COMPUTER PROGRAM USER'S MANUAL FOR ... - CAFE Foundation

COMPUTER PROGRAM USER'S MANUAL FOR ... - CAFE Foundation

COMPUTER PROGRAM USER'S MANUAL FOR ... - CAFE Foundation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

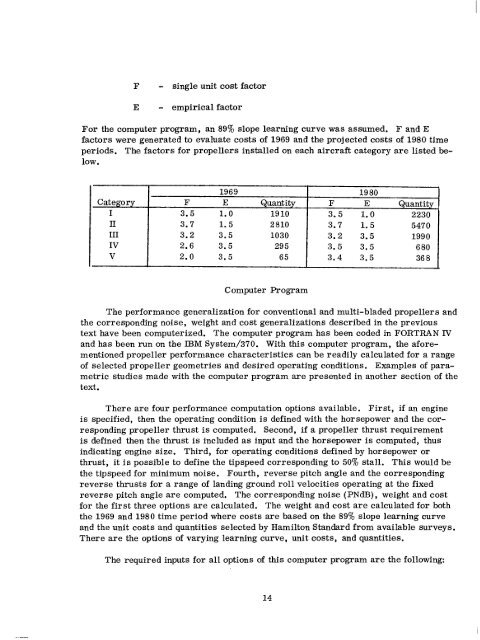

F - single unit cost factor<br />

E - empirical factor<br />

For the computer program, an 89% slope learning curve was assumed. F and E<br />

factors were generated to evaluate costs of 1969 and the projected costs of 1980 time<br />

periods. The factors for propellers installed on each aircraft category are listed be-<br />

low.<br />

196 9 19 80<br />

Category<br />

I<br />

F<br />

3.5<br />

E<br />

1.0<br />

Quantity<br />

19<br />

F<br />

10 3.5<br />

E Quantity<br />

1.0 2230<br />

I1<br />

3.7 1.5 2810 3.7 1.5 5470<br />

I11<br />

3.2 3.5 1030 3.2 3.5 1990<br />

IV<br />

2.6 3.5 29 5 3.5 3.5 6 80<br />

V<br />

2.0 3.5 3.4 65 3.5 36 8<br />

Computer Program<br />

The performance generalization for conventional and multi-bladed propellers and<br />

the corresponding noise, weight and cost generalizations described in the previous<br />

text have been computerized. The computer program has been coded in <strong>FOR</strong>TRAN Tv<br />

and has been run on the IBM System/370. With this computer program, the aforementioned<br />

propeller performance characteristics can be readily calculated for a range<br />

of selected propeller geometries and desired operating conditions. Examples of parametric<br />

studies made with the computer program are presented in another section of the<br />

text.<br />

There are four performance computation options available. First, if an engine<br />

is specified, then the operating condition is defined with the horsepower and the cor-<br />

responding propeller thrust is computed. Second, if a propeller thrust requirement<br />

is defined then the thrust is included as input and the horsepower is computed, thus<br />

indicating engine size. Third, for operating conditions defined by horsepower or<br />

thrust, it is possible to define the tipspeed corresponding to 50% stall. This would be<br />

the tipspeed for minimum noise. Fourth, reverse pitch angle and the corresponding<br />

reverse thrusts for a range of landing ground roll velocities operating at the fixed<br />

reverse pitch angle are computed. The corresponding noise (PNdB), weight and cost<br />

for the first three options are calculated. The weight and cost are calculated for both<br />

the 1969 and 1980 time period where costs are based on the 89% slope learning curve<br />

and the unit costs and quantities selected by Hamilton Standard from available surveys.<br />

There are the options of varying learning curve, unit costs, and quantities.<br />

The required inputs for all options of this computer program are the following:<br />

14