> next page.)<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

14 Call: 1-800-922-7533

SECTION 3—INSTALLATION OF COMPONENTS<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

CONTROL MODULE ASSEMBLY<br />

The solid-state c<strong>on</strong>trol module assembly below, Part No. FTL-068, is 8 3 ⁄4” high x 8 1 ⁄4” wide x 4” deep. It is c<strong>on</strong>sidered an open device and must be<br />

installed inside a NEMA 12 rated enclosure. Four (4) shock/vibrati<strong>on</strong> mounting pads and four (4) 1 ⁄4-20 socket head cap screws are used to secure it<br />

to an enclosure subpanel. The module cover is held in place with four (4) 8-32 socket butt<strong>on</strong>-head screws <str<strong>on</strong>g>for</str<strong>on</strong>g> easy removal during troubleshooting.<br />

LED indicators <strong>on</strong> each input and output are used as aids in troubleshooting problems. Inputs to the press c<strong>on</strong>trol may be c<strong>on</strong>figured <str<strong>on</strong>g>for</str<strong>on</strong>g> sinking<br />

or sourcing inputs. Whichever type is selected, ALL inputs must be sinking or ALL inputs must be sourcing. Mixing of sinking and sourcing<br />

inputs is NOT allowed.<br />

Output<br />

LEDs<br />

User<br />

Input LEDs<br />

Port P3<br />

Terminal Strip<br />

P6<br />

Top Cover<br />

Terminal Strip<br />

P7<br />

Terminal Strip<br />

P4<br />

Terminal Strip<br />

P8<br />

Terminal Strip<br />

P5<br />

Input LEDs<br />

CPU LEDs<br />

Sync Switch Input LED<br />

(C<strong>on</strong>tinued <strong>on</strong> next page.)<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

Call: 1-800-922-7533 15

SECTION 3—INSTALLATION OF COMPONENTS<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

C<strong>on</strong>trol Module Assembly (c<strong>on</strong>tinued)<br />

If necessary, the cover of the module can be taken off by removing the screws <strong>on</strong> the corners and pulling the top straight off. The dual-CPU circuit<br />

board is then exposed as shown in the photo below.<br />

Photo 3.4<br />

C<strong>on</strong>trol Module without Cover<br />

Relays<br />

Core Module<br />

Fuse (F2)<br />

Fuse (F1)<br />

Fuse (F5)<br />

Fuse (F6)<br />

Fuse (F3)<br />

Fuse (F4)<br />

Battery<br />

User-serviceable parts <strong>on</strong> the dual CPU board are the relays, core module, fuses F1- F6, and the battery. If any changes to the circuit boards are<br />

required, instructi<strong>on</strong>s will be sent with the new parts.<br />

(C<strong>on</strong>tinued <strong>on</strong> next page.)<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

16 Call: 1-800-922-7533

SECTION 3—INSTALLATION OF COMPONENTS<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

Keypad/Display Assembly<br />

Photo 3.5<br />

Keypad/Display<br />

The keypad/display assembly, Part No. FTL- 062, is used to enter setup in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> and to m<strong>on</strong>itor machine operati<strong>on</strong>.<br />

The keypad/display can be furnished in a remote enclosure up to a maximum of 150’ from the c<strong>on</strong>trol module. All programming is accessed by a keyed<br />

selector switch <strong>on</strong> the keypad/display unit.<br />

If the keypad/display is supplied in a remote enclosure, please refer to the secti<strong>on</strong> <strong>on</strong> wiring and the electrical schematic prints that came with the c<strong>on</strong>trol<br />

box <strong>on</strong> the proper wiring c<strong>on</strong>necti<strong>on</strong>.<br />

Mounting the C<strong>on</strong>trol Box<br />

Solidly mount the c<strong>on</strong>trol box in an accessible locati<strong>on</strong>, either <strong>on</strong> or near the machine to be c<strong>on</strong>trolled. A c<strong>on</strong>venient locati<strong>on</strong> will keep c<strong>on</strong>duit runs<br />

to a minimum length.<br />

Although operati<strong>on</strong> of this c<strong>on</strong>trol will not be adversely affected by normal machine operati<strong>on</strong>, excessive shock or vibrati<strong>on</strong> may require shock<br />

mounting in specific applicati<strong>on</strong>s.<br />

The key must be removed from the off/run/program selector switch after the c<strong>on</strong>trol is programmed and be<str<strong>on</strong>g>for</str<strong>on</strong>g>e<br />

the machine is released to producti<strong>on</strong>. All keys must be supervisory c<strong>on</strong>trolled at all times.<br />

(C<strong>on</strong>tinued <strong>on</strong> next page.)<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

Call: 1-800-922-7533 17

SECTION 3—INSTALLATION OF COMPONENTS<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

PART NO. CTL-525 - PALM BUTTON ASSEMBLY (If furnished, see <str<strong>on</strong>g>Installati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Manual</str<strong>on</strong>g> No. <str<strong>on</strong>g>KSL</str<strong>on</strong>g>-071 or <str<strong>on</strong>g>KSL</str<strong>on</strong>g>-073)<br />

When the standard modes of operati<strong>on</strong> of off, inch, single stroke, automatic, and auto single are furnished, the palm butt<strong>on</strong> assembly will c<strong>on</strong>sist<br />

of four butt<strong>on</strong>s (two run/inch butt<strong>on</strong>s with ring guards, <strong>on</strong>e red emergency-stop butt<strong>on</strong>, and <strong>on</strong>e yellow return/inch-up butt<strong>on</strong>). Al<strong>on</strong>g with these<br />

butt<strong>on</strong>s will be four mounting boxes (three double hub and <strong>on</strong>e single hub). Opti<strong>on</strong>ally available are the Touchdown or chrome “light push” palm<br />

butt<strong>on</strong>s. These may be furnished in place of the standard black run/inch palm butt<strong>on</strong>s. The palm butt<strong>on</strong>s can be assembled as shown in Photo 3.7<br />

and mounted according to the requirements of the applicati<strong>on</strong>. Nipples <str<strong>on</strong>g>for</str<strong>on</strong>g> c<strong>on</strong>necting and running wire are not furnished.<br />

Install the palm “run” butt<strong>on</strong>s in such a way that it requires the use of both hands to cycle the machine.<br />

Photo 3.7<br />

NOTE: These operator c<strong>on</strong>trols are furnished when<br />

the “automatic” mode of operati<strong>on</strong> is provided.<br />

Black Run/Inch Butt<strong>on</strong><br />

Yellow Return/Inch-Up Butt<strong>on</strong><br />

Prior-Acti<strong>on</strong> Push Butt<strong>on</strong><br />

Red Emergency-Stop<br />

Butt<strong>on</strong><br />

Black Run/Inch Butt<strong>on</strong><br />

The two “run” palm butt<strong>on</strong>s, <strong>on</strong> hydraulic machines, can be used to initiate a machine cycle and as a method of safeguarding the point of operati<strong>on</strong>.<br />

ANSI’s B11.2 has established certain requirements <str<strong>on</strong>g>for</str<strong>on</strong>g> these butt<strong>on</strong>s when used as a safeguarding method. According to ANSI B11.2 - 1995, the<br />

total stopping time of the press should include the total resp<strong>on</strong>se time of the c<strong>on</strong>trol system and the time it takes the press to cease slide moti<strong>on</strong>.<br />

The following <str<strong>on</strong>g>for</str<strong>on</strong>g>mula should be used when calculating the safety distance:<br />

D s = K (T s + T c + T r + T spm ) where:<br />

D s =minimum safety distance between the device<br />

and the nearest point-of-operati<strong>on</strong> hazard (inches)<br />

K<br />

= the hand speed c<strong>on</strong>stant = 63 inches/sec<strong>on</strong>d.<br />

T s = the stop time of the machine tool measured at the<br />

final c<strong>on</strong>trol element<br />

T c = the resp<strong>on</strong>se time of the c<strong>on</strong>trol system.<br />

NOTE: T s + T c are usually measured by a portable or built-in<br />

stop-time measuring device.<br />

T r<br />

= resp<strong>on</strong>se time of any hand c<strong>on</strong>trol device, if provided,<br />

including its interface<br />

T spm = the additi<strong>on</strong>al time allowed <str<strong>on</strong>g>for</str<strong>on</strong>g> the stopping per<str<strong>on</strong>g>for</str<strong>on</strong>g>mance<br />

m<strong>on</strong>itor to compensate <str<strong>on</strong>g>for</str<strong>on</strong>g> variati<strong>on</strong>s in the normal stopping time<br />

When applying the two palm “run” butt<strong>on</strong>s to meet the requirements <str<strong>on</strong>g>for</str<strong>on</strong>g> a “point-of-operati<strong>on</strong> safeguarding<br />

device,” make certain these butt<strong>on</strong>s are located <strong>on</strong> the machine so they meet the minimum safety distance<br />

required by the ANSI <str<strong>on</strong>g>for</str<strong>on</strong>g>mula.<br />

Simply stated, safety distance is the mounting and locati<strong>on</strong> of the palm butt<strong>on</strong>s at a distance where the operator<br />

cannot reach into the point-of-operati<strong>on</strong> hazard be<str<strong>on</strong>g>for</str<strong>on</strong>g>e the ram has stopped or completed its downward travel.<br />

To obtain the stopping time, a portable stop-time measurement unit can be used.<br />

(For a portable unit, please c<strong>on</strong>tact Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC.)<br />

(C<strong>on</strong>tinued <strong>on</strong> next page.)<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

18 Call: 1-800-922-7533

SECTION 3—INSTALLATION OF COMPONENTS<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

Red Emergency-Stop Palm Butt<strong>on</strong> (Required)<br />

Photo 3.8<br />

The red emergency-stop butt<strong>on</strong> is used to stop the machine anywhere in its cycle. When the operator depresses<br />

the butt<strong>on</strong>, it should stop the hazardous moti<strong>on</strong> of the machine immediately by shutting off the hydraulic drive pump<br />

motor. This palm butt<strong>on</strong> assembly includes a double hub mounting box. It can be located between the two “run” palm<br />

butt<strong>on</strong>s as part of the operator’s c<strong>on</strong>trol stati<strong>on</strong>. (Please refer to page 18.) This butt<strong>on</strong> has a mechanical latch that<br />

must be reset after depressing the butt<strong>on</strong>.<br />

NOTE: More than <strong>on</strong>e emergency-stop butt<strong>on</strong> may be furnished <str<strong>on</strong>g>for</str<strong>on</strong>g> additi<strong>on</strong>al c<strong>on</strong>trol stati<strong>on</strong>s or <str<strong>on</strong>g>for</str<strong>on</strong>g> c<strong>on</strong>venience.<br />

Yellow Return/Inch-Up Butt<strong>on</strong><br />

Photo 3.9<br />

The yellow return/inch-up butt<strong>on</strong> is used to stop the machine when it is in the “automatic” mode of operati<strong>on</strong>. When<br />

the operator depresses the butt<strong>on</strong>, almost anywhere in the stroke of the machine, it will return the ram to the up<br />

positi<strong>on</strong>. This palm butt<strong>on</strong> assembly includes a double hub mounting box. It can be located between the two “run”<br />

palm butt<strong>on</strong>s, al<strong>on</strong>g with the red emergency-stop butt<strong>on</strong>, as part of the operator’s c<strong>on</strong>trol stati<strong>on</strong>. (Please refer to<br />

page 18.)<br />

Automatic Prior-Acti<strong>on</strong> Pushbutt<strong>on</strong> Stati<strong>on</strong> (Part No. LLD-6100 Automatic and Automatic Single Stroke)<br />

Photo 3.10<br />

According to ANSI B11.2 - 1995, c<strong>on</strong>trol systems that include an automatic cycle mode shall require:<br />

“Selecti<strong>on</strong> of the automatic mode; and a prior or deliberate acti<strong>on</strong> by the operator; and operati<strong>on</strong> of the actuating<br />

means; and an intended acti<strong>on</strong> by the operator be<str<strong>on</strong>g>for</str<strong>on</strong>g>e an interrupted cycle may be resumed.”<br />

These prior-acti<strong>on</strong> stati<strong>on</strong>s have a recessed push butt<strong>on</strong> that must be depressed and released by the operator be<str<strong>on</strong>g>for</str<strong>on</strong>g>e<br />

depressing the two palm butt<strong>on</strong>s in order to initiate the c<strong>on</strong>tinuous or automatic RUN type of press operati<strong>on</strong>. This is<br />

sometimes referred to as “walk-away” c<strong>on</strong>tinuous.<br />

Mount the remote stati<strong>on</strong>s <strong>on</strong> the machine so that it is c<strong>on</strong>venient <str<strong>on</strong>g>for</str<strong>on</strong>g> the operator to depress and release these push<br />

butt<strong>on</strong>s prior to depressing the two palm butt<strong>on</strong>s. These butt<strong>on</strong>s may be mounted as part of the operator’s c<strong>on</strong>trol<br />

stati<strong>on</strong>. After releasing the butt<strong>on</strong>, the operator has a 5-sec<strong>on</strong>d time period in which to depress the run butt<strong>on</strong>s. If the<br />

operator should wait l<strong>on</strong>ger than this time setting, the prior acti<strong>on</strong> must be depressed and released again.<br />

(C<strong>on</strong>tinued <strong>on</strong> next page.)<br />

Rock<str<strong>on</strong>g>for</str<strong>on</strong>g>d <str<strong>on</strong>g>Systems</str<strong>on</strong>g>, LLC<br />

Call: 1-800-922-7533 19

SECTION 3—INSTALLATION OF COMPONENTS<br />

<str<strong>on</strong>g>RHPC</str<strong>on</strong>g> <strong>Hydraulic</strong> Press Solid-State C<strong>on</strong>trol<br />

PART NO. CTD-011— FOOT SWITCH (opti<strong>on</strong>al) (See enclosed <str<strong>on</strong>g>Installati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Manual</str<strong>on</strong>g> No. <str<strong>on</strong>g>KSL</str<strong>on</strong>g>-001)<br />

Photo 3.11<br />

If a foot switch c<strong>on</strong>trol is used, all pers<strong>on</strong>nel must be warned that it is NOT a point-ofoperati<strong>on</strong><br />

safeguard. It is the resp<strong>on</strong>sibility of the employer (user) to always provide<br />

an appropriate guard and/or device to prevent bodily injury whenever a foot switch is<br />

used to initiate a machine cycle. (See ANSI B11.2 <str<strong>on</strong>g>for</str<strong>on</strong>g> safeguarding.)<br />

When using a foot switch, please see page 11 <str<strong>on</strong>g>for</str<strong>on</strong>g> in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> <strong>on</strong> electrically interlocking or mechanically guarding<br />

the point of operati<strong>on</strong>. When installing the opti<strong>on</strong>al foot switch, be sure that the wiring schematics are referenced<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> proper c<strong>on</strong>necti<strong>on</strong>s. Be sure to maintain the foot switch in first-class c<strong>on</strong>diti<strong>on</strong>. It must always be wired properly<br />

and the protecti<strong>on</strong> <strong>on</strong> the top, sides and fr<strong>on</strong>t must always remain in place.<br />

Never use a foot switch to operate this machine unless a point-of-operati<strong>on</strong> guard or device is provided and<br />

properly maintained.<br />

The mechanical guard or device must be properly installed, used and maintained. It must always prevent all<br />

pers<strong>on</strong>nel from bodily injury.<br />

If the mechanical guard or device is not used, is removed or is defeated, an electrically interlocked method of<br />

safeguarding must be used and c<strong>on</strong>nected to the safeguard interlock terminals (P7-5 and P7-6).<br />

PART NO. LLD-6101—SUPERVISORY CONTROL STATION (Required <str<strong>on</strong>g>for</str<strong>on</strong>g> multiple operator stati<strong>on</strong>s)<br />

PART NO. LLD-283—SUPERVISORY CONTROL STATION (Required <str<strong>on</strong>g>for</str<strong>on</strong>g> multiple operator stati<strong>on</strong>s and when a USC-000 is used—see below)<br />