ITW DEVCON ENGINEERED COATINGS - ITW Futura Coatings

ITW DEVCON ENGINEERED COATINGS - ITW Futura Coatings

ITW DEVCON ENGINEERED COATINGS - ITW Futura Coatings

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6.8. <strong>Futura</strong>-Bond 610HS shall be applied within eight (8) hours of the completion of abrasive blast<br />

cleaning and before any flash rusting occurs.<br />

6.9. <strong>Futura</strong>-Bond 610HS has a minimum drying time of ten (10) hours and a maximum of twenty-four<br />

(24) hours, at 75°F for application of the Irabond UU 96.<br />

6.9.1. If more than twenty-four (24) hours and less than forty-eight (48) hours drying time, at 75°F<br />

occurs with any <strong>Futura</strong>-Bond 610HS coat, an additional coat of <strong>Futura</strong>-Bond 610HS must be<br />

applied prior to the application of Irabond UU 96.<br />

6.10. All of the above recoat times are temperature sensitive. Temperatures below 70°F will lengthen<br />

the recommended recoat times while temperatures above 70°F will shorten the recommended<br />

recoat times.<br />

6.11. Uncured <strong>Futura</strong>-Bond 610HS shall be protected against damage from dust, detrimental foreign<br />

matter, and rain.<br />

6.12. Before proceeding with the coating application it is necessary to generally inspect the substrate<br />

There must be no sharp corners and all edges should be rounded. Surface tension of the coating<br />

will cause reduced thickness in these locations and acceptable coating gauge may not be<br />

obtained. Acceptable rounded edges will be approximately 0.090 inches radius or larger.<br />

7.0 ADHESIVE APPLICATION<br />

7.1. Irabond UU96 should be used with <strong>Futura</strong>-Bond 610HS or if Irathane 155 recoat has<br />

exceeded as indicated in Section 8.<br />

7.2. Irabond UU 96 is a one component adhesive system that can be spray or roller applied over<br />

<strong>Futura</strong>-Bond 610HS surfaces and should be applied at a 2-3 mil wet film thickness.<br />

7.2.1. Power mix the Irabond UU 96 to a smooth uniform consistency.<br />

7.2.2. Do not thin or cut Irabond UU 96.<br />

7.3. Irabond UU 96 must be applied to the <strong>Futura</strong>-Bond 610HS within the recoat parameters indicated<br />

in Section 6.0.<br />

7.4. The minimum recoat window for Irabond UU 96 is fifty (50) minutes and the maximum recoat<br />

window is five (5) hours at 75°F. TO AVOID ADDITIONAL WORK, DO NOT SURPASS THIS<br />

RECOAT WINDOW.<br />

7.5. If the Irabond UU 96 recoat window is surpassed, by less than twenty-four (24) hours at 75°F, an<br />

additional coat of Irabond UU 96 must be applied. If it is more than twenty-four (24) hours, the<br />

surface must be abrasive blasted back to the original surface preparation requirements in<br />

accordance with Section 4.0 and primed with <strong>Futura</strong>-Bond 610HS.<br />

Page 5 of 9<br />

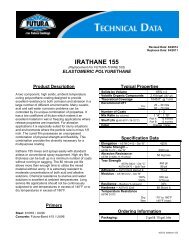

04/10 Irathane 155 Steel