Ancorsteel® AMH - GKN

Ancorsteel® AMH - GKN

Ancorsteel® AMH - GKN

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

0810-AS<strong>AMH</strong>-D-1<br />

Iron Powders for Chemical Applications<br />

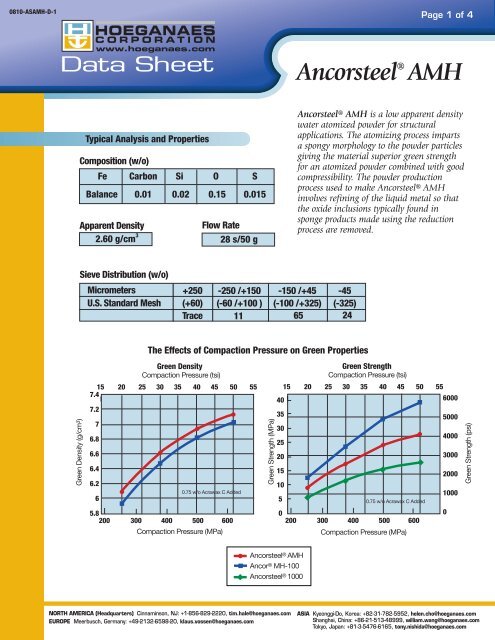

Green Density (g/cm 3)<br />

Typical Analysis and Properties<br />

Composition (w/o)<br />

Green Density<br />

Compaction Pressure (tsi)<br />

15<br />

7.4<br />

20 25 30 35 40 45 50 55<br />

7.2<br />

7<br />

6.8<br />

6.6<br />

6.4<br />

6.2<br />

6<br />

Fe Carbon Si O S<br />

Balance 0.01 0.02 0.15 0.015<br />

Apparent Density<br />

2.60 g/cm 3<br />

Sieve Distribution (w/o)<br />

Micrometers<br />

U.S. Standard Mesh<br />

Flow Rate<br />

0.75 w/o Acrawax C Added<br />

5.8<br />

200 300 400 500 600<br />

Compaction Pressure (MPa)<br />

28 s/50 g<br />

+250 -250 /+150 -150 /+45 -45<br />

(+60) (-60 /+100 ) (-100 /+325) (-325)<br />

Trace 11 65 24<br />

The Effects of Compaction Pressure on Green Properties<br />

NORTH AMERICA (Headquarters) Cinnaminson, NJ: +1-856-829-2220, tim.hale@hoeganaes.com<br />

EUROPE Meerbusch, Germany: +49-2132-6598-20, klaus.vossen@hoeganaes.com<br />

Green Strength (MPa)<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

Ancorsteel ® <strong>AMH</strong><br />

Ancor ® MH-100<br />

Ancorsteel ® 1000<br />

Page 1 of 4<br />

Ancorsteel ® <strong>AMH</strong><br />

<strong>Ancorsteel®</strong> <strong>AMH</strong> is a low apparent density<br />

water atomized powder for structural<br />

applications. The atomizing process imparts<br />

a spongy morphology to the powder particles<br />

giving the material superior green strength<br />

for an atomized powder combined with good<br />

compressibility. The powder production<br />

process used to make <strong>Ancorsteel®</strong> <strong>AMH</strong><br />

involves refining of the liquid metal so that<br />

the oxide inclusions typically found in<br />

sponge products made using the reduction<br />

process are removed.<br />

Green Strength<br />

Compaction Pressure (tsi)<br />

15 20 25 30 35 40 45 50 55<br />

0.75 w/o Acrawax C Added<br />

0<br />

200 300 400 500 600<br />

Compaction Pressure (MPa)<br />

6000<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

Green Strength (psi)<br />

ASIA Kyeonggi-Do, Korea: +82-31-782-5952, helen.cho@hoeganaes.com<br />

Shanghai, China: +86-21-513-48999, william.wang@hoeganaes.com<br />

Tokyo, Japan: +81-3-5476-6165, tony.nishida@hoeganaes.com<br />

0

0810-AS<strong>AMH</strong>-D-1<br />

Data Sheet<br />

Ancorsteel ® <strong>AMH</strong><br />

Comparison of Sintered Properties with Ancor ® MH-100<br />

Composition: Mixes contain 1.1 w/o graphite and 1 w/o zinc stearate<br />

Sintered in dissociated ammonia at 1120 ºC (2050 ºF) for 30 minutes<br />

Transverse Rupture Stength (MPa)<br />

Dimensional Change (% From Die Size)<br />

Apparent Hardness (HRB)<br />

850<br />

750<br />

650<br />

550<br />

NORTH AMERICA (Headquarters) Cinnaminson, NJ: +1-856-829-2220, tim.hale@hoeganaes.com<br />

EUROPE Meerbusch, Germany: +49-2132-6598-20, klaus.vossen@hoeganaes.com<br />

130<br />

120<br />

110<br />

100<br />

70<br />

60<br />

6.2 6.4 6.6 6.8 7.0 7.2<br />

Sintered Density (g/cm3) 450<br />

0.55<br />

0.50<br />

0.45<br />

0.40<br />

0.35<br />

0.30 6.2 6.4 6.6 6.8 7.0 7.2<br />

85<br />

80<br />

75<br />

70<br />

65<br />

60<br />

55<br />

50<br />

Sintered Density (g/cm 3)<br />

45 6.2 6.4 6.6 6.8 7.0 7.2<br />

Sintered Density (g/cm 3)<br />

90<br />

80<br />

Transverse Rupture Stength (psi10 3)<br />

Ancorsteel ® <strong>AMH</strong><br />

Ancor ® MH-100<br />

Pg 2 of 4<br />

ASIA Kyeonggi-Do, Korea: +82-31-782-5952, helen.cho@hoeganaes.com<br />

Shanghai, China: +86-21-513-48999, william.wang@hoeganaes.com<br />

Tokyo, Japan: +81-3-5476-6165, tony.nishida@hoeganaes.com

0810-AS<strong>AMH</strong>-D-1<br />

Data Sheet<br />

Ancorsteel ® <strong>AMH</strong><br />

Comparison of Sintered Properties with Ancor ® MH-100<br />

Composition: Mixes contain 1.1 w/o graphite, 2 w/o copper and 1 w/o zinc stearate<br />

Sintered in dissociated ammonia at 1120 ºC (2050 ºF) for 30 minutes<br />

Transverse Rupture Stength (MPa)<br />

Dimensional Change (% From Die Size)<br />

Apparent Hardness (HRB)<br />

1300<br />

1200<br />

1100<br />

1000<br />

900<br />

800<br />

700<br />

NORTH AMERICA (Headquarters) Cinnaminson, NJ: +1-856-829-2220, tim.hale@hoeganaes.com<br />

EUROPE Meerbusch, Germany: +49-2132-6598-20, klaus.vossen@hoeganaes.com<br />

200<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

6.2 6.4 6.6 6.8 7.0 7.2<br />

Sintered Density (g/cm3) 600<br />

0.55<br />

0.50<br />

0.45<br />

0.40<br />

0.35<br />

0.30<br />

0.25<br />

0.20<br />

6.2 6.4 6.6 6.8 7.0 7.2<br />

Sintered Density (g/cm 3)<br />

95<br />

90<br />

85<br />

80<br />

75<br />

70<br />

65<br />

60 6.2 6.4 6.6 6.8 7.0 7.2<br />

Sintered Density (g/cm 3)<br />

Transverse Rupture Stength (psi10 3)<br />

Ancorsteel ® <strong>AMH</strong><br />

Ancor ® MH-100<br />

Pg 3 of 4<br />

ASIA Kyeonggi-Do, Korea: +82-31-782-5952, helen.cho@hoeganaes.com<br />

Shanghai, China: +86-21-513-48999, william.wang@hoeganaes.com<br />

Tokyo, Japan: +81-3-5476-6165, tony.nishida@hoeganaes.com

0810-AS<strong>AMH</strong>-D-1<br />

Data Sheet<br />

Ancorsteel ® <strong>AMH</strong><br />

Typical Powder Morphology<br />

SEM Photomicrograph of <strong>Ancorsteel®</strong> <strong>AMH</strong> 800X<br />

SEM Photomicrograph of <strong>Ancorsteel®</strong> A1000 800X<br />

SEM Photomicrograph of Ancor MH-100 800X<br />

NORTH AMERICA (Headquarters) Cinnaminson, NJ: +1-856-829-2220, tim.hale@hoeganaes.com<br />

EUROPE Meerbusch, Germany: +49-2132-6598-20, klaus.vossen@hoeganaes.com<br />

Pg 4 of 4<br />

IMPORTANT NOTICE: The data shown are based on laboratory processing standard test specimens. Results may vary from those obtained in production processing.<br />

ASIA Kyeonggi-Do, Korea: +82-31-782-5952, helen.cho@hoeganaes.com<br />

Shanghai, China: +86-21-513-48999, william.wang@hoeganaes.com<br />

Tokyo, Japan: +81-3-5476-6165, tony.nishida@hoeganaes.com