You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

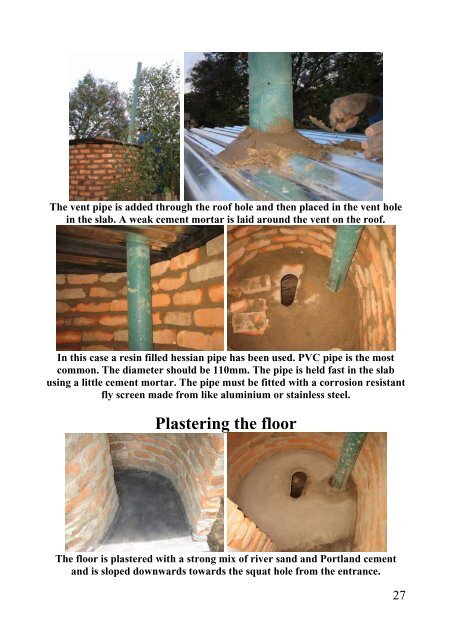

<strong>The</strong> vent pipe is added through the roof hole and then placed in the vent hole<br />

in the slab. A weak cement mortar is laid around the vent on the roof.<br />

In this case a resin filled hessian pipe has been used. PVC pipe is the most<br />

common. <strong>The</strong> diameter should be 110mm. <strong>The</strong> pipe is held fast in the slab<br />

using a little cement mortar. <strong>The</strong> pipe must be fitted with a corrosion resistant<br />

fly screen made from like aluminium or stainless steel.<br />

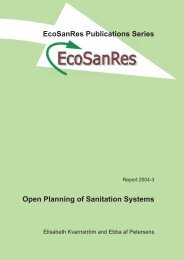

Plastering the floor<br />

<strong>The</strong> floor is plastered with a strong mix of river sand and Portland cement<br />

and is sloped downwards towards the squat hole from the entrance.<br />

27

![Project Document [PDF: 2.31 MB] - EcoSanRes](https://img.yumpu.com/51279385/1/184x260/project-document-pdf-231-mb-ecosanres.jpg?quality=85)

![Latrines à compost [high-resolution colour PDF: 12.3MB] - EcoSanRes](https://img.yumpu.com/31726141/1/185x260/latrines-a-compost-high-resolution-colour-pdf-123mb-ecosanres.jpg?quality=85)