ITW DEVCON ENGINEERED COATINGS - ITW Futura Coatings

ITW DEVCON ENGINEERED COATINGS - ITW Futura Coatings

ITW DEVCON ENGINEERED COATINGS - ITW Futura Coatings

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1.0 GENERAL.<br />

SPECIFICATION AND APPLICATION GUIDELINE FOR<br />

COATING STEEL SURFACES WITH<br />

IRATHANE 155<br />

Page 1 of 9<br />

Revised Date: 04/2010<br />

Replaces Date: 01/2008<br />

1.1. This specification guideline establishes the minimum technical requirements and describes the<br />

work to be performed for the application of Irathane 155 and related systems on to steel surfaces.<br />

This work is to include total responsibility for surface preparation, cleaning, environmental control<br />

of the work area, abrasive cleanup and the application of the elastomeric polyurethane system.<br />

1.2. The contractor is to supply suitable equipment of all manner required to prepare specified<br />

surfaces for application of lining system and apply same.<br />

1.3. Insure that all Product Data Sheets and Material Safety Data Sheets are the current versions.<br />

1.4. Operations shall comply to all company, state, local and federal safety codes and regulations.<br />

1.5. Materials shall be delivered to the jobsite in the manufacturer's original unopened containers. The<br />

containers shall include the following information on the label: supplier, name or number of the<br />

material, manufacture date or batch code. All materials shall be carefully handled and stored to<br />

prevent inclusion of foreign materials or exposure to temperatures below 55°F or exceeding 90°F.<br />

Components outdated as indicated by shelf life shall not be used.<br />

1.6. Applicator training is required and spray equipment must be approved by <strong>ITW</strong> <strong>Futura</strong> <strong>Coatings</strong><br />

prior to the application of any coating materials.<br />

2.0 JOB CONDITIONS AND SAFETY REQUIREMENTS.<br />

2.1. Conditions which may be detrimental to start up, completion or performance of the specified work<br />

shall be reported in writing to the on-site inspector, plant manager, or project engineer in charge of<br />

the program, prior to commencing work. Work shall not be started until defects are corrected or<br />

specific approval has been given in writing.<br />

2.2. All coating materials shall be stored, mixed and applied at 55-90°F material temperature.<br />

2.3. Ambient temperatures must be between 55°F and 90°F during application of coating materials.<br />

Relative humidity must be below 85%.<br />

01/08 Irathane 155 Steel

2.4. Substrate surface temperature shall be above 55°F and lower than 100°F, and must be at least<br />

5°F above the dewpoint.<br />

2.4.1. Substrate temperature must be steady or increasing.<br />

2.4.2. Avoid direct sunlight on the substrate during all phases of coating work.<br />

2.5. Adequate ventilation is to be maintained at all times in the work area. Open fires and spark<br />

producing equipment shall not be used in or near work areas during the application of all coating<br />

materials.<br />

2.6. Post "No Smoking", “Fire Hazard” and other warning signs as required in work areas during and<br />

for at least forty-eight (48) hours following the application of all coating materials.<br />

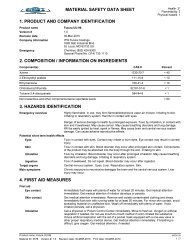

2.7. All personnel shall wear and utilize all safety equipment as recommended in the Material Safety<br />

Data Sheets when handling, mixing and applying coating materials.<br />

2.7.1. Fresh air respirators are required during the application of Irathane 155.<br />

2.8. Adequate lighting shall be provided to sufficiently light up all areas to be worked on without<br />

Inclusion of shadow areas.<br />

2.9. All coating materials should be handled in accordance with all precautions recommended in their<br />

Material Safety Data Sheets and Product Data Sheets.<br />

2.10. All cured and uncured coating materials, solvents and other chemicals shall be disposed of in<br />

accordance with all local, state and federal regulations.<br />

3.0 INSPECTION.<br />

3.1. All work including rigging of staging, lighting, ventilation, surface preparation, application and<br />

curing of the coating system shall be carried out to the satisfaction and approval of the<br />

Inspector(s) and/or Owner.<br />

3.2. Any proposed deviation from the specified procedures as contained herein, that may be deemed<br />

necessary, shall be reported in writing in accordance with Section 2.1.<br />

3.3. A daily log must be maintained by the Inspector(s) to record application conditions.<br />

3.4. A final inspection of the coating system should be performed after installation of equipment to<br />

assure a holiday free lining.<br />

3.5. Specific inspections should be performed for each stage of coating work as specified.<br />

4.0 SURFACE PREPARATION<br />

4.1. Compressed air used for all surface preparation and coating work shall be free of oil, water, or<br />

other contaminants. Oil and water filter/separators shall be installed in the air supply.<br />

4.2. All areas that are not to be coated should be properly protected prior to the commencement of<br />

surface preparation procedures.<br />

Page 2 of 9<br />

04/10 Irathane 155 Steel

4.3. Prior to abrasive blast cleaning remove all deposits of dirt, oil, grease, or other contaminants in<br />

accordance with SSPC-SP1.<br />

4.4. All immersion-service steel surfaces shall be prepared in accordance with SSPC-SP5, White<br />

Metal Blast Cleaning.<br />

4.4.1. All non-immersion areas can be prepared in accordance with SSPC-SP10, Near White Metal<br />

Blast Cleaning.<br />

4.5. All steel surfaces shall have a surface profile (anchor pattern) of 3 to 4 mils.<br />

4.5.1. Heavily corroded steel, containing grooving or pinholes, shall be opened up and sharp edges<br />

removed through the use of an appropriate mixture of non-metallic, abrasive blast media.<br />

4.5.2. The surface profile (anchor pattern) shall be verified through the use of replica tape in<br />

accordance with ASTM D4417, “Standard Test Methods for Field Measurement of Surface<br />

Profile of Blast Cleaned Steel”.<br />

4.6. All welds must be continuous. Skip or intermittent welds must be made continuous by welding.<br />

4.7. All welds must be clean and free of spatter or sharp projections.<br />

4.8. All welds must be ground to remove sharp edges, undercutting, pinholes or any other<br />

irregularities. Relative smooth, ripple finish welds are acceptable.<br />

4.9. All welds must meet NACE RP0178 Designation “C” as a minimum.<br />

4.10. All lap joints must receive a continuous fillet weld.<br />

4.11. All corners and sharp edges must be ground to a minimum 1/8” radius.<br />

4.12. All inlet and outlet ports must be welded pads or flanges, not threaded.<br />

4.13. All internal bracing or reinforcement with open ends must be capped and seal welded.<br />

4.14. Prior to coating application, all prepared surfaces shall be vacuumed or blown down with clean,<br />

dry compressed air to remove dust, grit, or abrasives.<br />

4.15. Surfaces to be coated shall be tested for soluble salts contamination. Salt contamination levels in<br />

excess of 40 micrograms per square centimeter shall be rejected, and additional cleaning with<br />

steam or fresh water to flush away the soluble salts will be required.<br />

4.16. Simultaneous coating application and abrasive blasting operations shall not be conducted where<br />

possible contamination of the coating can occur.<br />

4.17. If surface preparation is conducted in sections, no coating may be applied within six (6) inches of<br />

the temporary boundary of a cleaned area.<br />

4.18. Abrasive blasted surfaces shall be coated within eight (8) hours maximum and prior to any rust<br />

bloom occurring. No metal shall be coated that exhibits visible rust bloom.<br />

Page 3 of 9<br />

04/10 Irathane 155 Steel

5.0 APPLICATION - GENERAL<br />

5.1. <strong>Coatings</strong> shall be applied in accordance with the requirements of this specification guideline, to<br />

clean, dry surfaces during periods of favorable temperature and humidity conditions.<br />

5.1.1. Surface temperature of the substrate should be at least 5°F above the dew point and rising,<br />

before any coating work is attempted.<br />

5.1.2. No coating work shall be done at a relative humidity above 85%.<br />

5.1.3. Coating application shall be restricted to ambient temperatures in the 55 to 90°F range.<br />

5.1.4. Coating application shall be restricted to substrate temperatures in the 55 to 90°F range.<br />

5.2. Surfaces to be coated shall have the specified surface preparation at the time of coating<br />

application. If surfaces have degraded or become contaminated subsequent to surface<br />

preparation and prior to coating, they shall be restored to the specified degree before coating<br />

application.<br />

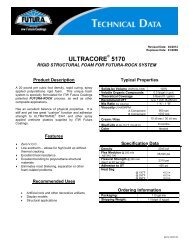

5.3. Stripe coat, using a brush, all welds, edges, corners, bolt heads, rivets. This operation shall be<br />

done before the application of the initial <strong>Futura</strong>-Bond 610HS coat.<br />

5.4. Observe recommended recoat intervals between the initial application and subsequent overcoats.<br />

6.0 PRIMER APPLICATION<br />

6.1. <strong>Futura</strong>-Bond 610HS is a two component urethane primer that can be spray or roller applied over<br />

properly prepared metal surfaces at a dry film thickness of 2 - 4 mils and should be applied to all<br />

properly prepared surfaces. All <strong>Futura</strong>-Bond 610HS primed surfaces must be inspected prior to<br />

the application of Irathane 155.<br />

6.2. Recommended application equipment: 30:1 ratio or larger airless spray unit with a minimum<br />

output of 2 ½ gallons per minute, Teflon packings and either nylon or Teflon lined material hoses.<br />

Spray tip sizes can range from 0.015 to 0.031inches.<br />

6.2.1. Purge all lines and equipment with clean Xylene or Toluene thinner prior to and after spraying<br />

Irathane 155 to prevent a build up of material inside the spray unit and material hoses. Do not<br />

use Ketones, such as MEK, MIBK or Acetone. The use of Ketones will severely affect the<br />

cure of the Irathane 155.<br />

6.3. Do not mix <strong>Futura</strong>-Bond 610HS until all surfaces are properly prepared and accepted for coating<br />

application.<br />

6.4. <strong>Futura</strong>-Bond 610HS has a one and a half (1 1/2) hour pot life at 75°F, do not mix more material<br />

than can be applied in this period of time.<br />

6.5. <strong>Futura</strong>-Bond 610HS may be thinned with acetone up to 15% by volume. N. Butyl Acetate may be<br />

added up to that allowable by local regulations.<br />

6.6. <strong>Futura</strong>-Bond 610HS should not be applied in direct sunlight.<br />

6.7. Refer to the current <strong>Futura</strong>-Bond 610HS Product Data Sheet for mixing and application<br />

instructions.<br />

Page 4 of 9<br />

04/10 Irathane 155 Steel

6.8. <strong>Futura</strong>-Bond 610HS shall be applied within eight (8) hours of the completion of abrasive blast<br />

cleaning and before any flash rusting occurs.<br />

6.9. <strong>Futura</strong>-Bond 610HS has a minimum drying time of ten (10) hours and a maximum of twenty-four<br />

(24) hours, at 75°F for application of the Irabond UU 96.<br />

6.9.1. If more than twenty-four (24) hours and less than forty-eight (48) hours drying time, at 75°F<br />

occurs with any <strong>Futura</strong>-Bond 610HS coat, an additional coat of <strong>Futura</strong>-Bond 610HS must be<br />

applied prior to the application of Irabond UU 96.<br />

6.10. All of the above recoat times are temperature sensitive. Temperatures below 70°F will lengthen<br />

the recommended recoat times while temperatures above 70°F will shorten the recommended<br />

recoat times.<br />

6.11. Uncured <strong>Futura</strong>-Bond 610HS shall be protected against damage from dust, detrimental foreign<br />

matter, and rain.<br />

6.12. Before proceeding with the coating application it is necessary to generally inspect the substrate<br />

There must be no sharp corners and all edges should be rounded. Surface tension of the coating<br />

will cause reduced thickness in these locations and acceptable coating gauge may not be<br />

obtained. Acceptable rounded edges will be approximately 0.090 inches radius or larger.<br />

7.0 ADHESIVE APPLICATION<br />

7.1. Irabond UU96 should be used with <strong>Futura</strong>-Bond 610HS or if Irathane 155 recoat has<br />

exceeded as indicated in Section 8.<br />

7.2. Irabond UU 96 is a one component adhesive system that can be spray or roller applied over<br />

<strong>Futura</strong>-Bond 610HS surfaces and should be applied at a 2-3 mil wet film thickness.<br />

7.2.1. Power mix the Irabond UU 96 to a smooth uniform consistency.<br />

7.2.2. Do not thin or cut Irabond UU 96.<br />

7.3. Irabond UU 96 must be applied to the <strong>Futura</strong>-Bond 610HS within the recoat parameters indicated<br />

in Section 6.0.<br />

7.4. The minimum recoat window for Irabond UU 96 is fifty (50) minutes and the maximum recoat<br />

window is five (5) hours at 75°F. TO AVOID ADDITIONAL WORK, DO NOT SURPASS THIS<br />

RECOAT WINDOW.<br />

7.5. If the Irabond UU 96 recoat window is surpassed, by less than twenty-four (24) hours at 75°F, an<br />

additional coat of Irabond UU 96 must be applied. If it is more than twenty-four (24) hours, the<br />

surface must be abrasive blasted back to the original surface preparation requirements in<br />

accordance with Section 4.0 and primed with <strong>Futura</strong>-Bond 610HS.<br />

Page 5 of 9<br />

04/10 Irathane 155 Steel

8.0 TOPCOAT APPLICATION<br />

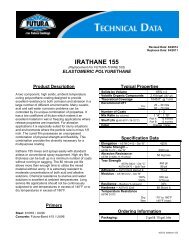

8.1. Irathane 155 is a 65% solids by volume, two (2) component (1:1 mix ratio by volume) elastomeric<br />

polyurethane coating that must be sprayed over Irabond UU 96 coated surfaces.<br />

8.2. Recommended application equipment: 30:1 ratio or larger airless spray unit with a minimum<br />

output of 2 ½ gallons per minute, Teflon packings and either nylon or Teflon lined material hoses.<br />

Spray tip sizes can range from 0.015 to 0.031inches.<br />

8.2.1. Purge all lines and equipment with clean Xylene or Toluene thinner prior to and after spraying<br />

Irathane 155 to prevent a build up of material inside the spray unit and material hoses. Do not<br />

use Ketones, such as MEK, MIBK or Acetone. The use of Ketones will severely affect the<br />

cure of the Irathane 155.<br />

8.3. Refer to the current Irathane 155 Product Data Sheet for mixing and application instructions.<br />

8.3.1. Power mix the "B" component for a minimum of three (3) minutes before combining with the<br />

"A" component in a single container.<br />

8.3.1.1. The “A” component (iso) does not require mixing.<br />

8.3.2. After combining the components, power mix for a minimum of five (5) minutes, scraping the<br />

sides and bottom of the mixing container to blend any unmixed materials, and then "box" to<br />

ensure good mixing.<br />

8.3.2.1. “Boxing” is a method of mixing Irathane products. Following the initial mix in a large<br />

mixing container, pour the mixed material back into the original “A” and “B” component<br />

pails and power mix each for a minimum of one (1) minute. Re-pour these containers<br />

back into the large mixing container and power mix for an additional two (2) minutes.<br />

8.3.2.2. Box mixing assures proper mixing and proportioning of all components as well as<br />

reduces hazardous waste since mixed and cured material can typically be disposed of<br />

as non-hazardous waste.<br />

8.3.2.3. All waste must be handled in accordance with all local, state and federal regulations.<br />

8.3.3. Only full kits of Irathane 155 should be mixed. Do not mix partial kits.<br />

8.3.4. Do not thin or cut the Irathane 155.<br />

8.4. All coating work shall be preceded by a brush-applied, “stripe coat” application to welds, seams,<br />

and edges of difficult to coat surfaces.<br />

8.5. Irathane 155 shall be applied in two (2) or more build passes, using a cross-hatch spray<br />

technique.<br />

8.5.1. The first coat of Irathane 155 shall be applied utilizing a “tack coat” or “mist coat” technique<br />

allowing a dry time of 5 – 15 minutes, followed by a multi-pass build coat of 20-40 mils wet film<br />

thickness.<br />

Page 6 of 9<br />

04/10 Irathane 155 Steel

8.5.2. The second and/or subsequent coats of Irathane 155 shall be applied utilizing the procedure<br />

shown in Section 8.5.1 but the tack coat may be omitted and the Irathane 155 applied up to<br />

20-40 mils wet film thickness per multi-pass coat.<br />

8.6. Allow a minimum recoat time between Irathane 155 applications of fifteen (15) minutes at 75°F<br />

and a maximum of eight (8) hours. The preferred recoat time is from thirty (30) minutes to four (4)<br />

hours. If the recoat time exceeds eight (8) hours, but is less than sixteen (16) hours, a coat of<br />

Irabond UU 96 must be applied over the semi-cured Irathane 155 prior to additional build coats of<br />

Irathane 155 being applied. TO AVOID ADDITIONAL WORK, DO NOT SURPASS THIS<br />

RECOAT WINDOW.<br />

8.7. If the recoat time exceeds sixteen (16) hours, the cured surface must be roughened or abraded,<br />

cleaned, and Irabond UU 96 applied prior to any additional Irathane 155 applications.<br />

8.8. Good painting practice shall be used to produce a high-quality application that has uniform dry film<br />

thickness and is free of excessive runs, sags, surface contaminants, overspray, or dry spray.<br />

8.9. Uncured Irathane 155 shall be protected against damage from dust, detrimental foreign matter,<br />

and rain.<br />

8.10. Observe all recommended minimum curing times. Curing should not be attempted below 55°F<br />

without the addition of external, supplemental heat, corresponding adjustments to lengthen curing<br />

time, or both.<br />

8.11. Cure time is also contingent upon the maintenance of sufficient ventilation in the area(s) coated to<br />

carry off solvents released during the curing process. Such ventilation, where necessary, shall be<br />

provided and maintained around the clock.<br />

9.0 REPAIR<br />

8.11.1. A Durometer hardness test shall be used to determine an acceptable level of Irathane 155<br />

cure. ASTM D2240, “Durometer Hardness”, used in conjunction with a Type "Shore A"<br />

Durometer, shall be used to determine these values. A Durometer reading of eighty (80) after<br />

two days of cure at 75°F is considered an acceptable value. The Irathane 155 system should<br />

produce a Durometer reading of ninety-two (92) after 30 days of curing at 75°F.<br />

9.1. In the event the cured Irathane 155 coating becomes damaged, or the application recoat time of<br />

the Irathane 155 exceeds sixteen (16) hours, the following procedures shall be employed:<br />

9.1.1. Thoroughly abrade or roughen the surface of the coating around the damaged area, or region<br />

to be re-coated, using air powered grinders with No.16 or 24 Carborundum pads or equal.<br />

Areas of large repairs may be abrasive blasted to obtain the desired roughness and should<br />

extend at least six (6) inches on each side.<br />

9.1.1.1. Do not abrade Irathane 155 too rapidly or too long in one spot so as to cause heat<br />

build-up and melting of the Irathane 155. A melted Irathane 155 surface will not<br />

develop adhesion with subsequent coats.<br />

9.1.2. Wipe down the abraded areas with a clean cotton cloth that has been saturated with clean<br />

Xylene.<br />

Page 7 of 9<br />

04/10 Irathane 155 Steel

9.1.3. Areas of bare metal shall receive a coat of <strong>Futura</strong>-Bond 610HS in accordance with Section<br />

6.0.<br />

9.1.4. Brush or spray apply Irabond UU 96 to primed and abraded areas only, at a wet film thickness<br />

of 2-3 Mils Allow a fifty (50) minute drying time and a maximum drying time of five (5) hours at<br />

75°F.<br />

9.1.5. Brush or spray apply Irathane 155 over the properly prepared areas to the recommended dry<br />

film thickness.<br />

9.1.6. Do not apply Irathane 155 to surfaces that have not been properly prepared or primed.<br />

9.2. The repair of small surface areas, such as those damaged during coating operations, shall be<br />

accomplished with power tools to remove all damaged coating(s), provide a surface roughness,<br />

and return exposed metal to a bright and roughened condition.<br />

9.3. Adjacent, sound areas of coating shall be feathered, tapered, or roughened by hand or power<br />

tools for a minimum overlap distance of two (2) inches in all directions.<br />

9.4. Prepared surfaces shall be re-coated in accordance with Section 5.0 and other applicable<br />

Sections.<br />

9.4.1. Irathane 155 repairs are permitted using less than the standard unit quantities provided that<br />

the Irathane 155 is mixed at a 1:1 by volume ratio of the component “A” to component “B”.<br />

10.0 INSPECTION<br />

10.1. All work and materials supplied under this specification guideline shall be subject to competent<br />

and timely inspection by the contractor or his authorized representative.<br />

10.2. The contractor shall, throughout the course of the coating work described in this specification<br />

guideline, impose a program of inspection and quality surveillance to ensure that the coating<br />

system is installed in a manner that complies with the requirements of this specification guideline<br />

and the Project/Job Specification.<br />

10.3. Mandatory inspections shall be conducted to determine compliance with the "hold points" detailed<br />

in the Project/Job Specification, and "signed off" in the areas provided.<br />

10.4. Inspections shall be conducted, a minimum of four (4) times per shift, or more frequently when<br />

coating work operations or changing environmental conditions require particular surveillance.<br />

10.5. Cured coating shall be tested for holidays (pin holes) using a high-voltage DC holiday detector or<br />

equivalent instrument adjusted and operated in accordance with ASTM D5162-91(B),<br />

Discontinuity (Holiday) Testing of Non-conductive Protective Coating on Metallic Substrates.<br />

Irathane 155 can be tested at a rate of 100 volts/mil. All holidays should be repaired in<br />

accordance with Section 9.0 of this specification guideline.<br />

10.6. Timely and daily completion of inspection documents by the inspector(s), contractor, or his<br />

designate, is highly recommended throughout the course of the job. These documents should<br />

record the following inspections: Surface preparation, surface temperature, dew point of<br />

substrate, temperature and humidity of ventilating air, batch numbers and identification of mixed<br />

coating components, wet film thickness or application rate of individual coats, dry film thickness of<br />

individual coats, recoat intervals, Location and repair of pinholes and determination of degree of<br />

cure.<br />

Page 8 of 9<br />

04/10 Irathane 155 Steel

10.7. All coating inspection instruments, inspection standards, calibration standards, and testing<br />

materials shall be in good working order, appropriate for the use intended, and where required,<br />

shall have been calibrated within twelve (12) months of their use. The owner shall have access to<br />

all required calibration certificates.<br />

10.8. Coating dry film thickness shall be determined by the use of magnetic thickness instruments used<br />

and calibrated in accordance with SSPC, Paint Application Standard PA2.<br />

10.9. Coating areas that fail to meet the minimum dry film thickness requirements of the SSPC-PA2<br />

survey method shall be repaired in accordance with the guidelines presented in Section 9.0.<br />

Page 9 of 9<br />

04/10 Irathane 155 Steel