ITW DEVCON ENGINEERED COATINGS - ITW Futura Coatings

ITW DEVCON ENGINEERED COATINGS - ITW Futura Coatings

ITW DEVCON ENGINEERED COATINGS - ITW Futura Coatings

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

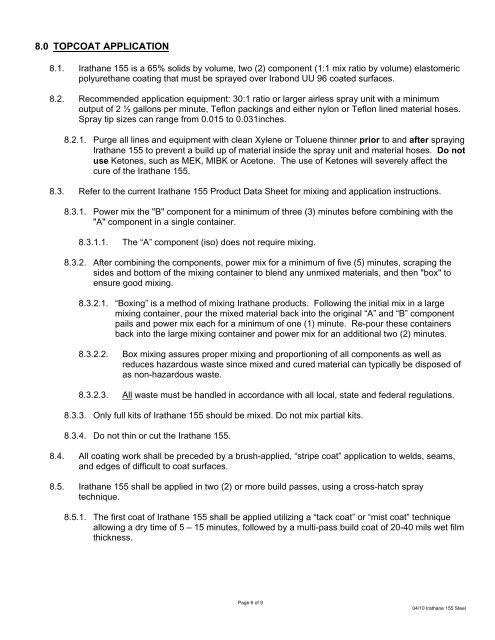

8.0 TOPCOAT APPLICATION<br />

8.1. Irathane 155 is a 65% solids by volume, two (2) component (1:1 mix ratio by volume) elastomeric<br />

polyurethane coating that must be sprayed over Irabond UU 96 coated surfaces.<br />

8.2. Recommended application equipment: 30:1 ratio or larger airless spray unit with a minimum<br />

output of 2 ½ gallons per minute, Teflon packings and either nylon or Teflon lined material hoses.<br />

Spray tip sizes can range from 0.015 to 0.031inches.<br />

8.2.1. Purge all lines and equipment with clean Xylene or Toluene thinner prior to and after spraying<br />

Irathane 155 to prevent a build up of material inside the spray unit and material hoses. Do not<br />

use Ketones, such as MEK, MIBK or Acetone. The use of Ketones will severely affect the<br />

cure of the Irathane 155.<br />

8.3. Refer to the current Irathane 155 Product Data Sheet for mixing and application instructions.<br />

8.3.1. Power mix the "B" component for a minimum of three (3) minutes before combining with the<br />

"A" component in a single container.<br />

8.3.1.1. The “A” component (iso) does not require mixing.<br />

8.3.2. After combining the components, power mix for a minimum of five (5) minutes, scraping the<br />

sides and bottom of the mixing container to blend any unmixed materials, and then "box" to<br />

ensure good mixing.<br />

8.3.2.1. “Boxing” is a method of mixing Irathane products. Following the initial mix in a large<br />

mixing container, pour the mixed material back into the original “A” and “B” component<br />

pails and power mix each for a minimum of one (1) minute. Re-pour these containers<br />

back into the large mixing container and power mix for an additional two (2) minutes.<br />

8.3.2.2. Box mixing assures proper mixing and proportioning of all components as well as<br />

reduces hazardous waste since mixed and cured material can typically be disposed of<br />

as non-hazardous waste.<br />

8.3.2.3. All waste must be handled in accordance with all local, state and federal regulations.<br />

8.3.3. Only full kits of Irathane 155 should be mixed. Do not mix partial kits.<br />

8.3.4. Do not thin or cut the Irathane 155.<br />

8.4. All coating work shall be preceded by a brush-applied, “stripe coat” application to welds, seams,<br />

and edges of difficult to coat surfaces.<br />

8.5. Irathane 155 shall be applied in two (2) or more build passes, using a cross-hatch spray<br />

technique.<br />

8.5.1. The first coat of Irathane 155 shall be applied utilizing a “tack coat” or “mist coat” technique<br />

allowing a dry time of 5 – 15 minutes, followed by a multi-pass build coat of 20-40 mils wet film<br />

thickness.<br />

Page 6 of 9<br />

04/10 Irathane 155 Steel