ITW DEVCON ENGINEERED COATINGS - ITW Futura Coatings

ITW DEVCON ENGINEERED COATINGS - ITW Futura Coatings

ITW DEVCON ENGINEERED COATINGS - ITW Futura Coatings

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5.0 APPLICATION - GENERAL<br />

5.1. <strong>Coatings</strong> shall be applied in accordance with the requirements of this specification guideline, to<br />

clean, dry surfaces during periods of favorable temperature and humidity conditions.<br />

5.1.1. Surface temperature of the substrate should be at least 5°F above the dew point and rising,<br />

before any coating work is attempted.<br />

5.1.2. No coating work shall be done at a relative humidity above 85%.<br />

5.1.3. Coating application shall be restricted to ambient temperatures in the 55 to 90°F range.<br />

5.1.4. Coating application shall be restricted to substrate temperatures in the 55 to 90°F range.<br />

5.2. Surfaces to be coated shall have the specified surface preparation at the time of coating<br />

application. If surfaces have degraded or become contaminated subsequent to surface<br />

preparation and prior to coating, they shall be restored to the specified degree before coating<br />

application.<br />

5.3. Stripe coat, using a brush, all welds, edges, corners, bolt heads, rivets. This operation shall be<br />

done before the application of the initial <strong>Futura</strong>-Bond 610HS coat.<br />

5.4. Observe recommended recoat intervals between the initial application and subsequent overcoats.<br />

6.0 PRIMER APPLICATION<br />

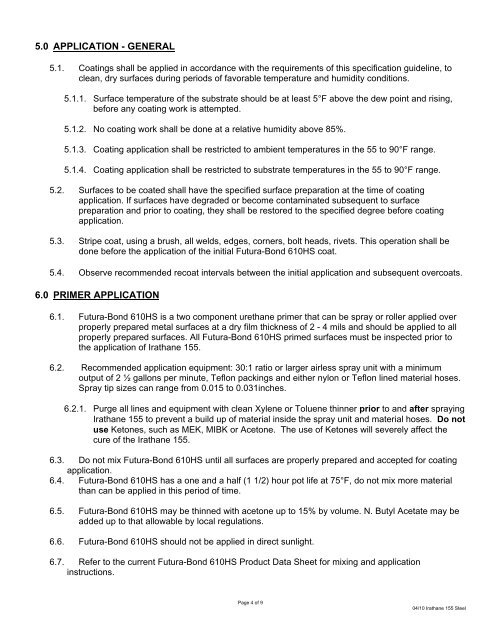

6.1. <strong>Futura</strong>-Bond 610HS is a two component urethane primer that can be spray or roller applied over<br />

properly prepared metal surfaces at a dry film thickness of 2 - 4 mils and should be applied to all<br />

properly prepared surfaces. All <strong>Futura</strong>-Bond 610HS primed surfaces must be inspected prior to<br />

the application of Irathane 155.<br />

6.2. Recommended application equipment: 30:1 ratio or larger airless spray unit with a minimum<br />

output of 2 ½ gallons per minute, Teflon packings and either nylon or Teflon lined material hoses.<br />

Spray tip sizes can range from 0.015 to 0.031inches.<br />

6.2.1. Purge all lines and equipment with clean Xylene or Toluene thinner prior to and after spraying<br />

Irathane 155 to prevent a build up of material inside the spray unit and material hoses. Do not<br />

use Ketones, such as MEK, MIBK or Acetone. The use of Ketones will severely affect the<br />

cure of the Irathane 155.<br />

6.3. Do not mix <strong>Futura</strong>-Bond 610HS until all surfaces are properly prepared and accepted for coating<br />

application.<br />

6.4. <strong>Futura</strong>-Bond 610HS has a one and a half (1 1/2) hour pot life at 75°F, do not mix more material<br />

than can be applied in this period of time.<br />

6.5. <strong>Futura</strong>-Bond 610HS may be thinned with acetone up to 15% by volume. N. Butyl Acetate may be<br />

added up to that allowable by local regulations.<br />

6.6. <strong>Futura</strong>-Bond 610HS should not be applied in direct sunlight.<br />

6.7. Refer to the current <strong>Futura</strong>-Bond 610HS Product Data Sheet for mixing and application<br />

instructions.<br />

Page 4 of 9<br />

04/10 Irathane 155 Steel