Wood In Architecture Issue 1, 2022

First published in 2017, Wood in Architecture (WIA) is a bi-annual trade magazine devoted to the international timber construction sector. The newest addition to the Panels & Furniture Group of wood magazines, WIA features in-depth insights to the latest industry news, incredible projects and leading trade events. WIA is an advocate for timber as a material of choice for today’s built environment, and is the perfect source of inspiration for architects, builders, engineers and interior designers across the globe.

First published in 2017, Wood in Architecture (WIA) is a bi-annual trade magazine devoted to the international timber construction sector. The newest addition to the Panels & Furniture Group of wood magazines, WIA features in-depth insights to the latest industry news, incredible projects and leading trade events. WIA is an advocate for timber as a material of choice for today’s built environment, and is the perfect source of inspiration for architects, builders, engineers and interior designers across the globe.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MATERIALS AND TECHNOLOGY<br />

Clicking into place<br />

with Threespine<br />

By Yap Shi Quan<br />

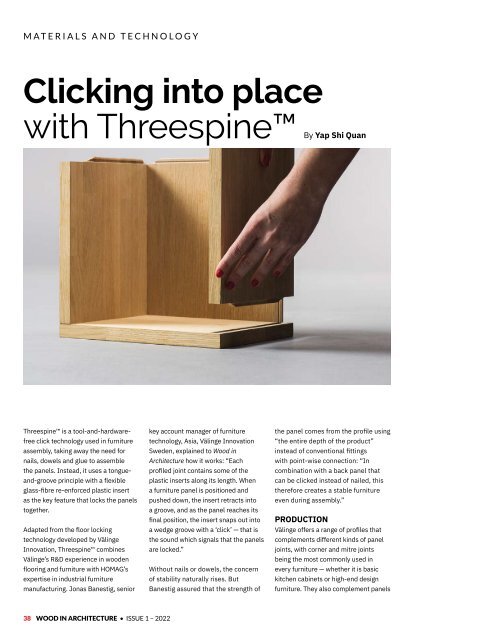

Threespine is a tool-and-hardwarefree<br />

click technology used in furniture<br />

assembly, taking away the need for<br />

nails, dowels and glue to assemble<br />

the panels. <strong>In</strong>stead, it uses a tongueand-groove<br />

principle with a flexible<br />

glass-fibre re-enforced plastic insert<br />

as the key feature that locks the panels<br />

together.<br />

Adapted from the floor locking<br />

technology developed by Välinge<br />

<strong>In</strong>novation, Threespine combines<br />

Välinge’s R&D experience in wooden<br />

flooring and furniture with HOMAG’s<br />

expertise in industrial furniture<br />

manufacturing. Jonas Banestig, senior<br />

key account manager of furniture<br />

technology, Asia, Välinge <strong>In</strong>novation<br />

Sweden, explained to <strong>Wood</strong> in<br />

<strong>Architecture</strong> how it works: “Each<br />

profiled joint contains some of the<br />

plastic inserts along its length. When<br />

a furniture panel is positioned and<br />

pushed down, the insert retracts into<br />

a groove, and as the panel reaches its<br />

final position, the insert snaps out into<br />

a wedge groove with a ‘click’ — that is<br />

the sound which signals that the panels<br />

are locked.”<br />

Without nails or dowels, the concern<br />

of stability naturally rises. But<br />

Banestig assured that the strength of<br />

the panel comes from the profile using<br />

“the entire depth of the product”<br />

instead of conventional fittings<br />

with point-wise connection: “<strong>In</strong><br />

combination with a back panel that<br />

can be clicked instead of nailed, this<br />

therefore creates a stable furniture<br />

even during assembly.”<br />

PRODUCTION<br />

Välinge offers a range of profiles that<br />

complements different kinds of panel<br />

joints, with corner and mitre joints<br />

being the most commonly used in<br />

every furniture — whether it is basic<br />

kitchen cabinets or high-end design<br />

furniture. They also complement panels<br />

38 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2022</strong>