Bedpan washer disinfectors: An in-use evaluation of ... - CCIH

Bedpan washer disinfectors: An in-use evaluation of ... - CCIH

Bedpan washer disinfectors: An in-use evaluation of ... - CCIH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

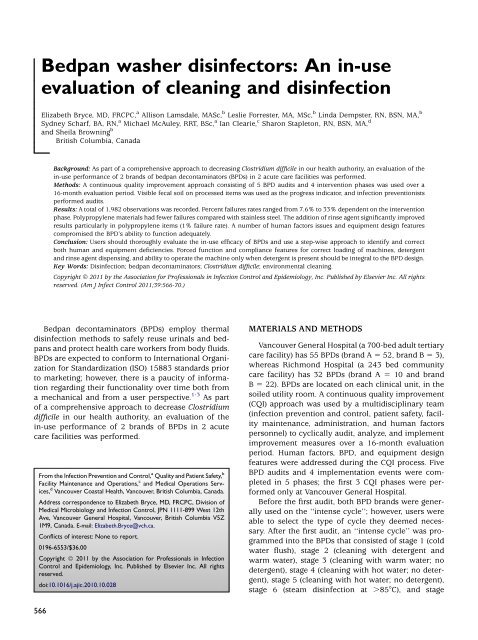

<strong>Bedpan</strong> <strong>washer</strong> <strong>dis<strong>in</strong>fectors</strong>: <strong>An</strong> <strong>in</strong>-<strong>use</strong><br />

<strong>evaluation</strong> <strong>of</strong> clean<strong>in</strong>g and dis<strong>in</strong>fection<br />

Elizabeth Bryce, MD, FRCPC, a Allison Lamsdale, MASc, b Leslie Forrester, MA, MSc, b L<strong>in</strong>da Dempster, RN, BSN, MA, b<br />

Sydney Scharf, BA, RN, a Michael McAuley, RRT, BSc, a Ian Clearie, c Sharon Stapleton, RN, BSN, MA, d<br />

and Sheila Brown<strong>in</strong>g b<br />

British Columbia, Canada<br />

Background: As part <strong>of</strong> a comprehensive approach to decreas<strong>in</strong>g Clostridium difficile <strong>in</strong> our health authority, an <strong>evaluation</strong> <strong>of</strong> the<br />

<strong>in</strong>-<strong>use</strong> performance <strong>of</strong> 2 brands <strong>of</strong> bedpan decontam<strong>in</strong>ators (BPDs) <strong>in</strong> 2 acute care facilities was performed.<br />

Methods: A cont<strong>in</strong>uous quality improvement approach consist<strong>in</strong>g <strong>of</strong> 5 BPD audits and 4 <strong>in</strong>tervention phases was <strong>use</strong>d over a<br />

16-month <strong>evaluation</strong> period. Visible fecal soil on processed items was <strong>use</strong>d as the progress <strong>in</strong>dicator, and <strong>in</strong>fection preventionists<br />

performed audits.<br />

Results: A total <strong>of</strong> 1,982 observations was recorded. Percent failures rates ranged from 7.6% to 33% dependent on the <strong>in</strong>tervention<br />

phase. Polypropylene materials had fewer failures compared with sta<strong>in</strong>less steel. The addition <strong>of</strong> r<strong>in</strong>se agent significantly improved<br />

results particularly <strong>in</strong> polypropylene items (1% failure rate). A number <strong>of</strong> human factors issues and equipment design features<br />

compromised the BPD’s ability to function adequately.<br />

Conclusion: Users should thoroughly evaluate the <strong>in</strong>-<strong>use</strong> efficacy <strong>of</strong> BPDs and <strong>use</strong> a step-wise approach to identify and correct<br />

both human and equipment deficiencies. Forced function and compliance features for correct load<strong>in</strong>g <strong>of</strong> mach<strong>in</strong>es, detergent<br />

and r<strong>in</strong>se agent dispens<strong>in</strong>g, and ability to operate the mach<strong>in</strong>e only when detergent is present should be <strong>in</strong>tegral to the BPD design.<br />

Key Words: Dis<strong>in</strong>fection; bedpan decontam<strong>in</strong>ators; Clostridium difficile; environmental clean<strong>in</strong>g.<br />

Copyright ª 2011 by the Association for Pr<strong>of</strong>essionals <strong>in</strong> Infection Control and Epidemiology, Inc. Published by Elsevier Inc. All rights<br />

reserved. (Am J Infect Control 2011;39:566-70.)<br />

<strong>Bedpan</strong> decontam<strong>in</strong>ators (BPDs) employ thermal<br />

dis<strong>in</strong>fection methods to safely re<strong>use</strong> ur<strong>in</strong>als and bedpans<br />

and protect health care workers from body fluids.<br />

BPDs are expected to conform to International Organization<br />

for Standardization (ISO) 15883 standards prior<br />

to market<strong>in</strong>g; however, there is a paucity <strong>of</strong> <strong>in</strong>formation<br />

regard<strong>in</strong>g their functionality over time both from<br />

a mechanical and from a <strong>use</strong>r perspective. 1-3 As part<br />

<strong>of</strong> a comprehensive approach to decrease Clostridium<br />

difficile <strong>in</strong> our health authority, an <strong>evaluation</strong> <strong>of</strong> the<br />

<strong>in</strong>-<strong>use</strong> performance <strong>of</strong> 2 brands <strong>of</strong> BPDs <strong>in</strong> 2 acute<br />

care facilities was performed.<br />

From the Infection Prevention and Control, a Quality and Patient Safety, b<br />

Facility Ma<strong>in</strong>tenance and Operations, c and Medical Operations Services,<br />

d Vancouver Coastal Health, Vancouver, British Columbia, Canada.<br />

Address correspondence to Elizabeth Bryce, MD, FRCPC, Division <strong>of</strong><br />

Medical Microbiology and Infection Control, JPN 1111-899 West 12th<br />

Ave, Vancouver General Hospital, Vancouver, British Columbia V5Z<br />

1M9, Canada. E-mail: Elizabeth.Bryce@vch.ca.<br />

Conflicts <strong>of</strong> <strong>in</strong>terest: None to report.<br />

0196-6553/$36.00<br />

Copyright ª 2011 by the Association for Pr<strong>of</strong>essionals <strong>in</strong> Infection<br />

Control and Epidemiology, Inc. Published by Elsevier Inc. All rights<br />

reserved.<br />

doi:10.1016/j.ajic.2010.10.028<br />

566<br />

MATERIALS AND METHODS<br />

Vancouver General Hospital (a 700-bed adult tertiary<br />

care facility) has 55 BPDs (brand A 5 52, brand B 5 3),<br />

whereas Richmond Hospital (a 243 bed community<br />

care facility) has 32 BPDs (brand A 5 10 and brand<br />

B 5 22). BPDs are located on each cl<strong>in</strong>ical unit, <strong>in</strong> the<br />

soiled utility room. A cont<strong>in</strong>uous quality improvement<br />

(CQI) approach was <strong>use</strong>d by a multidiscipl<strong>in</strong>ary team<br />

(<strong>in</strong>fection prevention and control, patient safety, facility<br />

ma<strong>in</strong>tenance, adm<strong>in</strong>istration, and human factors<br />

personnel) to cyclically audit, analyze, and implement<br />

improvement measures over a 16-month <strong>evaluation</strong><br />

period. Human factors, BPD, and equipment design<br />

features were addressed dur<strong>in</strong>g the CQI process. Five<br />

BPD audits and 4 implementation events were completed<br />

<strong>in</strong> 5 phases; the first 3 CQI phases were performed<br />

only at Vancouver General Hospital.<br />

Before the first audit, both BPD brands were generally<br />

<strong>use</strong>d on the ‘‘<strong>in</strong>tense cycle’’; however, <strong>use</strong>rs were<br />

able to select the type <strong>of</strong> cycle they deemed necessary.<br />

After the first audit, an ‘‘<strong>in</strong>tense cycle’’ was programmed<br />

<strong>in</strong>to the BPDs that consisted <strong>of</strong> stage 1 (cold<br />

water flush), stage 2 (clean<strong>in</strong>g with detergent and<br />

warm water), stage 3 (clean<strong>in</strong>g with warm water; no<br />

detergent), stage 4 (clean<strong>in</strong>g with hot water; no detergent),<br />

stage 5 (clean<strong>in</strong>g with hot water; no detergent),<br />

stage 6 (steam dis<strong>in</strong>fection at .858C), and stage

www.ajicjournal.org<br />

Vol. 39 No. 7<br />

Table 1. Cont<strong>in</strong>uous improvement results and improvement measures implemented<br />

Phase<br />

7 (cool<strong>in</strong>g cycle with cold water and r<strong>in</strong>se agent).<br />

A functional ma<strong>in</strong>tenance review also occurred at<br />

this time to ensure that the BPDs were meet<strong>in</strong>g manufacturer’s<br />

specifications. In phase 2, the ‘‘<strong>in</strong>tensive<br />

cycle’’ was aga<strong>in</strong> reprogrammed to now become the<br />

default sett<strong>in</strong>g with a steam dis<strong>in</strong>fection cycle <strong>of</strong> 90<br />

seconds. Mach<strong>in</strong>es were also programmed not to<br />

work if the detergent dispenser was empty. Phase 3<br />

foc<strong>use</strong>d on small group <strong>in</strong>tensive education sessions<br />

on 2 pilot wards. Phases 4 and 5 expanded the <strong>in</strong>tensive<br />

education campaign to <strong>in</strong>volve all wards and<br />

<strong>in</strong>cluded Richmond Hospital <strong>in</strong> the CQI process.<br />

Mach<strong>in</strong>es were adjusted to operate only with both<br />

r<strong>in</strong>se agent and detergent present <strong>in</strong> phase 5. Temperature<br />

probes were <strong>use</strong>d dur<strong>in</strong>g phase 5 on all<br />

BPDs to confirm that mach<strong>in</strong>es were achiev<strong>in</strong>g thermal<br />

dis<strong>in</strong>fection as per ISO standards.<br />

Audits for the presence <strong>of</strong> visible fecal soil on processed<br />

items were conducted by <strong>in</strong>fection preventionists<br />

after the improvement measures were implemented at<br />

each phase <strong>of</strong> the <strong>evaluation</strong>. Item type, material composition<br />

(polypropylene vs sta<strong>in</strong>less steel), presence or absence<br />

<strong>of</strong> r<strong>in</strong>se agent and detergent, and cl<strong>in</strong>ical unit were<br />

also recorded.<br />

RESULTS<br />

No. items<br />

audited<br />

Table 1 describes the CQI cycle, audit results, and<br />

improvement measures implemented. A total <strong>of</strong><br />

1,982 visual <strong>in</strong>spections was conducted <strong>in</strong> the audits.<br />

% Failure<br />

rate Postaudit <strong>in</strong>tervention measures<br />

1 141 23 Staff education<br />

Repost<strong>in</strong>g <strong>of</strong> <strong>in</strong>structions for proper <strong>use</strong><br />

Mach<strong>in</strong>e error codes reviewed and functional issues addressed<br />

Temperature adjusted to 908C<br />

2 359 27% Automatic default <strong>of</strong> mach<strong>in</strong>es to <strong>in</strong>tensive detergent cycle<br />

Mach<strong>in</strong>e programmed to halt if detergent dispenser empty<br />

Error code <strong>in</strong>terpretation simplified<br />

System for ma<strong>in</strong>tenance to report all malfunctions to ward management established<br />

3* 531 19.4 Vendor provides <strong>in</strong>tensive education on all shifts on 2 pilot units<br />

Infection Control supervises and monitors all BPDs on 2 pilot wards<br />

4 y<br />

511 7.6 Intensive education campaign expanded to <strong>in</strong>volve all wards<br />

Ma<strong>in</strong>tenance revises quality program to regularly review functionality <strong>of</strong> mach<strong>in</strong>es<br />

Richmond Hospital <strong>in</strong>cluded to determ<strong>in</strong>e if results and observations are similar <strong>in</strong> another<br />

facility<br />

5 440 33 All mach<strong>in</strong>es adjusted to <strong>use</strong> only both r<strong>in</strong>se agent and detergent<br />

Processed items not pass<strong>in</strong>g <strong>in</strong>spection cont<strong>in</strong>ue to be sent to Sterile Process<strong>in</strong>g for clean<strong>in</strong>g<br />

and dis<strong>in</strong>fection<br />

Trial <strong>of</strong> manual clean<strong>in</strong>g <strong>of</strong> spray heads on selected mach<strong>in</strong>es<br />

Comparison <strong>of</strong> functionality and mach<strong>in</strong>e age conducted<br />

*Phase 3 <strong>in</strong>volved 2 pilot units (<strong>in</strong>tensive care unit and a medical floor) only.<br />

y Phases 4 and 5 <strong>in</strong>volved Richmond Hospital.<br />

Bryce et al. 567<br />

Failure rates decl<strong>in</strong>ed to 7.6% on 2 pilot wards only<br />

after an <strong>in</strong>tensive education campaign was conducted<br />

and was comb<strong>in</strong>ed with daily monitor<strong>in</strong>g <strong>of</strong> processed<br />

items by the Infection Prevention and Control<br />

team. This level <strong>of</strong> monitor<strong>in</strong>g and education could<br />

not be susta<strong>in</strong>ed both on the pilot unit and the<br />

rest <strong>of</strong> the facility, and failure rates returned to previous<br />

levels with<strong>in</strong> 2 months. When Richmond<br />

Hospital was <strong>in</strong>cluded <strong>in</strong> the CQI process, failure<br />

rates were similar, <strong>in</strong>dicat<strong>in</strong>g that this was not an isolated<br />

<strong>in</strong>stitutional issue. Brands A and B had similar<br />

performance failures. All mach<strong>in</strong>es passed temperature<br />

probes tests (phase 5) dur<strong>in</strong>g their entire wash/<br />

dis<strong>in</strong>fection cycle us<strong>in</strong>g the ‘‘<strong>in</strong>tensive’’ dis<strong>in</strong>fection sett<strong>in</strong>g.<br />

All mach<strong>in</strong>es passed the functional ma<strong>in</strong>tenance<br />

check <strong>in</strong> phase 1 (phase 4 for Richmond Hospital).<br />

Table 2 compares results when r<strong>in</strong>se agent was present<br />

dur<strong>in</strong>g the wash/dis<strong>in</strong>fection cycle. Interest<strong>in</strong>gly,<br />

<strong>in</strong>clusion <strong>of</strong> the r<strong>in</strong>se agent, while not decreas<strong>in</strong>g the<br />

failure rate to acceptable levels, resulted <strong>in</strong> a significant<br />

improvement. Polypropylene materials had a lower<br />

failure rate compared with sta<strong>in</strong>less steel items; the<br />

failure rates for polypropylene and r<strong>in</strong>se agent <strong>in</strong> comb<strong>in</strong>ation<br />

were 1% (P , .0006).<br />

Observations by <strong>in</strong>fection preventionists that the<br />

spray heads were occasionally visibly contam<strong>in</strong>ated<br />

with fecal soil and <strong>in</strong>dividual apertures appeared to<br />

be obstructed led to a comparison <strong>of</strong> mach<strong>in</strong>e age and<br />

failure rates (Table 3). Mach<strong>in</strong>es that were less than<br />

2 years past <strong>in</strong>stallation had significantly fewer process<strong>in</strong>g<br />

failures. Both human factors issues and BPD

568 Bryce et al. American Journal <strong>of</strong> Infection Control<br />

September 2011<br />

Table 2. Comparison <strong>of</strong> failure rates when r<strong>in</strong>se agent present<br />

Item<br />

mach<strong>in</strong>e features and equipment design flaws were<br />

identified and are listed <strong>in</strong> Table 4.<br />

DISCUSSION<br />

Safe reprocess<strong>in</strong>g <strong>of</strong> equipment is a priority <strong>in</strong> prevent<strong>in</strong>g<br />

the spread <strong>of</strong> <strong>in</strong>fection to patients and staff.<br />

One <strong>of</strong> the most commonly <strong>use</strong>d reprocess<strong>in</strong>g mach<strong>in</strong>es<br />

is the bedpan <strong>washer</strong>/dis<strong>in</strong>fector or BPD, which,<br />

importantly, m<strong>in</strong>imizes the risk <strong>of</strong> staff exposure to<br />

body fluids and fecal material. ISO standards clearly<br />

outl<strong>in</strong>e the expected performance parameters; however,<br />

BPDs are seldom subjected to field trials where<br />

human factors, mach<strong>in</strong>e design functionality, and<br />

equipment features that <strong>in</strong>fluence the clean<strong>in</strong>g and decontam<strong>in</strong>ation<br />

process are evaluated and addressed.<br />

The emergence <strong>of</strong> hypervirulent stra<strong>in</strong>s <strong>of</strong> Clostridium<br />

difficile and reports <strong>of</strong> <strong>in</strong>creas<strong>in</strong>g rates <strong>of</strong> C difficilerelated<br />

<strong>in</strong>fection emphasize the need to rigorously<br />

evaluate the equipment clean<strong>in</strong>g process and implement<br />

<strong>in</strong>terventions to m<strong>in</strong>imize the potential for cross<br />

transmission. 4-6<br />

The percent <strong>of</strong> processed items with visible fecal soil<br />

<strong>in</strong> the audits was disturb<strong>in</strong>g. The <strong>in</strong>itial plan was to<br />

evaluate visible soil<strong>in</strong>g followed by microbiologic and<br />

ultraviolet light test<strong>in</strong>g if fecal soil was not detected.<br />

However, the high percentage <strong>of</strong> process<strong>in</strong>g failures<br />

readily detected by observation alone made microbiologic<br />

and ultraviolet marker test<strong>in</strong>g somewhat moot,<br />

and the multidiscipl<strong>in</strong>ary group elected to pursue process<br />

improvement measures us<strong>in</strong>g visual observation<br />

as the progress <strong>in</strong>dicator.<br />

Previous studies by Alfa et al us<strong>in</strong>g TOSI test<strong>in</strong>g devices<br />

(Pereg GmBH, Waldkraiburg, Germany) and microbial<br />

and ultraviolet assessments demonstrated that<br />

ward BPDs did not provide an equivalent level <strong>of</strong> clean<strong>in</strong>g<br />

compared to sterile process<strong>in</strong>g department <strong>washer</strong><br />

R<strong>in</strong>se agent No r<strong>in</strong>se agent<br />

Total Failure, n (%) Total Failure, n (%)<br />

P value<br />

Metal bedpans and pot handles 77 17 (35) 187 93 (50) ,.0004<br />

Polypropylene bedpans and slipper pots 71 4 (1) 73 20 (27) ,.0006<br />

Totals 148 21 (14) 260 113 (44) ,.0001<br />

NOTE. Fischer exact test (2-tailed).<br />

Table 3. Comparison <strong>of</strong> failures rates and mach<strong>in</strong>e age<br />

Year <strong>of</strong> <strong>in</strong>stallation<br />

Number <strong>of</strong><br />

observations<br />

Failures,<br />

n (%) Significance<br />

Before 2008 (n 5 32) 321 123 (38.3) P , .001<br />

After 2008 (n 5 6) 80 6 (7.5)<br />

<strong>dis<strong>in</strong>fectors</strong>. 2 Of particular <strong>in</strong>terest was that the presence<br />

<strong>of</strong> ultraviolet light marker after the wash cycle<br />

highlighted the <strong>in</strong>adequacy <strong>of</strong> wash<strong>in</strong>g by ward BPDs.<br />

These observations were made despite controlled conditions<br />

us<strong>in</strong>g tra<strong>in</strong>ed personnel and ensur<strong>in</strong>g that items<br />

were placed properly and processed promptly. Under<br />

normal ward operat<strong>in</strong>g conditions and <strong>in</strong> the presence<br />

<strong>of</strong> a considerable prote<strong>in</strong> load, it is not surpris<strong>in</strong>g that<br />

higher failure rates were detected.<br />

The <strong>evaluation</strong> <strong>of</strong> medical equipment us<strong>in</strong>g human<br />

factors pr<strong>in</strong>ciples identifies quality and safety issues<br />

<strong>of</strong> equipment <strong>in</strong> health care <strong>in</strong>stitutions. 7-11 A number<br />

<strong>of</strong> human factors issues contributed to the process<strong>in</strong>g<br />

failures <strong>of</strong> the BPDs. Staff did not always process soiled<br />

equipment promptly leav<strong>in</strong>g human waste to dry onto<br />

surfaces, a practice that likely enhanced the protection<br />

<strong>of</strong> microorganisms aga<strong>in</strong>st thermal dis<strong>in</strong>fection. 12 Infection<br />

preventionists observed that items were frequently<br />

double stacked <strong>in</strong> the BPDs, compromis<strong>in</strong>g<br />

the ability <strong>of</strong> the mach<strong>in</strong>es to effectively clean items.<br />

Although there was a signed and dated checklist posted<br />

for both clean<strong>in</strong>g and ward staff to check detergent dispensers<br />

to ensure they were filled, this was not rout<strong>in</strong>ely<br />

done, and empty detergent dispensers were<br />

observed. Many staff also <strong>in</strong>dicated that they were<br />

not sure how to properly load the bedpan(s) <strong>in</strong>to<br />

the decontam<strong>in</strong>ator. Staff found the load<strong>in</strong>g racks confus<strong>in</strong>g<br />

and could not clearly identify where a bedpan<br />

should be properly placed <strong>in</strong> the BPD. Staff would <strong>in</strong>clude<br />

per<strong>in</strong>eal care pads as part <strong>of</strong> the bedpan contents<br />

when process<strong>in</strong>g, result<strong>in</strong>g <strong>in</strong> sewer l<strong>in</strong>e blockages and<br />

further mach<strong>in</strong>e failures. Prior to the CQI process, dur<strong>in</strong>g<br />

one 6-month period, over 500 ma<strong>in</strong>tenance calls<br />

for mach<strong>in</strong>e failures (largely beca<strong>use</strong> <strong>of</strong> blockages)<br />

were recorded.<br />

As identified by the Institute <strong>of</strong> Medic<strong>in</strong>e, ‘‘To err is<br />

human,’’ a major contributor to error <strong>in</strong> health care is<br />

poor device design. 11 Design flaws <strong>of</strong> the BPD that contributed<br />

to human error were identified. The <strong>use</strong>r <strong>in</strong>terface<br />

and BPD display was confus<strong>in</strong>g <strong>in</strong> that errors were<br />

displayed as codes that staff could not <strong>in</strong>terpret. The<br />

display on older mach<strong>in</strong>es was also poorly illum<strong>in</strong>ated,<br />

mak<strong>in</strong>g it easier not to notice an error code signal. The<br />

BPD could be operated with an empty detergent

www.ajicjournal.org<br />

Vol. 39 No. 7<br />

Table 4. Factors contribut<strong>in</strong>g to process<strong>in</strong>g failures<br />

Human Soiled items not processed immediately after <strong>use</strong><br />

Improper load<strong>in</strong>g <strong>of</strong> BPD<br />

Load<strong>in</strong>g <strong>of</strong> more than one item <strong>in</strong>to mach<strong>in</strong>e<br />

Disposal <strong>of</strong> paper products other than toilet tissue <strong>in</strong> mach<strong>in</strong>e lead<strong>in</strong>g to mach<strong>in</strong>e failure<br />

Failure to fill mach<strong>in</strong>es with detergent and/or r<strong>in</strong>se agent<br />

Placement <strong>of</strong> s<strong>in</strong>gle <strong>use</strong> ur<strong>in</strong>als <strong>in</strong>to BPDs for process<strong>in</strong>g<br />

Mach<strong>in</strong>e Error codes not expla<strong>in</strong>ed<br />

No warn<strong>in</strong>g light when detergent dispenser empty<br />

<strong>Bedpan</strong> contents spill over spray head when door closed<br />

R<strong>in</strong>se agent and detergent dispenser connections not clearly identified<br />

Design <strong>of</strong> BPD rack does not provide physical cues or <strong>in</strong>dicators <strong>of</strong> where soiled items should be loaded<br />

Operation <strong>of</strong> door not hands free<br />

No forced compliance features for proper load<strong>in</strong>g<br />

Higher temperature facilitates bak<strong>in</strong>g <strong>of</strong> fecal material to sta<strong>in</strong>less steel surfaces<br />

Accessory equipment Inner rims <strong>of</strong> certa<strong>in</strong> brands <strong>of</strong> bedpans <strong>in</strong>accessible to spray heads<br />

Metal predisposes to bak<strong>in</strong>g <strong>of</strong> fecal material if <strong>in</strong>adequately washed<br />

Physical design <strong>of</strong> bedpans does not properly fit <strong>in</strong>to BPD rack<br />

Used pericare items clog the BPD<br />

BPD, bedpan decontam<strong>in</strong>ators.<br />

dispenser beca<strong>use</strong> the <strong>use</strong>r was provided no feedback<br />

that the detergent or r<strong>in</strong>se agent was empty. These<br />

items are all violations <strong>of</strong> Nielsen’s usability heuristics,<br />

a set <strong>of</strong> 12 pr<strong>in</strong>ciples for optimal <strong>use</strong>r <strong>in</strong>terface design.<br />

Pr<strong>in</strong>ciples <strong>of</strong> particular <strong>in</strong>terest <strong>in</strong> this <strong>evaluation</strong> <strong>in</strong>cluded<br />

(1) the match between the design and the real<br />

world (the system should speak the <strong>use</strong>rs’ language,<br />

eg, error codes that are easily <strong>in</strong>terpreted); (2) error prevention<br />

(careful design that prevents the problem from<br />

occurr<strong>in</strong>g <strong>in</strong> the first place, eg, spray heads that are not<br />

exposed dur<strong>in</strong>g disposal <strong>of</strong> fecal material); (3) recognition<br />

rather than recall (mak<strong>in</strong>g objects, actions, and options<br />

visible through clear accessible <strong>in</strong>structions, eg,<br />

clearly label<strong>in</strong>g r<strong>in</strong>se and detergent connections); (4)<br />

consistency and standards (eg, ability to understand<br />

what cycle to <strong>use</strong>); and (5) visibility <strong>of</strong> system status<br />

(eg, ability to detect the work<strong>in</strong>g or nonwork<strong>in</strong>g state<br />

<strong>of</strong> the BPD: empty detergent, clean bedpan <strong>in</strong> BPD). 13<br />

These human factors and mach<strong>in</strong>e design issues<br />

were largely addressed by policy and procedural<br />

changes, and requests to the vendor on forcefunction<strong>in</strong>g<br />

the design <strong>of</strong> the BPD to <strong>in</strong>clude customized<br />

racks, clearly def<strong>in</strong>ed error codes, and device operation.<br />

Forced compliance features so that mach<strong>in</strong>es could<br />

only operate on the ‘‘<strong>in</strong>tense cycle’’ and could not function<br />

without detergent, methods to permit disposal <strong>of</strong><br />

per<strong>in</strong>eal pads us<strong>in</strong>g an alternate system, clearly outl<strong>in</strong><strong>in</strong>g<br />

who was responsible for ensur<strong>in</strong>g detergent dispensers<br />

were filled, and the performance <strong>of</strong> quality<br />

ma<strong>in</strong>tenance checks addressed most <strong>of</strong> the previously<br />

described issues. New signage and education to complement<br />

these adm<strong>in</strong>istrative and eng<strong>in</strong>eer<strong>in</strong>g controls<br />

were implemented. Despite these <strong>in</strong>terventions, failures<br />

persisted. A significant decrease <strong>in</strong> process failures was<br />

noted only when a very <strong>in</strong>tensive one-on-one education<br />

Bryce et al. 569<br />

campaign was comb<strong>in</strong>ed with daily monitor<strong>in</strong>g and supervision<br />

by Infection Prevention and Control team staff<br />

on 2 pilot wards. Such measures proved unsusta<strong>in</strong>able<br />

over the long-term and impractical for implementation<br />

throughout the facility. The CQI process, when extended<br />

to the Richmond community facility, confirmed<br />

that this was not an isolated facility issue.<br />

Several <strong>of</strong> the auditors observed that, on occasion,<br />

the spray head apertures appeared to be clogged. The<br />

mach<strong>in</strong>e design was such that human waste was<br />

dumped over the spray heads when the door was<br />

shut and the bedpans emptied; this likely compromised<br />

the spray apertures. Process<strong>in</strong>g failures were<br />

most evident <strong>in</strong> mach<strong>in</strong>es more than 2 years old, aga<strong>in</strong><br />

suggest<strong>in</strong>g that, over time, spray heads could become<br />

obstructed. These observations lead to the theory that<br />

the addition <strong>of</strong> the r<strong>in</strong>se agent (which has a descal<strong>in</strong>g<br />

chemical) might improve clean<strong>in</strong>g efficacy, and results<br />

were reanalyzed to compare mach<strong>in</strong>es with or without<br />

the presence <strong>of</strong> r<strong>in</strong>se agent at the time <strong>of</strong> the observations.<br />

Mach<strong>in</strong>es that <strong>use</strong>d r<strong>in</strong>se agent did show a statistically<br />

significant decrease <strong>in</strong> failed items; comb<strong>in</strong>ed<br />

with the <strong>in</strong>creased failures noted with <strong>in</strong>creas<strong>in</strong>g<br />

mach<strong>in</strong>e age, it is likely that obstructed spray heads<br />

contribute to BPD dis<strong>in</strong>fection failures. The multidiscipl<strong>in</strong>ary<br />

team recommended that all mach<strong>in</strong>es <strong>use</strong> r<strong>in</strong>se<br />

agent and the procedural change was communicated to<br />

all the floors. Unfortunately, the dispenser connections<br />

for r<strong>in</strong>se agent and detergent were not clearly identified<br />

creat<strong>in</strong>g a potential for staff to <strong>in</strong>correctly connect<br />

the fluids. Facility ma<strong>in</strong>tenance subsequently had to<br />

color code the dispens<strong>in</strong>g l<strong>in</strong>es for detergent and r<strong>in</strong>se<br />

agent as a mitigation measure.<br />

Sta<strong>in</strong>less steel items failed more <strong>of</strong>ten than polypropylene,<br />

likely beca<strong>use</strong> the surface temperature <strong>of</strong> the

570 Bryce et al. American Journal <strong>of</strong> Infection Control<br />

September 2011<br />

latter items was higher and, without adequate wash<strong>in</strong>g,<br />

fecal material baked onto the surface. 14 The hospitals<br />

are currently <strong>in</strong> the process <strong>of</strong> <strong>in</strong>creas<strong>in</strong>g the <strong>in</strong>ventory<br />

<strong>of</strong> polypropylene items and remov<strong>in</strong>g metal bedpans<br />

wherever possible. F<strong>in</strong>ally, spray heads that did not<br />

reach <strong>in</strong>to all surfaces <strong>of</strong> processed items were a BPD<br />

mach<strong>in</strong>e design flaw that contributed to the impaired<br />

clean<strong>in</strong>g efficacy. This was particularly evident with<br />

one brand <strong>of</strong> bedpan that had a deeper bowl and rolled<br />

edges and highlights that one must consider the equipment<br />

<strong>use</strong>d on the cl<strong>in</strong>ical units when evaluat<strong>in</strong>g clean<strong>in</strong>g<br />

efficacy.<br />

The multidiscipl<strong>in</strong>ary team cont<strong>in</strong>ues to work on a<br />

program to clean and replace spray heads, re<strong>in</strong>force<br />

education, and facilitate immediate and correct load<strong>in</strong>g<br />

and process<strong>in</strong>g <strong>of</strong> items. In the <strong>in</strong>terim, items that rema<strong>in</strong><br />

visibly soiled after process<strong>in</strong>g through the BPD<br />

are sent to the Sterile Supply Department for thorough<br />

clean<strong>in</strong>g and dis<strong>in</strong>fection.<br />

BPDs perform an important function <strong>in</strong> m<strong>in</strong>imiz<strong>in</strong>g<br />

risk <strong>of</strong> exposure to body fluid and fecal material, however,<br />

our data strongly suggest that <strong>use</strong>rs should thoroughly<br />

evaluate the <strong>in</strong>-<strong>use</strong> efficacy <strong>of</strong> BPDs (ideally<br />

prior to procurement) and <strong>use</strong> a step-wise approach<br />

to correct any identified human and equipment deficiencies.<br />

BPDs should not only be simple to operate<br />

and <strong>use</strong>r friendly, but be designed to m<strong>in</strong>imize human<br />

errors (eg, when load<strong>in</strong>g the mach<strong>in</strong>e and when replac<strong>in</strong>g<br />

detergent and r<strong>in</strong>se agent). Furthermore, they<br />

should be designed so that component parts are<br />

shielded from fecal soil dur<strong>in</strong>g the disposal stages <strong>of</strong><br />

operation. Regular <strong>in</strong>spection <strong>of</strong> the mach<strong>in</strong>es by<br />

ma<strong>in</strong>tenance personnel to ensure that spray heads<br />

are fully operational and the mach<strong>in</strong>es are function<strong>in</strong>g<br />

optimally is suggested. (In retrospect, it may have been<br />

beneficial to evaluate the mach<strong>in</strong>es us<strong>in</strong>g either TOSI<br />

tests or a dye monitor particularly upon <strong>in</strong>itial procurement.)<br />

Forced compliance features for correct load<strong>in</strong>g<br />

<strong>of</strong> mach<strong>in</strong>es and detergent and r<strong>in</strong>se agent dispens<strong>in</strong>g<br />

with mach<strong>in</strong>e operation only <strong>in</strong> the presence <strong>of</strong> the latter<br />

agent should be <strong>in</strong>tegral to the BPD design. A sett<strong>in</strong>g<br />

that <strong>in</strong>corporates multiple r<strong>in</strong>ses and clean<strong>in</strong>g cycles<br />

with a prolonged steam dis<strong>in</strong>fection is recommended.<br />

Consideration should be given to the preferential <strong>use</strong><br />

<strong>of</strong> polypropylene items where practical and where<br />

<strong>evaluation</strong> suggests that reprocess<strong>in</strong>g failures could<br />

be decreased. Purchasers <strong>of</strong> BPDs are encouraged to<br />

<strong>in</strong>volve <strong>use</strong>r groups and stakeholders upfront and<br />

advocate for these design changes through further<br />

technical and usability <strong>in</strong>-<strong>use</strong> studies.<br />

This report highlights the importance <strong>of</strong> evaluat<strong>in</strong>g<br />

equipment for usability from an <strong>in</strong>fection control perspective<br />

<strong>in</strong> a work<strong>in</strong>g health care environment. The authors<br />

hope that it also serves as an example <strong>of</strong> the need<br />

to <strong>in</strong>tegrate human factors analysis <strong>in</strong> the health care<br />

procurement process <strong>of</strong> medical devices and equipment.<br />

References<br />

1. International Organization for Standardization. ISO 15883-3 <strong>washer</strong><br />

<strong>dis<strong>in</strong>fectors</strong>—part 3: requirements and tests for <strong>washer</strong>-<strong>dis<strong>in</strong>fectors</strong><br />

employ<strong>in</strong>g thermal dis<strong>in</strong>fection for human waste conta<strong>in</strong>ers. Geneva<br />

(Switzerland): International Organization for Standardization; 2006.<br />

2. Alfa MJ, Olson N, Buelow-Smith L. Simulated-<strong>use</strong> test<strong>in</strong>g <strong>of</strong> bedpan<br />

and ur<strong>in</strong>al <strong>washer</strong> <strong>dis<strong>in</strong>fectors</strong>: <strong>evaluation</strong> <strong>of</strong> Clostridium difficile spore<br />

survival and clean<strong>in</strong>g efficacy. Am J Infect Control 2008;36:5-11.<br />

3. Dempsey KM, Chiew RF, McKenzie JA, Mitchell DH. Evaluation <strong>of</strong> the<br />

clean<strong>in</strong>g and dis<strong>in</strong>fection efficacy <strong>of</strong> the DEKO-190; award-based<br />

automated <strong>washer</strong>/dis<strong>in</strong>fector. J Hosp Infect 2000;46:50-4.<br />

4. Vonberg RP, Kuijper EJ, Wilcox MH, Barbut F, T€ull P, Gastmeier P, et al.<br />

Infection control measures to limit the spread <strong>of</strong> Clostridium difficile.<br />

Cl<strong>in</strong> Microbiol Infect 2008;14(Suppl 5):2-20.<br />

5. Pep<strong>in</strong> J, Alary ME, Valiquette L, Raiche E, Ruel J, Fulop K, et al. Increas<strong>in</strong>g<br />

risk <strong>of</strong> relapse after treatment <strong>of</strong> Clostridium difficile colitis <strong>in</strong> Quebec,<br />

Canada. Cl<strong>in</strong> Infect Dis 2005;49:1591-7.<br />

6. Centers for Disease Control and Prevention. Data and statistics<br />

about Clostridium difficile <strong>in</strong>fections Web page. Available from:<br />

http://www.cdc.gov/ncidod/dhqp/id_Cdiff_data.html. Accessed July<br />

23, 2010.<br />

7. Gagnon R, Laberge J, Lamsdale A, Histon J, Hudson C, Davies J, et al.<br />

A <strong>use</strong>r-centered <strong>evaluation</strong> <strong>of</strong> three <strong>in</strong>travenous <strong>in</strong>fusion pumps. Proceed<strong>in</strong>gs<br />

<strong>of</strong> the 48th <strong>An</strong>nual Human Factors and Ergonomics Society<br />

Meet<strong>in</strong>g. Santa Monica (CA): Human Factors and Ergonomics Society;<br />

2004. p. 1773-7.<br />

8. Lamsdale A, Chisholm S, Gagnon R, Davies J, Caird JK. A usability <strong>evaluation</strong><br />

<strong>of</strong> an <strong>in</strong>fusion pump by nurses us<strong>in</strong>g a patient simulator. Proceed<strong>in</strong>gs<br />

<strong>of</strong> the 49th <strong>An</strong>nual Meet<strong>in</strong>g <strong>of</strong> the Human Factors and<br />

Ergonomics Society. Santa Monica (CA): Human Factors and Ergonomics<br />

Society; 2005. p. 1024-8.<br />

9. G<strong>in</strong>sburg G. Human factors eng<strong>in</strong>eer<strong>in</strong>g: a toll for medical device <strong>evaluation</strong><br />

<strong>in</strong> hospital procurement decision-mak<strong>in</strong>g. J Biomed Inform<br />

2005;38:213-9.<br />

10. L<strong>in</strong> L, Vicente KJ, Doyle DJ. Patient safety, potential adverse drug<br />

events, and medical device design: a human factors eng<strong>in</strong>eer<strong>in</strong>g approach.<br />

J Biomed Inform 2001;34:274-84.<br />

11. Institute <strong>of</strong> Medic<strong>in</strong>e, Committee on Quality <strong>of</strong> Health Care <strong>in</strong> America.<br />

In: Kohn LT, Corrigan JM, Donaldson MS, editors. To err is human:<br />

Build<strong>in</strong>g a safer health system. Wash<strong>in</strong>gton, DC: National Academy<br />

Press; 2000.<br />

12. Diab-Elschahawi M, F€urnkranz U, Blacky A, Bachh<strong>of</strong>ner N, Koller W.<br />

Re-<strong>evaluation</strong> <strong>of</strong> current A0 value recommendations for thermal dis<strong>in</strong>fection<br />

<strong>of</strong> reusable human waste conta<strong>in</strong>ers based on new experimental<br />

data. J Hosp Infect 2010;73:62-5.<br />

13. Nielsen J. Usability <strong>in</strong>spection methods. Proceed<strong>in</strong>g from Computer-<br />

Human Interaction (CHI). New York (NY): Association for Comput<strong>in</strong>g<br />

Mach<strong>in</strong>ery; 1994.<br />

14. Ayliffe GA, Coll<strong>in</strong> BJ, Deverill CEA. Tests <strong>of</strong> dis<strong>in</strong>fection by heat <strong>in</strong> a<br />

bedpan wash<strong>in</strong>g mach<strong>in</strong>e. J Cl<strong>in</strong> Pathol 1974;27:760-3.