KOB Pyrot Installation & Operation

KOB Pyrot Installation & Operation

KOB Pyrot Installation & Operation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

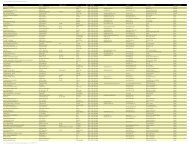

Mastercontrol [Art. No. ECO-M1]<br />

Mastercontrol improves the overall generation of heat by two biomass boilers (PYROT double-unit system), incl. the<br />

control of a bivalent boiler (oil-fired boiler, gas-fired boiler or electric boiler) as a redundant unit and/or as a peak-load<br />

boiler.<br />

Function:<br />

- Heat management system: optimum breakdown of the necessary heating capacity among the two biomass boilers<br />

with the main load on the primary boiler and the remaining load on the secondary boiler, this being done by means of<br />

output specification. The output specification is carried out in weather-guided fashion, depending on the desired<br />

temperature set in a joint hydraulic switcher. Automatic change between the two boilers to guarantee even loading of<br />

the boilers over a long operating period. (Example: weekly changeover)<br />

- Loader system: If the fuel for the two biomass boilers is taken from a joint fuel storage unit, then the loader system is<br />

controlled by the Mastercontrol system up to the fuel distribution.<br />

- Data management system:<br />

A complete package for transferring all the data to an external customer-provided IT-workplace for visualization,<br />

remote maintenance and archiving of operational data for the PYROT boiler system. Hardware, incl. modem and<br />

software, are integrated in the Mastercontrol system. All the adjustable parameters can be changed from the external<br />

IT-workplace.<br />

<strong>Operation</strong>:<br />

<strong>Operation</strong> is carried out either by means of a touch screen built into the control cabinet (extra charge for touch screen) or<br />

by the monitor, keyboard and PC-mouse provided by the customer.<br />

Includes:<br />

- Switch cabinet, uninstalled; surface powder-coated in RAL 7035 (gray) texture<br />

Designed in accordance with ÖVE/VDE guidelines, ready-wired on series terminals<br />

Feed: 208 V/3/60Hz; control voltage: 120 / 240V/1/60Hz or 24 V<br />

- Freely programmable control system, CE-tested; battery-supported program and real-time clock<br />

- Industrial PC<br />

- Starttec for all loader system drives (208V/3/60) in accordance with the separate price items<br />

- DVI-interface for a TFT monitor and USB-interface for keyboard, mouse and printer built into the cable lead through<br />

bar on the control cabinet.<br />

- Floating output (error report)<br />

In the door:<br />

- 4-pin master switch<br />

- Documentation, including bound circuit diagram, terminal connection plan with cable identification in document<br />

sleeve<br />

- Accumulator management system, 5 sensors (QA)<br />

- 5 PT100 sensors, with dipping shell 1/2" x 280 mm<br />

- Output specifications for both biomass boilers<br />

- Output specifications for both biomass boilers for further processing in the lower-level boiler control systems via<br />

serial interface<br />

- Visualization per modem<br />

- Analogue modem in switch cabinet<br />

- Windows operating system, pc-Anywhere remote-maintenance software and visualization/archiving software<br />

installed and tested on an industrial PC<br />

Screen images:<br />

- Three-dimensional boiler cross-section with display fields<br />

- <strong>Installation</strong> diagram, heat generation, with display fields<br />

- Parameter table (with editing feature)<br />

To be carried out by the customer:<br />

- Electric connection from telephone line to modem<br />

Touch Screen [Art. No. ECO-TSC]<br />

Spec Sheet<br />

<strong>Pyrot</strong> Rotation Heating System<br />

Mastercontrol<br />

vIESmAnn<br />

6850-1<br />

The touch screen (15") is built into the door of the control cabinet and can be used to call up and change all the relevant<br />

boiler and loader system parameters.