CHAPTER 5 CONCRETE PAVEMENTS - TU Delft

CHAPTER 5 CONCRETE PAVEMENTS - TU Delft

CHAPTER 5 CONCRETE PAVEMENTS - TU Delft

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

In some case gravel may be used as coarse aggregate in the concrete mix. For<br />

heavily trafficked pavements however crushed stone shall be used to improve the<br />

skid resistance. Because of the difference in costs between gravel and crushed stone<br />

in those cases the concrete pavement is sometimes constructed in two sub-layers<br />

(‘wet in wet’, i.e. by means of two slipformpavers closely behind each other), i.e. a<br />

bottom layer of gravel concrete and a 60 to 80 mm thick upper layer of stone<br />

concrete. The alternative of course is to use stone concrete over the whole concrete<br />

pavement thickness, in this case only one slipformpaver is required.<br />

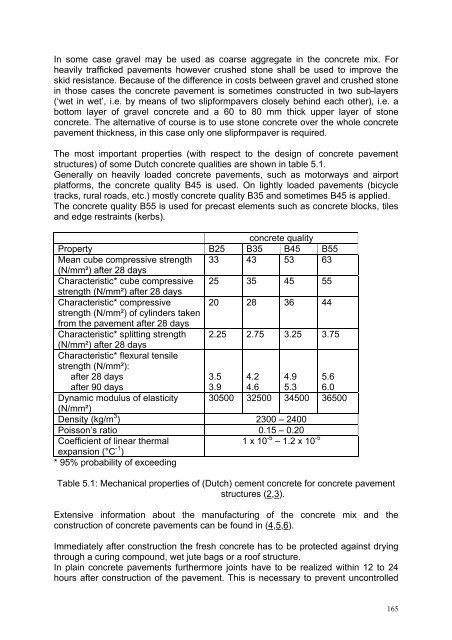

The most important properties (with respect to the design of concrete pavement<br />

structures) of some Dutch concrete qualities are shown in table 5.1.<br />

Generally on heavily loaded concrete pavements, such as motorways and airport<br />

platforms, the concrete quality B45 is used. On lightly loaded pavements (bicycle<br />

tracks, rural roads, etc.) mostly concrete quality B35 and sometimes B45 is applied.<br />

The concrete quality B55 is used for precast elements such as concrete blocks, tiles<br />

and edge restraints (kerbs).<br />

concrete quality<br />

Property B25 B35 B45 B55<br />

Mean cube compressive strength<br />

(N/mm²) after 28 days<br />

33 43 53 63<br />

Characteristic* cube compressive<br />

strength (N/mm²) after 28 days<br />

25 35 45 55<br />

Characteristic* compressive<br />

strength (N/mm²) of cylinders taken<br />

from the pavement after 28 days<br />

20 28 36 44<br />

Characteristic* splitting strength<br />

(N/mm²) after 28 days<br />

Characteristic* flexural tensile<br />

strength (N/mm²):<br />

2.25 2.75 3.25 3.75<br />

after 28 days<br />

3.5 4.2 4.9 5.6<br />

after 90 days<br />

3.9 4.6 5.3 6.0<br />

Dynamic modulus of elasticity<br />

(N/mm²)<br />

30500 32500 34500 36500<br />

Density (kg/m 3 ) 2300 – 2400<br />

Poisson’s ratio 0.15 – 0.20<br />

Coefficient of linear thermal<br />

expansion (°C -1 )<br />

1 x 10 -5 – 1.2 x 10 -5<br />

* 95% probability of exceeding<br />

Table 5.1: Mechanical properties of (Dutch) cement concrete for concrete pavement<br />

structures (2,3).<br />

Extensive information about the manufacturing of the concrete mix and the<br />

construction of concrete pavements can be found in (4,5,6).<br />

Immediately after construction the fresh concrete has to be protected against drying<br />

through a curing compound, wet jute bags or a roof structure.<br />

In plain concrete pavements furthermore joints have to be realized within 12 to 24<br />

hours after construction of the pavement. This is necessary to prevent uncontrolled<br />

165