guide to specification - Reid Construction Systems

guide to specification - Reid Construction Systems

guide to specification - Reid Construction Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

S4.6 Accessories - Installation<br />

4.6.1 75mm and 90mm Timber Nails<br />

A number of 75mm and 90mm timber nails are<br />

required <strong>to</strong> provide adequate fixing between the timber<br />

floor trusses where the modules meet. These nails are<br />

required through the bot<strong>to</strong>m chords.<br />

4.6.2 Metal tek Screws<br />

Metal Tek Screws are required if specified in any fixing<br />

details.<br />

4.6.3 Coach Bolts and Screws<br />

For applications where the Flexus Floor is required<br />

<strong>to</strong> be fixed <strong>to</strong> an I-Beam, timber packers are required<br />

within the I-Beam flanges. Coach Screws and Bolts<br />

can be specified as the fixing method for the stringer<br />

on the module in<strong>to</strong> the timber packers.<br />

4.6.4 Metal Timber Connec<strong>to</strong>rs<br />

For timber <strong>to</strong> timber or concrete connections use Pryda<br />

Knuckle Nailplates, Multigrips, Sheet Brace Straps,<br />

Joist Hanger, Tim-Con Brackets, Framing Bracket,<br />

Concealed Purlin Cleats as specified.<br />

4.6.5 <strong>Reid</strong> 2FA170 Swiftlift Anchor<br />

For shear connection of Flexus Modular floor.<br />

4.6.6 Non-shrink grout<br />

Ramset Premium Grout MP for jointing modules if<br />

required.<br />

S4.7 Conditions<br />

4.7.1 Moisture Content<br />

Maximum moisture content of timber framing <strong>to</strong><br />

NZS 3602.<br />

4.7.2 Building<br />

Ensure foundations or wall frames are constructed in<br />

accordance with NZS3604.<br />

4.7.3 S<strong>to</strong>rage<br />

Timber expands in thickness and depth when allowed<br />

<strong>to</strong> get wet.<br />

To ensure the Flexus Floor Modules stay dry, straight<br />

and true at the time of installation, the following<br />

recommendations regarding s<strong>to</strong>rage are made :<br />

• Stack on evenly spaced level bearers <strong>to</strong> keep flat<br />

and straight.<br />

• Provide a surface for the materials <strong>to</strong> be placed on<br />

that is in plane.<br />

• Stack well clear of the ground for good ventilation.<br />

• S<strong>to</strong>re under cover <strong>to</strong> keep dry prior <strong>to</strong> installation.<br />

4.7.4 Handling<br />

• Handle with extreme care. Protect edges,<br />

corners, truss and surface finish from damage.<br />

• A crane or Hiab is required for the placement<br />

of modules – for example a 6mx2.4m Module<br />

weighs approx. 1.1 <strong>to</strong>nne.<br />

• Module weight = approx 82kg/m2 (based on<br />

module with overall depth of 450mm)<br />

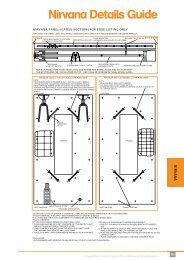

• Specially Modified <strong>Reid</strong> Swiftlift Face Lifting<br />

anchors (installed in<strong>to</strong> 30mm ECC <strong>to</strong>pping) are<br />

used with a <strong>Reid</strong> Swiftlift Lifting Clutch <strong>to</strong> safely lift<br />

the Modules.<br />

• Standard Personal Safety Equipment applicable<br />

<strong>to</strong> the activity must be worn when handling<br />

Flexus Floor modules. Refer Department<br />

of Labour Health and Safety in Employment<br />

regulations and information.<br />

4.7.5 Substrate<br />

Do not commence work until the substrate is of the<br />

standard required by the relevant manufacturer’s<br />

technical literature for the specified finish; plumb, level<br />

and in true alignment. Maximum moisture content of<br />

timber framing <strong>to</strong> NZS 3602.<br />

Fastening the modules <strong>to</strong> the framing.<br />

13