2. Design of Welded Connections - Awssection.org

2. Design of Welded Connections - Awssection.org

2. Design of Welded Connections - Awssection.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

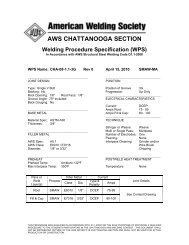

AASHTO/AWS D1.5M/D1.5:2002 DESIGN OF WELDED CONNECTIONS<br />

Reproduced with the permission <strong>of</strong> the American Welding Society (AWS), Miami, Florida - 09/15/2011.<br />

Single-bevel-groove (4)<br />

T-joint (T)<br />

Corner joint (C)<br />

FOR CORNER AND T-JOINT<br />

RESTRICTIONS, SEE <strong>2.</strong>11<br />

FOR BUTT JOINT RESTRICTIONS,<br />

SEE <strong>2.</strong>14<br />

Welding<br />

Process<br />

Joint<br />

<strong>Design</strong>ation<br />

Base Metal Thickness<br />

(U = unlimited)<br />

T 1<br />

SMAW TC-P4 U U<br />

GMAW<br />

FCAW<br />

T 2<br />

TC-P4-GF 6 min U<br />

SAW TC-P4-S 11 min U<br />

See Notes on Page 43<br />

Root Opening<br />

Root Face<br />

Groove Angle<br />

R = 0<br />

f = 3 min<br />

α = 45°<br />

R = 0<br />

f = 3 min<br />

α = 45°<br />

R = 0<br />

f = 6 min<br />

α = 60°<br />

Groove Preparation<br />

‡ Fit-up tolerance, see 3.3.2, for rolled shapes R may be 8 mm in thick plates if backing is provided.<br />

Double-bevel-groove weld (5)<br />

T-joint (T)<br />

Corner joint (C)<br />

FOR CORNER AND T-JOINT<br />

RESTRICTIONS, SEE <strong>2.</strong>11<br />

FOR BUTT JOINT RESTRICTIONS,<br />

SEE <strong>2.</strong>14<br />

Welding<br />

Process<br />

Joint<br />

<strong>Design</strong>ation<br />

Base Metal Thickness<br />

(U = unlimited)<br />

T 1<br />

SMAW TC-P5 8 min U<br />

GMAW<br />

FCAW<br />

T 2<br />

TC-P5-GF 12 min U<br />

SAW TC-P5-S 20 min U<br />

α α<br />

Root Opening<br />

Root Face<br />

Groove Angle<br />

R = 0<br />

f = 3 min<br />

α = 45°<br />

R = 0<br />

f = 3 min<br />

α = 45°<br />

R = 0<br />

f = 6 min<br />

α = 60°<br />

‡ Fit-up tolerance, see 3.3.2, for rolled shapes R may be 8 mm in thick plates if backing is provided.<br />

Figure <strong>2.</strong>5 (Continued) (Millimeters)<br />

34<br />

As Detailed<br />

(see <strong>2.</strong>13.1)<br />

+2, – 0<br />

Unlimited<br />

+10°, – 0°<br />

+2, – 0<br />

Unlimited<br />

+10°, – 0°<br />

±0<br />

Unlimited<br />

+10°, – 0°<br />

Tolerances<br />

Groove Preparation<br />

As Detailed<br />

(see <strong>2.</strong>13.1)<br />

+2, – 0<br />

Unlimited<br />

+10°, – 0°<br />

+2, – 0<br />

Unlimited<br />

+10°, – 0°<br />

±0<br />

Unlimited<br />

+10°, – 0°<br />

Tolerances<br />

As Fit-Up<br />

(see 3.3.4)<br />

+3, – 2<br />

±2<br />

+10°, – 5°<br />

+3, – 2<br />

±2<br />

+10°, – 5°<br />

+2, – 0 ‡<br />

±2<br />

+10°, – 5°<br />

As Fit-Up<br />

(see 3.3.4)<br />

+3, – 2<br />

±2<br />

+10°, – 5°<br />

+3, – 2<br />

±2<br />

+10°, – 5°<br />

+2, – 0<br />

±2<br />

+10°, – 5°<br />

Allowed<br />

Welding<br />

Positions<br />

All S– 3<br />

All S– 3<br />

F S<br />

Allowed<br />

Welding<br />

Positions<br />

All<br />

All<br />

Weld Size<br />

(E) Notes<br />

1, 2, 4,<br />

6, 11<br />

2, 4, 6,<br />

11<br />

2, 4, 6,<br />

11<br />

Total<br />

Weld Size<br />

(E 1 + E 2) Notes<br />

(S 1 + S 2)<br />

– 6<br />

(S 1 + S 2)<br />

– 6<br />

F S 1 + S 2<br />

Reproduced with the permission <strong>of</strong> the American Welding Society (AWS), Miami, Florida - 09/15/2011<br />

1, 4, 6,<br />

8, 11<br />

4, 6, 8,<br />

11<br />

4, 6, 8,<br />

11