Alco Controls

Alco Controls

Alco Controls

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Network Communication and System Management<br />

A2.5.1/1003/E<br />

The <strong>Alco</strong> EC Series of drivers and controllers utilise<br />

the very latest in communication technology which<br />

is setting new standards in the refrigeration industry.<br />

Energy saving algorithms are incorporated into many<br />

of the controllers including: Adaptive superheat<br />

and thermostat modulation, defrost on demand &<br />

suction and discharge setpoint shift.<br />

All EC2 or EC3 controllers are available in two<br />

communication protocols TCP/IP Ethernet and<br />

LON.<br />

TCP/IP Ethernet:<br />

The controllers are Ethernet based enabling them<br />

to be connected directly to any computer via the<br />

Ethernet port (RJ45 connector). The controllers act as<br />

web server enabling the engineer to pick-up standard<br />

configuration pages directly from the controllers<br />

without the need of any additional hardware or<br />

software. Each controller can be connected to the PC<br />

using a crossover cable however, the most convenient<br />

way to connect a controller to the PC is to use a router<br />

that will automatically assign a TCP/IP address. Either<br />

way, the engineer can access the monitoring and<br />

parameter configuration pages by entering the TCP/<br />

IP number into the address line of an Internet browser<br />

such as Mozilla or Microsoft Internet Explorer. User<br />

name and password protection is provided to protect<br />

the controller from unauthorized access.<br />

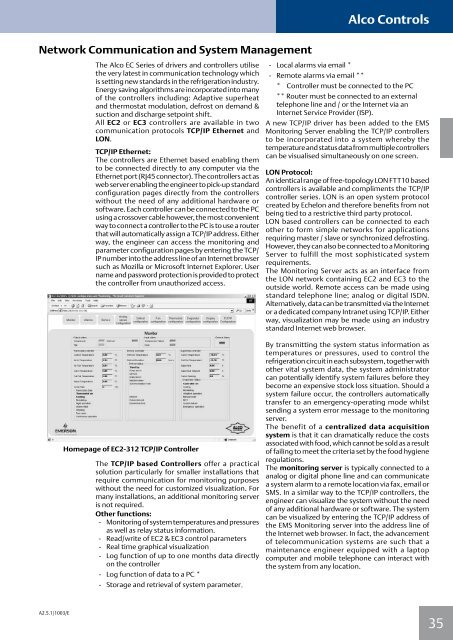

Homepage of EC2-312 TCP/IP Controller<br />

The TCP/IP based Controllers offer a practical<br />

solution particularly for smaller installations that<br />

require communication for monitoring purposes<br />

without the need for customized visualization. For<br />

many installations, an additional monitoring server<br />

is not required.<br />

Other functions:<br />

- Monitoring of system temperatures and pressures<br />

as well as relay status information.<br />

- Read/write of EC2 & EC3 control parameters<br />

- Real time graphical visualization<br />

- Log function of up to one months data directly<br />

on the controller<br />

- Log function of data to a PC *<br />

- Storage and retrieval of system parameter *<br />

<strong>Alco</strong> <strong>Controls</strong><br />

- Local alarms via email *<br />

- Remote alarms via email **<br />

* Controller must be connected to the PC<br />

** Router must be connected to an external<br />

telephone line and / or the Internet via an<br />

Internet Service Provider (ISP).<br />

A new TCP/IP driver has been added to the EMS<br />

Monitoring Server enabling the TCP/IP controllers<br />

to be incorporated into a system whereby the<br />

temperatureandstatusdatafrommultiplecontrollers<br />

can be visualised simultaneously on one screen.<br />

LON Protocol:<br />

An identical range of free-topology LON FTT10 based<br />

controllers is available and compliments the TCP/IP<br />

controller series. LON is an open system protocol<br />

created by Echelon and therefore benefits from not<br />

being tied to a restrictive third party protocol.<br />

LON based controllers can be connected to each<br />

other to form simple networks for applications<br />

requiring master / slave or synchronized defrosting.<br />

However, they can also be connected to a Monitoring<br />

Server to fulfill the most sophisticated system<br />

requirements.<br />

The Monitoring Server acts as an interface from<br />

the LON network containing EC2 and EC3 to the<br />

outside world. Remote access can be made using<br />

standard telephone line; analog or digital ISDN.<br />

Alternatively, data can be transmitted via the Internet<br />

or a dedicated company Intranet using TCP/IP. Either<br />

way, visualization may be made using an industry<br />

standard Internet web browser.<br />

By transmitting the system status information as<br />

temperatures or pressures, used to control the<br />

refrigeration circuit in each subsystem, together with<br />

other vital system data, the system administrator<br />

can potentially identify system failures before they<br />

become an expensive stock loss situation. Should a<br />

system failure occur, the controllers automatically<br />

transfer to an emergency-operating mode whilst<br />

sending a system error message to the monitoring<br />

server.<br />

The benefit of a centralized data acquisition<br />

system is that it can dramatically reduce the costs<br />

associated with food, which cannot be sold as a result<br />

of failing to meet the criteria set by the food hygiene<br />

regulations.<br />

The monitoring server is typically connected to a<br />

analog or digital phone line and can communicate<br />

a system alarm to a remote location via fax, email or<br />

SMS. In a similar way to the TCP/IP controllers, the<br />

engineer can visualize the system without the need<br />

of any additional hardware or software. The system<br />

can be visualized by entering the TCP/IP address of<br />

the EMS Monitoring server into the address line of<br />

the Internet web browser. In fact, the advancement<br />

of telecommunication systems are such that a<br />

maintenance engineer equipped with a laptop<br />

computer and mobile telephone can interact with<br />

the system from any location.<br />

35