Panels & Furniture Asia May/June 2020

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>May</strong> / <strong>June</strong> <strong>2020</strong>, Issue 3 | <strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> WOOD CLINIC | 61<br />

7. Drilling machine<br />

- The setting of log mortises for the louvered door post and<br />

the transom with the drilling machine must be based on the<br />

specifications of the louvered door design drawing. The<br />

operator must also check the accuracy of the mortises<br />

regularly using a special mould to make sure the mortises<br />

are n place.<br />

8. Nail dowels<br />

- Make sure the dowels in the upper, middle and lower<br />

transoms of the louvered door are nailed as well as uniformly<br />

glued and of the same height. Ensure strict control of the<br />

quality of dowels and that the chamfering of both ends of the<br />

dowel is in place to reduce the possibility of pressure<br />

damage to the door post when assembling the louvered<br />

door.<br />

9. Colour matching of the louvered door components<br />

- The color of the components of each louvered door and the<br />

number of slats (tied in a bundle) should be allocated before<br />

assembling the louvered door. It will improve the efficiency<br />

of the louvered door assembly.<br />

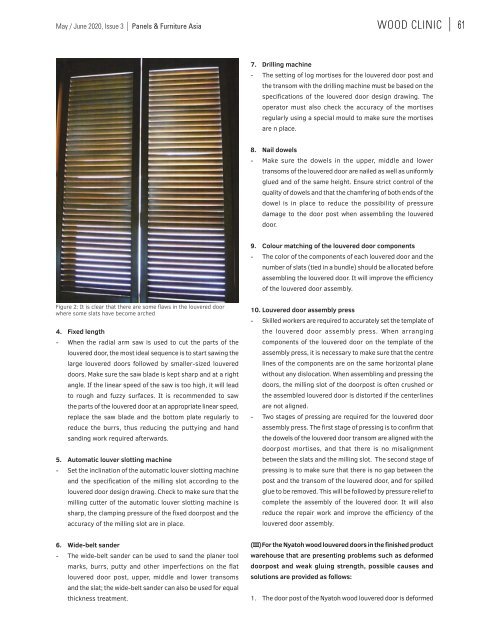

Figure 2: It is clear that there are some flaws in the louvered door<br />

where some slats have become arched<br />

4. Fixed length<br />

- When the radial arm saw is used to cut the parts of the<br />

louvered door, the most ideal sequence is to start sawing the<br />

large louvered doors followed by smaller-sized louvered<br />

doors. Make sure the saw blade is kept sharp and at a right<br />

angle. If the linear speed of the saw is too high, it will lead<br />

to rough and fuzzy surfaces. It is recommended to saw<br />

the parts of the louvered door at an appropriate linear speed,<br />

replace the saw blade and the bottom plate regularly to<br />

reduce the burrs, thus reducing the puttying and hand<br />

sanding work required afterwards.<br />

5. Automatic louver slotting machine<br />

- Set the inclination of the automatic louver slotting machine<br />

and the specification of the milling slot according to the<br />

louvered door design drawing. Check to make sure that the<br />

milling cutter of the automatic louver slotting machine is<br />

sharp, the clamping pressure of the fixed doorpost and the<br />

accuracy of the milling slot are in place.<br />

10. Louvered door assembly press<br />

- Skilled workers are required to accurately set the template of<br />

the louvered door assembly press. When arranging<br />

components of the louvered door on the template of the<br />

assembly press, it is necessary to make sure that the centre<br />

lines of the components are on the same horizontal plane<br />

without any dislocation. When assembling and pressing the<br />

doors, the milling slot of the doorpost is often crushed or<br />

the assembled louvered door is distorted if the centerlines<br />

are not aligned.<br />

- Two stages of pressing are required for the louvered door<br />

assembly press. The first stage of pressing is to confirm that<br />

the dowels of the louvered door transom are aligned with the<br />

doorpost mortises, and that there is no misalignment<br />

between the slats and the milling slot. The second stage of<br />

pressing is to make sure that there is no gap between the<br />

post and the transom of the louvered door, and for spilled<br />

glue to be removed. This will be followed by pressure relief to<br />

complete the assembly of the louvered door. It will also<br />

reduce the repair work and improve the efficiency of the<br />

louvered door assembly.<br />

6. Wide-belt sander<br />

- The wide-belt sander can be used to sand the planer tool<br />

marks, burrs, putty and other imperfections on the flat<br />

louvered door post, upper, middle and lower transoms<br />

and the slat; the wide-belt sander can also be used for equal<br />

thickness treatment.<br />

(III) For the Nyatoh wood louvered doors in the finished product<br />

warehouse that are presenting problems such as deformed<br />

doorpost and weak gluing strength, possible causes and<br />

solutions are provided as follows:<br />

1. The door post of the Nyatoh wood louvered door is deformed