Jeweller - June 2021

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.morrisandwatson.com<br />

NEW ZEALAND | 0800 500 654<br />

AUSTRALIA | 1800 469 088<br />

Designing the future | <strong>2021</strong> CAD/CAM REPORT<br />

SPOTLIGHT ON<br />

3D SCANNING<br />

<strong>2021</strong> CAD/CAM REPORT | Designing the future<br />

utility and versatility. When revolutionary materials are combined<br />

with the unique structures 3D printers can create, the end products<br />

better meet the needs and expectations of consumers.”<br />

Castable Wax 40 Resin – a 40 per cent wax-filled material – is<br />

designed to produce results “similar to blue carving wax, the<br />

traditional material used in lost wax casting,” according to Formlabs.<br />

Gabriel has observed an “explosion in availability” of different resins:<br />

“Most resin suppliers are searching for the ‘Holy Grail’ of a material<br />

that behaves like a resin when printing and like a wax when casting.<br />

“This is an ongoing quest and the results are varied; it becomes the<br />

problem of the casting house to work out how to best cast these<br />

various new materials.”<br />

One relatively recent innovation in the CAD/CAM sector is 3D<br />

scanning. The scanner creates a digital 3D model of a real-world<br />

object which can then be used as the basis for future designs.<br />

David Gabriel, director Lenrose, explains the process: “We apply a<br />

non-reflective coating to the object that is to be scanned that does not<br />

damage the piece. This allows the scanner to register and scan the<br />

surface. The scanner uses a very soft light source to scan, and there is<br />

no damage at all to jewellery or gemstones.<br />

“In general any piece of jewellery or gemstone can be scanned but as<br />

with every process there are size and geometry limitations.”<br />

Gabriel says preparing pieces for scanning usually takes longer than<br />

the scanning process itself, which he estimates is about 15 to 20<br />

minutes per piece.<br />

Right: Moulds of<br />

wax cast designs.<br />

Below: Computeraided<br />

design in<br />

action. Image<br />

credits: Palloys<br />

As CAD/CAM technology has matured,<br />

innovations have been incremental,<br />

centred on making software interfaces<br />

more accessible, as well as improving<br />

the affordability, accuracy, and<br />

efficiency of existing products, rather<br />

than drastic change<br />

“We started scanning about three years ago,” he continues. “The benefit<br />

to our customers is that we can better produce CAD models to their exact<br />

specifications. Many gemstones have unusual shapes, so we scan the<br />

gems and then produce CAD models that fit the gemstones exactly.”<br />

He adds, “When fitted wedding bands are required it is much easier to<br />

scan the engagement ring and simply CAD the fitted band to suit – you<br />

just know it is going to fit perfectly every time. There are so many varied<br />

applications; it really makes life for everyone so much easier. It has<br />

really been a tremendous advantage to us and allowed us to take on<br />

more complex jobs that otherwise would have been impossible to do.”<br />

At Chemgold, Darren Sher notes, “Improved technology in printing<br />

allows finer and more intricate pieces to be printed and cast easily,<br />

when using the correct software and machine.<br />

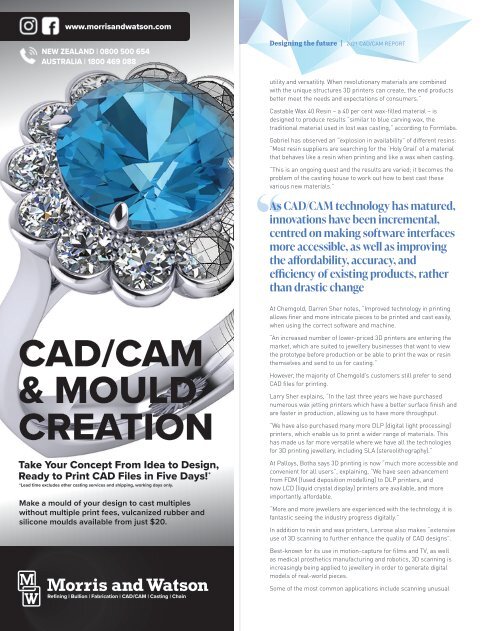

CAD/CAM<br />

& MOULD<br />

CREATION<br />

Take Your Concept From Idea to Design,<br />

Ready to Print CAD Files in Five Days!<br />

*<br />

*Lead time excludes other casting services and shipping, working days only.<br />

Make a mould of your design to cast multiples<br />

without multiple print fees, vulcanized rubber and<br />

silicone moulds available from just $20.<br />

Refining | Bullion | Fabrication | CAD/CAM | Casting | Chain<br />

“An increased number of lower-priced 3D printers are entering the<br />

market, which are suited to jewellery businesses that want to view<br />

the prototype before production or be able to print the wax or resin<br />

themselves and send to us for casting.”<br />

However, the majority of Chemgold’s customers still prefer to send<br />

CAD files for printing.<br />

Larry Sher explains, “In the last three years we have purchased<br />

numerous wax jetting printers which have a better surface finish and<br />

are faster in production, allowing us to have more throughput.<br />

“We have also purchased many more DLP [digital light processing]<br />

printers, which enable us to print a wider range of materials. This<br />

has made us far more versatile where we have all the technologies<br />

for 3D printing jewellery, including SLA [stereolithography].”<br />

At Palloys, Botha says 3D printing is now “much more accessible and<br />

convenient for all users”, explaining, “We have seen advancement<br />

from FDM [fused deposition modelling] to DLP printers, and<br />

now LCD [liquid crystal display] printers are available, and more<br />

importantly, affordable.<br />

“More and more jewellers are experienced with the technology, it is<br />

fantastic seeing the industry progress digitally.”<br />

In addition to resin and wax printers, Lenrose also makes “extensive<br />

use of 3D scanning to further enhance the quality of CAD designs”.<br />

Best-known for its use in motion-capture for films and TV, as well<br />

as medical prosthetics manufacturing and robotics, 3D scanning is<br />

increasingly being applied to jewellery in order to generate digital<br />

models of real-world pieces.<br />

Some of the most common applications include scanning unusual<br />

Celebrating 35 Years<br />

Highest Quality Personalised Service<br />

METALS<br />

CASTING<br />

CAD/CAM<br />

REFINING<br />

FINDINGS<br />

1300 984 751<br />

sales@chemgold.com | www.chemgold.com