Heat Shrinkable Moulded Shapes Brochure - RB Racing

Heat Shrinkable Moulded Shapes Brochure - RB Racing

Heat Shrinkable Moulded Shapes Brochure - RB Racing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8<br />

<strong>Heat</strong> <strong>Shrinkable</strong><br />

<strong>Moulded</strong> <strong>Shapes</strong> Expertise<br />

<strong>Heat</strong> <strong>Shrinkable</strong> <strong>Moulded</strong> <strong>Shapes</strong> Expertise<br />

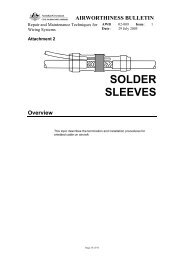

HellermannTyton heat shrinkable moulded shapes combine the advantages<br />

of quick, easy installation with high electric strength, mechanical toughness<br />

and superior chemical and environmental resistance. Our products offer<br />

important functional and cost saving benefits for electrical and electronic<br />

applications ranging from insulation and protection of individual components<br />

to fabrication of complete inter-connecting cable harness assemblies.<br />

Strain-relieving boots, transitions and connector backshell covers, as well as<br />

other specialised shapes, are available in a wide range of sizes and options.<br />

HellermannTyton's extensive product line includes low profile, bulbous and<br />

lipped types for use on circular and D-type connectors as well as complex<br />

multiway transitions. Only a minimum number of shapes are needed to<br />

cover a full range of applications as the products have high shrink ratios of<br />

up to 5:1.<br />

Applications<br />

The use of our heat shrinkable moulded shapes in conjunction with our<br />

specialist heat shrinkable tubings makes it easy to fabricate complete jacketed<br />

wire and cable harnessing and interconnection systems of the highest quality.<br />

<strong>Heat</strong> shrinkable shapes are available for the complete range of electrical<br />

and electronic harnessing applications. They can be sealed with our special<br />

adhesives and encapsulants to ensure the proper degree of mechanical<br />

support, strain relief and environmental protection. Encapsulating the complete<br />

harnessing and interconnection system to the desired configuration is easily<br />

and neatly accomplished, with minimum weight and bulk.<br />

Choice of Materials<br />

A range of specially formulated materials is available to meet a variety of<br />

performance requirements. Material selection can be made according to<br />

individual applications. We also have the ability to make customized<br />

materials to suit special requirements.<br />

Technical Capabilities<br />

Our materials are formulated in our own laboratory and produced in the<br />

HellermannTyton factory. We have experience and knowledge of all major<br />

applications and offer full technical support from design through to<br />

prototyping, to service.<br />

NOTE:<br />

Copyright to all drawings in this brochure is reserved by HellermannTyton.<br />

They are issued on condition that they are not copied, reproduced or<br />

disclosed to any third party either wholly or in part, without the written<br />

consent of HellermannTyton.