Jeweller - November 2023

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Left: Wedding band<br />

manufactured by Palloys.<br />

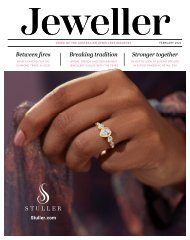

Casting and refining requires<br />

extreme heat.<br />

Bracken explains.<br />

“How we source and manufacture our products impacts our<br />

planet, and this program is our first major foray into jewellery<br />

circularity and evolving the jewellery industry towards a more<br />

sustainable and ethically responsible future.”<br />

The program was launched in partnership with Morris and<br />

Watson, a family-owned precious metal refiner and casting<br />

house operating for nearly 100 years.<br />

Head of sustainability, Kerrie Hockless, reported that the<br />

company recycled more than $200,000 of gold between April<br />

and July.<br />

“We know through research that for every one gram of pure<br />

gold we can push back into recycling engineered products<br />

saves around three tonnes of mining ore and 16 kilos of carbon<br />

emissions,” she told Ragtrader.<br />

Morris and Watson has previously described its precious<br />

metals recycling program as its ‘edge’ in the market, with finetuned<br />

refining designed with environmental impact in mind.<br />

For example, melted and burnt exhaust is evacuated through<br />

afterburners and state-of-the-art smoke and particulate<br />

scrubbing systems. The refinery also uses a custom-designed<br />

air extraction system with an automatic pH dosing system<br />

monitored and recorded daily.<br />

The company also has a comprehensive system of rainwater<br />

usage via roof catchment and tank storage used for melt<br />

machine cooling and recycling.<br />

Best is yet to come<br />

Perhaps the most pleasing factor in this matter is that<br />

Australia’s casting and refining specialists acknowledge that<br />

while the progress has been positive, much work remains to<br />

be done.<br />

Both Chemgold and Morris and Watson are members of the<br />

Responsible <strong>Jeweller</strong>y Council, and Sher said that provided a<br />

valuable framework to structure these initiatives.<br />

“Our membership is a testament to our unwavering<br />

commitment to upholding the highest standards of quality and<br />

ethical conduct. This membership ensures our strict adherence<br />

to the RJC's Code of Practices, encompassing business ethics,<br />

human rights, social impact, and environmental performance,”<br />

he explains.<br />

K E Y FIGURES<br />

Casting & Refining<br />

3200BC<br />

Earliest evidence of<br />

casting processes<br />

discover by<br />

anthropologists.<br />

$US46B<br />

Expected market<br />

value of 3D printing<br />

worldwide by 2026.<br />

$AU23B<br />

The contribution of<br />

Australia's gold industry<br />

to the economy in 2021.<br />

92.5%<br />

Of sterling silver which<br />

is pure silver.<br />

2020<br />

Entry level 3D printers<br />

dropped in price,<br />

leading to a surge of<br />

recreational users.<br />

“As a member of the RJC, we consistently uphold the highest<br />

standards in our industry. These initiatives are an integral<br />

component of our core values and set us apart as a responsible<br />

and sustainable leader in the precious metals and fine<br />

jewellery industry.”<br />

At BECKS, Ingham says that his company has some significant<br />

plans concerning environmental strategy to work towards in<br />

the immediate future.<br />

“We have begun an exciting journey to strategise our net zero<br />

pathway with our ultimate goal to become a carbon-neutral<br />

business before 2030,” he says.<br />

“As part of this major initiative, we are not only addressing our<br />

carbon emission within our direct operations but also across<br />

our entire value chain. By addressing Scope 3 emissions, we<br />

aim to minimise the environmental impact of our business<br />

activities, further contributing to a cleaner, healthier planet.”<br />

Casting and refining have a rich history, with historians<br />

suggesting that South American societies such as the Incas<br />

and Mayans used wax carving to create jewellery thousands<br />

of years ago.<br />

Farago says this attachment to tradition has proven to be<br />

a double-edged sword regarding an increasing desire for<br />

‘sustainable’ practices.<br />

The desire to stick with ‘tried and tested’ methods discourages<br />

companies from exploring newly developed and more<br />

environmentally friendly techniques.<br />

On the other hand, traditional methods tend to use less energy<br />

because they were designed when mass manufacturing was<br />

less advanced and energy-dependent.<br />

“<strong>Jeweller</strong>y is a very ‘old’ trade, and it can be difficult to find<br />

room for development,” he explains.<br />

“Casting practices have changed over time, and 3D printing has<br />

been introduced, but we are using many of the same processes<br />

invented 50 to 100 years ago. We are also manufacturing the<br />

same products we always have, so we just have to do it better."<br />

If the trend of ‘environmentally conscious’ consumers<br />

continues to increase, it’s important that your business can<br />

ease any concerns potential customers may have confidently.<br />

Fortunately, many of Australia’s precious metals suppliers are<br />

moving in the same direction.<br />

<strong>November</strong> <strong>2023</strong> | 43