LP Modeling - Past, Present and Future

LP Modeling - Past, Present and Future

LP Modeling - Past, Present and Future

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

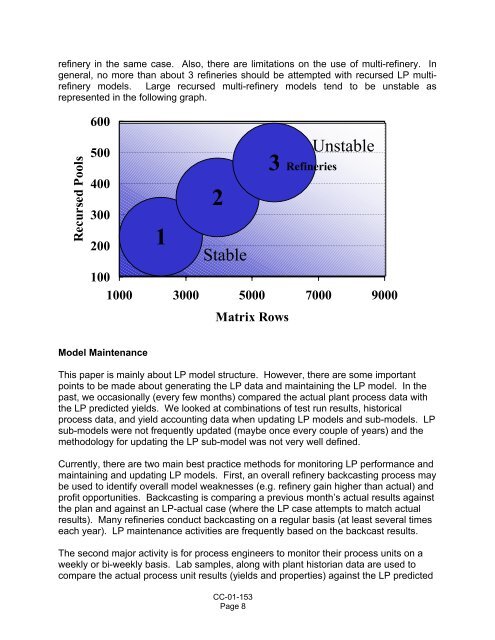

efinery in the same case. Also, there are limitations on the use of multi-refinery. In<br />

general, no more than about 3 refineries should be attempted with recursed <strong>LP</strong> multirefinery<br />

models. Large recursed multi-refinery models tend to be unstable as<br />

represented in the following graph.<br />

Recursed Pools<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

1000 3000 5000 7000 9000<br />

Model Maintenance<br />

1<br />

2<br />

Stable<br />

Matrix Rows<br />

3 Refineries<br />

Unstable<br />

This paper is mainly about <strong>LP</strong> model structure. However, there are some important<br />

points to be made about generating the <strong>LP</strong> data <strong>and</strong> maintaining the <strong>LP</strong> model. In the<br />

past, we occasionally (every few months) compared the actual plant process data with<br />

the <strong>LP</strong> predicted yields. We looked at combinations of test run results, historical<br />

process data, <strong>and</strong> yield accounting data when updating <strong>LP</strong> models <strong>and</strong> sub-models. <strong>LP</strong><br />

sub-models were not frequently updated (maybe once every couple of years) <strong>and</strong> the<br />

methodology for updating the <strong>LP</strong> sub-model was not very well defined.<br />

Currently, there are two main best practice methods for monitoring <strong>LP</strong> performance <strong>and</strong><br />

maintaining <strong>and</strong> updating <strong>LP</strong> models. First, an overall refinery backcasting process may<br />

be used to identify overall model weaknesses (e.g. refinery gain higher than actual) <strong>and</strong><br />

profit opportunities. Backcasting is comparing a previous month’s actual results against<br />

the plan <strong>and</strong> against an <strong>LP</strong>-actual case (where the <strong>LP</strong> case attempts to match actual<br />

results). Many refineries conduct backcasting on a regular basis (at least several times<br />

each year). <strong>LP</strong> maintenance activities are frequently based on the backcast results.<br />

The second major activity is for process engineers to monitor their process units on a<br />

weekly or bi-weekly basis. Lab samples, along with plant historian data are used to<br />

compare the actual process unit results (yields <strong>and</strong> properties) against the <strong>LP</strong> predicted<br />

CC-01-153<br />

Page 8