MARC Steam Turbines The Modular Steam Turbine Generation

MARC Steam Turbines The Modular Steam Turbine Generation

MARC Steam Turbines The Modular Steam Turbine Generation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>The</strong> turbo generator unit comprises the<br />

following modules:<br />

<strong>Steam</strong> turbine<br />

Gearbox/generator unit<br />

LP lubricating oil system<br />

HP control oil system<br />

Control cabinet<br />

<strong>The</strong> lubricating oil module, control oil<br />

module and the control cabinet can be<br />

individually arranged around the unit.<br />

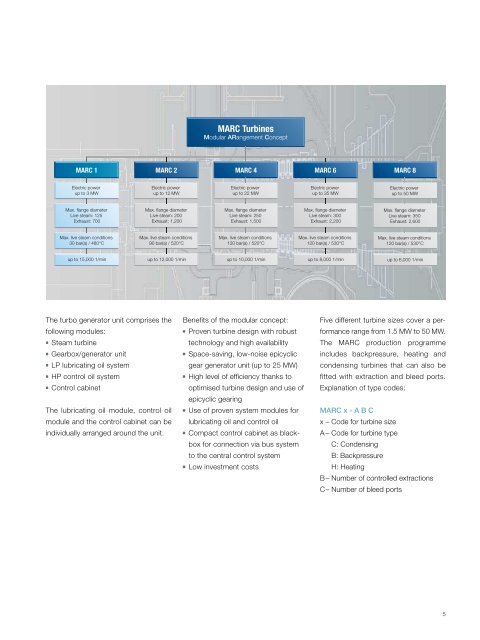

<strong>MARC</strong> <strong><strong>Turbine</strong>s</strong><br />

<strong>Modular</strong> ARangement Concept<br />

<strong>MARC</strong> 1 <strong>MARC</strong> 2<br />

<strong>MARC</strong> 4<br />

<strong>MARC</strong> 6<br />

<strong>MARC</strong> 8<br />

Electric power<br />

up to 3 MW<br />

Max. flange diameter<br />

Live steam: 125<br />

Exhaust: 700<br />

Max. live steam conditions<br />

30 bar(a) / 480°C<br />

up to 15,000 1/min<br />

Electric power<br />

up to 12 MW<br />

Max. flange diameter<br />

Live steam: 200<br />

Exhaust: 1,200<br />

Max. live steam conditions<br />

90 bar(a) / 520°C<br />

up to 12,000 1/min<br />

Electric power<br />

up to 22 MW<br />

Max. flange diameter<br />

Live steam: 250<br />

Exhaust: 1,500<br />

Max. live steam conditions<br />

120 bar(a) / 520°C<br />

up to 10,000 1/min<br />

Benefits of the modular concept:<br />

Proven turbine design with robust<br />

technology and high availability<br />

Space-saving, low-noise epicyclic<br />

gear generator unit (up to 25 MW)<br />

High level of efficiency thanks to<br />

optimised turbine design and use of<br />

epicyclic gearing<br />

Use of proven system modules for<br />

lubricating oil and control oil<br />

Compact control cabinet as blackbox<br />

for connection via bus system<br />

to the central control system<br />

Low investment costs<br />

Electric power<br />

up to 35 MW<br />

Max. flange diameter<br />

Live steam: 300<br />

Exhaust: 2,200<br />

Max. live steam conditions<br />

120 bar(a) / 530°C<br />

up to 8,000 1/min<br />

Electric power<br />

up to 50 MW<br />

Max. flange diameter<br />

Live steam: 350<br />

Exhaust: 2,600<br />

Max. live steam conditions<br />

120 bar(a) / 530°C<br />

up to 6,000 1/min<br />

Five different turbine sizes cover a performance<br />

range from 1.5 MW to 50 MW.<br />

<strong>The</strong> <strong>MARC</strong> production programme<br />

includes backpressure, heating and<br />

condensing turbines that can also be<br />

fitted with extraction and bleed ports.<br />

Explanation of type codes:<br />

<strong>MARC</strong> x - A B C<br />

x–Code for turbine size<br />

A– Code for turbine type<br />

C: Condensing<br />

B: Backpressure<br />

H: Heating<br />

B– Number of controlled extractions<br />

C– Number of bleed ports<br />

5