You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

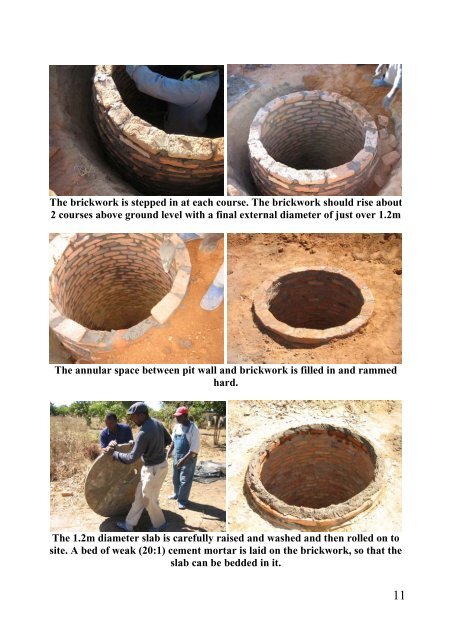

<strong>The</strong> brickwork is stepped in at each course. <strong>The</strong> brickwork should rise about<br />

2 courses above ground level with a final external diameter of just over 1.2m<br />

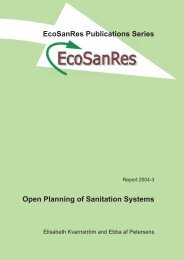

<strong>The</strong> annular space between pit wall and brickwork is filled in and rammed<br />

hard.<br />

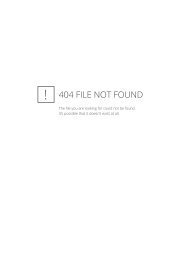

<strong>The</strong> 1.2m diameter slab is carefully raised and washed and then rolled on to<br />

site. A bed of weak (20:1) cement mortar is laid on the brickwork, so that the<br />

slab can be bedded in it.<br />

11

![Project Document [PDF: 2.31 MB] - EcoSanRes](https://img.yumpu.com/51279385/1/184x260/project-document-pdf-231-mb-ecosanres.jpg?quality=85)

![Latrines à compost [high-resolution colour PDF: 12.3MB] - EcoSanRes](https://img.yumpu.com/31726141/1/185x260/latrines-a-compost-high-resolution-colour-pdf-123mb-ecosanres.jpg?quality=85)