February 2024

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

How a history of innovation has helped develop the roof<br />

membrane of the future<br />

Specifiers and contractors want practical solutions for delivering resilient, sustainable<br />

buildings designed with the future in mind. Considering the need for future-proofed solutions,<br />

Iain Fairnington, Technical Director at A. Proctor Group, explains how the next generation of<br />

air permeable roof membranes is set to help.<br />

Pitched roof underlays are often described using the catch-all<br />

term ‘breather membranes’. The generic description doesn’t<br />

reflect the distinction between high-resistance (HR) and lowresistance<br />

(LR) membranes. And LR membranes themselves<br />

can be air tight or air permeable.<br />

indoor environment.<br />

Water resistance on the external side must not impact on the<br />

vapour permeability – or air and vapour permeability, if both<br />

are offered – from the internal side.<br />

Roofing membranes must meet a host of performance criteria,<br />

of which we’re going to focus on two: water resistance and<br />

vapour/air permeability.<br />

Ventilation in modern buildings, and especially dwellings, is<br />

often not well aligned with the energy efficiency performance<br />

Water resistance of membranes in a changing climate<br />

When a roofing system is installed, there is an inevitable<br />

period of time where the underlay will be in place without a<br />

roof covering to protect it. The underlay might therefore have<br />

to bear the brunt of any inclement weather. Good practice<br />

will dictate that this period should however be kept to a<br />

minimum and a temporary cover used if rain is expected.<br />

The NFRC’s Technical Bulletin TB06 describes how<br />

membranes should perform in terms of water resistance.<br />

It says an underlay with “a water hold out over 1m when<br />

tested to BS EN 20811 will be adequate.”<br />

As the frequency and intensity of extreme weather increases<br />

as a result of the changing climate, roof systems generally –<br />

and membranes as a specific part of those systems – need<br />

to be capable of withstanding more severe levels of rainfall.<br />

An underlay’s ability to perform with a 1m head of water is<br />

a minimum level of performance to look for during product<br />

selection.<br />

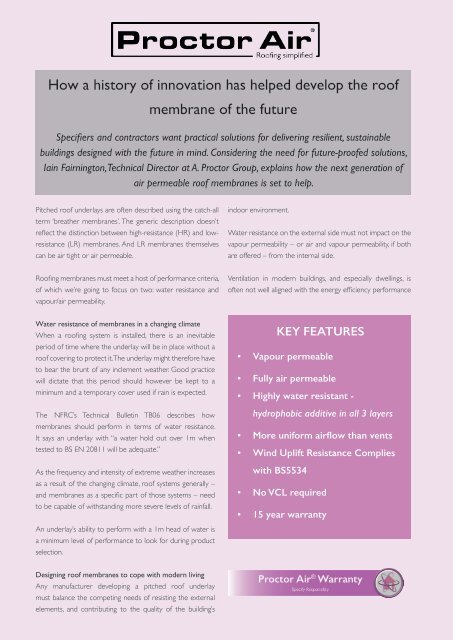

KEY FEATURES<br />

• Vapour permeable<br />

• Fully air permeable<br />

• Highly water resistant -<br />

hydrophobic additive in all 3 layers<br />

• More uniform airflow than vents<br />

• Wind Uplift Resistance Complies<br />

with BS5534<br />

• No VCL required<br />

• 15 year warranty<br />

Designing roof membranes to cope with modern living<br />

Any manufacturer developing a pitched roof underlay<br />

must balance the competing needs of resisting the external<br />

elements, and contributing to the quality of the building’s