Wood In Architecture Issue 1, 2022

First published in 2017, Wood in Architecture (WIA) is a bi-annual trade magazine devoted to the international timber construction sector. The newest addition to the Panels & Furniture Group of wood magazines, WIA features in-depth insights to the latest industry news, incredible projects and leading trade events. WIA is an advocate for timber as a material of choice for today’s built environment, and is the perfect source of inspiration for architects, builders, engineers and interior designers across the globe.

First published in 2017, Wood in Architecture (WIA) is a bi-annual trade magazine devoted to the international timber construction sector. The newest addition to the Panels & Furniture Group of wood magazines, WIA features in-depth insights to the latest industry news, incredible projects and leading trade events. WIA is an advocate for timber as a material of choice for today’s built environment, and is the perfect source of inspiration for architects, builders, engineers and interior designers across the globe.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.panelsfurnitureasia.com<br />

ISSUE 1, <strong>2022</strong><br />

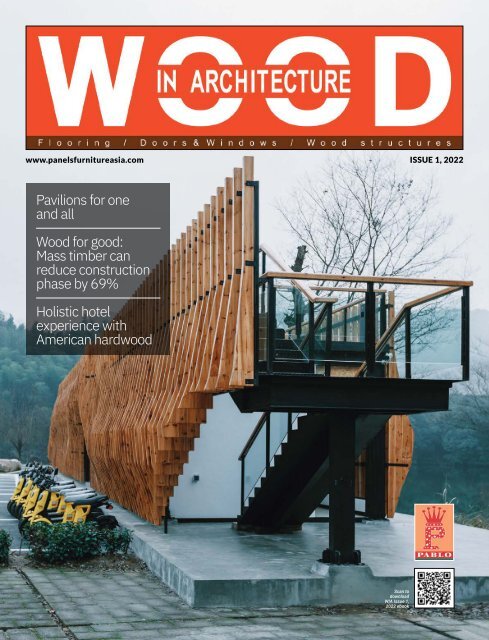

Pavilions for one<br />

and all<br />

<strong>Wood</strong> for good:<br />

Mass timber can<br />

reduce construction<br />

phase by 69%<br />

Holistic hotel<br />

experience with<br />

American hardwood<br />

Scan to<br />

download<br />

WIA <strong>Issue</strong> 1,<br />

<strong>2022</strong> ebook

y Panels & Furniture Group of wood magazines<br />

5 th Edition<br />

26 th - 28 th JUNE 2023<br />

SHANGHAI<br />

CHINA<br />

VENUE:<br />

99 XING YI ROAD<br />

SHANGHAI CHINA<br />

w w w . s y l v a w o o d e x p o . c o m<br />

ASIA’S SPECIALISED<br />

WOOD MATERIALS<br />

WOOD PRODUCTS<br />

TRADE SHOW<br />

Scan QR code for<br />

exhibition site<br />

JOINTLY ORGANISED BY<br />

WeChat<br />

China Timber &<br />

<strong>Wood</strong> Products<br />

Distribution Association<br />

Shanghai<br />

Timber Trade<br />

Association<br />

Shanghai Pablo<br />

Exhibition Co., Ltd.<br />

Enquiries For <strong>In</strong>ternational Exhibitors<br />

Pablo Publishing & Exhibition Pte Ltd.<br />

Tel: +(65) 6266 5512<br />

Email: williampang@pabloasia.com<br />

ENDORSED BY<br />

American<br />

Hardwood<br />

Export Council<br />

French<br />

Timber<br />

Softwood<br />

Export Council<br />

Canada <strong>Wood</strong><br />

Thai Timber<br />

Association<br />

Malaysian<br />

Timber<br />

Council<br />

National<br />

Hardwood Lumber<br />

Association

CONTENTS<br />

16<br />

28 32<br />

2 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong>

CONTENTS<br />

04 Editor’s Note<br />

06 News<br />

THE BIG PICTURE<br />

16 Pavilions for one and all<br />

SUSTAINABILITY<br />

28 CO2 storage in wood<br />

32 If companies want net-zero<br />

carbon offices, they need to<br />

focus on building materials<br />

35 <strong>Wood</strong> for good: Mass timber<br />

can reduce construction phase<br />

emissions by 69%<br />

MATERIALS AND<br />

TECHNOLOGY<br />

38 Clicking into place with<br />

Threespine TM<br />

41 A second life: Upcycling<br />

disposable chopsticks into<br />

ready-to-use panels<br />

DESIGN<br />

44 OMA reveals first quadrant of<br />

KaDeWe Berlin with wood-clad<br />

escalators<br />

46 Façade ribs made with local<br />

cedar wood<br />

STRUCTURAL<br />

ELEMENTS<br />

48 The public library at the<br />

heart of a compact, vibrant<br />

city<br />

52 Binzhou Yangxin Ten<br />

Thousand Mu Pear Garden<br />

tourism centre<br />

FLOORING<br />

54 “Nothing is lost, everything<br />

is transformed”: Cork<br />

flooring with Amorim Wise<br />

47 Antimicrobial power for the<br />

wood we walk on<br />

FIT-OUTS<br />

60 Holistic hotel experience<br />

with American hardwood<br />

63 KAB House: A home for<br />

housing<br />

66 Events Calendar<br />

67 <strong>In</strong>dex of Advertisers<br />

38<br />

56 44<br />

06<br />

WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong> 3

EDITOR’S NOTE<br />

The beautiful,<br />

the innovative,<br />

the eco-friendly<br />

Take a look around you — how many of your<br />

furniture or household items are made of<br />

wood, and what are they used for? Which<br />

parts of the wall, flooring or fit-outs are<br />

wood-clad, or designed with wood veneer?<br />

Chances are you have at least one furniture<br />

item or part of your house that is made<br />

of wood. It is everywhere. With recent<br />

innovations, wood is greatly expanding its<br />

applications across the furniture, furnishings<br />

and construction industries.<br />

<strong>In</strong> this issue, we showcase the best that<br />

wood has to offer us — the beautiful, the<br />

innovative, the eco-friendly. The cover story<br />

is a testament to that, showing how versatile<br />

wood can be in building pavilions (p.16).<br />

Whether it is arched roofs with wide spans,<br />

interlocked timber joints, or prefabricated<br />

panels, the five pavilions showcased<br />

highlight the innovativeness of wood in its<br />

structural applications.<br />

Material innovations are aplenty too.<br />

ChopValue SG recycles discarded chopsticks<br />

into wood-based panels to be used for<br />

furniture items, such as charcuterie boards<br />

or tables (p.41). Amorim Wise specialises<br />

in flooring made with cork wood waste,<br />

thus making it sustainable while making full<br />

use of cork properties suitable for flooring<br />

applications, such as acoustic and thermal<br />

insulation, and improvement of indoor air<br />

quality (p.54).<br />

With the recent COP26 pledge of reducing the<br />

global temperature by 1.5°C, more attention<br />

is turned to wood for its climate positive<br />

quality, especially in helping the construction<br />

industry to reduce its global greenhouse gas<br />

emissions. Ken Hickson advocates for more<br />

mass timber buildings, citing that mass timber<br />

can reduce construction phase emissions by<br />

69% (p.35). Meike Siegner and Cory Searcy<br />

from the Department of Mechanical and<br />

<strong>In</strong>dustrial Engineering, Ryerson University,<br />

likewise argue that net-zero carbon offices<br />

can reduce the carbon footprint of companies<br />

(p.32).<br />

Finally, we have various projects in this issue<br />

that exemplify the beauty of wood in its<br />

design applications, such as the Cozoo Tourist<br />

Centre by Continuum <strong>Architecture</strong> & Design,<br />

which features façade ribs made with cedar<br />

wood sourced locally in Anhui, China (p.46),<br />

the Rosewood Hotel Hong Kong made with<br />

American hardwoods like white oak, walnut<br />

and cherry (p.60), and many more.<br />

Take your time to pore over every project, and<br />

enjoy reading the issue!<br />

YAP SHI QUAN | Assistant Editor<br />

WOOD IN ARCHITECTURE<br />

PABLO SINGAPORE<br />

Publisher<br />

William Pang • williampang@pabloasia.com<br />

Senior Editor<br />

Josephine Tan • josephine@pabloasia.com<br />

Assistant Editor<br />

Yap Shi Quan • shiquan@pabloasia.com<br />

Business Development Manager<br />

Pang YanJun • yanjun@pabloasia.com<br />

Graphic Designer<br />

Goh Meng Yong • mengyong@pabloasia.com<br />

Circulation Manager<br />

Shu Ai Ling • circulation@pabloasia.com<br />

PABLO BEIJING<br />

General Manager<br />

Ellen Gao • pablobeijing@163.com<br />

PABLO SHANGHAI<br />

Editor<br />

Kresly Shen • pabloshanghai@163.net<br />

HEAD OFFICE<br />

PABLO PUBLISHING & EXHIBITION PTE LTD<br />

3 Ang Mo Kio Street 62, #01-23, Link@AMK,<br />

Singapore 569139<br />

Tel : +65 6266 5512<br />

Email: info@pabloasia.com<br />

www.panelsfurnitureasia.com<br />

Company Registration No: 200001473N<br />

Singapore MICA (P) No: 109/12/2021<br />

REGIONAL OFFICES (CHINA)<br />

PABLO BEIJING<br />

Tel : +86 10 6509 7728<br />

Email : pablobeijing@163.com<br />

PABLO SHANGHAI<br />

Tel : +86 21 5238 9737 / 36<br />

Email : pabloshanghai@163.net<br />

let's connect!<br />

@wood.ia<br />

All rights reserved. Views of writers do not necessarily reflect the views<br />

of the Publisher. No part of this publication may be reproduced in any<br />

form or by any means, without prior permission in writing from the Publisher<br />

and copyright owner. Whilst every care is taken to ensure accuracy<br />

of the information in this publication, the Publisher accepts no liability for<br />

damages caused by misinterpretation of information, expressed or implied,<br />

within the pages of the magazine. All advertisements are accepted on the<br />

understanding that the Advertiser is authorised to publish the contents of<br />

the advertisements, and in this respect, the Advertiser shall indemnify the<br />

Publisher against all claims or suits for libel, violation of right of privacy and<br />

copyright infringements. Panels & Furniture Asia is a controlled-circulation<br />

magazine with two issues a year. It is mailed free-of-charge to readers who<br />

meet a set of criteria. Paid subscription is available to those who do not<br />

fit our terms of control. Please refer to subscription form provided in the<br />

publication for more details.<br />

Printed by Times Printers Pte Ltd<br />

Scan to subscribe<br />

to WIA’s enewsletter<br />

4 WOOD IN ARCHITECTURE • ISSUE 1– <strong>2022</strong>

IN VIETNAM’S<br />

FURNITURE<br />

CLUSTER<br />

www.bifawoodvietnam.com<br />

NEW DATE: 8-11 AUGUST <strong>2022</strong><br />

NEW<br />

VENUE<br />

WTC Binh Duong New City Expo<br />

Lot A19, Hung Vuong Street, Hoa Phu Ward,<br />

Thu Dau Mot City, Binh Duong Province, Vietnam<br />

Google Map<br />

QR code<br />

Exhibition Site<br />

WOOD & WOODWORKING MACHINERY EXHIBITION<br />

Enquiries For <strong>In</strong>ternational Exhibitors<br />

Pablo Publishing & Exhibition Pte Ltd<br />

3 Ang Mo Kio Street 62<br />

#01-23 Link@AMK,<br />

Singapore 569139<br />

Tel: (65) 6266 5512<br />

Email: williampang@pabloasia.com<br />

info@pabloasia.com<br />

WeChat<br />

Jointly organised by<br />

• BINH DUONG FURNITURE ASSOCIATION (BIFA) • PANELS & FURNITURE Group<br />

BINH DUONG FURNITURE ASSOCIATION<br />

Photo: elena rouame, helena lopes, guzman barquin/unsplash

NEWS<br />

FIVE INDIAN FURNITURE DESIGNERS REMAKE THREE<br />

EXISTING PIECES IN AMERICAN HARDWOOD<br />

1 2<br />

On a whole, the designers all<br />

expressed satisfaction and<br />

fascination at being able to<br />

adapt American hardwoods into<br />

their designs, with some also<br />

commenting on their favourite<br />

choice of hardwoods. Bram Rouws,<br />

director of Bram <strong>Wood</strong>crafting<br />

Studio, commented on the<br />

versatility of American hardwood<br />

in terms of “the grain and finish”,<br />

and how the hardwood is carbon<br />

negative upon arrival in <strong>In</strong>dia, thus<br />

making it attractive in terms of its<br />

environmental and sustainability<br />

standards.<br />

1 Ergos by Bram<br />

<strong>Wood</strong>crafting<br />

Studio (Image:<br />

Govind<br />

Vishwanath)<br />

2 Comet console<br />

by Esvee Atelier<br />

(Image: Esvee<br />

Atelier)<br />

3 Drawer Poufs<br />

by Studio <strong>Wood</strong><br />

(Image: Vaibhav<br />

Bhatia)<br />

3<br />

Five <strong>In</strong>dian furniture designers have<br />

unveiled finished furniture items<br />

remade using American hardwoods<br />

as part of REMAKE, the first design<br />

collaboration in <strong>In</strong>dia led by the<br />

American Hardwood Export Council<br />

(AHEC). The project challenged these<br />

designers in selecting three pieces<br />

from their existing furniture range<br />

and remaking them using American<br />

hardwoods.<br />

REMAKE was conceived by AHEC<br />

as a response to the need for<br />

hands-on experience with American<br />

hardwoods in <strong>In</strong>dia’s evolving<br />

furniture manufacturing sector. This<br />

collaboration aims to inspire the next<br />

generation of furniture designers and<br />

help the <strong>In</strong>dian market discover the<br />

untapped potential of US hardwood.<br />

Launched in late 2020, the project<br />

involved designers such as Bram<br />

<strong>Wood</strong>crafting Studio, Esvee Atelier,<br />

Kam Ce Kam, Studio SFDW, and Studio<br />

<strong>Wood</strong>. Available hardwood species<br />

include American red oak, white oak,<br />

cherry, hard maple, tulipwood or<br />

hickory, all of which were supplied<br />

by AHEC from a stock of American<br />

hardwood species held in <strong>In</strong>dia, which<br />

was donated to AHEC by Allegheny<br />

<strong>Wood</strong> Products.<br />

Rouws elaborated: “I believe that<br />

American red oak and cherry have<br />

the potential to be big in <strong>In</strong>dia.<br />

As a company, we place great<br />

importance on the environmental<br />

credentials of the materials we<br />

work with and find in American<br />

hardwoods a way to continue<br />

fulfilling our timber requirements<br />

while consuming responsibly.”<br />

Despite the challenges posed by the<br />

global pandemic and the inability<br />

to travel to <strong>In</strong>dia, AHEC was able to<br />

remotely launch REMAKE with the<br />

five designer-makers. According to<br />

AHEC, the onset of COVID-19 and<br />

enforced lockdown enabled them<br />

to spend a lot of time conducting<br />

in-depth research into <strong>In</strong>dia’s<br />

furniture manufacturing sector and<br />

identify a number of companies<br />

previously unknown. Many of<br />

these companies are already using<br />

imported temperate hardwoods for<br />

their production, which is primarily<br />

targeted at <strong>In</strong>dia’s domestic<br />

market.<br />

Saif Faisal, founder of Studio<br />

SFDW, added: “Working with<br />

6 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong>

NEWS<br />

cherry was a new experience for<br />

me; it was quite fascinating as the<br />

wood is quite dense and the grains<br />

gorgeous. This inspired me to<br />

explore computer numerical control<br />

(CNC) milling with it for objects with<br />

finer details and smaller in scale.<br />

American white oak in contrast is<br />

very strong and its resilience to take<br />

any shape and structure. This made<br />

it possible for me to achieve a piece<br />

that is flatpack with neat joinery<br />

and details. The Nightstand in white<br />

oak is my favourite as it brings<br />

the beauty of natural wood and<br />

technology together in a harmonious<br />

way.” WIA<br />

4 5<br />

4 Mausam Side Table and Mera Chair by<br />

Kam Ce Kam (Image: Anmol Wahi)<br />

5 Split Bench by Studio SFDW (Image:<br />

Edwin Lawrence)<br />

WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong> 7

NEWS<br />

SCM AND RANDEK TEAM UP<br />

IN TIMBER CONSTRUCTION<br />

SCM and Swedish company Randek have<br />

sealed an agreement for the worldwide<br />

supply of all-round, integrated solutions for<br />

timber construction, where the aim is to be<br />

a one-stop supplier for the complete timber<br />

construction process, offering a range of<br />

solutions for beams, walls, timber frame,<br />

X-lam/cross-laminated timber (CLT) panels<br />

machining.<br />

Randek specialises in offering automation<br />

solutions for customers within the<br />

prefabricated house manufacturing<br />

industry. The new partnership also aims to<br />

further expand and strengthen the range<br />

of technological solutions already provided<br />

by both players across the globe and<br />

complementary to one another: SCM, for<br />

offering numeric control machining centres<br />

capable of processing different construction<br />

elements; and Randek, for its technologies<br />

in the prefabricated house sector.<br />

The partnership will also allow each<br />

company to offer the other party’s products.<br />

It also intends to increase the range of<br />

their products and expand the solution<br />

SCM’s area xl, a CNC<br />

machining centre<br />

(Photo: SCM)<br />

competence, production capacity and level<br />

of specialisation of both companies.<br />

“Our global partnership with Randek<br />

significantly and strategically expands<br />

our offer of products and services for<br />

timber construction, guaranteeing our<br />

customers access to a wide range of<br />

specific technological solutions dedicated<br />

to machining prefabricated walls with<br />

increased production efficiency and a better<br />

return on investment,” said Tommaso<br />

Martini, manager for timber construction<br />

business in SCM.<br />

“An agreement with a global leading group<br />

like SCM, with sound industrial expertise<br />

and an extensive international distribution<br />

network, means we can further strengthen<br />

our presence on the most relevant markets,<br />

offering the customer an even more direct,<br />

widespread service,” said Ola Lindh, CEO of<br />

Randek.<br />

Randek and SCM will develop and deliver<br />

equipment for an advanced house factory<br />

for the production of modules in wood and<br />

steel frame. The customer consulted Bosch<br />

Engineering and Production Services to<br />

perform an analysis of potential suppliers.<br />

“The decision to recommend our customer to<br />

choose Randek and SCM was based on their<br />

long experience in this kind of business and<br />

their high standardisation level. <strong>In</strong> addition,<br />

the visit at the suppliers’ premise was very<br />

impressive and has shown us that these are<br />

the right companies with the right spirit to<br />

fulfil the requirements and wishes of our<br />

customer,” said Markus Wörnle, senior project<br />

manager of Bosch Engineering and Production<br />

Services. WIA<br />

STORA ENSO INVESTS<br />

€9 MILLION IN AUTOMATED<br />

CLT COATING LINE<br />

Stora Enso will be investing €9 million in an automated cross-laminated<br />

timber (CLT) coating line at the Ybbs sawmill in Austria. The investment<br />

will further strengthen Stora Enso’s position as a provider of engineered<br />

wood products for low-carbon, sustainable buildings.<br />

Stora Enso aims to lead the development of the growing mass timber<br />

construction market. <strong>In</strong> the construction industry, there is a labour<br />

shortage and pressure to shorten the construction time on-site. The<br />

investment enables industrially pre-applied CLT coatings on the CLT walls<br />

and floors produced at Stora Enso’s Ybbs site. The automated coating<br />

solution results in shorter construction times and higher wood protection.<br />

“With this new automation line, we can apply high-quality water-based<br />

coating to approximately 500,000m² of CLT walls and floors per year. Our<br />

customers will benefit from improved protection of CLT against moisture,<br />

sunlight, insects and fire, as well as nicely coloured visual surfaces,” said<br />

Lars Völkel, executive vice-president of the wood products division.<br />

The automated CLT coating line is expected to be finalised in Q3 2023.<br />

The Ybbs sawmill is located to serve all markets in central Europe. WIA<br />

8 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong>

NEWS<br />

DOMOTEX TO<br />

TAKE PLACE IN<br />

JANUARY 2023<br />

Deutsche Messe has announced that the<br />

next edition of DOMOTEX will take place in<br />

Hannover, Germany, from 12-15 Jan 2023.<br />

The decision on the date in January 2023 was<br />

taken following market discussions. DOMOTEX<br />

will be a face-to-face event with additional<br />

digital offerings, which means exhibiting<br />

companies and trade show guests from all over<br />

the world will be able to exchange information<br />

on new products and current trends in the<br />

industry on-site and virtually.<br />

want to allow our customers to finally meet<br />

in person again, to be inspired and to forge<br />

new business relationships,” said Sonia<br />

Wedell-Castellano, global director DOMOTEX,<br />

Deutsche Messe, Hannover.<br />

“Having already had to cancel DOMOTEX twice<br />

due to the pandemic, we would have liked to<br />

give the industry its platform again this year.<br />

However, after intensive discussions with<br />

exhibiting companies, unfortunately, a majority<br />

couldn’t be found for a late summer edition of<br />

DOMOTEX in September <strong>2022</strong>. The preferred<br />

option of the entire market is to keep the usual<br />

date right at the beginning of the year.”<br />

Meanwhile, DOMOTEX Turkey, the trade<br />

show for carpets and floor coverings in<br />

Turkey and the Middle East, will continue to<br />

take place in Gaziantep, Turkey, from 14-17<br />

May <strong>2022</strong>. DOMOTEX asia/CHINAFLOOR,<br />

dedicated to the Asia-Pacific region, will<br />

also be held from 25-27 May <strong>2022</strong> in<br />

Shanghai, China, at the National Exhibition<br />

and Convention Centre (NECC). WIA<br />

“With the new date of DOMOTEX in January<br />

2023, we want to give the players in the carpet<br />

and floor coverings industry the greatest<br />

possible long-term planning security. We<br />

WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong> 9

NEWS<br />

AUSTRALIAN PROGRAMME<br />

TO INVEST AU$300 MILLION IN<br />

MASS TIMBER BUILDINGS<br />

On behalf of the Australian government, the<br />

Clean Energy Finance Corporation (CEFC) will<br />

be investing in an AU$300 million programme<br />

to encourage mass timber construction<br />

across the property sector in Australia.<br />

The Timber Building Programme aims to cut<br />

construction-related emissions, providing<br />

a greener alternative to conventional<br />

construction materials. The CEFC determined<br />

through research the need to transform<br />

the approach to construction to achieve<br />

an economy-wide transition to net zero<br />

emissions.<br />

The $300m will be invested in projects<br />

Australia wide, including commercial<br />

offices, retail, industrial, healthcare and<br />

education. Finance may also be available<br />

for multi-residential apartments, seniors<br />

living and student accommodation projects.<br />

Concessional finance may be available under<br />

certain circumstances.<br />

According to CEFC, eligible projects will be<br />

considered on a case-by-case basis and<br />

may include those which: use low-carbon<br />

engineered wood products in large-scale<br />

construction; have secured appropriate<br />

materials source, accreditation and embodied<br />

carbon outcomes; require $20-75m in<br />

CEFC debt finance; are commercially<br />

sound, reflecting the rigorous investment<br />

requirements of the CEFC; and comply with<br />

the CEFC <strong>In</strong>vestment Policies, Guidelines and<br />

Risk Approach.<br />

Ian Learmonth, CEO of CEFC, commented:<br />

“Timber has been used in construction for<br />

generations. <strong>In</strong>novations in engineered<br />

wood products have created new<br />

opportunities for mass timber construction<br />

to be used in larger projects, creating the<br />

potential for immediate and long-term<br />

environmental benefits.<br />

“Our new Timber Building Programme will<br />

help finance this transition by encouraging<br />

owners, developers and builders to use lower<br />

carbon engineered wood products in their<br />

projects. The CEFC has a strong track record<br />

in financing new market developments, from<br />

large-scale solar to cleantech start-ups.<br />

We are excited to bring this expertise to<br />

sustainable construction.”<br />

Founded in 2012, the CEFC is an Australian<br />

government-owned establishment, dedicated<br />

to accelerating investments in Australia’s<br />

transition to net-zero emissions. WIA<br />

WINNERS AND DESIGN TRENDS OF ICONIC AWARDS <strong>2022</strong>:<br />

INNOVATION INTERIOR REVEALED<br />

The Iconic Awards <strong>2022</strong>: <strong>In</strong>novation <strong>In</strong>terior,<br />

helmed by the German Design Council,<br />

has announced the winners of its “Best of<br />

Best”, “Winner” and “Selection” labels, and<br />

also trends in the furnishings industry and<br />

developments in interior design.<br />

As part of the German Design Council’s Iconic<br />

World platform, the Iconic Awards <strong>2022</strong>:<br />

<strong>In</strong>novation <strong>In</strong>terior shows developments and<br />

trends in design and furnishings each year, and<br />

brings together architects, product designers<br />

and property developers with the furnishings<br />

industry. The German Design Council, since<br />

1953, has been a centre of expertise in<br />

communication and knowledge transfer within<br />

design, branding and innovation.<br />

The COVID-19 pandemic was again a theme for<br />

this year’s awards. Explaining its choices, the<br />

jury said, “The pandemic is resulting in a variety<br />

of deep changes to day-to-day life. There<br />

are numerous designers responding to these<br />

changes with vision. Work meetings and private<br />

events are being held by video conferences,<br />

and online delivery services and retailers are<br />

supplying people with basic food and goods.<br />

“Meanwhile the range of digital entertainment<br />

media has reached record levels. The added<br />

burden and the increased stress factor at work<br />

and among families are paired with a loss of<br />

options for relaxation, exercise and recreation.<br />

Travelling to exotic destinations or partying is<br />

out of the question. Many of our priorities have<br />

changed. This has had a substantial impact<br />

on design, as we saw during our evaluation of<br />

the many entries for the Iconic Awards <strong>2022</strong>:<br />

<strong>In</strong>novative <strong>In</strong>terior.”<br />

Some of the trends outlined by the German<br />

Design Council include increasing demand for<br />

hygiene products and new hygiene concepts<br />

in a wide variety of design domains, all while<br />

incorporating smart technology; the pandemic’s<br />

effect on the formal and aesthetic design of the<br />

The V-Alpin is a project by Martin Ballendat which<br />

was awarded the “Winner” label, manufactured by<br />

Voglauer Gschwandtner & Zwilling (Image: German<br />

Design Council)<br />

objects, culminating in a shift towards cool, muted<br />

tones, a clean design language and minimalism<br />

involving only the essentials; high demand<br />

for mobility, in a working world which values<br />

flexibility, remote working and adaptability; and<br />

material innovations that crease new forms and<br />

objects, and minimise carbon emissions, all while<br />

improving users’ well-being. WIA<br />

10 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong>

NEWS<br />

QUEBEC WOOD EXPORT BUREAU DEVELOPS TOOL TO<br />

CALCULATE CO2 IMPACT IN BUILDING DESIGNS<br />

Robotics & <strong>In</strong>novation has<br />

reported that the Quebec <strong>Wood</strong><br />

Export Bureau (QWEB), a nonprofit<br />

organisation for wood<br />

product manufacturers in Canada,<br />

has developed a machine learning<br />

tool with global AI consultancy<br />

Brainpool.ai which calculates the<br />

impact of CO2 in choices of earlyphase<br />

building design.<br />

According to QWEB and<br />

Brainpool.ai, the tool CarbonFixer<br />

aims to help the building<br />

and construction industry<br />

decarbonise by showing how<br />

much CO2 is emitted in their<br />

design-related choices of<br />

using concrete and steel, in<br />

comparative scenarios with<br />

wood and bio-sourced building<br />

materials.<br />

The building industry is<br />

responsible for 38% of the<br />

total global energy-related CO2<br />

emissions, mainly due to the<br />

use of steel and concrete, with<br />

concrete alone accounting for<br />

8%. The partnership between<br />

QWEB and Brainpool.ai hence<br />

aims to explore carbon-neutral<br />

alternatives of building materials.<br />

Eli Gould, US architect liaison<br />

and software project lead for<br />

QWEB, described CarbonFixer<br />

as “like using a mortgage<br />

calculator before going to the<br />

bank, it gives an idea of what<br />

to expect”. Architects and<br />

sustainability professionals<br />

can feed the tool basic building<br />

data, such as dimensions, area<br />

and structural data, to produce<br />

scenarios that compare the use<br />

of steel, concrete or timber.<br />

It also has pre-sets for fire<br />

resistance and acoustics and<br />

offers design considerations<br />

with industry-specific<br />

knowledge and norm.<br />

“Attitudes to using wood in<br />

construction are changing,”<br />

said Gould. “We wanted to<br />

build a tool that counters the<br />

greenwashing around nonsustainable<br />

building materials<br />

and gives architects and<br />

construction firms the data and<br />

confidence to explore timber<br />

options.<br />

“The Brainpool.ai team has<br />

been instrumental in developing<br />

the CarbonFixer, they were fast<br />

Photo: BAM/Trevor Palin<br />

Photo: BAM/Trevor Palin<br />

and passionate and have created<br />

something very robust that we can<br />

soon launch to market.”<br />

Kasia Borowska, co-founder and<br />

managing director of Brainpool.ai,<br />

added: “CarbonFixer is a complex<br />

application because of the volume<br />

of data that has to be collected.<br />

Our team of backend developers<br />

and ML experts collated the data<br />

quickly and built a robust proofof-concept<br />

for the application,<br />

which the CarbonFixer team<br />

can develop further into the<br />

future. The project shows how<br />

environmental AI has a growing<br />

role in the construction industry<br />

PEFC/01-00-01<br />

Constructing Constructing the Future with<br />

Sustainable the<br />

Timber the Future with<br />

Sustainable Timber<br />

Photo: BAM/Trevor Palin<br />

PEFC/01-00-01<br />

PEFC/01-00-01<br />

Discover more at:<br />

Discover www.pefc.org<br />

Discover more more at: at:<br />

www.pefc.org<br />

from proving how sustainability is<br />

feasible, through to automating<br />

building designs to find the most<br />

eco-efficient plans.”<br />

Robotics & <strong>In</strong>novation explained<br />

that the final version of the<br />

tool will incorporate a machine<br />

learning engine which will<br />

continuously improve the accuracy<br />

of calculations and inputs. Future<br />

plans include integrations with<br />

popular design software and a<br />

bank of archetype structures<br />

ready to be used and customised<br />

by design studios. WIA<br />

Source: Robotics & <strong>In</strong>novation<br />

Your assurance of<br />

Your assurance of<br />

responsibly Your assurance sourced of timber<br />

responsibly sourced timber<br />

responsibly sourced timber<br />

Ask your suppliers for PEFC-certified<br />

Ask<br />

wood Ask your your products<br />

suppliers for for PEFC-certified<br />

wood wood products<br />

Choose PEFC<br />

Choose PEFC<br />

Choose Caring for our PEFC forests<br />

Caring globally and locally<br />

Caring for for our our forests forests<br />

globally globally and and locally locally<br />

PEFC/01-00-01<br />

PEFC/01-00-01<br />

PEFC – Programme for the Endorsement of Forest Certification<br />

PEFC – Programme for the Endorsement of Forest Certification<br />

PEFC – Programme for the Endorsement of Forest Certification<br />

Image: Darwin Vegher/Unsplash<br />

PEFC INFOGRAPHIC AD MAY 2020 (B).indd 1 31/07/2020 11:03<br />

PEFC INFOGRAPHIC PEFC INFOGRAPHIC AD MAY 2020 AD (B).indd MAY 20201 (B).indd 1 31/07/2020 31/07/202011:03<br />

11:03<br />

WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong> 11

NEWS<br />

SLOW: A PROJECT BY AMERICAN<br />

HARDWOOD EXPORT COUNCIL<br />

Berlin’s Museum of Decorative Arts,<br />

Kunstgewerbemuseum, has opened its<br />

permanent collection for an intervention from<br />

26 Nov 2021 to 20 Feb <strong>2022</strong>, showcasing<br />

and celebrating emerging design talent and<br />

the sustainability and versatility of wood as a<br />

design material.<br />

<strong>In</strong>itiated by the American Hardwood Export<br />

Council (AHEC), Slow consists of nine projects<br />

from emerging designers working with<br />

American red oak, cherry and hard and soft<br />

maple. Woven among the museum’s existing<br />

exhibits, these contemporary designs represent<br />

design voices that articulate new ways of<br />

thinking about sustainability and accountability<br />

in terms of design, materiality and production<br />

process.<br />

From one or more of the aforementioned<br />

hardwoods, each designer has created an<br />

object that reflects their approach towards the<br />

theme “slow design for fast change”. The result<br />

is a range of products, including bowls, chairs,<br />

benches, shelving systems, tables and modular<br />

furniture elements. This variety reflects voices<br />

and ideas that are united by an emphasis on<br />

sustainability, longevity and a focus on quality.<br />

Nine young designers were hand-picked by<br />

a selection panel comprising their university<br />

tutors, the project’s manufacturing partner,<br />

German workshop Holzfreude, three mentors –<br />

Hanne Willmann, Sebastian Herkner and Garth<br />

Roberts – and the AHEC team.<br />

“RE;Collection” by Hansil<br />

Heo, displayed during<br />

American Hardwood<br />

Export Council’s Slow<br />

exhibition<br />

The designers are: Maximilian Beck, Clémence<br />

Buytaert, Simon Gehring, Hansil Heo, Sarah<br />

Hossli and Lorenz Noelle, Anna Koppmann,<br />

Haus Otto (Nils Körner and Patrick Henry Nagel),<br />

Theo Luvisotto, and Maximilian Rohregger.<br />

According to AHEC, the concept of “slow” – as<br />

understood in terms of slow fashion or slow<br />

food – is a response to the lifestyle changes<br />

borne from COVID-19. Products that keep<br />

materials in circulation for as long as possible are<br />

increasingly appealing. All over the world, oncehectic<br />

routines have been forced to slow down<br />

drastically, making people even more aware<br />

of what and how they consume. As such, the<br />

concept of “slow” has come to entail a holistic<br />

approach to creative thinking, processes and<br />

products.<br />

Among some of the pieces designed and were<br />

displayed in Kunstgewerbemuseum include:<br />

“Leftover Synthesis” by Simon Gehring, which<br />

explores better use of wood scraps from furniture<br />

production, combined with computational design<br />

methods, using American cherry, maple and red<br />

oak; “Rocking Chair” by Clémence Buytaert,<br />

a rocking chair made using American red oak;<br />

“RE;Collection” by Hansil Heo, a sculptural<br />

storage system inspired by historic Korean<br />

culture, and made using American cherry, maple<br />

and red oak; and others.<br />

“Strong, tactile and visually appealing, wood is<br />

essential in an era of plastics, over-consumption<br />

and climate change, because of its low impact on<br />

the environment and the fact that it can be easily<br />

recycled,” commented David Venables, European<br />

director of AHEC. “As well as being a material for<br />

making, it is also a low-impact fuel and a carbon<br />

store. This project presents four underused<br />

timbers and questions the assumption that the<br />

most well-known varieties of wood are always<br />

the only ‘right’ woods to use.” WIA<br />

BECK LAUNCHES LIGNOLOC WOODEN NAILS<br />

WITH HEAD FOR FAÇADE APPLICATIONS<br />

After LIGNOLOC received the German general<br />

construction technique permit in 2020, the<br />

new wooden nail system with head tailored for<br />

façade applications will be launched in <strong>2022</strong>.<br />

Developed by Austria-based fastening<br />

developer Beck, LIGNOLOC is a collated<br />

wooden nail for future-oriented use in<br />

industrial production and ecological wood<br />

processing. Made with central European beech<br />

wood, the design of the LIGNOLOC nail point<br />

and the large amount of heat generated by<br />

friction when the nail is driven in at a high<br />

speed will cause the lignin of the wooden nail<br />

to weld with the surrounding wood to form a<br />

substance-to-substance bond.<br />

The most recent version of the LIGNOLOC F60<br />

pneumatic nailer has already been adapted to<br />

accept nails with head and is available now.<br />

The main target application is horizontal and<br />

vertical wood cladding. The nail with head<br />

allows exterior cladding panels to be held<br />

securely in position.<br />

According to Beck, it has a blunt anti-splitting<br />

point and is suitable for the most common<br />

softwood façades as well as a range of other<br />

LIGNOLOC (Image: Beck)<br />

applications, both indoors and outdoors, such<br />

as privacy screens, garden sheds, gazebos,<br />

room dividers, among others. WIA<br />

12 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong>

NEWS<br />

AURECON APPOINTS<br />

NEW MANAGING<br />

DIRECTOR TO DRIVE<br />

GROWTH IN GREATER<br />

CHINA<br />

Alton Chow, new managing<br />

director of Aurecon, Greater<br />

China (Image: Aurecon)<br />

<strong>In</strong>ternational design, engineering and advisory<br />

company Aurecon has appointed Alton Chow<br />

as its new managing director of Greater China.<br />

With this new appointment, Chow will take the<br />

lead to grow Aurecon’s business in Greater<br />

China and work with the team to deliver<br />

innovative and sustainable solutions to clients.<br />

This move is part of Aurecon’s strategy<br />

to further strengthen its position in the<br />

infrastructure and engineering sector in<br />

Greater China. Recent years have seen the<br />

company bolster its leadership team and grow<br />

its presence steadily in the region. The team<br />

has been winning and working on noteworthy<br />

projects such as the recent MTR Hung Shui Kiu<br />

Station, Tuen Ma Line extension, the Hong Kong<br />

West Kowloon Terminus, The Mills, and Tseung<br />

Kwan O – Lam Tin Tunnel.<br />

Approximately HK$100 billion (US$12.8 billion)<br />

is expected to be invested annually in Hong<br />

Kong’s infrastructure over the next decade,<br />

in addition to the $120bn stimulus package<br />

announced earlier this year. <strong>In</strong>frastructure<br />

development is also a key highlight in this<br />

year’s Chief Executive’s Policy Address<br />

2021 where there is a focus on Smart Cities,<br />

developing a new Northern Metropolis,<br />

establishing transport infrastructureled<br />

developments and building an ecoenvironment,<br />

among other initiatives.<br />

Commenting on his new role, Chow said: “It is<br />

refreshing to see an innovative company like<br />

Aurecon pivot towards growth and expanding its<br />

operations with purposeful and deliberate intent.<br />

I also appreciate that Aurecon is committed to<br />

quality and has grown a culture that focuses on<br />

talent. This is crucial to any consulting business,<br />

especially in the design, engineering and advisory<br />

sectors.<br />

“Along with that, I see immense potential in<br />

the region, and I am confident that together as<br />

a team, we can and will collectively advance<br />

our growth and maximise this region’s market<br />

opportunities.”<br />

Prior to this appointment, Alton was with AECOM<br />

for over seven years. He served as vice-president<br />

and global head of commercial development as<br />

well as Asia head of architecture. <strong>In</strong> these roles,<br />

he expanded the company’s market share in<br />

the US, Middle East and Asia through strategic<br />

alignments with key global clients. Earlier in<br />

his career with the organisation, Alton was the<br />

managing director for Mainland China where he<br />

was responsible for the business’ restructure,<br />

driving record growth during his tenure. WIA<br />

NATURAL RESOURCES CANADA SUPPORTING SUSTAINABLE AND<br />

INNOVATIVE WOOD CONSTRUCTION<br />

Jonathan Wilkinson, the Canadian Minister<br />

of Natural Resources, has announced a<br />

CA$887,000 investment to support the<br />

replacement of the Duchesnay Creek<br />

Bridge that connects the City of North Bay,<br />

Ontario, Canada, and the Nipissing First<br />

Nation, Ontario. The Government of Ontario<br />

contributed $17m.<br />

This is in line with Canada’s goal of investing in<br />

the increased use of wood in the construction<br />

industry, to achieve their climate change<br />

goals while increasing the demand for<br />

Canadian wood products and creating jobs for<br />

Canadians. The goal is supported by Natural<br />

Resources Canada, a department of the<br />

Federal Government of Canada that researches<br />

and develops policies on natural resources,<br />

energy, minerals and metals, forests, earth<br />

sciences, mapping, and remote sensing.<br />

Wilkinson said: “There is no solution to climate<br />

change that does not involve our forests.<br />

Creating new markets for Canadian timber<br />

supports our forestry workers, creates jobs<br />

and gets us to net-zero. By supporting the<br />

use of wood in construction, we are taking<br />

action to protect our planet and support our<br />

communities.”<br />

Funding for this project is provided through<br />

Natural Resources Canada’s Green<br />

Construction through <strong>Wood</strong> programme, which<br />

encourages the use of wood in non-traditional<br />

construction projects, such as tall and lowrise<br />

non-residential buildings and bridges.<br />

The programme aims to position Canada as a<br />

world leader in innovative timber construction<br />

systems and technologies and in the lowcarbon<br />

economy, and also help Canada achieve<br />

its 2030 climate change goals.<br />

The funding supported the design and<br />

construction of the new replacement bridge<br />

and was made to maintain the original timber<br />

aesthetic of the old bridge. By building with<br />

wood, this project will result in a total carbon<br />

benefit of 991 tonnes of CO2, which is<br />

equivalent to taking over 190 cars off the road<br />

for a full year. The bridge was built through a<br />

limited partnership of Nipissing First Nation and<br />

Miller Paving, which provided employment and<br />

training opportunities for the community.<br />

Patty Hajdu, Minister of <strong>In</strong>digenous Services,<br />

concluded: “Using green construction materials<br />

and including employment and training<br />

opportunities with the local community, this<br />

project shows others how to make sure what<br />

we build as a country can help with our goals<br />

of a cleaner and more inclusive country. A big<br />

congratulations to all involved.” WIA<br />

WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong> 13

NEWS<br />

ASCENT TOPS OFF AS “WORLD’S TALLEST MASS TIMBER<br />

HYBRID TOWER”: NEW LAND ENTERPRISES<br />

Top-down view of Ascent. (Photo: Korb + Associates Architects)<br />

<strong>In</strong> mid-December 2021, the final mass<br />

timber beams, columns and cross-laminated<br />

timber (CLT) roof were set into place at<br />

downtown Milwaukee’s Ascent construction<br />

site. This makes Ascent 284ft, or roughly<br />

86.5m-tall, making it officially “the world’s<br />

tallest mass timber hybrid tower” at the time<br />

of going to press, according to New Land<br />

Enterprises, the real estate development<br />

and property management company behind<br />

Ascent.<br />

Ascent, a mass timber structure in<br />

Milwaukee, US, broke ground at the<br />

intersection of Kilbourn and Van Buren in<br />

August 2020, with timber construction<br />

commencing in June 2021. Six months later,<br />

general contractor C.D. Smith Construction<br />

topped off the innovative tower at 25 storeys.<br />

The construction process used prefabricated<br />

columns and beams with factory integrated<br />

connectors, making the construction process<br />

approximately 25% faster.<br />

“Today is the culmination of years of<br />

determination and innovation for New<br />

Land and our partners,” commented Tim<br />

Gokhman, managing director of New Land<br />

Enterprises. “Together, we’ve shown that<br />

we can build a more beautiful, sustainable<br />

and precise building faster, paving the way<br />

to transform development in the US. The<br />

crews involved in construction have done<br />

an amazing job and should be very proud of<br />

today’s milestone.”<br />

New Land Enterprises did not set out to break<br />

the world record when the project began<br />

more than three years ago, but after several<br />

design revisions, the height of the tower<br />

climbed four feet taller than the current<br />

record holder in Norway.<br />

“This continues to be a job of amazing<br />

scale as we top off the building and<br />

proceed with the buildout,” said Chris<br />

Johansen, project manager at C.D. Smith<br />

Construction. “We have a veteran-led<br />

team of talented craftsmen that really<br />

took ownership and are always looking<br />

for ways to build faster, smarter, safer.”<br />

With timber installation complete and<br />

glazing mostly up, the project is already<br />

moving into its final phase of interior<br />

buildout. The building’s 259 luxury<br />

apartment homes will feature exposed<br />

timber ceilings and columns, finishes<br />

and appointed fixtures. Ascent will also<br />

offer amenities including an indoor and<br />

outdoor seventh-floor pool, a rooftop<br />

cinema, a golf simulator, and a fitness<br />

centre. It is scheduled to open this<br />

summer. WIA<br />

14 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong>

BIG PICTURE<br />

Pavilions<br />

for one and all<br />

A shelter for the weary, an outdoor classroom for youths, a performance<br />

venue for curious passers-by — these are a few of the many possibilities<br />

that pavilions can offer to the public. Here, we invite everyone to<br />

imagine themselves within these pavilions, admire their versatility, and<br />

marvel at how wood is an integral part of their structural beauty.<br />

16 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong>

BIG PICTURE<br />

Efficient, economical,<br />

ecological and<br />

expressive<br />

PROJECT: BUGA <strong>Wood</strong> Pavilion<br />

LOCATION: Heilbronn, Baden-Württemberg, Germany<br />

ARCHITECTS: Computational Design and Construction<br />

(ICD) and the <strong>In</strong>stitute for Building Structures and<br />

Structural Design (ITKE) at the University of Stuttgart<br />

COVERED AREA: 500m²<br />

SHELL AREA: 600m²<br />

PHOTOGRAPHY: ICD/ITKE University of Stuttgard<br />

TEXT: ICD and ITKE<br />

The BUGA <strong>Wood</strong> Pavilion celebrates a new approach to<br />

digital timber construction. Its segmented wood shell is<br />

based on biological principles found in the plate skeleton<br />

of sea urchins, which have been studied by the <strong>In</strong>stitute<br />

for Computational Design and Construction (ICD) and the<br />

<strong>In</strong>stitute for Building Structures and Structural Design (ITKE)<br />

at the University of Stuttgart for almost a decade.<br />

As part of the project, a robotic manufacturing platform<br />

was developed for the automated assembly and milling of<br />

the pavilion’s 376 hollow wood segments. This fabrication<br />

process ensures that all segments fit together with submillimetre<br />

precision like a big, three-dimensional puzzle. The<br />

wooden roof spans 30m over one of BUGA’s main event and<br />

concert venues, using a minimum amount of material while<br />

also generating an architectural space.<br />

WOOD IN ARCHITECTURE • ISSUE 1– <strong>2022</strong> 17

BIG PICTURE<br />

1 2<br />

1 Finished hollow<br />

wood segment with<br />

finger joints and bolt<br />

holes<br />

2 Preformatted plates<br />

and finished hollow<br />

wood shell segments<br />

3 Detail view of spine<br />

arch of the BUGA<br />

<strong>Wood</strong> Pavilion<br />

4 <strong>In</strong>terior and flexible<br />

event space of the<br />

BUGA <strong>Wood</strong> Pavilion<br />

BIOMIMETIC LIGHTWEIGHT<br />

CONSTRUCTION<br />

The BUGA <strong>Wood</strong> pavilion provides an<br />

architectural attraction at the central summer<br />

island of the Bundesgartenschau 2019 in<br />

Heilbronn, Baden-Württemberg, Germany.<br />

Following the precursor research building of<br />

the same project team, the LAGA Exhibition<br />

Hall in Schwaebisch Gmuend, the research<br />

goal of the BUGA <strong>Wood</strong> Pavilion is pushing<br />

the architectural articulation and structural<br />

performance of biomimetic segmented wood<br />

shells onto a new level: With the same small<br />

amount of wood per square meter as in the<br />

LAGA project, is it possible to build a shell<br />

that reaches triple the span? And can this<br />

structure remain fully reusable, so that it can<br />

be deployed on a different site after the BUGA<br />

without any loss of performance?<br />

To achieve this goal, the pavilion builds on the<br />

biomimetic principle of using less material<br />

by having more form, both on the level of the<br />

overall shell and its individual segments. <strong>In</strong><br />

order to minimise material consumption and<br />

weight, each wood segment is built up from<br />

two thin plates that plank a ring of edgebeams<br />

on top and bottom, forming large scale<br />

hollow wooden cases with polygonal forms.<br />

The bottom plate includes a large opening,<br />

which constitutes a distinctive architectural<br />

feature and provides access to the hidden<br />

connections during assembly. The lightweight<br />

building elements are connected by finger<br />

joints, which follow the morphological principles<br />

of anatomic features found on the edge of sea<br />

urchins’ plates. <strong>In</strong> the assembled state, the<br />

shell works as a form-active structure through<br />

its doubly-curved geometry.<br />

INTEGRATIVE (CO)DESIGN<br />

New ways of building require new ways of<br />

designing and manufacturing. The BUGA <strong>Wood</strong><br />

pavilion was conceived under the paradigm<br />

of co-design, where possibilities in design,<br />

engineering and fabrication are explored<br />

through continuous computational feedback<br />

within an interdisciplinary team. <strong>In</strong> this<br />

project, the co-design algorithms developed<br />

by the project team generate the shape of<br />

each element of the pavilion according to<br />

architectural design intent and structural<br />

requirements, while all robotic fabrication<br />

aspects are directly embedded and negotiated.<br />

The design of the pavilion happens concurrently<br />

and in feedback with the design of the robotic<br />

manufacturing set-up, which is a bespoke<br />

development for the project.<br />

The integrative process enables the design and<br />

engineering of 376 plate segments with 17,000<br />

different finger joints in response to multifaceted<br />

18 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong>

BIG PICTURE<br />

3 4<br />

design criteria, from the scale of the overall<br />

structure down to sub-millimetre details.<br />

Without any loss of precision, this multi-scale<br />

approach allows addressing architectural and<br />

structural considerations concurrently. Despite<br />

the pioneering character of the project, and<br />

despite a short development time of only 13<br />

months from commission to the opening, the<br />

integrative computational process allows for<br />

the careful design of each building element in<br />

minute detail.<br />

ROBOTIC PREFABRICATION<br />

Compared to a solid wood plate, the hollow<br />

building segments reduce weight and<br />

material, but they increase the number of<br />

building parts eightfold and lead to more<br />

complex manufacturing. Thus, striving for<br />

higher resource efficiency needs to go hand in<br />

hand with automated robotic manufacturing of<br />

the shell segments. For this, a transportable,<br />

14-axes robotic timber-manufacturing<br />

platform was developed by ICD University of<br />

Stuttgart and BEC, a manufacturer of robotic<br />

applications for industrial automisation,<br />

and located at the industrial partner<br />

MuellerBlaustein Holzbauwerke<br />

for production. The platform includes two<br />

high-payload industrial robots mounted<br />

on a 20-foot standard container base. The<br />

flexibility of industrial robots allows the<br />

integration of all prefabrication steps of the<br />

pavilion’s segments within one manufacturing<br />

unit.<br />

During production, each shell segment<br />

is robotically assembled. This entails the<br />

placement of preformatted timber plates<br />

and beams, their temporary fixation with<br />

beech nails, and the controlled application for<br />

the structural glue joint between plate and<br />

beam. <strong>In</strong> a second step, the finger-joints and<br />

openings are machined into the segments<br />

with 300μm accuracy. From the assembly of<br />

beams and plates, to multi-tool machining<br />

and sensorial process- and image-based<br />

quality control, everything happens in a fully<br />

automated workflow, controlled by two million<br />

custom lines of robotic code that were directly<br />

exported from the computational design<br />

framework, according to ICD and ITKE. On<br />

average, the assembly time per segment is<br />

eight minutes, with the high precision-milling<br />

taking another 20-40 minutes.<br />

A NOVEL STRUCTURE AND<br />

ARCHITECTURAL SPACE<br />

The prefabricated shell segments were<br />

assembled in within 10 working days by a<br />

team of two craftsmen, as reported by ICD and<br />

ITKE, without the usually required extensive<br />

scaffolding or formwork. After connecting<br />

all segments with removable bolts, a layer of<br />

ethylene propylene diene monomer (EPDM) foil<br />

was rolled over the pavilion in eight strips to<br />

provide waterproofing. Untreated larch facade<br />

plates provide the external cladding of the<br />

pavilion. All building elements are designed for<br />

disassembly and reuse on a different site.<br />

The pavilion’s loadbearing wood shell achieves<br />

a column-free span of 30m, but weighs<br />

36kg/m². Drawing a line from traditional<br />

carpentry to high-tech robotic fabrication<br />

methods, the BUGA <strong>Wood</strong> Pavilion showcases<br />

the possibilities for efficient, economical,<br />

ecological and expressive wood architecture<br />

that arises at the intersection of master craft,<br />

digital innovation and scientific research.<br />

The BUGA <strong>Wood</strong> Pavilion is located at a central<br />

crossroad within the wavy landscape of the<br />

BUGA summer island. Three arches form<br />

openings in the main directions and guide<br />

visitors into the pavilion’s interior. Hosting<br />

concerts and public events, the shell creates<br />

a smoothly-curved space that provides good<br />

acoustics and generates an architectural<br />

atmosphere. This is especially true at night,<br />

when thousands of LED lights embedded in<br />

the shells inner openings light up and bathe<br />

the pavilion’s interior in subtle, warm and<br />

welcoming light.<br />

WOOD IN ARCHITECTURE • ISSUE 1– <strong>2022</strong> 19

BIG PICTURE<br />

Designed and fabricated by Skidmore,<br />

Owings & Merrill (SOM) and the<br />

University of Michigan Taubman<br />

College of <strong>Architecture</strong> and Urban<br />

Planning, the pavilion is an open-air<br />

learning lab and gathering space for a<br />

high school in Chicago’s South Shore.<br />

Prefabricated<br />

and sustainable<br />

PROJECT: SPLAM Pavilion<br />

LOCATION: Chicago, Illinois, US<br />

CLIENT: EPIC Academy<br />

ARCHITECTS: Skidmore, Owings & Merrill,<br />

and University of Michigan Taubman<br />

College of <strong>Architecture</strong> and Urban Planning<br />

IMAGES: Kendall McCaugherty and Dave Burk<br />

The SPLAM pavilion, which stands for<br />

SPatial LAMinated timber, showcases<br />

the potential for prefabricated<br />

timber framing panels using robotic<br />

technology to advance more<br />

sustainable and efficient methods of<br />

design and construction.<br />

Spatial-laminated timber (SLT)<br />

proposes an evolution of conventional<br />

framing systems using an optimised<br />

timber structure. The pavilion, unveiled<br />

20 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong>

BIG PICTURE<br />

in September 2021 at the opening of<br />

the Chicago <strong>Architecture</strong> Biennial, is a<br />

full-scale prototype of a single-storey<br />

SLT structural framing system used in<br />

mid-rise, fire-resistant construction.<br />

Lighter in weight than conventional<br />

building framing methods, SLT reduces<br />

material use by 46% compared to a<br />

cross-laminated timber (CLT) panel.<br />

The pavilion demonstrates a solution<br />

that could reduce timber consumption<br />

and overall carbon footprint if used to<br />

construct an entire building.<br />

“Weaving together timber beams like<br />

threads in fabric, SPLAM explores<br />

the idea of using smaller pieces of<br />

wood than conventional mass timber<br />

construction systems. Doing so means<br />

that the wood can be sourced from<br />

more rapidly renewable forests, or,<br />

in theory, even from the salvaged<br />

components of deconstructed<br />

buildings,” said Scott Duncan, SOM<br />

design partner.<br />

The team chose timber for its inherent<br />

sustainable qualities, as a renewable<br />

resource which has the capacity<br />

to sequester carbon compared to<br />

conventional concrete slabs. The<br />

pavilion comes together using<br />

interlocking timber joints, which allows<br />

for shorter and salvaged wood beams<br />

to be used.<br />

“Automated manufacturing<br />

technologies enable us to precisely<br />

and efficiently prefabricate a kit<br />

of parts which can be delivered to<br />

the construction site on demand,<br />

leveraging skilled labour where it<br />

is most effective in the process,”<br />

said professors Ng Tsz Yan and Wes<br />

McGee.<br />

SPLAM is a permanent addition to EPIC<br />

Academy’s South Shore high school<br />

campus. The pavilion will host a series<br />

of performances during the Biennial,<br />

and will function as an outdoor<br />

classroom and performance venue<br />

afterwards, contributing to the future of<br />

post-pandemic teaching and learning.<br />

The pavilion was designed and<br />

constructed in partnership with<br />

Autodesk, McHugh Construction,<br />

Gremley & Biedermann, and REX<br />

Engineering Group.<br />

WOOD IN ARCHITECTURE • ISSUE 1– <strong>2022</strong> 21

BIG PICTURE<br />

1<br />

22 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong>

BIG PICTURE<br />

A structural<br />

beauty<br />

PROJECT: CLT Park Harumi<br />

LOCATION: Tokyo, Japan<br />

ARCHITECTS: Kengo Kuma & Associates<br />

COMPLETION DATE: 5 Dec 2019<br />

IMAGES: Kawasumi Kobayashi Kenji<br />

Photograph Office / Satoshi Takae / Hiroshi Kuwahara<br />

TEXT: Kengo Kuma & Associates<br />

Kengo Kuma & Associates designed<br />

a temporary cross-laminated<br />

timber (CLT) pavilion for events and<br />

performances for an open area in<br />

the district of Harumi, Tokyo, Japan.<br />

<strong>In</strong> the semi-outdoor space, the CLT<br />

Park Harumi was built by weaving<br />

leaves made from CLT panels of<br />

160cmx350cm and 21cm-thick with<br />

a steel frame, creating a structure that<br />

appears to be reaching up in a spiral<br />

shape towards the sky.<br />

Transparent kite-shaped pieces made<br />

from TEFKA fluororesin film were used<br />

to close off the gap between the CLT<br />

panels in order to prevent the entrance<br />

of rain and wind, while allowing light to<br />

filter through the CLT leaves like trees<br />

in a forest.<br />

The Meiken Lamwood Corporation<br />

used Japanese cypress from Maniwa<br />

city in Okayama prefecture to make<br />

the CLT panels. After their period of<br />

use in Harumi comes to an end, the<br />

panels will be transported back to the<br />

Hiruzen National Park in Maniwa and<br />

reassembled in an area surrounded by<br />

greenery.<br />

WOOD IN ARCHITECTURE • ISSUE 1– <strong>2022</strong> 23

BIG PICTURE<br />

A resting point<br />

PROJECT: Helsinki<br />

Biennial Pavilion<br />

LOCATION: Lyypekinlaituri,<br />

Helsinki, Finland<br />

SCALE: 187m 2<br />

CLIENT: City of Helsinki,<br />

Urban Environmental Division<br />

ARCHITECTURE AND<br />

DESIGN FIRM: Verstas Architects<br />

TEXT: Verstas Architects<br />

This pavilion is the entry to the Helsinki<br />

Biennial, an art festival that takes place on<br />

the island of Vallisaari, Helsinki, Finland.<br />

Ferries from the pavilion will take visitors<br />

from the harbour in the old town of Helsinki<br />

to the archipelago. The wooden swirl of<br />

the pavilion stands out in contrast to the<br />

19th-century maritime city. The Market<br />

Square and the façade of neoclassical and<br />

neo-Renaissance buildings, such as the City<br />

Hall, the Old Market Hall and the Cathedral<br />

surround the pavilion. <strong>In</strong>stead, the form of<br />

the temporary pavilion, reminiscent of a<br />

giant’s kettle, echoes the coastal cliffs of<br />

Vallisaari that the ice age has rounded. Its<br />

deck connotes wooden ships that still visit<br />

the harbour during a herring market. Verstas<br />

Architects designed the temporary pavilion to<br />

prepare the visitor for the journey to the art<br />

festival on the Vallisaari island.<br />

A TERMINAL FOR THE ART<br />

BIENNIAL<br />

The Helsinki Biennial is expected to attract<br />

300,000 visitors. It is part of Helsinki’s<br />

strategy to make the archipelago more<br />

accessible, attractive and better serviced for<br />

the public. The Vallisaari island, previously a<br />

military area, has recently been opened to the<br />

public. The Biennial Pavilion will house tourist<br />

information as well as ancillary spaces in a<br />

simple rectangular volume next to the pavilion<br />

proper. The pavilion is a place to wait for the<br />

ferry in all weathers. <strong>In</strong> sun, one can rest on<br />

the sloping deck that provides a vantage point<br />

to the Market Square and the Baltic Sea. <strong>In</strong><br />

case of rain, there are benches to wait under<br />

the tent-like roof, which triangular timber<br />

frames support.<br />

DESIGN AND CONSTRUCTION<br />

Verstas Architects studied the form of the<br />

pavilion with the help of modelling clay models<br />

and then designed it digitally. The digital 3D<br />

building model guided the construction in the<br />

wood workshop directly, without conventional<br />

construction drawings. The workshop, too,<br />

was in a port town, hence the pieces were<br />

brought to Helsinki in a barge. The pavilion<br />

is assembled of prefabricated elements<br />

connected with bolts. Open elements consist<br />

of glue-laminated timber frames and steel<br />

ties, clad with laminated veneer lumber and<br />

topped with fine-sawn pine battens. Lighting is<br />

hidden in slots between the frames. The deck<br />

is made of oiled pine planks, while the round<br />

yard is paved with greyed crosscut logs and<br />

white quartz sand.<br />

1<br />

24 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong>

BIG PICTURE<br />

2<br />

3 4<br />

1 The wooden pavilion is reminiscent of the cliffs<br />

of Vallisaari or old wooden ships (Image: Tuomas<br />

Uusheimo)<br />

2 The Market Square and the façade of neoclassical<br />

and neo-Renaissance buildings surround the pavilion<br />

(Image: Pyry Kantonen)<br />

3 The visitors can wait for the ferry under a tent-like roof<br />

(Image: Pyry Kantonen)<br />

4 The inner courtyard is paved with cross-cut logs and<br />

quartz sand (Image: Pyry Kantonen)<br />

WOOD IN ARCHITECTURE • ISSUE 1– <strong>2022</strong> 25

BIG PICTURE<br />

An experiment<br />

with archetypes<br />

PROJECT NAME: <strong>Wood</strong>en Pavilion #1 —<br />

Experiment on Space Prototype<br />

ARCHITECTS: LIN Architects<br />

LOCATION: Zhenjiang, Jiangsu, China<br />

AREA: 50m²<br />

COMPLETION YEAR: December 2021<br />

TEACHING RESEARCH AND<br />

MATERIALS SUPPORT: RAC Studio<br />

PHOTOGRAPHY: Liu Songkai<br />

and Lin Lifeng<br />

TEXT: Lin Lifeng<br />

THREE KEYWORDS<br />

Are there any new architectural space<br />

prototypes that can be discussed? This<br />

question is the starting point of LIN<br />

Architect’s experimental project, which<br />

is located near the river in the tourist<br />

area of Jiangxin Island in Zhenjiang,<br />

Jiangsu province. <strong>In</strong> this project,<br />

the architects sacrificed functional<br />

elements and looked for keywords<br />

that can define spatial elements in the<br />

environment.<br />

After analysing the site, they<br />

focused on three keywords for the<br />

design: ergonomics, proxemics,<br />

and behaviourology.<br />

Ergonomics: The scale of human<br />

behaviour is one of the concerns<br />

of this project. By observing and<br />

understanding the behaviour<br />

of people, the architects can<br />

discover all kinds of possibilities<br />

of space.<br />

Space proxemics: Proxemics<br />

is a concept developed by<br />

anthropologist Edward T. Hall in his<br />

book, The Hidden Dimension. For<br />

<strong>Wood</strong>en Pavilion #1, the architects<br />

deepened and extended this<br />

concept of proxemics, applying it to<br />

the category of physical space, and<br />

discussed how intimate, private,<br />

social and public spaces are<br />

defined and designed at different<br />

scales.<br />

26 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong>

BIG PICTURE<br />

Behaviourology: On behaviour,<br />

from the perspective of architects<br />

Yoshiharu Tsukamoto and Momoyo<br />

Kaijima, human, nature and<br />

architecture are discussed as a whole,<br />

because the study of this project does<br />

not involve the category of urban daily<br />

life pattern.<br />

Therefore, the behaviourology of<br />

various elements in the natural<br />

environment was studied and<br />

explored. Breeze, sunshine, sound<br />

of waves, drizzle, sweet Osmanthus<br />

fragrance, all of which affect the feel,<br />

perception, touch, hearing, visual<br />

elements, are the design materials.<br />

ARCHETYPE DESIGN<br />

Through keyword research, LIN<br />

Architects began to create new forms<br />

of space in response to the various<br />

design elements surrounding it.<br />

Human behaviour, such as sitting,<br />

squatting, lying down, meditating,<br />

listening, peeping, wandering,<br />

overlooking and staring, forms the<br />

space. The act of light, such as the<br />

rising and setting of the sun, the<br />

passing of the last light, the coming<br />

of the lamp, and the illumination, is<br />

a dialogue between space and time.<br />

Finally, surrounding environment<br />

elements like the brushing sea breeze,<br />

rustling leaves, chirping frogs and<br />

singing cicadas, is the medium of<br />

dialogue between people and space.<br />

MATERIALS AND STRUCTURE<br />

LIN Architects prioritised the<br />

combination of steel and wood<br />

structure. Steel is easy to be hot-bent<br />

to shape the main structure matching<br />

the spatial form, while wooden keel<br />

is the secondary structure, and<br />

the texture and characteristics of<br />

wood interact with the surrounding<br />

environmental elements, producing<br />

new traces. Steel and wood are<br />

prefabricated in the factory and<br />

welded together on site. WIA<br />

3<br />

WOOD IN ARCHITECTURE • ISSUE 1– <strong>2022</strong> 27

SUSTAINABILITY<br />

CO2 storage in wood<br />

By Per Friis Knudsen, director, Global Timber Asia<br />

The storage of CO2 – how it is tied up<br />

in wood, and how the well-being of our<br />

forests globally is necessary so that it<br />

stays healthy and continues to tie up all<br />

that CO2 – is a topic of interest to me.<br />

<strong>Wood</strong> is one of the keys to a sustainable<br />

future. That is not news for our industry<br />

and our followers, and hopefully, this is<br />

what our children learn in school.<br />

<strong>Wood</strong> is a renewable resource as it<br />

feeds on CO2, water, nutritious soil, and<br />

sun rays. <strong>Wood</strong> stores approximately<br />

1 tonne of CO2 per 1m 3 of wood.<br />

<strong>Wood</strong> does not use any machinery<br />

to grow and to store CO2 and it is<br />

thereby CO2-negative. It can replace<br />

other materials that are CO2-positive<br />

materials that are manufactured using<br />

heavy machinery such as steel and<br />

concrete, used, for example, in the<br />

construction of housing. The best thing<br />

is if we help forests to stay healthy, it will<br />

tie up even more CO2 in wood.<br />

Per Friis Knudsen is the director of Global Timber<br />

Asia and is responsible for sales and trades in Asia. He<br />

has years of experience in the global wood industry<br />

and is a qualified furniture maker with comprehensive<br />

expertise in the wood furniture business. Before<br />

joining Global Timber in 2013, Knudsen worked and<br />

travelled across countries and cultures. With Asia<br />