Green Economy Journal Issue 48

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WASTE<br />

WASTE<br />

THE ROAD TO<br />

SUSTAINABILITY<br />

The use of waste materials in<br />

South African road construction<br />

The Council for Scientific and Industrial Research has recently been<br />

involved in several new research initiatives geared towards providing<br />

alternative waste material products, specifically to be used by the<br />

asphalt pavement industry in South Africa.<br />

The research focus of the CSIR has been centred around creating<br />

a more inclusive and sustainable approach to future road<br />

construction, particularly through increasing the potential for job<br />

creation, increasing economic benefits, producing better performing<br />

roads and trying to resolve South Africa’s environmental challenges.<br />

One of the CSIR’s recent successes has been around the adoption of<br />

locally produced waste alternatives (opposed to importing costly<br />

conventional road and waste products).<br />

CASE STUDY ON THE SUSTAINABLE USE<br />

OF RECYCLED TYRES<br />

Construction of a road section in Roodepoort, Gauteng<br />

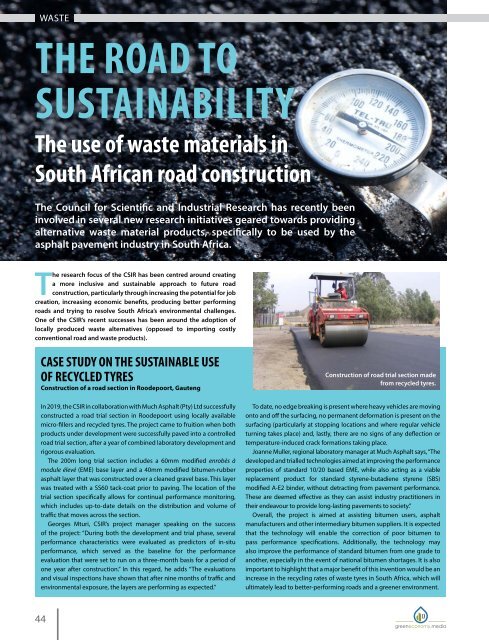

In 2019, the CSIR in collaboration with Much Asphalt (Pty) Ltd successfully<br />

constructed a road trial section in Roodepoort using locally available<br />

micro-fillers and recycled tyres. The project came to fruition when both<br />

products under development were successfully paved into a controlled<br />

road trial section, after a year of combined laboratory development and<br />

rigorous evaluation.<br />

The 200m long trial section includes a 60mm modified enrobés à<br />

module élevé (EME) base layer and a 40mm modified bitumen-rubber<br />

asphalt layer that was constructed over a cleaned gravel base. This layer<br />

was treated with a SS60 tack-coat prior to paving. The location of the<br />

trial section specifically allows for continual performance monitoring,<br />

which includes up-to-date details on the distribution and volume of<br />

traffic that moves across the section.<br />

Georges Mturi, CSIR’s project manager speaking on the success<br />

of the project: “During both the development and trial phase, several<br />

performance characteristics were evaluated as predictors of in-situ<br />

performance, which served as the baseline for the performance<br />

evaluation that were set to run on a three-month basis for a period of<br />

one year after construction.” In this regard, he adds “The evaluations<br />

and visual inspections have shown that after nine months of traffic and<br />

environmental exposure, the layers are performing as expected.”<br />

44<br />

Construction of road trial section made<br />

from recycled tyres.<br />

To date, no edge breaking is present where heavy vehicles are moving<br />

onto and off the surfacing, no permanent deformation is present on the<br />

surfacing (particularly at stopping locations and where regular vehicle<br />

turning takes place) and, lastly, there are no signs of any deflection or<br />

temperature-induced crack formations taking place.<br />

Joanne Muller, regional laboratory manager at Much Asphalt says, “The<br />

developed and trialled technologies aimed at improving the performance<br />

properties of standard 10/20 based EME, while also acting as a viable<br />

replacement product for standard styrene-butadiene styrene (SBS)<br />

modified A-E2 binder, without detracting from pavement performance.<br />

These are deemed effective as they can assist industry practitioners in<br />

their endeavour to provide long-lasting pavements to society.”<br />

Overall, the project is aimed at assisting bitumen users, asphalt<br />

manufacturers and other intermediary bitumen suppliers. It is expected<br />

that the technology will enable the correction of poor bitumen to<br />

pass performance specifications. Additionally, the technology may<br />

also improve the performance of standard bitumen from one grade to<br />

another, especially in the event of national bitumen shortages. It is also<br />

important to highlight that a major benefit of this invention would be an<br />

increase in the recycling rates of waste tyres in South Africa, which will<br />

ultimately lead to better-performing roads and a greener environment.<br />

CASE STUDY ON THE USE OF WASTE PLASTIC<br />

Construction of road sections on Road P159/1 (R80) in City of Tshwane, Gauteng<br />

The CSIR, along with the Department of Science and Innovation (DSI),<br />

as well as the plastics and roads industry, have recently worked on a<br />

demonstration project in South Africa to evaluate the feasibility of using<br />

waste plastic in road construction. The project aimed to identify lowvalue<br />

plastic types and evaluate their potential usage in asphalt road<br />

surfacing in accordance with South African road design standards and<br />

environmental conditions.<br />

The culmination point for the project was the construction of<br />

Gauteng’s first “waste plastic” road trial section, currently located on<br />

Construction of road trial section<br />

made from waste plastic.<br />

the R80. This trial section was used by the CSIR’s Smart Mobility Cluster<br />

for proof-testing plastic-road technology in South Africa. The CSIR<br />

has to date successfully completed a full-scale research investigation<br />

and laboratory programme that was validated through Heavy Vehicle<br />

Simulator (HVS) testing.<br />

The project’s sponsors and key stakeholders from the DSI, Roadmac<br />

Surfacing (Pty) Ltd (Raubex Group) and Much Asphalt were crucial in<br />

supporting the CSIR’s project team throughout construction.<br />

Although technical findings from the project are still currently being<br />

published, the CSIR’s project team stated: “The project has successfully<br />

showed potential in using specified waste plastic materials to design<br />

rut resistant asphalt mixes without compromising on other asphalt<br />

performance requirements. The approach requires the adoption of<br />

necessary criteria to establish a consistent source of waste plastic.”<br />

The research project highlights the need to understand the<br />

mechanism that improves rut resistance to ensure that this benefit<br />

is realised through controlling performance criteria and handling of<br />

the asphalt mix. The research identified requirements for measuring<br />

additional asphalt properties that would quantify the contribution of<br />

the asphalt layer to safety, health and environmental sustainability.<br />

Project team included: Georges AJ Mturi, Johan S O’Connell, Imraan<br />

Akhalwaya, Theresa George, Vincent O Ojijo, Tladi Mofokeng, Nonzwakazi<br />

Ncolosi, Michandre Smit and Linda Godfrey.<br />

The end of the road<br />

Feedback from these case studies is aimed at encouraging government<br />

and road industry stakeholders to adopt the use of waste materials for<br />

environmental benefits, as well as for the improved performance of road<br />

surfaces. The technologies will require the development of application<br />

guidelines to promote a better understanding of the suitability of waste<br />

materials for road projects and therefore lower the risk of premature<br />

failure of roads.<br />

45