Panels & Furniture Asia July/August 2020

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

28 | FURNITURE MANUFACTURING<br />

<strong>July</strong> / <strong>August</strong> <strong>2020</strong>, Issue 4 | <strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong><br />

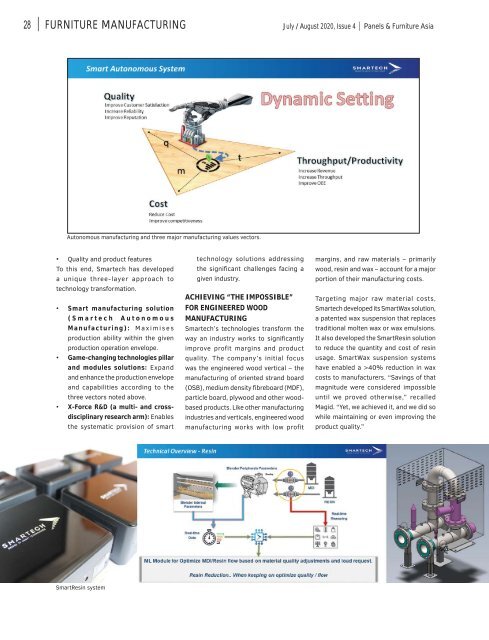

Autonomous manufacturing and three major manufacturing values vectors.<br />

• Quality and product features<br />

To this end, Smartech has developed<br />

a unique three-layer approach to<br />

technology transformation.<br />

• Smart manufacturing solution<br />

(Smartech Autonomous<br />

Manufacturing): Maximises<br />

production ability within the given<br />

production operation envelope.<br />

• Game-changing technologies pillar<br />

and modules solutions: Expand<br />

and enhance the production envelope<br />

and capabilities according to the<br />

three vectors noted above.<br />

• X-Force R&D (a multi- and crossdisciplinary<br />

research arm): Enables<br />

the systematic provision of smart<br />

technology solutions addressing<br />

the significant challenges facing a<br />

given industry.<br />

ACHIEVING “THE IMPOSSIBLE”<br />

FOR ENGINEERED WOOD<br />

MANUFACTURING<br />

Smartech’s technologies transform the<br />

way an industry works to significantly<br />

improve profit margins and product<br />

quality. The company’s initial focus<br />

was the engineered wood vertical – the<br />

manufacturing of oriented strand board<br />

(OSB), medium density fibreboard (MDF),<br />

particle board, plywood and other woodbased<br />

products. Like other manufacturing<br />

industries and verticals, engineered wood<br />

manufacturing works with low profit<br />

margins, and raw materials – primarily<br />

wood, resin and wax – account for a major<br />

portion of their manufacturing costs.<br />

Targeting major raw material costs,<br />

Smartech developed its SmartWax solution,<br />

a patented wax suspension that replaces<br />

traditional molten wax or wax emulsions.<br />

It also developed the SmartResin solution<br />

to reduce the quantity and cost of resin<br />

usage. SmartWax suspension systems<br />

have enabled a >40% reduction in wax<br />

costs to manufacturers. “Savings of that<br />

magnitude were considered impossible<br />

until we proved otherwise,” recalled<br />

Magid. “Yet, we achieved it, and we did so<br />

while maintaining or even improving the<br />

product quality.”<br />

SmartResin system