Dental Asia July/August 2022

For more than two decades, Dental Asia is the premium journal in linking dental innovators and manufacturers to its rightful audience. We devote ourselves in showcasing the latest dental technology and share evidence-based clinical philosophies to serve as an educational platform to dental professionals. Our combined portfolio of print and digital media also allows us to reach a wider market and secure our position as the leading dental media in the Asia Pacific region while facilitating global interactions among our readers.

For more than two decades, Dental Asia is the premium journal in linking dental innovators and manufacturers to its rightful audience. We devote ourselves in showcasing the latest dental technology and share evidence-based clinical philosophies to serve as an educational platform to dental professionals. Our combined portfolio of print and digital media also allows us to reach a wider market and secure our position as the leading dental media in the Asia Pacific region while facilitating global interactions among our readers.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BEHIND THE SCENES<br />

of bone exposed during CBCT<br />

radiation to perform an accurate and<br />

minimally invasive osteotomy (Fig. 1).<br />

Plan and design with Geomagic<br />

Freeform<br />

Next, Iraimudi virtually planned and<br />

designed customised subperiosteal<br />

implants for every step of the<br />

procedure using Oqton’s Geomagic<br />

Freeform software and a Touch haptic<br />

device.<br />

Fig. 2 Fig. 3<br />

He imported the converted STL file<br />

into Geomagic Freeform as an exact<br />

virtual replica of the patient’s jaw.<br />

He then used Geomagic Freeform<br />

and a Touch haptic device to design<br />

the implant framework for location,<br />

length, depth, and angle using the<br />

interocclusal distance to position the<br />

abutment length and angulation for<br />

the prosthetic replacement<br />

(Fig. 2).<br />

By superimposing the pre-operative<br />

impression over the mandibular<br />

STL file in Geomagic Freeform, he<br />

designed a custom implant and saved<br />

time by assessing the procedure<br />

50–60% faster, avoiding clinical<br />

obstacles, and eliminating multiple<br />

post-operative impressions and<br />

patient appointments.<br />

3D printing anatomical models and<br />

implants with plastic and metal AM<br />

Next, Iraimudi used the mandibular<br />

STL file to 3D print an anatomical<br />

model of the patient’s jaw and<br />

customised implants for the surgical<br />

procedure with a combination<br />

of plastic and metal additive<br />

manufacturing (AM) technologies<br />

(Fig. 3).<br />

He had the anatomical model of the<br />

patient’s jaw 3D printed on a plastic<br />

3D printer with fused deposition<br />

modelling (FDM) technology using<br />

PLA. He had the customised implants<br />

3D printed on a metal 3D printer<br />

using medical-grade titanium<br />

Fig. 4 Fig. 5<br />

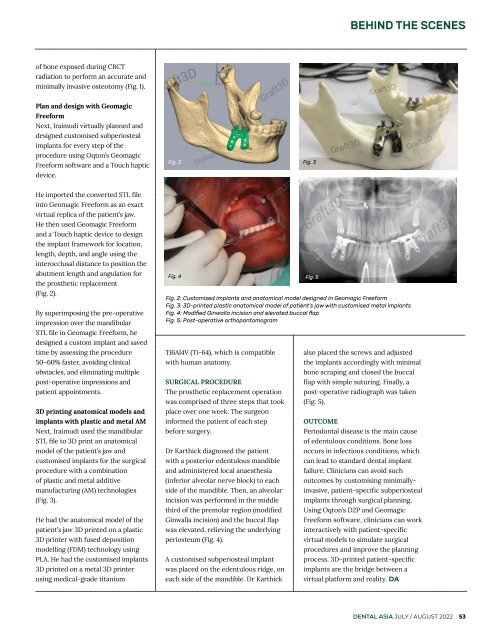

Fig. 2: Customised implants and anatomical model designed in Geomagic Freeform<br />

Fig. 3: 3D-printed plastic anatomical model of patient’s jaw with customised metal implants<br />

Fig. 4: Modified Ginwalla incision and elevated buccal flap<br />

Fig. 5: Post-operative orthopantomogram<br />

Ti6Al4V (Ti-64), which is compatible<br />

with human anatomy.<br />

SURGICAL PROCEDURE<br />

The prosthetic replacement operation<br />

was comprised of three steps that took<br />

place over one week. The surgeon<br />

informed the patient of each step<br />

before surgery.<br />

Dr Karthick diagnosed the patient<br />

with a posterior edentulous mandible<br />

and administered local anaesthesia<br />

(inferior alveolar nerve block) to each<br />

side of the mandible. Then, an alveolar<br />

incision was performed in the middle<br />

third of the premolar region (modified<br />

Ginwalla incision) and the buccal flap<br />

was elevated, relieving the underlying<br />

periosteum (Fig. 4).<br />

A customised subperiosteal implant<br />

was placed on the edentulous ridge, on<br />

each side of the mandible. Dr Karthick<br />

also placed the screws and adjusted<br />

the implants accordingly with minimal<br />

bone scraping and closed the buccal<br />

flap with simple suturing. Finally, a<br />

post-operative radiograph was taken<br />

(Fig. 5).<br />

OUTCOME<br />

Periodontal disease is the main cause<br />

of edentulous conditions. Bone loss<br />

occurs in infectious conditions, which<br />

can lead to standard dental implant<br />

failure. Clinicians can avoid such<br />

outcomes by customising minimallyinvasive,<br />

patient-specific subperiosteal<br />

implants through surgical planning.<br />

Using Oqton’s D2P and Geomagic<br />

Freeform software, clinicians can work<br />

interactively with patient-specific<br />

virtual models to simulate surgical<br />

procedures and improve the planning<br />

process. 3D-printed patient-specific<br />

implants are the bridge between a<br />

virtual platform and reality. DA<br />

DENTAL ASIA JULY / AUGUST <strong>2022</strong> 53