SPX Flow Technology Innovation Centre

SPX Flow Technology Innovation Centre

SPX Flow Technology Innovation Centre

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

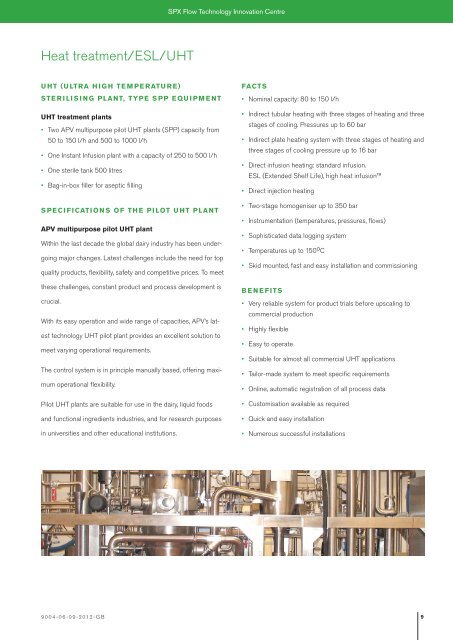

Heat treatment/ESL/UHT<br />

UHT (ULTRA HIGH TEMPERATURE)<br />

STERILISING PLANT, TYPE SPP EQUIPMENT<br />

UHT treatment plants<br />

• Two APV multipurpose pilot UHT plants (SPP) capacity from<br />

50 to 150 l/h and 500 to 1000 l/h<br />

• One Instant Infusion plant with a capacity of 250 to 500 l/h<br />

• One sterile tank 500 litres<br />

• Bag-in-box filler for aseptic filling<br />

SPECIFICATIONS OF THE PILOT UHT PLANT<br />

APV multipurpose pilot UHT plant<br />

Within the last decade the global dairy industry has been under-<br />

going major changes. Latest challenges include the need for top<br />

quality products, flexibility, safety and competitive prices. To meet<br />

these challenges, constant product and process development is<br />

crucial.<br />

With its easy operation and wide range of capacities, APV’s lat-<br />

est technology UHT pilot plant provides an excellent solution to<br />

meet varying operational requirements.<br />

The control system is in principle manually based, offering maxi-<br />

mum operational flexibility.<br />

Pilot UHT plants are suitable for use in the dairy, liquid foods<br />

and functional ingredients industries, and for research purposes<br />

in universities and other educational institutions.<br />

9004-06-09-2012-GB<br />

<strong>SPX</strong> <strong>Flow</strong> <strong>Technology</strong> <strong>Innovation</strong> <strong>Centre</strong><br />

FACTS<br />

• Nominal capacity: 80 to 150 l/h<br />

• Indirect tubular heating with three stages of heating and three<br />

stages of cooling. Pressures up to 60 bar<br />

• Indirect plate heating system with three stages of heating and<br />

three stages of cooling pressure up to 16 bar<br />

• Direct infusion heating: standard infusion.<br />

ESL (Extended Shelf Life), high heat infusion<br />

• Direct injection heating<br />

• Two-stage homogeniser up to 350 bar<br />

• Instrumentation (temperatures, pressures, flows)<br />

• Sophisticated data logging system<br />

• Temperatures up to 150 o C<br />

• Skid mounted, fast and easy installation and commissioning<br />

BENEFITS<br />

• Very reliable system for product trials before upscaling to<br />

commercial production<br />

• Highly flexible<br />

• Easy to operate<br />

• Suitable for almost all commercial UHT applications<br />

• Tailor-made system to meet specific requirements<br />

• Online, automatic registration of all process data<br />

• Customisation available as required<br />

• Quick and easy installation<br />

• Numerous successful installations<br />

9