European Database for Cartonboard and Carton Production 2023

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

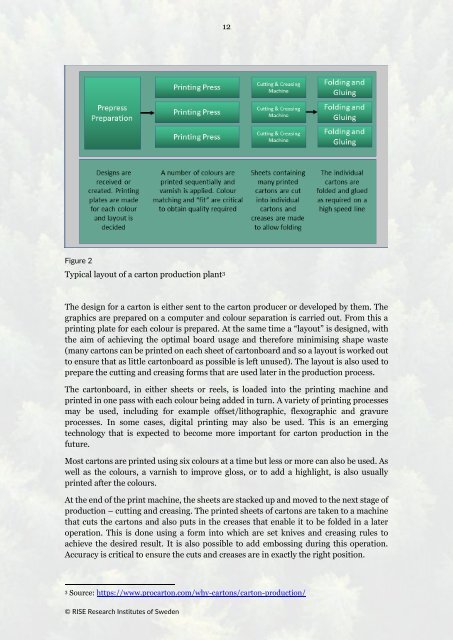

12<br />

Figure 2<br />

Typical layout of a carton production plant 3<br />

The design <strong>for</strong> a carton is either sent to the carton producer or developed by them. The<br />

graphics are prepared on a computer <strong>and</strong> colour separation is carried out. From this a<br />

printing plate <strong>for</strong> each colour is prepared. At the same time a “layout” is designed, with<br />

the aim of achieving the optimal board usage <strong>and</strong> there<strong>for</strong>e minimising shape waste<br />

(many cartons can be printed on each sheet of cartonboard <strong>and</strong> so a layout is worked out<br />

to ensure that as little cartonboard as possible is left unused). The layout is also used to<br />

prepare the cutting <strong>and</strong> creasing <strong>for</strong>ms that are used later in the production process.<br />

The cartonboard, in either sheets or reels, is loaded into the printing machine <strong>and</strong><br />

printed in one pass with each colour being added in turn. A variety of printing processes<br />

may be used, including <strong>for</strong> example offset/lithographic, flexographic <strong>and</strong> gravure<br />

processes. In some cases, digital printing may also be used. This is an emerging<br />

technology that is expected to become more important <strong>for</strong> carton production in the<br />

future.<br />

Most cartons are printed using six colours at a time but less or more can also be used. As<br />

well as the colours, a varnish to improve gloss, or to add a highlight, is also usually<br />

printed after the colours.<br />

At the end of the print machine, the sheets are stacked up <strong>and</strong> moved to the next stage of<br />

production – cutting <strong>and</strong> creasing. The printed sheets of cartons are taken to a machine<br />

that cuts the cartons <strong>and</strong> also puts in the creases that enable it to be folded in a later<br />

operation. This is done using a <strong>for</strong>m into which are set knives <strong>and</strong> creasing rules to<br />

achieve the desired result. It is also possible to add embossing during this operation.<br />

Accuracy is critical to ensure the cuts <strong>and</strong> creases are in exactly the right position.<br />

3 Source: https://www.procarton.com/why-cartons/carton-production/<br />

© RISE Research Institutes of Sweden