Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

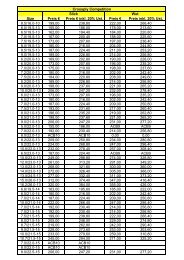

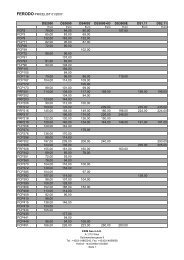

84<br />

2.00<br />

8.00<br />

15.00<br />

Actuation<br />

Balance Bars<br />

CP5507-2 BALANCE BAR. CP5520-13 TRUNNION BALANCE BAR.<br />

38.50<br />

66.60<br />

91.60<br />

117.00<br />

25.00<br />

8.00 8.00<br />

26.00<br />

33.40 O/D<br />

OF HOUSING<br />

A-A<br />

35.00<br />

RUBBER<br />

BOOT<br />

49.00<br />

56.00<br />

30.00<br />

38.00<br />

15.00<br />

23.00 THREAD LENGTH<br />

5/16”x24UNF THREAD<br />

Ø12.00<br />

Ø10.00<br />

BARREL NUT<br />

SPHERICAL<br />

BEARING<br />

INTERNAL<br />

BAR<br />

WASHER<br />

EXTERNAL<br />

WASHER<br />

Ø4.00 FOR<br />

CABLE ADJUSTER<br />

AP RACING CABLE<br />

ADJUSTER CP2905-18<br />

AND STEPPER MOTOR<br />

KIT CP5500-14<br />

AVAILABLE ON<br />

REQUEST<br />

M12x1.0 THREAD<br />

1 TURN= 1.0MM OF<br />

BEARING MOVEMENT<br />

96.50<br />

BRAKE CLEVIS<br />

HOUSING GRUB SCREW<br />

BALANCE<br />

RUBBER BOOT<br />

ADJUSTER SIDE<br />

INSTALLATION.<br />

1. Position housing into a<br />

hole of required diameter<br />

(33.50) in the brake pedal.<br />

This hole should be<br />

positioned such that under<br />

normal braking loads the<br />

centre is in line with the<br />

master cylinder bores.<br />

2. Weld or bond the<br />

housing in position.<br />

3. Grease the bore of the housing and the outer race of the<br />

spherical bearing.<br />

4. Insert the balance bar with the bearing attached, into the<br />

housing with the adjuster end at the desired side.<br />

5. Insert the 2 internal washers into the housing & retain with<br />

circlips.<br />

6. Place external washers over balance bar and then screw on<br />

both clevis’s and barrel nuts until they start to bind. Then rotate<br />

one of them back one turn.<br />

Tip: Half turn adjustments can be made by taking one clevis<br />

and barrel nut back to the end of the balance bar, fl ipping the<br />

clevis over, and then threading the barrel nut back into place.<br />

7. Stretch boots over the clevis’s and locate them on the<br />

grooves on the housing and clevis’s.<br />

8. Attach adjuster to the end of the balance bar using grub<br />

screws.<br />

9. Screw in push rods and adjust so that under normal braking<br />

the balance bar lies perpendicular to the push rods and the<br />

pedal is vertical. It is not important if the balance bar is not<br />

square when released, but it should be whilst braking for<br />

maximum effi ciency.<br />

Tip: Adjustment of the push rods is made easier by running one<br />

of the two nuts supplied with each master cylinder to the end of<br />

the thread to allow the use of a spanner.<br />

2.00<br />

4 HOLES M4x0.7<br />

6.0MM FULL<br />

THREAD<br />

48.52 57.00<br />

APPLY LOAD THIS<br />

DIRECTION ONLY<br />

NB: CP5520-2 AVAILABLE WITHOUT<br />

CLEVIS ASSEMBLIES<br />

INSTALLATION.<br />

A. Fitting the Balance Bar<br />

to the Pedal<br />

1. Make 4 holes in the<br />

pedal of the recommended<br />

dimensions The centre has<br />

to be at the same height<br />

as the master cylinder centreline when pedal is square to the<br />

master cylinder.<br />

2. In positioning the balance bar on the pedal, please take<br />

notice of the direction of load, as shown. It may effect the<br />

position you choose.<br />

B. Fitting the Clevis to the Balance Bar<br />

1. Install balance bar (1) inside the central trunnion sub-assy (2).<br />

2. Push the clevis sub-assy (4) on to balance bar (1).<br />

3. Push the washer (5) against the clevis sub-assy (4)<br />

4. Push circlip (3) in to place on balance bar (1) to hold clevis<br />

sub-assy (4) in place.<br />

C. Setting up the Balance Bar<br />

1. Install remote cable and retaining screws (6).<br />

2. Install nuts provided on master cylinder pushrods.<br />

3. Adjust the pushrods so that the balance bar is perpendicular to<br />

the pushrods under maximum load. The system is then square.<br />

It is not important that the system is square when released, but<br />

it has to be under load.<br />

For maximum effi ciency, it is recommended that the pedal is at<br />

right angle with the pushrods under maximum braking load; and<br />

also keeping the balance bar central with better selection of<br />

master cylinder sizes helps to reduce ineffi ciencies. Also make<br />

sue that the master cylinder pistons fully return before use. This<br />

can be checked by feeling the pushrods for slight movements<br />

there should not be any excessive loose movement.<br />

www.apracing.com +44 (0)24 7663 9595<br />

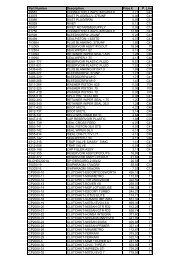

14.00<br />

24.00<br />

51.60<br />

71.60<br />

91.60<br />

(3)<br />

CIRCLIP - CP5517-123<br />

BALANCE BAR<br />

THREAD M14x1.0<br />

12.00<br />

24.00<br />

17.00 30.00<br />

(5) SPACER -<br />

CP5517-124<br />

5/16”x24UNF EACH CLEVIS<br />

(2) CENTRAL<br />

TRUNNION<br />

SUB ASSEMBLY<br />

(4) CLEVIS<br />

SUB-ASSY<br />

20.00<br />

FULL THREAD<br />

(6) CABLE SCREW<br />

CP5500-113<br />

39.50<br />

(1) BALANCE BAR -<br />

CP5517-127