Yellow. The Klingspor customer magazine - Edition 2|2020

The new Klingspor customer magazine!

The new Klingspor customer magazine!

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8<br />

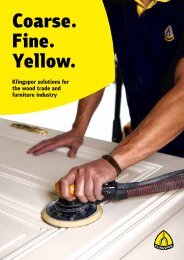

GRIT SIZE SEQUENCE<br />

<strong>Yellow</strong>. <strong>The</strong> <strong>Klingspor</strong> Customer Magazine <strong>2|2020</strong><br />

Grinding tips for<br />

professionals<br />

Part 8:<br />

Grit size<br />

sequence<br />

For more info, visit<br />

www.klingspor.de<br />

What is the correct grit size sequence to follow when sanding wood with a<br />

random orbital sander? Our expert, Marcin Grzesiak, explains how to sand wood<br />

with exceptional fineness and precision.<br />

Following the correct grit size<br />

sequence ensures that scratches<br />

resulting from sanding with a coarser<br />

grit are removed reliably. This is of<br />

particular importance when you sand<br />

against the grain, as the resulting<br />

scratches are difficult to remove if the<br />

jumps in grit size are too large. <strong>The</strong> correct<br />

sequence will save you any nasty surprises<br />

during staining. <strong>The</strong> problem during the<br />

sanding process: skipping too many steps<br />

in the grit sequence may keep a fine grit<br />

from removing scratches that may have<br />

been caused by a coarser grit.<br />

<strong>The</strong>refore, the dependable removal of<br />

scratches from the wood surface requires<br />

that you never skip more than one grit size<br />

in the grit sequence.<br />

A good example of the correct practice<br />

could be accomplished by preparing a<br />

wooden surface with the grit sequence<br />

P80, P120, and P180.<br />

If you follow a P80 grit directly with a<br />

P180 grit, you may still be able to produce<br />

a flat and beautiful surface. You will just<br />

have to invest more time and effort.<br />

However, you cannot be certain of a<br />

particular result until the stain has been<br />

applied on the surface. If the scratches are<br />

still visible following this application, the<br />

workpiece will need to be sanded and<br />

stained again. ■<br />

Advice from the expert<br />

If you wish to ensure that all scratches are<br />

removed, you should refrain from skipping more<br />

than one grit size in your work steps.<br />

<strong>The</strong> test parameters we apply<br />

Type of wood:<br />

Pine<br />

Machine used:<br />

DeWalt random orbital sander<br />

Product diameter:<br />

150 mm<br />

Abrasives used:<br />

PS33K self-fastening discs<br />

Hole pattern: GLS 3<br />

Grit sequence:<br />

P80, P120, P180<br />

<strong>The</strong> surface after being sanded with different grits. <strong>The</strong> surface appears to be scratch-free.<br />

Your professional partner<br />

<strong>The</strong> image illustrates: the swirl marks caused by sanding with a coarser grit could not be<br />

removed entirely in the subsequent work steps (due to too many skipped sizes in the grit<br />

sequence) and reappeared following the staining of the surface.