Jeweller - June 2021

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Once, the words<br />

‘CounterSketch’<br />

and ‘3D printer’<br />

might have<br />

been met with<br />

a confused or<br />

dismissive look.”<br />

Excellence in<br />

<strong>Jeweller</strong>y Casting<br />

Available Now<br />

50 New Features<br />

20 New Tools<br />

For For more information contact<br />

A selection of resins from Formlabs.<br />

at Palloys<br />

Always Made with 100% Australian Gold<br />

.com.au<br />

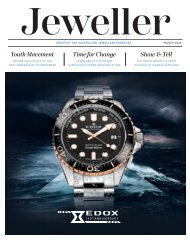

Form 33 SLA 3D 3D Printer<br />

Starting from<br />

$6640 ex ex gst gst<br />

For For more information contact<br />

48 | April <strong>2021</strong><br />

.com.au<br />

Chris Botha<br />

Palloys<br />

Darren<br />

Sher<br />

Chemgold<br />

David Gabriel<br />

Lenrose<br />

“CAD and CAM<br />

technology has<br />

evolved from a volume<br />

production tool to a<br />

fundamental production<br />

tool in any sized<br />

jewellery business... Now<br />

there are many more<br />

user-friendly, lower-cost<br />

options available.”<br />

“<strong>Jeweller</strong>s are becoming<br />

increasingly aware<br />

of the quality we can<br />

produce from CAD.<br />

Our leading technology<br />

resin and wax printers<br />

ensure customers<br />

receive the absolute<br />

best surface finish from<br />

their CAD files.”<br />

“It is a very competitive<br />

market and jewellers<br />

only have two hands,<br />

so they have realised<br />

that CAD/CAM is<br />

an amazingly costeffective<br />

way for them<br />

to increase their own<br />

production and grow<br />

their business.”<br />

“<strong>Jeweller</strong>s are becoming increasingly aware of<br />

the quality we can produce from CAD. Our leading<br />

technology resin and wax printers ensure customers<br />

receive the absolute best surface finish from their<br />

CAD files, along with the highest quality castings,”<br />

explains Darren Sher.<br />

Says Tok, “[At Tok Bros] since 2018, we have updated our<br />

fleet of 3D printers and fine-tuned the resins that we use<br />

to achieve a smoother print and cast surface finish.<br />

“We have also improved the quality of our rendered<br />

images to eliminate as much guesswork as possible<br />

– these images are then used by jewellers with their<br />

customers and on their social media accounts.”<br />

Gabriel has observed a “proliferation of much smaller –<br />

and therefore more affordable – resin printing machines”<br />

which have enabled jewellers to produce their own<br />

high-quality resin prints; “Previously, we needed hugely<br />

expensive machines to achieve this quality,” he adds.<br />

Meanwhile, improvements in resins have also become<br />

a focus for the sector.<br />

In January <strong>2021</strong>, Formlabs – a 3D printing technology<br />

developer and manufacturer based in the US –<br />

introduced Castable Wax 40 Resin, which was developed<br />

with the Gemological Institute of America (GIA) and<br />

international jewellery findings, tools, and equipment<br />

supplier Rio Grande.<br />

Formlabs noted in a statement, “The introduction of<br />

Castable Wax 40 Resin further demonstrates that the<br />

next era of 3D printing won’t be driven by hardware,<br />

but by materials.”<br />

David Lakatos, chief product officer at Formlabs, added,<br />

“The advancements happening in material science are<br />

At Palloys, we pride ourselves on casting from responsibly sourced<br />

and accredited Australian gold.<br />

Coupled with superior quality and utilising the latest technologies,<br />

Palloys casts daily.<br />

Receive instant online quotes at palloys.com today.<br />

It all comes together at Palloys<br />

1300 886 108 | AUSTRALIA WIDE<br />

palloys.com