FOOD LINE Brochure EN

FOOD LINE Brochure EN

FOOD LINE Brochure EN

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

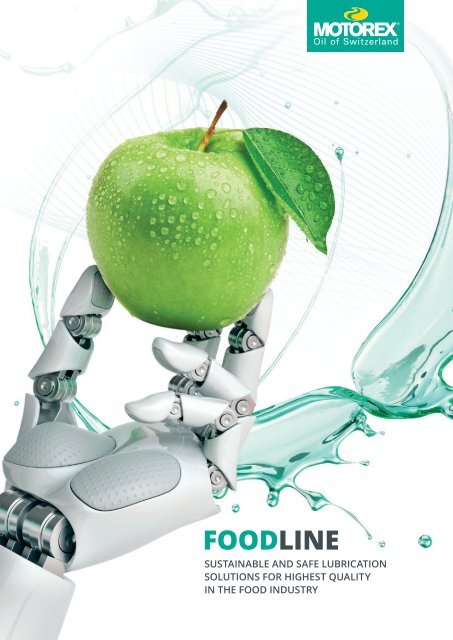

<strong>FOOD</strong><strong>LINE</strong><br />

SUSTAINABLE AND SAFE LUBRICATION<br />

SOLUTIONS FOR HIGHEST QUALITY<br />

IN THE <strong>FOOD</strong> INDUSTRY

FROM RAW MATERIAL<br />

TO <strong>EN</strong>D PRODUCT<br />

<strong>EN</strong>SURING QUALITY - THROUGHOUT THE <strong>EN</strong>TIRE PROCESS<br />

The best for man and machine<br />

From cocoa bean to premium chocolate. From vineyard to first-class wine.<br />

Quality is only achieved when the highest standards are maintained throughout<br />

the entire production chain.<br />

MOTOREX offers high-quality lubricants for the production of food, cosmetics<br />

and pharmaceutical products as well as animal feed, packaging and<br />

process equipment. The wide range covers all applications, meets the<br />

highest quality standards and ensures process reliability.<br />

Each step of food production requires the use of specific lubricants.<br />

MOTOREX provides the best-suited product for your requirement and thus<br />

the best for man and machine. The lubricants are designed to enhance the<br />

quality of the products produced and to protect the consumers‘ health.<br />

The lubricants meet the legal requirements and provide economic value.<br />

Equipment efficiency increases, while energy requirements and maintenance<br />

costs decrease.<br />

Our products meet demanding requirements and comply to safety standards<br />

at all stages. From development to production through to sales.<br />

A complete range<br />

for every sector<br />

I Agriculture and animal feed industry<br />

I Dairy processing industry<br />

I Bakery and confectionery industry<br />

I Meat and poultry industry<br />

I Beverage industry and breweries<br />

I Packaging industry and mechanical<br />

engineering<br />

As a MOTOREX customer,<br />

you benefit from the<br />

following services<br />

I Expert technical support in the classification<br />

of contamination risks<br />

I On-site help in selecting the appropriate<br />

lubricant<br />

I Technical customer service hotline<br />

I Support in drawing up lubrication schedules<br />

I Selection of containers according to customer<br />

requirements: from barrel to handy small<br />

containers (5L)<br />

I Fast delivery directly from our warehouse<br />

in Langenthal or our European logistic hub<br />

I Used oil analyses by the MOTOREX laboratory<br />

2 I <strong>FOOD</strong><strong>LINE</strong>

PERFECTLY ADAPTED<br />

TO ANIMALS AND NATURE<br />

SAFETY FROM THE SOURCE ONWARDS<br />

Lubrication solutions for agriculture<br />

and the production of animal feed<br />

Clean feed without any mineral oil contamination is the basis for safe<br />

food. The lubricants in the MOTOREX <strong>FOOD</strong><strong>LINE</strong> offer maximum safety<br />

even during the processing of the valuable raw materials for food production.<br />

This applies to harvesting as well as to the production of animal feed<br />

for a wide variety of animal species: farm animals, poultry, fish and pets.<br />

8 million tonnes of dried fodder<br />

per year in Switzerland<br />

Delivery, receipt<br />

and storage of<br />

raw materials<br />

Grinding,<br />

proportioning,<br />

pre-mixing<br />

Pre-conditioning,<br />

compacting<br />

Pressing / Extrusion,<br />

cooling<br />

5 I <strong>FOOD</strong><strong>LINE</strong>

THE BEST FOR MILK<br />

FOR HIGHEST STANDARDS AND PURE PRODUCTS<br />

Lubricant solutions for the milk processing industry<br />

State-of-the-art technology is used to preserve milk and process it to<br />

cheese, yoghurt, butter or mozzarella. Products for daily use, millions of<br />

tonnes of which are consumed every year.<br />

Hygiene has the highest priority. No contamination is tolerated throughout<br />

the process. For this reason, manufacturers of dairy products use<br />

MOTOREX <strong>FOOD</strong><strong>LINE</strong> food-grade lubricants. A reliable alternative for all<br />

lubrication points in modern production facilities.<br />

22.2 tonnes of milk consumption per second<br />

700 billion litres of milk per year worldwide<br />

Separation and standardisation<br />

(reception, pretreatment,<br />

skimming)<br />

Centrifugation and<br />

homogenisation<br />

Pasteurisation<br />

and sterilisation<br />

Filling, packaging<br />

and labelling<br />

Palletising,<br />

cooling, freezing<br />

and storing<br />

6 I <strong>FOOD</strong><strong>LINE</strong>

A CLASS OF ITS OWN<br />

FOR HIGH DEMANDS<br />

FOR PERFECT CREATIONS TO SUCCEED<br />

Lubrication solutions for bakery, confectionery<br />

and convenience food<br />

From -65 to +300 degrees centigrade. Manufacturers of bakery products<br />

and convenience food produce quality products under extreme conditions.<br />

High heat resistance and stability of the lubricants are crucial.<br />

Lubricants are subject to continuous testing and analysis by the MOTOREX<br />

research department to ensure their suitability for the most demanding<br />

applications. The specialists thus ensure that our food grade lubricants<br />

perform at the highest level. The result: safe and reliable production and<br />

manufacturing processes. At all times and in all processes.<br />

21.5 tonnes of wheat consumption per second<br />

679 million tonnes per year worldwide<br />

for food production<br />

Delivery,<br />

reception,<br />

storage<br />

Mixing,<br />

kneading<br />

Proofing,<br />

baking<br />

Cutting,<br />

wrapping<br />

Labelling,<br />

packaging,<br />

cold storage<br />

8 I <strong>FOOD</strong><strong>LINE</strong>

PRESERVE<br />

TASTE AND FRESHNESS<br />

BY <strong>EN</strong>SURING OPTIMUM USE OF OPERATING MATERIALS<br />

Lubrication solutions for the meat<br />

and poultry industry<br />

It takes a lot of experts to make a juicy steak or a tender chicken breast.<br />

Not only skilled manual work, but also reliable machines for processing are<br />

required. Packaging in a protective atmosphere guarantees freshness and<br />

taste. MOTOREX food grade lubricants help to meet the high quality and<br />

safety requirements for processing and packaging.<br />

At the same time, the lubricants contribute to the viability of a company.<br />

<strong>FOOD</strong><strong>LINE</strong> lubrication solutions ensure smooth and effective production<br />

processes, which extends the service life of equipment and reduces costs.<br />

9 tonnes of meat consumption per second<br />

286.2 million tonnes of meat per year worldwide<br />

Slaughtering,<br />

gutting,<br />

butchering,<br />

washing<br />

Portioning,<br />

cutting,<br />

crushing<br />

Seasoning,<br />

mixing, shaping,<br />

cooking<br />

Whipping,<br />

frying,<br />

freezing,<br />

filling<br />

Packaging,<br />

labelling,<br />

cooling,<br />

freezing,<br />

storing<br />

10 I <strong>FOOD</strong><strong>LINE</strong>

SMOOTH<br />

QUALITY PROCESSES<br />

FROM ITS ORIGIN TO THE FILLING PLANT<br />

Lubrication solutions for breweries<br />

and the beverage industry<br />

Whenever precision is essential. When every minute and every degree<br />

counts. Manufacturers depend on machines that operate reliably and<br />

securely. The choice of the right lubricant is therefore crucial.<br />

The manufacturing of beverages and related products places the highest<br />

demands on the lubricants used. Brewing, mixing, preserving, bottling –<br />

the MOTOREX <strong>FOOD</strong><strong>LINE</strong> products ensure that every manufacturing<br />

process is clean and sustainable.<br />

Consumption of pre-packaged beverages:<br />

43 tonnes per second<br />

1,383 billion litres per year worldwide<br />

Blow moulding,<br />

filtering<br />

Filling,<br />

capping,<br />

labelling<br />

Packaging,<br />

palletising<br />

12 I <strong>FOOD</strong><strong>LINE</strong>

TOP QUALITY IN ALL<br />

SHAPES AND SIZES<br />

SAFE PACKAGING PRODUCTION AND FILLING<br />

Lubrication solutions for the production<br />

and use of primary packaging<br />

Products manufactured with the greatest care need a clean and protective<br />

casing when transferred from production to the consumer. Whether bottles,<br />

tubes, cans or blisters – products can be wrapped in many different ways.<br />

In addition to the wide range of options for selecting the right packaging<br />

material, hygiene regulations and high food standards must be taken into<br />

account.<br />

The products are in direct contact with the primary packaging. Therefore,<br />

the choice of the most suitable lubricant for the production of packaging<br />

and the subsequent packaging process is of utmost importance. Despite all<br />

precautions, unforeseen contamination with lubricant can occur. The consistent<br />

use of food processing lubricants helps minimise risks and also prevents<br />

serious and costly repercussions. In addition, the appropriate lubricants<br />

ensure high durability of equipment and improve cost efficiency.<br />

MOTOREX <strong>FOOD</strong><strong>LINE</strong> products are food grade lubricants designed for packaging<br />

and filling lines for food and beverages, cosmetics, pharmaceutical<br />

products as well as medical devices and appliances for medical technology.<br />

On the other hand, <strong>FOOD</strong><strong>LINE</strong> lubricants ensure maximum safety in the<br />

lubrication and maintenance of systems manufacturing packaging of all kinds.<br />

High quality <strong>FOOD</strong><strong>LINE</strong> lubricants<br />

meet the highest demands:<br />

I PET blower (PET bottle production)<br />

I Thermoforming machines (plastic trays)<br />

I Vacuum pumps<br />

I Die-cutting and printing machines for primary packaging<br />

I Can sealer (cans for preserves/beverages)<br />

I Bottling plants (drinks, milk, yoghurt etc.)<br />

I Packaging lines for cosmetics and pharmaceutical products<br />

14 I <strong>FOOD</strong><strong>LINE</strong>

<strong>EN</strong>JOY WITH<br />

TOTAL RELIANCE<br />

HIGHEST SAFETY REQUIREM<strong>EN</strong>TS<br />

Approvals guarantee best quality<br />

Producers of food and feed are under obligation to undertake all necessary<br />

measures to prevent any risks for the consumer. This includes the limitation<br />

of any contamination with mineral oil, which can be detected by increasingly<br />

sensitive analysis. If a contamination is detected, the manufacturer is susceptible<br />

to have to destroy the goods entailing an extensive loss of reputation.<br />

Over 40 years ago, various categories of operating aids had already been<br />

defined which, among other things, regulate the use of lubricants with a<br />

possible but not intended contact with food (H1) or as separating agents for<br />

direct food contact (3H). Today, such food processing lubricants are registered<br />

by independent authorities such as NSF International or 2Probity and<br />

are recognised worldwide.<br />

All MOTOREX <strong>FOOD</strong><strong>LINE</strong> lubricants are registered with 2Probity and/or NSF<br />

International in the appropriate categories. They are manufactured according<br />

to ISO 21469. This ISO standard specifies hygiene requirements for manufacturing<br />

and handling of lubricants.<br />

MOTOREX <strong>FOOD</strong><strong>LINE</strong> products<br />

protect consumers and equipment<br />

Summary of our certifications:<br />

I Free from ingredients of animal origin<br />

I Free from allergens and genetically<br />

modified organisms (GMO)<br />

2Probity.eu/<br />

c e r t i fi c a t e s<br />

HALAL<br />

KOSCHER<br />

I 2Probity / NSF (H1, 3H, HT1)<br />

I HALAL<br />

I KOSCHER<br />

16 I <strong>FOOD</strong><strong>LINE</strong>

CONSIST<strong>EN</strong>TLY IN<br />

THE GRE<strong>EN</strong> RANGE<br />

AWARDED FOR SUSTAINABILITY<br />

Decades of commitment honoured<br />

MOTOREX is future-oriented – with an eye to society, employees, customers<br />

and the environment. We have been ISO-certified since 1992. Sustainability<br />

has been a strategic pillar for decades. In an initial certification in Corporate<br />

Social Responsibility, the independent institute EcoVadis awarded us the<br />

silver medal in 2019.<br />

For many years we have been cooperating voluntarily with the energy<br />

agency EnAw to improve our internal energy and C02 efficiency. In the<br />

area of research and development, MOTOREX actively promotes the use<br />

of sustainable basic raw materials and is constantly working on optimising<br />

service life, low-friction resistance and lubrication performance.<br />

The high-quality MOTOREX lubrication solutions contribute to the reliable<br />

operation of plants and to improved economic efficiency. Machine exploitation<br />

is increased, maintenance intervals are reduced and service life is<br />

extended.<br />

YOUR VANTAGES WH<strong>EN</strong> USING<br />

MOTOREX LUBRICANTS<br />

I Reduced energy costs<br />

I Improved plant efficiency<br />

I Extended maintenance intervals<br />

I Reduced lubricant consumption<br />

I Reduced replacement costs and less waste<br />

I Reduced costs for your production line<br />

We are aware of our responsibility<br />

The initial testing and certification by the independent testing company<br />

EcoVadis awards MOTOREX an excellent performance: with 59 points achieved,<br />

MOTOREX was awarded a „Silver“ rating, the second-best rating for<br />

its corporate social responsibility (CSR).<br />

CSR stands for the responsibility of companies and their impact on society<br />

and comprises social, ecological and economic aspects. The analysis<br />

system used includes 21 criteria from the areas of environment, fair<br />

labour practices, ethics and fair business practices and supply chain.<br />

18 I <strong>FOOD</strong><strong>LINE</strong>

<strong>FOOD</strong><strong>LINE</strong><br />

RELIABLY, ECONOMICALLY AND SUSTAINABLY<br />

DESIGN YOUR PRODUCTION WITH LUBRICATION<br />

SOLUTIONS FROM MOTOREX<br />

LUBRICANTS AND PROCESS SOLUTIONS SINCE 1917<br />

I Metalworking Industry<br />

I Food Industry<br />

I Racing and Motor Sport<br />

I Alpine Infrastructure & Operation<br />

I Bike Industry & Care<br />

I Automotive Drive Technology<br />

I Old- and Youngtimers<br />

I Construction Machinery & Equipment<br />

I Agriculture and Forestry<br />

I Marine Propulsion Technology<br />

I Transport & Maintenance<br />

INDUSTRIAL<strong>LINE</strong><br />

<strong>FOOD</strong><strong>LINE</strong><br />

MOTO<strong>LINE</strong><br />

ALPINE<strong>LINE</strong><br />

BIKE<strong>LINE</strong><br />

CAR<strong>LINE</strong><br />

CLASSIC<strong>LINE</strong><br />

CONSTRUCTION<strong>LINE</strong><br />

FARMER FOREST & GARD<strong>EN</strong><strong>LINE</strong><br />

MARINE<strong>LINE</strong><br />

TRUCK<strong>LINE</strong><br />

12/2020-452247<br />

MOTOREX AG<br />

Bern-Zürich-Strasse 31, 4901 Langenthal, Switzerland<br />

Tel. +41 62 919 75 75 I www.motorex.com