VIDAR™ SUPREME Hot work tool steel - Uddeholm

VIDAR™ SUPREME Hot work tool steel - Uddeholm

VIDAR™ SUPREME Hot work tool steel - Uddeholm

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

T OOL STEEL FACTS<br />

VIDAR <strong>SUPREME</strong><br />

<strong>Hot</strong> <strong>work</strong> <strong>tool</strong> <strong>steel</strong><br />

Wherever <strong>tool</strong>s are made<br />

Wherever <strong>tool</strong>s are used

2<br />

VIDAR<br />

<strong>SUPREME</strong><br />

This information is based on our present state of knowledge and is<br />

intended to provide general notes on our products and their uses.<br />

It should not therefore be construed as a warranty of specific<br />

properties of the products described or a warranty for fitness for a<br />

particular purpose.

General<br />

VIDAR <strong>SUPREME</strong> is a chromium-molybdenumvanadium<br />

alloyed hot <strong>work</strong> <strong>tool</strong> <strong>steel</strong> which is<br />

characterized by:<br />

• High level of resistance to thermal shock and<br />

thermal fatigue<br />

• Good high-temperature strength<br />

• Excellent toughness and ductility in all<br />

directions<br />

• Uniform and high level of machinability<br />

• Excellent through-hardening properties<br />

• Good dimensional stability during hardening.<br />

Typical C Si Mn Cr Mo V<br />

analysis % 0,38 1,0 0,4 5,0 1,3 0,4<br />

Standard AISI H11, B H11, W.-Nr. 1.2343,<br />

specification<br />

Delivery<br />

AFNOR Z38 CDV 5,<br />

UNI X37 CrMoV 51 KU,<br />

UNE X37 CrMoV 5<br />

condition Soft annealed to approx.180 HB<br />

Colour code Orange/red<br />

IMPROVED TOOLING PERFORMANCE<br />

The name “<strong>SUPREME</strong>” implies that by special<br />

processing techniques and close process control,<br />

the <strong>steel</strong> attains high purity and a very fine structure.<br />

Further, VIDAR <strong>SUPREME</strong> shows significant<br />

improvements in isotropic properties compared to<br />

conventionally produced material of the X38 CrMo<br />

V 51 (W.-Nr. 1.2343) type.<br />

These improved isotropic properties are particularly<br />

valuable for <strong>tool</strong>ing subjected to high mechanical<br />

and thermal stresses, e.g. die casting dies and<br />

forging <strong>tool</strong>s. In practical terms, <strong>tool</strong>s may be used<br />

at somewhat higher <strong>work</strong>ing hardnesses (2 HRC)<br />

without loss of toughness. Since increased service<br />

hardness limits the formation of heat checking<br />

cracks, improved <strong>tool</strong> performance can be expected.<br />

Applications<br />

TOOLS FOR DIE CASTING<br />

Tin, lead,<br />

Aluminium-,<br />

Magnesium<br />

zinc alloys alloys<br />

Part HRC HRC<br />

Dies 46–50 42–48<br />

Fixed inserts, cores 48–52 46–50<br />

Sprue parts (ORVAR) (ORVAR)<br />

Nozzles (ORVAR) (ORVAR)<br />

Ejector pins (nitrided)<br />

Plunger, shot-sleeve<br />

(ORVAR) (ORVAR)<br />

(normally nitrided) (ORVAR) (ORVAR)<br />

Austenitizing 990°C 1000°C<br />

temperature (1814°F) (1832°F)<br />

TOOLS FOR HOT PRESSING<br />

VIDAR<br />

<strong>SUPREME</strong><br />

Material<br />

Aluminium,<br />

Austenitizing<br />

temperature (approx.) HRC<br />

magnesium 1000°C (1832°F) 44–52<br />

Copper alloys 1000°C (1832°F) 44–52<br />

Steel 1000°C (1832°F) 40–50<br />

OTHER APPLICATIONS<br />

Application<br />

Austenitizing<br />

temperature (approx.) HRC<br />

Severe cold 1000°C (1832°F)<br />

punching, Tempering: 52–54<br />

scarp shears 250°C (482°F)<br />

Shrink rings 1000°C (1832°F)<br />

(e.g. for cemented Tempering:<br />

carbide dies) 575–600°C<br />

(1067–1112°F)<br />

45–50<br />

Wear-resisting 1000°C (1832°F) Core<br />

parts Tempering: 50–52<br />

575°C (1067°F) Surface<br />

+ Nitriding ~1000 HV0,2<br />

3

4<br />

VIDAR<br />

<strong>SUPREME</strong><br />

Properties<br />

PHYSICAL DATA<br />

All specimens are taken from the centre of a 500 x<br />

110 mm (19,7" x 4,3") bar. Unless otherwise is indicated<br />

all specimens were hardened from 1000°C<br />

(1832°F), quenched in air and tempered 2 + 2h at<br />

610°C (1130°F). The hardness were 45 ±1 HRC.<br />

Temperature 20°C 400°C 600°C<br />

Density,<br />

(68°F) (750°F) (1010°F)<br />

kg/m3 7 800 7 700 7 600<br />

lbs/in3 Modulus of elasticity<br />

0,281 0,277 0,274<br />

MPa 210 000 180 000 140 000<br />

psi 30,5 x 106 26,1 x 106 20,3 x 106 Coefficient of<br />

thermal expansion<br />

per °C from 20°C – 12,6 x 10 –6 13,2 x 10 –6<br />

per °F from 68°F – 7,0 x 10 –6 7,3 x 10 –6<br />

Thermal<br />

conductivity<br />

W/m °C 25 29 30<br />

Btu in/(ft 2 h°F) 176 204 211<br />

MECHANICAL PROPERTIES<br />

Approximate tensile strength at room temperature.<br />

Hardness 44 HRC<br />

Tensile strength, Rm 1410 MPa 144 kp/mm2 Yield strength, Rp0,2 1170 MPa 119 kp/mm 2<br />

Elongation, A5 12%<br />

Reduction in area, Z 50%<br />

Approximate strength at elevated temperatures<br />

Longitudinal direction.<br />

psi Rm, Rp0.2<br />

1000x MPa<br />

290 2000<br />

261 1800<br />

232 1600<br />

203 1400<br />

174 1200<br />

145 1000<br />

116 800<br />

87 600<br />

58 400<br />

29 200<br />

0<br />

Rp0,2<br />

A5<br />

Rm<br />

A5,<br />

Z %<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

100 200 300 400 500 600 700 °C<br />

210 390 570 750 930 1110 1290 °F<br />

Testing temperature<br />

Z<br />

Effect of time at high temperatures on hardness<br />

Hardness, HRC<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

1 10 100 1000<br />

Time, h<br />

Effect of testing temperatures on impact energy<br />

Charpy V specimens, short transverse direction.<br />

ft. lbs Impact energy, J<br />

74<br />

59<br />

44<br />

30<br />

15<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

650°C (1202°F)<br />

500°C<br />

(932°F)<br />

550°C (1022°F)<br />

600°C<br />

(1112°F)<br />

45 HRC<br />

100 200 300 400 500 °C<br />

210 390 570 750 930 °F<br />

Testing temperature °C

Heat treatment<br />

SOFT ANNEALING<br />

Protect the <strong>steel</strong> and heat through to 850°C<br />

(1562°F). Then cool in furnace at 10°C (20°F) per<br />

hour to 650°C (1202°F), then freely in air.<br />

STRESS RELIEVING<br />

After rough machining the <strong>tool</strong> should be heated<br />

through to 650°C (1202°F), holding time 2 hours.<br />

Cool slowly to 500°C (932°F), then freely in air.<br />

HARDENING<br />

Preheating temperature: 600–850°C (1112–1562°F)<br />

(normally two preheating steps).<br />

Austenitizing temperature: 990–1010°C (1814–<br />

1850°F), normally 990–1000°C (1814–1832°F).<br />

Soaking time: 30–45 minutes. Soaking time = time<br />

at austenitizing temperature after the <strong>tool</strong> is fully<br />

heated through.<br />

Protect the <strong>tool</strong> against decarburization and oxidation<br />

during austenitizing.<br />

CCT graph<br />

Austenitizing temperature1000°C (1832°F). Holding time 30 minutes.<br />

°F °C<br />

2000 1100<br />

1800 1000<br />

900<br />

1600<br />

800<br />

1400<br />

700<br />

1200<br />

600<br />

1000<br />

500<br />

800<br />

400<br />

600 300<br />

M<br />

s<br />

400<br />

200<br />

200<br />

100<br />

M<br />

f<br />

Carbides<br />

Martensite<br />

Pearlite<br />

Bainite<br />

1 2 3 4 5 6 7 8<br />

Austenitizing temperature 1000°C (1832°F)<br />

Holding time 30 min.<br />

1 10 100 1000 1 000 10 10 000 100 100 000 Seconds<br />

1 10 100 1000 1 000 Minutes<br />

1 10 100 Hours<br />

Air cooling<br />

Air cooling of<br />

0,2 1,5 10 90 600 bars, of bars,Ø Ø mm mm<br />

0,0079 0,059 0,394 3,54 23,6 inchØ<br />

inch<br />

=<br />

VIDAR<br />

<strong>SUPREME</strong><br />

QUENCHING MEDIA<br />

• High speed gas/circulating atmosphere.<br />

• Vacuum (high speed gas with sufficient positive<br />

pressure).<br />

• Martempering bath (salt or fluidized bed) at<br />

500–550°C (932–1022°F).<br />

• Martempering bath (salt or fluidized bed) at<br />

180–220°C (356–428°F).<br />

• Warm oil.<br />

Note 1: Temper the <strong>tool</strong> as soon as its temperature<br />

reaches 50–70°C (122–158°F).<br />

Note 2: In order to obtain the optimum properties<br />

for the <strong>tool</strong>, the cooling rate should be fast, but not<br />

at a level that gives excessive distortion or cracks.<br />

A 915°C (1680°F)<br />

C3<br />

A 850°C (1562°F)<br />

C1<br />

Cooling Hardcurve<br />

ness T 800–500<br />

No. HV 10 (sec)<br />

1 715 2<br />

2 715 13<br />

3 695 125<br />

4 654 374<br />

5 642 623<br />

6 642 1248<br />

7 559 5200<br />

8 459 10400<br />

5

6<br />

VIDAR<br />

<strong>SUPREME</strong><br />

Hardness, grain size and retained austenite as a<br />

function of austenitizing temperature<br />

Grain size<br />

ASTM Hardness, HRC<br />

Retained austenite %<br />

10 60<br />

58<br />

Hardness<br />

8 56<br />

6<br />

54<br />

52<br />

50<br />

Grain size<br />

4<br />

48<br />

8<br />

2<br />

46<br />

44<br />

Retained austenite<br />

6<br />

4<br />

42<br />

2<br />

Tempering graph<br />

Air cooling of specimen 15 x 15 x 40 mm (0,6" x<br />

0,6" x 1,6")<br />

Hardness, HRC Retained austenite %<br />

58<br />

56<br />

54<br />

52<br />

50<br />

48<br />

46<br />

44<br />

42<br />

40<br />

38<br />

36<br />

34<br />

32<br />

30<br />

28<br />

26<br />

980 990 1000 1010 1020 °C<br />

1796 1814 1832 1850 1868 °F<br />

Austenitizing temperature<br />

TEMPERING<br />

Choose the tempering temperature according to<br />

the hardness required by reference to the tempering<br />

graph below. Temper twice with intermediate<br />

cooling to room temperature. Lowest tempering<br />

temperature 180°C (356°F). Holding time at temperature<br />

minimum 2 hours. To avoid brittleness do<br />

not temper in the range 425–550°C (797–1022°F).<br />

Austenitizing temperature<br />

1000°C (1832°F)<br />

Retained austenite<br />

100 200 300 400 500 600 700 800 °C<br />

212 392 572 752 932 1112 1292 1472 °F<br />

Tempering temperature (2 + 2h)<br />

8<br />

6<br />

4<br />

2<br />

0<br />

Approximate impact strength at different tempering<br />

temperatures.<br />

Charpy V specimens, short transverse direction.<br />

ft.lb.<br />

74<br />

59<br />

44<br />

30<br />

15<br />

Impact strength<br />

- KV Joule<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

100 200 300 400 500 600 °C<br />

200 400 600 800 1000 1200 °F<br />

Tempering temperature (2h + 2h)<br />

Tempering within the range 425–550°C (797–<br />

1022°F) is normally not recommended due to<br />

impaired toughness.<br />

DIMENSIONAL CHANGES DURING<br />

HARDENING AND TEMPERING<br />

During hardening and tempering the die is exposed<br />

to thermal as well as transformation<br />

stresses. This will inevitably result in dimensional<br />

changes and in the <strong>work</strong> case distortion. It is therefore<br />

recommended to always leave a machining<br />

allowance after machining before the die is hardened<br />

and tempered. Normally the size in the largest<br />

direction will shrink and the size in the smallest<br />

direction might increase but this is also a matter of<br />

the die size, the die design as well as the cooling<br />

rate after hardening.<br />

For VIDAR <strong>SUPREME</strong> it is recommended to leave<br />

a machining allowance of 0,2 per cent of the dimension<br />

in length, width and thickness.<br />

NITRIDING AND NITROCARBURIZING<br />

Nitriding and nitrocarburizing result in a hard surface<br />

layer which is very resistant to wear and erosion.<br />

The nitrided layer is, however, brittle and my<br />

crack or spall when exposed to mechanical or thermal<br />

shock, the risk increasing with layer thickness.<br />

Before nitriding, the <strong>tool</strong> should be hardened<br />

and tempered at a temperature at least 50°C<br />

(120°F) above the nitriding temperature.<br />

Nitriding in ammonia gas at 510°C (950°F) or<br />

plasma nitriding in a 75% hydrogen/25% nitrogen<br />

at 480°C (896°F) both result in a surface hardness<br />

of 1100 HV0,2. In general, plasma nitriding is the<br />

preferred method because of better control over<br />

nitrogen potential; in particular, formation of the<br />

so-called “white layer”, which is not recommended<br />

of hot-<strong>work</strong> service, can readily be avoided. However,<br />

careful gas nitriding can give perfectly acceptable<br />

results.

VIDAR <strong>SUPREME</strong> can also be nitrocarburized in<br />

either gas or salt bath. The surface hardness after<br />

nitrocarburizing is 900–1000 HV0,2.<br />

DEPTH OF NITRIDING<br />

Depth<br />

Process Time mm inch<br />

Gas nitriding 10 h 0,12 0,0047<br />

at 510°C (950°F) 30 h 0,20 0,0079<br />

Plasma nitriding 10 h 0,14 0,0055<br />

at 480°C (895°F)<br />

Nitrocarburizing<br />

– in gas at<br />

30 h 0,19 0,0075<br />

580°C (1075°F)<br />

– in salt bath at<br />

2,5 h 0,12 0,0047<br />

580°C (1075°F) 1 h 0,07 0,0028<br />

* Depth of case = distance from surface where hardness<br />

is 50 HV 0,2 over base hardness.<br />

Nitriding to case depths >0,3 mm (0,012") is not<br />

recommended for hot-<strong>work</strong> applications. VIDAR<br />

<strong>SUPREME</strong> can also be nitrided in the soft annealed<br />

condition. The hardness and depth of case<br />

will, however, be reduced somewhat in this case.<br />

Cutting data<br />

recommendations<br />

The cutting data below are to be considered as<br />

guiding values which must be adapted to existing<br />

local condition.<br />

DRILLING<br />

High speed <strong>steel</strong> twist drill<br />

Drill diameter Cutting Feed (f)<br />

speed (vc)<br />

mm inch m/min f.p.m. mm/r i.p.r.<br />

– 5 –3/16 17* 56* 0,08–0,20 0,003–0,008<br />

5–10 3/16–3/8 17* 56* 0,20–0,30 0,008–0,012<br />

10–15 3/8–5/8 17* 56* 0,30–0,35 0,012–0,014<br />

15–20 5/8–3/4 17* 56* 0,35–0,40 0,014–0,016<br />

1) For coated HSS drill vc ~24 m/min. (80 f.p.m.).<br />

Carbide drill<br />

Cutting data Indexable<br />

Type of drill<br />

Solid Brazed<br />

parameters insert carbide carbide1) Cutting<br />

speed (vc)<br />

m/min 180–220 80 60<br />

f.p.m.<br />

Feed (f)<br />

600–735 265 200<br />

mm/r 0,03–0,102) 0,10–0,252) 0,15–0,252) i.p.r. 0,001–0,0042) 0,004–0,012) 0,006–0,012) 1) Drill with internal cooling channels and brazed carbide<br />

tip.<br />

2) Depending on drill diameter.<br />

TURNING<br />

VIDAR<br />

<strong>SUPREME</strong><br />

Turning with Turning<br />

carbide with high<br />

Cutting data speed <strong>steel</strong><br />

parameters Rough turning Fine turning Fine turning<br />

Cutting<br />

speed (vc)<br />

m/min 150–200 200–250 30<br />

f.p.m.<br />

Feed (f)<br />

500–665 665–835 100<br />

mm/r 0,3–0,6 –0,3 –0,3<br />

i.p.r.<br />

Depth<br />

0,01–0,024 –0,01 –0,01<br />

of cut (ap)<br />

mm 2–6 –2 –2<br />

inch<br />

Carbide<br />

designation<br />

0,08–0,24 –0,08 –0,08<br />

ISO P20–P30 P10 –<br />

Coated carbide Coated carbide<br />

or cermet<br />

MILLING<br />

Face- and square shoulder milling<br />

Milling with Milling<br />

carbide with high<br />

Cutting data speed <strong>steel</strong><br />

parameters<br />

Cutting<br />

Rough milling Fine milling Fine milling<br />

speed (vc)<br />

m/min 160–210 210–280 35<br />

f.p.m. 535–700 700–930 115<br />

Feed (fz)<br />

mm/tooth 0,2–0,4 0,1–0,2 0,1<br />

inch/tooth<br />

Depth<br />

0,008–0,016 0,004–0,008 0,004<br />

of cut (ap)<br />

mm 2–5 –2 –2<br />

inch<br />

Carbide<br />

designation<br />

0,08–0,20 –0,08 –0,08<br />

ISO P20–P40 P10–P20 —<br />

Coated Coated<br />

carbide carbide or<br />

cermet<br />

End milling<br />

Cutting data Solid<br />

Type of milling<br />

Carbide<br />

indexable High<br />

parameters<br />

Cutting<br />

carbide insert speed <strong>steel</strong><br />

speed (vc)<br />

m/min 70 130–180 351) f.p.m. 235 435–600 1151) Type of milling<br />

Feed (fz)<br />

mm/tooth 0,03–0,20 2) 0,08–0,20 2) 0,05–0,35 2)<br />

inch/tooth 0,001–0,008 2) 0,003–0,008 2) 0,002–0,014 2)<br />

Carbide<br />

designation<br />

ISO K10, P40 P20–P30 –<br />

1) For coated HSS end mill vc ~45 m/min. (150 f.p.m.).<br />

2) Depending on radial depth of cut and cutter diameter.<br />

7

8<br />

VIDAR<br />

<strong>SUPREME</strong><br />

GRINDING<br />

A general grinding wheel recommendation is<br />

given below. More information can be found in the<br />

<strong>Uddeholm</strong> publication “Grinding of Tool Steel”.<br />

Wheel recommendation<br />

Soft annealed Hardened<br />

Type of grinding<br />

Face grinding<br />

condition condition<br />

straight wheel<br />

Face grinding<br />

A 46 HV A 46 GV<br />

segments A 24 GV A 36 GV<br />

Cylindrical grinding A 46 LV A 60 JV<br />

Internal grinding A 46 JV A 60 IV<br />

Profile grinding A 100 LV A 120 JV<br />

Electrical-discharge<br />

machining<br />

If spark-erosion is performed in the hardened and<br />

tempered condition, the white re-cast layer should<br />

be removed mechanically e.g. by grinding or stoning.<br />

The <strong>tool</strong> should then be given an additional<br />

temper at approx. 25°C (50°F) below the previous<br />

tempering temperature.<br />

Welding<br />

Welding of <strong>tool</strong> <strong>steel</strong> can be performed with good<br />

results if proper precautions are taken regarding<br />

elevated temperature, joint preparation, choice of<br />

consumables and welding procedure.<br />

Welding method TIG MMA<br />

Working 325–375°C 325–375°C<br />

temperature (620–710°F)<br />

QRO 90<br />

(620–710°F)<br />

Filler metals<br />

Hardness<br />

TIG-WELD QRO 90 WELD<br />

after welding 50–55 HRC 50–55 HRC<br />

Heat treatment after welding<br />

Hardened Temper at 25°C (50°F) below the<br />

condition original tempering temperature.<br />

Soft annealed Soft-anneal the material at 850°C<br />

condition (1560°F) in protected atmosphere.<br />

Then cool in the furnace at 10°C<br />

(20°F) per hour to 650°C (1200°F)<br />

then freely in air.<br />

More detailed information can be found in the<br />

<strong>Uddeholm</strong> brochure “Welding of <strong>tool</strong> <strong>steel</strong>”.<br />

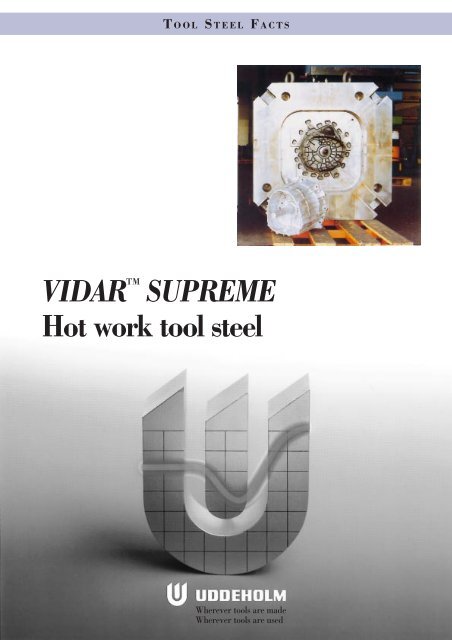

A die casting die in VIDAR <strong>SUPREME</strong>.

Hard-chromium<br />

plating<br />

After plating, parts should be tempered at 180°C<br />

(360°F) for 4 hours to avoid the risk of hydrogen<br />

embrittlement.<br />

Photo-etching<br />

VIDAR <strong>SUPREME</strong> is particularly suitable for<br />

texturing by the photo-etching method. Its high<br />

level of homogeneity and low sulphur content<br />

ensures accurate and consistent pattern reproduction.<br />

Polishing<br />

VIDAR <strong>SUPREME</strong> exhibits good polishability in<br />

the hardened and tempered condition. Polishing<br />

after grinding can be effected using aluminium<br />

oxide or diamond paste.<br />

Typical procedure:<br />

1. Rough grinding to 180–320 grain size using a<br />

wheel or stone.<br />

2. Fine grinding with abrasive paper or powder<br />

down to 400–800 grain size.<br />

3. Polish with diamond paste grade 15 (15μm grain<br />

size) using a polishing <strong>tool</strong> of soft wood or fibre.<br />

4. Polish with diamond paste 3 (3μm grain size)<br />

using a polishing <strong>tool</strong> of soft wood or fibre.<br />

5. When demands on surface finish are high,<br />

grade 1 (1μm grain size) diamond paste can be<br />

used for final polishing with a fibre polishing<br />

pad.<br />

Further information<br />

Please contact your local <strong>Uddeholm</strong> office for further<br />

information on the selection, heat treatment,<br />

application and availability of <strong>Uddeholm</strong> <strong>tool</strong> <strong>steel</strong>s.<br />

VIDAR<br />

<strong>SUPREME</strong><br />

9

UDDEHOLM EUROPE<br />

AUSTRIA<br />

EASTERN EUROPE<br />

Bulgaria, Jugoslavia, Roumania.<br />

SSB SWEDSTEEL BAIER<br />

Ges. m.b.H. & Co KG<br />

Herzog-Ernst-Gasse 24<br />

A-8600 Bruck/Mur<br />

Austria<br />

Telephone: +43 3862 568 03<br />

Telefax: +43 3862 569 81<br />

BELGIUM<br />

UDDEHOLM N.V.<br />

Waterstraat 4<br />

B-9160 Lokeren<br />

Telephone: +32 9 349 11 00<br />

Telefax: +32 9 349 11 1<br />

ESTONIA<br />

UDDEHOLM TOOLING<br />

Silikatsiidi 7<br />

EE-0012 Tallinn<br />

Telephone: +372 655 90 83, 90 84<br />

Telefax: +372 655 90 85<br />

FRANCE<br />

UDDEHOLM S.A.<br />

12 Rue Mercier, Z.I. de Mitry-Compans<br />

F-77297 Mitry Mory Cedex<br />

Telephone: +33 1 609 380 06<br />

Telefax: +33 1 609 380 03<br />

Branch office<br />

UDDEHOLM S.A.<br />

31 Rue Francine-Fromont Z.A. Est<br />

F-69120 Vaulx en Velin<br />

Telephone: +33 478 80 88 88<br />

Telefax: +33 472 04 68 28<br />

UDDEHOLM S.A.<br />

77bis, rue de Vesoul<br />

La Nef aux Métiers<br />

F-25000 Besançon<br />

Telephone: +33 381 53 12 19<br />

Telefax: +33 381 53 13 20<br />

GERMANY<br />

Head office<br />

UDDEHOLM GmbH<br />

Hansaallee 321, D-40549 Düsseldorf<br />

Telephone: +49 211 535 10<br />

Telefax: +49 211 535 12 80<br />

Branch offices<br />

UDDEHOLM GmbH<br />

Falkenstraße 21, D-65812 Bad Soden/TS.<br />

Telephone: +49 6196 659 60<br />

Telefax: +49 6196 659 625<br />

UDDEHOLM GmbH<br />

Robert Bosch Straße 8<br />

D-73760 Ostfildern Nellingen<br />

Telephone: +49 711 34 83 60<br />

Telefax: +49 711 348 36 25<br />

RAVENÉ POSSEHL-STAHL AG<br />

Industriestraße 32-37, D-12099 Berlin 42<br />

Telephone: +49 30 700 40<br />

Telefax: +49 30 700 43 04<br />

GREECE<br />

UDDEHOLM STEEL TRADING COMPANY<br />

20, Athinon Street, G-Piraeus 18540<br />

Telephone: +30 1 417 21 09/412 98 20<br />

Telefax: +30 1 417 27 67<br />

SKLERO S.A.<br />

Steel Trading Comp. and Hardening Shop<br />

Frixou 11/Nikif. Ouranou<br />

G-54627 Thessaloniki<br />

Telephone: +30 31 51 46 77<br />

Telefax +30 31 54 12 50<br />

GREAT BRITAIN, IRELAND<br />

UDDEHOLM LIMITED<br />

European Business Park<br />

Oldbury<br />

Warley<br />

West Midlands B69 2BF<br />

Telephone: +44 121 552 55 11<br />

Telefax: +44 121 544 29 11<br />

London +44 71 222 14 93<br />

Dublin +353 1 45 14 01<br />

HUNGARY<br />

UDDEHOLM TOOLING/BOK<br />

Ceglédi út 19.<br />

H-1107 Budapest<br />

Telephone/Telefax: +36 1 261 60 35<br />

ITALY<br />

UDDEHOLM S.p.A.<br />

Via Palizzi, 90<br />

I-20157 Milano<br />

Telephone: +39 2 35 79 41<br />

Telefax: +39 2 390 024 82<br />

LATVIA<br />

UDDEHOLM TOOLING AB<br />

Hospitalu iela 18, Riga<br />

LV-1013 Latvia<br />

Telephone: +371 7 31 32 35, 31 31 99<br />

Telefax: +371 7 33 95 61<br />

LITHUANIA<br />

JETIS UAB<br />

Laisvés al. 30A–402<br />

LT-3000 Kaunas<br />

Lithuania – Leituva<br />

Telephone:/Telefax: +370 72 213 56<br />

THE NETHERLANDS<br />

UDDEHOLM B.V.<br />

Isolatorweg 30<br />

NL-1014 AS Amsterdam<br />

Telephone: +31 20 581 71 11<br />

Telefax: +31 20 684 86 13<br />

POLAND<br />

UDDEHOLM TRADING AB<br />

Biuro Branzowe w Warszawie<br />

ul. Lektykarska 25 m. 18 A<br />

PL-01-687 Warzsawa<br />

Telephone: +48 22 33 17 21<br />

Telefax: +48 22 33 28 97<br />

PORTUGAL<br />

F RAMADA Aços e Industrias S.A.<br />

P.O. Box 10<br />

P-3881 Ovar Codex<br />

Telephone: +351 56 58 61 11<br />

Telefax: +351 56 58 60 24<br />

SPAIN<br />

UDDEHOLM S.A.<br />

Guifré 690-692<br />

E-08918 Badalona, Barcelona<br />

Telephone: +34 3 460 10 45<br />

Telefax: +34 3 460 00 55<br />

Branch office<br />

UDDEHOLM S.A.<br />

Barrio San Martin de Arteaga, 132<br />

Pol.Ind. Torrelarragoiti<br />

E-48016 Zamudio<br />

(Bizkaia)<br />

Telephone: +34 4 452 13 03<br />

Telefax: +34 4 452 13 58<br />

SWITZERLAND<br />

HERTSCH & CIE AG<br />

General Wille Strasse 19<br />

CH-8027 Zürich<br />

Telephone: +41 1 208 16 66<br />

Telefax: +41 1 201 46 15<br />

HANS KOHLER AG<br />

Claridenstrasse 20<br />

CH-8002 Zürich<br />

Telephone: +41 1 207 11 11<br />

Telefax: +41 1 20122 22<br />

UDDEHOLM<br />

NORDIC<br />

SWEDEN<br />

Head office<br />

UDDEHOLM TOOLING<br />

SVENSKA AB<br />

Aminogatan 25, S-431 53 Mölndal<br />

Telephone: +46 31 67 98 50<br />

Telefax: +46 31 27 02 94<br />

UDDEHOLM TOOLING<br />

SVENSKA AB<br />

Box 45<br />

S-334 21 Anderstorp<br />

Telephone: +46 371 160 15, 182 15<br />

Telefax: +46 371 154 10<br />

UDDEHOLM TOOLING<br />

SVENSKA AB<br />

Box 148<br />

S-631 03 Eskilstuna<br />

Telephone: +46 16 15 79 00<br />

Telefax: +46 16 51 55 05<br />

UDDEHOLM TOOLING<br />

SVENSKA AB<br />

Aminogatan 25<br />

S-431 53 Mölndal<br />

Telephone: +46 31 67 98 70<br />

Telefax: +46 31 27 49 03<br />

UDDEHOLM TOOLING<br />

SVENSKA AB<br />

Låsbomsgatan<br />

S-582 70 Linköping<br />

Telephone: +46 13 15 19 90<br />

Telefax: +46 13 15 27 03<br />

UDDEHOLM TOOLING<br />

SVENSKA AB<br />

Bronsyxegatan 9B<br />

S-213 75 Malmö<br />

Telephone: +46 40 22 32 05<br />

Telefax: +46 40 22 17 09<br />

UDDEHOLM TOOLING<br />

SVENSKA AB<br />

(Stockholm)<br />

Box 148<br />

S-631 03 Eskilstuna<br />

Telephone: +46 8 98 02 44<br />

Telefax: +46 8 98 02 62<br />

UDDEHOLM TOOLING<br />

SVENSKA AB<br />

Verkstadsgatan 18<br />

S-352 46 Växjö<br />

Telephone: +46 470 457 90<br />

Telefax: +46 470 274 32<br />

DENMARK<br />

UDDEHOLM A/S<br />

Kokmose 8<br />

Bramdrupdam<br />

DK-6000 Kolding<br />

Telephone: +45 75 51 70 66<br />

Telefax: +45 75 51 70 44<br />

FINLAND<br />

OY UDDEHOLM AB<br />

P.B. 8, SF-00371 Helsingfors 37<br />

Telephone: +358 9 55 31 66<br />

Telefax: +358 9 565 23 83<br />

NORWAY<br />

UDDEHOLM A/S<br />

Jernkroken 18<br />

Postboks 85<br />

Kalbakken, N-Oslo 9<br />

Telephone: +47 22 25 65 10<br />

Telefax: +47 22 25 99 11<br />

UDDEHOLM<br />

NORTH AMERICA<br />

USA<br />

Head office<br />

UDDEHOLM<br />

4902 Tollview Drive<br />

Rolling Meadows IL 60008<br />

Telephone: +1 847 577 22 20<br />

Telefax: +1 847 577 80 28<br />

UDDEHOLM<br />

548 Clayton Ct.,<br />

Wood Dale IL 60191<br />

Telephone: +1 630 350 10 00<br />

Telefax: +1 630 350 08 80<br />

UDDEHOLM<br />

9331 Santa Fe Springs Road<br />

Santa Fe Springs, CA 90670<br />

Telephone: +1 310 946 65 03<br />

Telefax: +1 310 946 42 74<br />

UDDEHOLM<br />

7900 Hub Parkway<br />

Cleveland OH 44125<br />

Telephone: +1 216 524 87 70<br />

Telefax: +1 216 642 10 42<br />

CANADA<br />

UDDEHOLM LIMITED<br />

6659 Ordan Drive<br />

Mississauga, Ont. L5T 1K6<br />

Telephone: +1 905 670 83 33<br />

Telefax: +1 905 795 82 49<br />

MEXICO<br />

UDDEHOLM<br />

Calle Ocho no 2, Letra "C"<br />

Fracc. Industrial Alce Blanco<br />

53370 Naucalpan de Juarez<br />

Estado de Mexico<br />

Telephone: +52 5-576-5422<br />

Telefax: +52 5-576-2139<br />

UDDEHOLM<br />

Lerdo de Tejada No.542<br />

Colonia Las Villas<br />

66420 San Nicolas de Los Garza, N.L.<br />

Telephone: +52 8-352-5239<br />

Telefax: +52 8-352-5356<br />

Wherever <strong>tool</strong>s are made<br />

Wherever <strong>tool</strong>s are used<br />

ASSAB<br />

ASSAB INTERNATIONAL<br />

Head office<br />

Gustavslundsvägen 151 G<br />

Hus 10, Alvik<br />

Box 413<br />

S-101 28 Stockholm, Sverige<br />

Telephone: +46 8 704 66 70<br />

Telefax: +46 8 25 02 37<br />

Subsidiaries/Branch offices<br />

Argentina, Iran<br />

ASSAB PACIFIC<br />

Head office<br />

ASSAB Pacific Pte. Ltd<br />

171, Chin Swee Road<br />

No. 07-02, San Centre<br />

Singapore 0316<br />

Telephone: +65 534 56 00<br />

Telefax: +65 534 06 55<br />

Subsidiaries<br />

CHINA<br />

ASSAB Tooling (Beijing)Ltd.<br />

Plant 703, No. 3 Yongchang Beilu<br />

BDA., 100076 Beijing, China<br />

Telephone: +86 (0)10 6788 00 21<br />

Telefax: +86 (0)10 6788 00 19<br />

JAPAN<br />

UDDEHOLM KK<br />

Skf Bldg. 7 F<br />

1-9-1, Shiba Daimon<br />

Minato-Ku, Tokyo 105<br />

Telephone: +81 3 547 346 41<br />

Telefax: +81 3 547 376 90<br />

HONG KONG<br />

ASSAB Steels (H.K.) Ltd<br />

Room 1701–1708<br />

Grand Central Plaza, Tower 2<br />

138 Shatin Rural Committee Road<br />

Shatin, N.T. – Hong Kong<br />

Telephone: +852 2487 19 91<br />

Telefax: +852 2489 09 38<br />

KOREA<br />

ASSAB Steels (Korea) Co Ltd<br />

C.P.O. Box 5196<br />

Seoul<br />

Telephone: +82 2 694 38 73<br />

Telefax: +82 2 694 38 75<br />

MALAYSIA<br />

ASSAB Steels (Malaysia) Sdn Bhd<br />

Lot 19, Jalan Perusahaan Dua<br />

Batu Caves Industrial Estate<br />

68100 Batu Caves, Selangor<br />

Telephone: +60 3 689 00 22<br />

Telefax: +60 3 689 00 55<br />

SINGAPORE<br />

ASSAB Steels Singapore (Pte) Ltd<br />

21 Joo Koon Road<br />

Singapore 628979<br />

Telephone: +65 862 22 00<br />

Telefax: +65 862 01 62<br />

TAIWAN<br />

ASSAB Steels (Taiwan) Ltd<br />

(No 112 Wu-Ku Ind. Zone<br />

Wu-kong 1st Road)<br />

P O Box 17-93, Hsin Chuang<br />

Taipei Hsien<br />

Taiwan R O C<br />

Telephone: +886 2 299 28 48<br />

Telefax: +886 2 299 01 47<br />

THAILAND<br />

ASSAB Steels (Thailand) Co Ltd<br />

9/8 Soi Sirichai Apartment<br />

Taeparak Road, K.M. 12<br />

Bangplee<br />

Samutprakarn 10540<br />

Telephone: +66 2 385 59 37<br />

Telefax: +66 2 385 59 43<br />

ASSAB AUSTRALIA<br />

Head office<br />

ASSAB Steels Pty. Ltd.<br />

2 A Cambridge Street<br />

Box Hill, Vic 3128<br />

Melbourne<br />

Telephone: +61 3 899 16 66<br />

Telefax: +61 3 899 06 05<br />

Subsidiaries/Branch offices<br />

Sydney, Adelaide, Newcastle<br />

Perth, Brisbane, Launceston<br />

3.98<br />

Edition: 3<br />

KLARTEXT U980315 03.98 1000 / Nermans 8030229