SEALING PLUGS SEALING PLUGS - TracePartsOnline.net

SEALING PLUGS SEALING PLUGS - TracePartsOnline.net

SEALING PLUGS SEALING PLUGS - TracePartsOnline.net

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

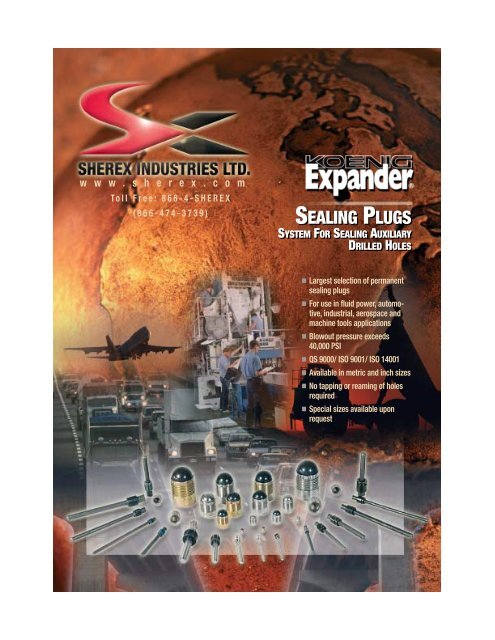

w w w . s h e r e x . c o m<br />

Toll Free: 866-4-SHEREX<br />

(866-474-3739)<br />

<strong>SEALING</strong> <strong>PLUGS</strong><br />

SYSTEM FOR <strong>SEALING</strong> AUXILIARY<br />

DRILLED HOLES<br />

■ Largest selection of permanent<br />

sealing plugs<br />

■ For use in fluid power, automotive,<br />

industrial, aerospace and<br />

machine tools applications<br />

■ Blowout pressure exceeds<br />

40,000 PSI<br />

■ QS 9000/ ISO 9001/ ISO 14001<br />

■ Available in metric and inch sizes<br />

■ No tapping or reaming of holes<br />

required<br />

■ Special sizes available upon<br />

request

© 2001 by KVT<br />

Sherex Industries Ltd.<br />

www.sherex.com<br />

Sherex Industries Ltd. has been the North American exclusive<br />

representative for Koenig Verbindungstechnik AG and the Koenig<br />

Expander Plugs since 1976. We are an award winning company<br />

who specializes in the distribution of niche Fluid Power products<br />

for both the Fluid Power and Automotive Markets. In this capacity,<br />

Sherex prides itself in the ability to act as the manufacturer here in<br />

North America. Sherex has degreed engineers on staff to assist<br />

customers in properly applying the products we sell. Visit us on<br />

the web at www.sherex.com for our other products and services.<br />

Sherex's award winning service includes:<br />

• Extensive In-House Stock ready for overnight delivery<br />

• 100% Technical Backup<br />

• JIT & Can-Ban Delivery Experience<br />

• EDI Compatible<br />

• Bar Coding<br />

• Returnable Packaging System Experience<br />

• QS 9000 & ISO 9000 Compliant<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

© 2001 by KVT<br />

SHEREX INDUSTRIES PRESENTS:<br />

KOENIG-Expander Sealing Plugs<br />

Leakproof Sealing<br />

of Auxiliary Drilled Holes<br />

Overview<br />

MB Series Plugs<br />

SK Series Plugs<br />

HK Series Plugs<br />

LK Series Plugs<br />

LP Series Plugs<br />

Technical Information<br />

i •<br />

T<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

I

Tension-Pressure Test Equipment:<br />

For verification of mechanical properties of<br />

raw materials and component parts as well<br />

as functional characteristics of Expanders.<br />

▲<br />

Roughness Measuring:<br />

For functional testing and tests<br />

where accurate hole roughness<br />

of base material is needed.<br />

II<br />

▲<br />

Production-Line<br />

KOENIG-Expander:<br />

The automated assembly<br />

equipment and outside<br />

diameter checking equipment<br />

is in the background.<br />

In the forefront is eddy<br />

current testing equipment<br />

for 100% comparison<br />

measurement of important<br />

characteristics of Expanders.<br />

▲<br />

▲ Pressure Testing Facility:<br />

Static burst pressure unit (left) heating/cooling<br />

chamber (right) for extended life cycle testing.

KOENIG-Expander Sealing Plugs<br />

System For Sealing Auxiliary Drilled Holes<br />

Unique sealing and tightening system for holes<br />

i<br />

The KOENIG Expander is a system to seal holes with absolute integrity in various components in the Mobile and Industrial<br />

Fluid Power Markets, as well as the Automotive Market. Compared to earlier methods, such as threaded<br />

plugs with or without sealing software, press-in pins, welding, etc., the KOENIG Expander distinguishes itself by its<br />

fast and reliable installation while incorporating reasonable installation tolerances. Thanks to the continuous<br />

expansion of our product offering along with the capability to custom design sealing components to customer<br />

specifications, Sherex offers a leak-tight sealing solution for every application.<br />

As designed, the KOENING Expander plug pressure<br />

ratings incorporate a minimum Factor of Safety to<br />

accommodate for pressure spikes and cyclic<br />

pressure loading. As a result of this reliable and leaktight<br />

sealing system, the expanders have found<br />

broad application on components such as: hydraulic<br />

and pneumatic control valves and manifolds,<br />

hydraulic pumps and motors, power transmission<br />

components, brake components, engine components,<br />

etc.<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

III

Applications<br />

KOENIG Expanders are used extensively in hydraulic and pneumatic components, for example:<br />

• Control and regulator valves<br />

• Pumps<br />

• Connecting and distribution manifolds<br />

• Power units<br />

• Cylinders<br />

• Hydraulic transmissions<br />

• etc.<br />

IV<br />

i<br />

The engineered process makes possible a quick and safe sealing of bores and channels. KOENIG EXPANDER has<br />

established a name world-wide in a variety of industries.<br />

Machine tools and other custom equipment<br />

• Clamping devices<br />

• Cooling and lubricating systems<br />

• Molds for injection molding machines<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Applications<br />

Mobile hydraulics/materials<br />

handling equipment<br />

• Control and drive units<br />

• Lifts and platforms<br />

• Elevators<br />

• Construction equipment<br />

• Fork lifts<br />

Transportation<br />

• ABS brake systems<br />

• Power steering<br />

• Vehicular dynamic control<br />

systems<br />

• Automatic door openers<br />

• Railroad brake systems<br />

Aircraft Industry<br />

• Control gear<br />

• Landing gear<br />

• Flight simulators<br />

Werksfoto Knorr-Bremse AG<br />

i<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

V

System for Sealing Auxiliary Drilled Holes<br />

VI<br />

i<br />

MB Series<br />

Expansion and anchorage of sleeve in hole<br />

wall is achieved by pressing the ball into the<br />

sleeve. The MB Series plug is designed for<br />

use in base materials from low to high<br />

hardness.<br />

SK Series<br />

Pull/Expand principle. The installation tool<br />

maintains sleeve position in the hole while<br />

pulling the mandrel into and expanding the<br />

sleeve until the mandrel breaks off at a<br />

predetermined point. Anchorage is achieved<br />

by the serrations on the outside of the sleeve<br />

anchoring into the base material, especially in<br />

soft material.<br />

HK Series<br />

This installation is also based on the<br />

Pull/Expand principle. Thanks to the soft<br />

sleeve material, anchorage is achieved by the<br />

flow of sleeve material into the surface<br />

roughness of the drilled hole. The HK Series<br />

plug is especially suitable for use in hard<br />

materials.<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

System for Sealing Auxiliary Drilled Holes<br />

LK Series<br />

Available in both steel and stainless steel,this<br />

plug has been designed for applications in the<br />

low pressure range. It has an anchorage<br />

principle similar to the SK Series plugs.<br />

LP Series<br />

This low pressure sealing plug is installed by<br />

pressing the plug into a tapered hole. The<br />

surface-hardened but flexible plug achieves<br />

anchorage by gripping the hole wall.<br />

i<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

VII

VIII<br />

NOTES<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

MB Series<br />

• Quantities in stock from 3 to 22 mm<br />

diameter, also available in inch<br />

versions<br />

• Corrosion resistant construction<br />

• Normal working tolerances<br />

0/+ 0.1mm<br />

• Simple, quick installation<br />

• Complete mechanical sealing<br />

through anchoring in base material<br />

Contents Page<br />

– MB 600 2<br />

– MB 600, Inch-Version 3<br />

– MB 700 4<br />

– MB 800 5<br />

– Installation instructions 6<br />

– Setting Tools 8<br />

– Automated Production Tools 9

MB 600 Series Sealing Plugs<br />

Sleeve: Stainless Steel<br />

DIN 1.4305, AISI 303<br />

Sleeve and Ball clear passivated per MIL S 5002<br />

Aerospace Quality<br />

Dimensions in MM<br />

2<br />

d 1<br />

l 1<br />

l2 ~<br />

d2 + 0.1<br />

0<br />

d 3<br />

max.<br />

l 3<br />

min.<br />

Ball: Stainless Steel<br />

DIN 1.4301, AISI 304<br />

x<br />

± 0.2<br />

3.0 3.6 4.6 3.0 2.2 3.4 0.4 MB 600-030 1000<br />

4.0 4.0 5.2 4.0 3.3 3.8 0.2 MB 600-040 1000<br />

5.0 5.5 7.0 5.0 4.3 5.3 0.4 MB 600-050 1000<br />

6.0 6.5 8.6 6.0 5.3 6.3 0.4 MB 600-060 500<br />

7.0 7.5 10.1 7.0 6.4 7.3 0.4 MB 600-070 250<br />

8.0 8.5 11.7 8.0 7.4 8.3 0.3 MB 600-080 250<br />

9.0 10.0 13.7 9.0 8.4 9.8 0.4 MB 600-090 250<br />

10.0 11.0 15.2 10.0 9.4 10.8 0.4 MB 600-100 250<br />

12.0 13.0 18.0 12.0 10.6 12.8 0.4 MB 600-120 100<br />

14.0 15.0 20.8 14.0 12.7 14.5 0.4 MB 600-140 100<br />

Type<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

MB 600 Series Inch-Version Sealing Plugs<br />

Sleeve: Stainless Steel<br />

DIN 1.4305, AISI 303<br />

Sleeve and ball clear passivated to MIL S 5002<br />

Aerospace Quality<br />

Dimension in Inches<br />

d 1<br />

l 1<br />

l2 ~<br />

d 2<br />

d 3<br />

max.<br />

Ball: Stainless Steel<br />

DIN 1.4034, AISI 420 (.093" Dia.)<br />

DIN 1.4301, AISI 304 (.125"-.281" Dia.)<br />

.093 ( 3 / 32") .100 .120 .0937 .062 .095 MB 600-093 A 1000<br />

.125 ( 1 / 8") .138 .170 .1250 .093 .125 MB 600-125 A 1000<br />

.156 ( 5 / 32") .150 .195 .1562 .125 .130 MB 600-156 A 1000<br />

.187 ( 3 / 16") .193 .260 .1875 .156 .152 MB 600-187 A 500<br />

.218 ( 7 / 32") .225 .300 .2187 .187 .187 MB 600-218 A 500<br />

.250 ( 1 / 4") .260 .350 .2500 .218 .212 MB 600-250 A 500<br />

.281 ( 9 + .002<br />

0<br />

+ .004<br />

0<br />

+ .004<br />

0<br />

.0<br />

+ .004<br />

to max.<br />

0<br />

.012<br />

+ .004<br />

0<br />

+ .004<br />

0<br />

/ + .004<br />

32") .285 .380 .2812 .250 .250 MB 600-281 A 500<br />

0<br />

l 3<br />

min.<br />

x<br />

Type<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

3

MB 700 Series Sealing Plugs<br />

Sleeve: Stainless Steel<br />

DIN 1.4305, AISI 303<br />

Dimensions in MM<br />

4<br />

d 1<br />

l 1<br />

l2 ~<br />

d2 + 0.1<br />

0<br />

d 3<br />

max.<br />

l 3<br />

min.<br />

Ball: Bearing Steel<br />

Heat Treated<br />

3.0 3.6 4.6 3.0 2.2 3.4 0.4 MB 700-030 1000<br />

4.0 4.0 5.2 4.0 3.3 3.8 0.2 MB 700-040 1000 / 5000<br />

5.0 5.5 7.0 5.0 4.3 5.3 0.4 MB 700-050 1000<br />

6.0 6.5 8.6 6.0 5.3 6.3 0.4 MB 700-060 1000 / 2000<br />

7.0 7.5 10.1 7.0 6.4 7.3 0.4 MB 700-070 1000<br />

8.0 8.5 11.7 8.0 7.4 8.3 0.3 MB 700-080 500<br />

9.0 10.0 13.7 9.0 8.4 9.8 0.4 MB 700-090 500<br />

10.0 11.0 15.2 10.0 9.4 10.8 0.4 MB 700-100 500<br />

12.0 13.0 18.0 12.0 10.6 12.8 0.4 MB 700-120 250<br />

14.0 15.0 20.8 14.0 12.7 14.5 0.4 MB 700-140 250<br />

16.0 17.0 23.7 16.0 14.7 16,5 0.6 MB 700-160 100<br />

18.0 19.0 26.3 18.0 16.7 18.5 0.6 MB 700-180 100<br />

20.0 22.0 30.5 20.0 18.7 21.5 0.8 MB 700-200 100<br />

22.0 25.0 34.2 22.0 20.7 24.5 0.8 MB 700-220 50<br />

x<br />

± 0.2<br />

Type<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

MB 800 Series Sealing Plugs<br />

Sleeve: Case Hardening Steel<br />

DIN 1.0403, AISI 10L15<br />

Zinc plated chromate finish<br />

Dimensions in MM<br />

d 1<br />

l 1<br />

l2 ~<br />

d2 + 0.1<br />

0<br />

d 3<br />

max.<br />

l 3<br />

min.<br />

Ball: Bearing Steel<br />

Heat Treated<br />

3.0 3.6 4.6 3.0 2.2 3.4 0.4 MB 800-030 1000<br />

4.0 4.0 5.2 4.0 3.3 3.8 0.2 MB 800-040 1000 / 5000<br />

5.0 5.5 7.1 5.0 4.3 5.3 0.4 MB 800-050 1000 / 2500<br />

6.0 6.5 8.7 6.0 5.3 6.3 0.4 MB 800-060 500 / 2000<br />

7.0 7.5 10.2 7.0 6.4 7.3 0.4 MB 800-070 1000<br />

8.0 8,5 11.6 8.0 7.4 8.3 0.3 MB 800-080 500<br />

9.0 10.0 13.6 9.0 8.4 9.8 0.4 MB 800-090 500<br />

10.0 11.0 15.2 10.0 9.4 10.8 0.4 MB 800-100 500<br />

12.0 13.0 17.9 12.0 10.6 12.8 0.4 MB 800-120 250<br />

14.0 15.0 20.6 14.0 12.7 14.5 0.4 MB 800-140 250<br />

16.0 17.0 23.4 16.0 14.7 16.5 0.6 MB 800-160 100<br />

18.0 19.0 26.4 18.0 16.7 18.5 0.6 MB 800-180 100<br />

20.0 22.0 30.1 20.0 18.7 21.5 0.8 MB 800-200 100<br />

22.0 25.0 34.0 22.0 20.7 24.5 0.8 MB 800-220 50<br />

x<br />

± 0.2<br />

Type<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

5

Installation Instruction for MB Series<br />

Drilled Hole<br />

• The drilled hole must be within the tolerances shown on the preceding dimensional sheets.<br />

• The counterbored hole (d 2 ) must be properly sized for the through hole (d 3 ) according to the dimensional sheets.<br />

• Holes must be round within 0.05 mm.<br />

• With hard materials the bore roughness should be from R z = 10 - 30 µm for best results.<br />

• Longitudinal rifles and spiral grooves should be avoided. These influence the sealing effectiveness.<br />

• The bore must be free of oil, grease and chips.<br />

Installation Chart<br />

6<br />

F<br />

Fig. 1<br />

Fig. 2<br />

Fig. 3<br />

d1 [in]<br />

.093 .125 .156 .187 .218 .250 .281<br />

S [in] Stroke .031 .047 .059 .079 .094 .109 .118<br />

X [in]<br />

MB 600 Series Inch-Version<br />

Position of top of ball<br />

relative to top of sleeve<br />

Flush to .012 below<br />

the sleeve<br />

Setting Procedure<br />

• With the ball facing out the KOENIG-Expander is<br />

inserted in the counterbored hole. The top sleeve<br />

should not be above the surface of the base material.<br />

(Fig. 1)<br />

• With only a slight or no counterbore, the base of the<br />

sleeve must be adequately supported during<br />

installation.<br />

• The ball can now be pressed in until the top of the<br />

ball is below the edge of the sleeve. (Fig. 2 and 3)<br />

Corresponding approximate values for stroke S as<br />

well as the dimensions X are from the Table below.<br />

• Note: Use the proper size setting tool for the<br />

KOENIG-Expander according to the Data Sheet.<br />

Press<br />

Small quantities or single parts can be installed with a<br />

hammer and setting tool. Installation can also be done<br />

with an arbor press. It is preferred to limit travel when<br />

using a press because insertion force is difficult to control.<br />

KOENIG-Expanders are also ideal for automated installation<br />

because they are problem free.<br />

d1 [mm]<br />

3 4 5 6 7 8 9 10 12 14 16 18 20 22<br />

S [mm] Stroke 1.2 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.5 6.35 7.0 8.0 9.0 10.0<br />

X [mm]<br />

±0.2<br />

Position of top of ball<br />

relative to top of sleeve<br />

MB 600 / MB 700 / MB 800<br />

0.4 0.2 0.4 0.4 0.4 0.3 0.4 0.4 0.4 0.4 0.6 0.6 0.8 0.8<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Installation Instructions MB Series<br />

Setting Force<br />

MB 600/700 MB 800 MB 600 Inch-Version<br />

d 1 d 1 d 1<br />

Note: 1 kN = 224.8 lbf<br />

Measured in steel with a tensile strength of 1,000 N/mm 2 (145 ksi) . When installing in material with less strength<br />

the values are less.<br />

a) Force with minimum bore diameter tolerance.<br />

b) Force with maximum bore diameter tolerance.<br />

Plug Removal<br />

With KOENIG-Expander MB Series removal of the plug is possible. The plug can be drilled out with a carbide tipped<br />

drill or with a high speed steel drill.<br />

MB 600-030 to 140, Ball HB ~200: High Speed Steel Drill<br />

MB 600-093 A, Ball HRC ~ 55: Carbide Tipped Drill<br />

MB 600-125 A to 281 A, Ball HB ~200: High Speed Steel Drill<br />

MB 700-030 to 220, Ball HRC ~ 45: Carbide Tipped Drill<br />

MB 800-030 to 220, Ball HRC ~ 45: Carbide Tipped Drill<br />

Procedure<br />

• To Expander Diameter 6 mm or .250 inch.<br />

Drill out, in one process, to the next larger diameter according to the Data Sheet.<br />

• Expander-Diameters over 6 mm or .250 inch:<br />

Drill out in several steps with last step to the next larger diameter according to the Data Sheet.<br />

• Clear chips, remnants of the sleeve, and oil and grease from the bore.<br />

• Install a new KOENIG-Expander.<br />

Note: After plug removal always use the next larger diameter Expander.<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

7

Setting Tools –MB Series<br />

Tools: Tool Steel<br />

Heat Treated Hardness ~ HRC 50<br />

8<br />

TOOLS<br />

d1 d3 - h9<br />

d2 l2 x<br />

Type<br />

l 1<br />

3.0 10 100 2.8 10 0.4 HT MB 030<br />

4.0 10 100 3.8 10 0.2 HT MB 040<br />

5.0 10 100 4.8 12 0.4 HT MB 050<br />

6.0 10 100 5.8 15 0.4 HT MB 060<br />

7.0 10 100 6.8 18 0.4 HT MB 070<br />

8.0 10 100 7.8 20 0.3 HT MB 080<br />

9.0 14 100 8.8 22 0.4 HT MB 090<br />

10.0 14 100 9.8 25 0.4 HT MB 100<br />

12.0 14 150 11.7 30 0.4 HT MB 120<br />

14.0 20 150 13.7 35 0.4 HT MB 140<br />

16.0 20 150 15.7 40 0.6 HT MB 160<br />

18.0 20 150 17.7 45 0.6 HT MB 180<br />

20.0 25 150 19.7 50 0.8 HT MB 200<br />

22.0 25 150 21.7 55 0.8 HT MB 220<br />

d 1<br />

d 3<br />

0<br />

–.002<br />

MB 600 / MB 700 / MB 800 (Dimensions in MM)<br />

MB 600 Inch-Version (Dimensions in Inches)<br />

.093 ( 3/32") .394 3.94 .082 .137 .012 HT MB 093 A<br />

.125 ( 1/8") .394 3.94 .117 .137 .012 HT MB 125 A<br />

.156 ( 5/32") .394 3.94 .148 .137 .012 HT MB 156 A<br />

.187 ( 3/16") .394 3.94 .180 .137 .012 HT MB 187 A<br />

.218 ( 7/32") .394 3.94 .211 .400 .012 HT MB 218 A<br />

.250 ( 1/4") .394 3.94 .242 .400 .012 HT MB 250 A<br />

.281 ( 9/32") .394 3.94 .273 .400 .012 HT MB 281 A<br />

± 0.2<br />

l 1 d 2 l 2 x<br />

0<br />

–.012<br />

Type<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Assembly Press–MB Series–Pressure and Stroke Control<br />

Type PH-450<br />

Type PH-550<br />

Technical Data PH-450<br />

AUTOMATION<br />

Hydropneumatic Table Press for the installation of MB<br />

and LP Series Koenig Sealing Plugs. Stroke control of<br />

press allows for consistent, repeatable installations to<br />

meet quality system performance goals. On-board<br />

monitoring of installation force with graph printing<br />

capabilities as well as computer data output.<br />

Further Equipment Styles: PH-400 / PH-500<br />

Table Press with stroke control but without<br />

installation force monitoring, graph printing capabilities,<br />

and data output.<br />

Dimensions Width 250 mm<br />

Width (control unit) 470 mm<br />

Height 1,190 mm<br />

Depth 750 mm<br />

Diameter Range 3 –7 mm (.093–.281 in.)<br />

Air Pressure 6 bar<br />

Air Consumption 5.3 L / Stroke<br />

Pressing Force 28 kN<br />

Power Stroke 3 mm<br />

Cylinder Ram ~ 60 mm<br />

Technical Data PH-550<br />

Dimensions Width 250 mm<br />

Width (control unit) 470 mm<br />

Height 1,190 mm<br />

Depth 750 mm<br />

Diameter Range 3 – 14 mm<br />

Air Pressure 6 bar<br />

Air Consumption 16 L / Stroke<br />

Pressing Force 40 kN<br />

Power Stroke max. 16 mm<br />

Cylinder Ram ~ 60 mm<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

9

10<br />

NOTES<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Sidex-SK Series<br />

• 4-10 mm diameter,<br />

Extended mandrels for below<br />

surface installation<br />

•Working pressure to 500 Bar<br />

(7,250 psi)<br />

• Shorter Installed Length<br />

• Larger working tolerances<br />

0/+0.12 mm<br />

• Installs directly into drilled holes<br />

• Clean mechanical sealing through<br />

positive anchoring<br />

• Quick installation using handy rivet<br />

type tools<br />

Contents Page<br />

– Sidex-SK Series 12<br />

– Installation Instructions 13<br />

– Spacers 14<br />

– Setting Tools 15

Sidex-SK Series<br />

Sleeve: Case Hardening Steel<br />

DIN 1.0403 ~ AISI 10L15<br />

Gun metal–finish<br />

One Piece Construction ideal for automated<br />

high production requirements.<br />

12<br />

d 1<br />

l3<br />

d1 l1 d2 l2 l3 max.<br />

l1<br />

d 2<br />

l 2<br />

l 4<br />

max.<br />

Mandrel: Heat Treatable Steel<br />

~ DIN 1.0728<br />

Special Oil Film Lubrication<br />

Bore Diameter<br />

4.0 4.5 2.50 39 9.0 6.5 4.0 SK 550-040 1000<br />

5.0 5.5 3.00 41 10.0 7.5 5.0 SK 550-050 1000<br />

6.0 6.5 3.40 43 12.0 8.0 6.0 SK 550-060 500<br />

7.0<br />

8.0<br />

7.5<br />

8.5<br />

4.10<br />

4.20<br />

38<br />

40<br />

14.0<br />

15.0<br />

9.0<br />

10.5<br />

7.0<br />

8.0<br />

+0.12<br />

0<br />

SK 550-070<br />

SK 550-080<br />

500<br />

500<br />

9.0 9.5 4.50 43 17.0 11.0 9.0 SK 550-090 250<br />

10.0 10.5 4.75 45 19.0 12.5 10.0 SK 550-100 250<br />

Extended Mandrel Version - allows insertion of up to 30 mm deep<br />

d1 l1 d2 l2 l3 max.<br />

l 4<br />

max.<br />

Bore Diameter<br />

4.0 4.5 2.50 69 9.0 6.5 4.0 SK 552-040 1000<br />

5.0 5.5 3.00 71 10.0 7.5 5.0 SK 552-050 500<br />

6.0 6.5 3.40 73 12.0 8.0 6.0 SK 552-060 500<br />

7.0<br />

8.0<br />

7.5<br />

8.5<br />

4.10<br />

4.20<br />

68<br />

70<br />

14.0<br />

15.0<br />

9.0<br />

10.5<br />

7.0<br />

8.0<br />

+0.12<br />

0<br />

SK 552-070<br />

SK 552-080<br />

250<br />

250<br />

9.0 9.5 4.50 73 17.0 11.0 9.0 SK 552-090 100<br />

10.0 10.5 4.75 75 19.0 12.5 10.0 SK 552-100 100<br />

l4<br />

Type<br />

Type<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Installation Instructions Sidex-SK<br />

Drilled Hole<br />

• The drilled hole must be within the tolerances shown on the preceding data sheets.<br />

• Holes must be round within 0.05 mm.<br />

• With hard materials the bore roughness should be from R z = 10 - 30 µm for best results.<br />

• Longitudinal rifles and spiral grooves should be avoided. These influence the sealing effectiveness.<br />

• The bore must be free of oil, grease and chips.<br />

Setting Procedure<br />

Fig. 1<br />

Fig. 2<br />

Fig. 3<br />

1. Insert the plug in the tool, making sure that the<br />

sleeve is against the nosepiece. (Fig. 1)<br />

2. After inserting the plug into the hole (making sure<br />

the tool is flush to the work surface) activate the tool<br />

to expand the plug. The mandrel will break apart<br />

when the proper tension has been reached.<br />

(Fig. 2 & 3)<br />

Note<br />

• The assembly of KOENIG-Expanders should only be<br />

done in a clean working area.<br />

• The sleeve and mandrel of the plug should not be<br />

cleaned or lubricated.<br />

Tools<br />

For trouble free installation of KOENIG-Expanders use the tools and appropriate components according to the data<br />

sheet.<br />

Plug Removal<br />

With KOENIG-Expander Sidex-SK Series plug removal is possible.<br />

Procedure:<br />

1. Drive the mandrel from the sleeve with a punch.<br />

2. Drill out the sleeve and remove the mandrel.<br />

3. Bore the hole to the next larger Expander diameter per the data sheet.<br />

4. Clear chips, remnants of the sleeve, and oil and grease from the bore.<br />

5. Install a new KOENIG-Expander.<br />

Note: After plug removal always install the next larger size plug.<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

13

Spacers, Sidex Series<br />

Case Hardening Steel<br />

DIN 1.0403, ~AISI 10L15<br />

Case Hardened<br />

For setting KOENIG-Expander Sidex SK<br />

plugs with 30 mm longer mandrels<br />

14<br />

Dimensions in MM<br />

d1 d2 Type<br />

Sidex SK Series<br />

4.0 2.7 4X30-SK SK 552-040<br />

5.0 3.2 5X30-SK SK 552-050<br />

6.0 3.7 6X30-SK SK 552-060<br />

7.0 4.6 7X30-SK SK 552-070<br />

8.0 4.8 8X30-SK SK 552-080<br />

9.0 5.2 9X30-SK SK 552-090<br />

10.0 5.6 10X30-SK SK 552-100<br />

TOOLS<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Setting Tools–SK Series<br />

TOOLS<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

15

Setting Tools–Sidex-SK Series<br />

Type KW-010 (shown)<br />

Hydraulic/Pneumatic Tool<br />

Type KW-010 MCS available.<br />

Features a vacuum mandrel collection system.<br />

Air Pressure max. 6.5 bar (95 psi)<br />

Air Consumption per Expander 1 dm 3 (61 in3 )<br />

Weight 2.1 kg (4.6 lb.)<br />

16<br />

4 SKW-104<br />

Type KW-020<br />

Hydraulic/Pneumatic Tool<br />

Air pressure max. 6.5 bar (95 psi)<br />

Weight 2.2 kg (4.9 lb.)<br />

d1 Nosepiece Jaw Case Jaws Jaw Pusher<br />

Tool<br />

TOOLS<br />

Type Type Type Type Type Type<br />

5 SKW-105 PRG740-11AE PRG540-46E<br />

6 SKW-106 PRG740-7A<br />

7 SKW--107<br />

8 SKW-108<br />

HKW-010308 HKW-014208 HKW-010508<br />

9 SKW-109 –<br />

10* SKW-110<br />

* For installation of d 1 =10 mm diameter plugs, the mandrel<br />

collection system must be turned off.<br />

PRG-14<br />

KW-010 KW-020<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

HK Series<br />

• Extensive available stock from<br />

3-12 mm diameter, special<br />

oversize version and extended<br />

mandrels for below surface<br />

installation<br />

• Normal working tolerances 0/+0.1<br />

mm or 0/+0.05 mm<br />

• Direct installation in Hydraulic<br />

Component through holes<br />

• Clean, mechanical sealing<br />

• Quick installation using hand rivet<br />

type tools<br />

Contents Page<br />

– HK 55 Series 18<br />

– Installation Instructions 20<br />

– Spacers 21<br />

– Setting Tools 22

HK 55 Series<br />

Sleeve: Case Hardening Steel<br />

DIN 1.0403, ~AISI 10L15<br />

Soft Annealed Gun Metal Finish<br />

Dimensions in MM<br />

18<br />

d1 l1 d2 l2 l3 max.<br />

l 4<br />

max.<br />

Bore Diameter<br />

Mandrel: Heat Treatable Steel<br />

~DIN 1.0728<br />

Special Oil Film Lubrication<br />

3.0 5.0 2.0 36.5 9.0 7.0 3.0 HK030-CK55-111 100<br />

4.0 5.0 2.2 38.0 9.5 8.0 4.0 HK040-CK55-111 100/1000<br />

5.0 6.0 2.8 43.0 11.0 9.5 5.0 HK050-CK55-111 100/1000<br />

6.0 6.5 2.8 43.0 12.0 10.0 6.0 HK060-CK55-111 100/1000<br />

7.0<br />

8.0<br />

7.5<br />

8.5<br />

3.8<br />

4.5<br />

43.0<br />

38.0<br />

13.0<br />

13.5<br />

11.0<br />

11.5<br />

7.0<br />

8.0<br />

+ 0.1<br />

0<br />

HK070-CK55-111<br />

HK080-CK55-111<br />

Standard<br />

100/500<br />

100/500<br />

9.0 9.5 4.5 41.0 14.5 13.0 9.0 HK090-CK55-111 100/500<br />

10.0 10.5 4.5 41.0 15.5 13.5 10.0 HK100-CK55-111 100/250<br />

4.3 5.0 2.2 38.0 9.5 8.0 4.3 HK043-CK55-111 Oversize<br />

5.3 6.0 2.8 43.0 11.0 9.5 5.3 HK053-CK55-111 Version<br />

6.3 6.5 2.8 43.0 12.0 10.0 6.3 HK063-CK55-111<br />

7.3<br />

8.3<br />

9.3<br />

7.5<br />

8.5<br />

9.5<br />

3.8<br />

4.5<br />

4.5<br />

43.0<br />

38.0<br />

41.0<br />

13.0<br />

13.5<br />

14.5<br />

11.0<br />

11.5<br />

13.0<br />

7.3<br />

8.3<br />

9.3<br />

+ 0.1<br />

0<br />

HK073-CK55-111<br />

HK083-CK55-111<br />

HK093-CK55-111<br />

100<br />

10.3 10.5 4.5 41.0 15.5 13.5 10.3 HK103-CK55-111<br />

HK 11 Series<br />

Sleeve: Aluminum Alloy<br />

DIN 3.0615, AlMgSiPb<br />

Plain Finish<br />

Dimensions in MM<br />

d1 l1 d2 l2 l3 max.<br />

l 4<br />

max.<br />

Bore Diameter<br />

Type<br />

Mandrel: Heat Treatable<br />

~DIN 1.0728<br />

Special Oil Film Lubrication<br />

12.0 12.0 6.0 40.0 17.5 15 12.0 + 0.5<br />

0<br />

HK120-CK11-111 Standard 250<br />

Type<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

19

20<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

TOOLS<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

21

22<br />

HKW-002103 •<br />

HKW-002104 •<br />

HKW-002103 •<br />

HKW-002104 •<br />

HKW-002105 •<br />

TOOLS<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Setting Tools – HK Series<br />

TOOLS<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

23

Setting Tools–HK-55<br />

Type KW-010 (shown)<br />

Hydraulic/Pneumatic Tool<br />

Type KW-010 MCS available.<br />

Features a vacuum mandrel collection system.<br />

Air Pressure max. 6.5 bar (95 psi)<br />

Air Consumption per Expander 1 dm3 (61 in3 )<br />

Weight 2.1 kg (4.6 lb.)<br />

24<br />

Type KW-020<br />

Hydraulic/Pneumatic Tool<br />

Air pressure max. 6.5 bar (95 psi)<br />

Weight 2.2 kg (4.9 lb.)<br />

TOOLS<br />

KW-010 KW-020<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Setting Tools–HK-11<br />

Type KW-010 (shown)<br />

Hydraulic/Pneumatic Tool<br />

Type KW-010 MSC available.<br />

Features a vacuum mandrel collection system.<br />

Air Pressure max. 6.5 bar (95 psi)<br />

Air Consumption per Expander 1 dm 3 (61 in3 )<br />

Weight 2.1 kg (4.6 lb.)<br />

Type KW-020<br />

Hydraulic/Pneumatic Tool<br />

Air pressure max. 6.5 bar (95 psi)<br />

Weight 2.2 kg (4.9 lb.)<br />

TOOLS<br />

KW-010 KW-020<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

25

26<br />

NOTES<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

LK Series<br />

• 4-12 mm diameter,<br />

•Working pressure to 60 Bar<br />

(870 psi)<br />

• Shortest Installed Length<br />

• Larger working tolerances<br />

0/+0.12 mm<br />

• Installs directly into drilled holes<br />

• Clean mechanical sealing through<br />

positive anchoring<br />

• Quick installation using handy rivet<br />

type tools<br />

• No axial loading imposed on<br />

component<br />

•Available in stainless steel<br />

Contents Page<br />

– LK 600 Series 28<br />

– LK 950 Series 29<br />

– Installation Instructions 30<br />

– Setting Tools 31

LK 600 Series<br />

Sleeve: Stainless Steel<br />

DIN 1.4305, Plain Finish<br />

Special Oil Film Lubrication<br />

One Piece Construction ideal for automated<br />

high production requirements.<br />

28<br />

d1 l1 d2 l2 l3 max.<br />

l 4<br />

max.<br />

Mandrel: Stainless Steel<br />

DIN 1.4305, Plain Finish<br />

Special Oil Film Lubrication<br />

Bore Diameter<br />

4.0 3.7 2.2 36 5.5 4.0 4.0 LK-600-040 100/1000<br />

5.0 4.5 2.95 36 6.9 4.8 5.0 LK-600-050 100/1000<br />

6.0 5.0 3.4 36 7.4 5.3 6.0 LK-600-060 100/1000<br />

7.0<br />

8.0<br />

5.5<br />

6.5<br />

4.2<br />

4.3<br />

34<br />

34<br />

8.0<br />

9.8<br />

5.8<br />

6.8<br />

7.0<br />

8.0<br />

+0.12<br />

0<br />

LK-600-070<br />

LK-600-080<br />

100/500<br />

100/500<br />

9.0 6.5 4.7 34 9.8 6.8 9.0 LK-600-090 100/500<br />

10.0 6.5 5.1 36 9.8 6.8 10.0 LK-600-100 100/500<br />

12.0 7.5 5.9 36 10.8 7.8 12.0 LK-600-120 100/250<br />

Type<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

LK 950 Series<br />

Sleeve: Case Hardening Steel<br />

Soft Annealed Gun Finish<br />

One Piece Construction ideal for automated<br />

high production requirements.<br />

d1 l1 d2 l2 l3 max.<br />

l 4<br />

max.<br />

Mandrel: Steel Plain Finish<br />

Special Oil Film Lubrication<br />

Bore Diameter<br />

4.0 3.7 2.2 36 5.5 4.0 4.0 LK-950-040 100/1000<br />

5.0 4.5 2.95 36 6.9 4.8 5.0 LK-950-050 100/1000<br />

6.0 5.0 3.4 36 7.4 5.3 6.0 LK-950-060 100/1000<br />

7.0<br />

8.0<br />

5.5<br />

6.5<br />

4.2<br />

4.3<br />

34<br />

34<br />

8.0<br />

9.8<br />

5.8<br />

6.8<br />

7.0<br />

8.0<br />

+0.12<br />

0<br />

LK-950-070<br />

LK-950-080<br />

100/500<br />

100/500<br />

9.0 6.5 4.7 34 9.8 6.8 9.0 LK-950-090 100/500<br />

10.0 6.5 5.1 36 9.8 6.8 10.0 LK-950-100 100/500<br />

12.0 7.5 5.9 36 10.8 7.8 12.0 LK-950-120 100/250<br />

Type<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

29

Installation Instructions LK Series<br />

Drilled Hole<br />

• The drilled hole must be within the tolerances shown on the preceding data sheets.<br />

• Holes must be round within 0.05 mm.<br />

• With hard materials the bore roughness should be from R z = 10 - 30 µm for best results.<br />

• Longitudinal rifles and spiral grooves should be avoided. These influence the sealing effectiveness.<br />

• The bore must be free of oil, grease and chips.<br />

Setting Procedure<br />

30<br />

Fig. 1<br />

Fig. 2<br />

Fig. 3<br />

1. Insert the plug in the tool, making sure that the<br />

sleeve is against the nosepiece. (Fig. 1)<br />

2. After inserting the plug into the hole activate the tool<br />

to expand the plug. The mandrel will break apart<br />

when the proper tension has been reached.<br />

(Fig. 2 & 3)<br />

Note<br />

• The assembly of KOENIG-Expanders should only be<br />

done in a clean working area.<br />

• The sleeve and mandrel of the plug should not be<br />

cleaned or lubricated.<br />

Tools<br />

For trouble free installation of KOENIG-Expanders use the tools and appropriate components according to the data<br />

sheet.<br />

Plug Removal<br />

With KOENIG-Expander LK Series plug removal is possible.<br />

Procedure:<br />

1. Drive the mandrel from the sleeve with a punch.<br />

2. Drill out the sleeve and remove the mandrel.<br />

3. Bore the hole to the next larger Expander diameter per the data sheet.<br />

4. Clear chips, remnants of the sleeve, and oil and grease from the bore.<br />

5. Install a new KOENIG-Expander.<br />

Note: After plug removal always install the next larger size plug.<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Setting Tools–LK Series<br />

TOOLS<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

31

Setting Tools–LK Series<br />

Type KW-010 (shown)<br />

Hydraulic/Pneumatic Tool<br />

Type KW-010 MCS available.<br />

Features a vacuum mandrel collection system.<br />

Air Pressure max. 6.5 bar (95 psi)<br />

Air Consumption per Expander 1 dm 3 (61 in3 )<br />

Weight 2.1 kg (4.6 lb.)<br />

32<br />

4 LKW-104<br />

Type KW-020<br />

Hydraulic/Pneumatic Tool<br />

Air pressure max. 6.5 bar (95 psi)<br />

Weight 2.2 kg (4.9 lb.)<br />

d1 Nosepiece Jaw Case Jaws Jaw Pusher<br />

Tool<br />

TOOLS<br />

Type Type Type Type Type Type<br />

5 LKW-105 PRG740-11AE PRG540-46E<br />

6 LKW-106 PRG740-7A<br />

7 LKW--107<br />

8 LKW-108<br />

9 LKW-109<br />

HKW 010308<br />

PRG-14<br />

HKW 014208 HKW 010508<br />

10 LKW-110<br />

12 LKW-112 HKW-014210 10X30<br />

KW-010 KW-020<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

LP Series<br />

• Mechanical labyrinth sealing<br />

• Satisfactory corrosion protection<br />

• Rated pressure performances up to<br />

60 bar (870 psi)<br />

• Suitable for fully automated<br />

installation<br />

Contents Page<br />

– LP 900 Series 34<br />

– Installation Instructions 35<br />

– Setting Tools 36

LP 900 Series Sealing Plugs<br />

Material: Free Cutting Steel<br />

Nitrocarburized, Lubricated<br />

34<br />

Dimensions in MM<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Installation Instructions LP Series<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

35

Setting Tools, LP Series<br />

Tools: Tool Steel<br />

Heat Treated Hardness – HRC50<br />

36<br />

TOOLS<br />

Email: info@sherex.com Toll free: 866-4-SHEREX (866-474-3739)<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Assembly Press–LP Series–Pressure and Stroke Control<br />

Type PH-450<br />

Type PH-550<br />

Technical Data PH-450<br />

AUTOMATION<br />

Hydropneumatic Table Press for the installation of MB<br />

and LP Series Koenig Sealing Plugs. Stroke control of<br />

press allows for consistent, repeatable installations to<br />

meet quality system performance goals. On-board<br />

monitoring of installation force with graph printing capabilities<br />

as well as computer data output.<br />

Further Equipment Styles: PH-400 / PH-500<br />

Table Press with stroke control but without<br />

installation force monitoring, graph printing capabilities,<br />

and data output.<br />

Dimensions Width 250 mm<br />

Width (control unit) 470 mm<br />

Height 1,190 mm<br />

Depth 750 mm<br />

Diameter Range 3 –7 mm (.093–.281 in.)<br />

Air Pressure 6 bar<br />

Air Consumption 5.3 L / Stroke<br />

Pressing Force 28 kN<br />

Power Stroke 3 mm<br />

Cylinder Ram ~ 60 mm<br />

Technical Data PH-550<br />

Dimensions Width 250 mm<br />

Width (control unit) 470 mm<br />

Height 1,190 mm<br />

Depth 750 mm<br />

Diameter Range 3 – 14 mm<br />

Air Pressure 6 bar<br />

Air Consumption 16 L / Stroke<br />

Pressing Force 40 kN<br />

Power Stroke max. 16 mm<br />

Cylinder Ram ~ 60 mm<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

37

38<br />

NOTES<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Technical<br />

Information<br />

Engineering:<br />

Design and development<br />

with state-of-the-art<br />

CAD-Design.<br />

Profile Projector –<br />

Measuring Instrument for in-process<br />

control of production.<br />

Contents Page<br />

– Pressure Performance Tests 41<br />

– Pressure Performance<br />

MB 600 42<br />

MB 600, Inch-Version 44<br />

MB 700 46<br />

MB 800 48<br />

Sidex-SK 50<br />

HK 55 52<br />

LK 600 54<br />

LK 950 56<br />

LP 900 58<br />

– Anchorage Principle 60<br />

– Hole Roughness: Requirements 62<br />

– Design Guidelines 63<br />

– Galvanic Corrosion 67<br />

– Chart: Hardness cross reference for<br />

plain and low alloy steels 69<br />

– SI-Units of Measurement 70<br />

– American and British<br />

Units of Measurement 72

40<br />

NOTES<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

T<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

41

42<br />

T<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Pressure Performance MB 600<br />

Installation Requirements<br />

The working pressure specifications on the preceding page are obtainable under the following conditions.<br />

➀<br />

➁<br />

➂<br />

➃<br />

➎<br />

➅<br />

➐<br />

Base Material of the<br />

Installation<br />

High Strength St.<br />

ETG-100<br />

AISI 1144<br />

Free Machining Case<br />

Hard. Stl.<br />

C15 Pb<br />

DIN 1.0403<br />

Cast Iron<br />

GG-25<br />

DIN 1691<br />

Ductile Cast Iron<br />

GGG-50<br />

DIN 1693<br />

Aluminum Alloy<br />

Al Mg Si Pb<br />

DIN 3.0615<br />

AA6262<br />

Aluminum Alloy<br />

Al Cu Mg 2<br />

DIN 3.1354<br />

AA2024<br />

Cast Al Alloy<br />

G-Al Si 7 Mg<br />

3.2371<br />

AA356-T6<br />

Tensile Strength<br />

(avg.) [N/mm 2 ]<br />

Elongation (min.)<br />

[%]<br />

1000 6 865 280<br />

560 6 300 180<br />

250 – – 160<br />

500 7 320 170<br />

340 8 300 90<br />

480 8 380 120<br />

300 4 250 80<br />

• Equivalent working pressure capability can be obtained when using base materials with similar mechanical<br />

characteristics. However, the appropriate installation instructions must be followed.<br />

• Applications for other non-ferrous metals and non-metallic materials upon request.<br />

• Factors which may lower the working pressure capability are:<br />

- anchorage principle<br />

- bore roughness requirements<br />

- design guidelines<br />

Ultimate Strength<br />

(avg.) Rp 0.2 [N/mm 2 ]<br />

Hardness<br />

(min.) HB<br />

Drilled Hole<br />

Tolerance [mm] Roughness R z [µm]<br />

• Anchorage between sleeve and base material is achieved when the sleeve is a minimum of HB=30 greater than<br />

the base material. If the hardness difference is less, hole roughness of 10 to 30 µm is needed to achieve<br />

indicated working pressures.<br />

Security Range<br />

The security range (the difference between working pressure and Test B pressure) allows for uncontrollable<br />

variations. For instance, dynamic loading at 1 million cycles and a frequency of 3-4Hz has shown that burst<br />

pressure Test A and Test B pressure are reduced about 20% after this point.<br />

+ 0.1<br />

0<br />

T<br />

10 to 30<br />

anchorage<br />

in<br />

base metal<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

43

Pressure Performance MB 600, Inch-Version<br />

Sleeve Material: X 10 CrNiS 18 9 Tensile Strength Rm = 640 N/mm 2<br />

DIN 1.4305 Hardness HB = 220<br />

44<br />

p [bar]<br />

1600<br />

1400<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

.093<br />

( 3/32")<br />

➀➁➂➃➅<br />

➎➐<br />

1,400 bar (20,300 psi)<br />

1,200 bar (17,400 psi)<br />

450 bar (6,500 psi)<br />

380 bar (5,500 psi)<br />

.125<br />

( 1/8")<br />

.156<br />

( 5/32")<br />

Proof Pressure Test B<br />

Base Material<br />

.187<br />

( 3/16")<br />

➀➁➂➃➅<br />

➎➐<br />

➀➁➂➃➅<br />

➎➐<br />

.218<br />

( 7/32")<br />

Expander Diameter [in]<br />

.250<br />

( 1/4")<br />

.281<br />

( 9/32")<br />

20,000<br />

15,000<br />

10,000<br />

5,000<br />

T<br />

p [psi]<br />

Max. Allowable Working Pressure = Nominal Pressure<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Pressure Performance MB 600, Inch-Version<br />

Installation Requirements<br />

The working pressure specifications on the preceding page are obtainable under the following conditions.<br />

➀<br />

➁<br />

➂<br />

➃<br />

➎<br />

➅<br />

➐<br />

Base Material of the<br />

Installation<br />

High Strength St.<br />

ETG-100<br />

AISI 1144<br />

Free Machining Case<br />

Hard. Stl.<br />

C15 Pb<br />

DIN 1.0403<br />

Cast Iron<br />

GG-25<br />

DIN 1691<br />

Ductile Cast Iron<br />

GGG-50<br />

DIN 1693<br />

Aluminum Alloy<br />

Al Mg Si Pb<br />

DIN 3.0615<br />

AA6262<br />

Aluminum Alloy<br />

Al Cu Mg 2<br />

DIN 3.1354<br />

AA2024<br />

Cast Al Alloy<br />

G-Al Si 7 Mg<br />

3.2371<br />

AA356-T6<br />

Tensile Strength<br />

(avg.) [N/mm 2 ]<br />

Elongation (min.)<br />

[%]<br />

Ultimate Strength<br />

(avg.) Rp 0.2 [N/mm 2 ]<br />

Hardness<br />

(min.) HB<br />

1000 6 865 280<br />

560 6 300 180<br />

250 – – 160<br />

500 7 320 170<br />

340 8 300 90<br />

480 8 380 120<br />

300 4 250 80<br />

Drilled Hole<br />

T<br />

Tolerance [in.] Roughness R z [µm]<br />

ø .093<br />

from<br />

ø .125<br />

+ 0.002<br />

0<br />

+ 0.004<br />

0<br />

10 to 30<br />

anchorage<br />

in<br />

base metal<br />

• Equivalent working pressure capability can be obtained when using base materials with similar mechanical<br />

characteristics. However, the appropriate installation instructions must be followed.<br />

• Applications for other non-ferrous metals and non-metallic materials upon request.<br />

• Factors which may lower the working pressure capability are:<br />

- anchorage principle<br />

- bore roughness requirements<br />

- design guidelines<br />

• Anchorage between sleeve and base material is achieved when the sleeve is a minimum of HB=30 greater than<br />

the base material. If the hardness difference is less, hole roughness of 10 to 30 µm is needed to achieve<br />

indicated working pressures.<br />

Security Range<br />

The security range (the difference between working pressure and Test B pressure) allows for uncontrollable<br />

variations. For instance, dynamic loading at 1 million cycles and a frequency of 3-4Hz has shown that burst<br />

pressure Test A and Test B pressure are reduced about 20% after this point.<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

45

Pressure Performance MB 700<br />

Sleeve Material: Stainless Steel, AISI 303 Tensile Strength Rm = 640 N/mm 2<br />

DIN 1.4305 Hardness HB = 220<br />

p [bar]<br />

46<br />

1600<br />

1400<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

3<br />

1,400 bar (20,300 psi)<br />

1,200 bar (17,400 psi)<br />

450 bar (6,500 psi)<br />

380 bar (5,500 psi)<br />

➀➁➂➃➅<br />

➎➐<br />

4 5 6 7 8 9 10 12 14 16 18 20 22<br />

Proof Pressure Test B<br />

Base Material<br />

➎➐<br />

➀➁➂➃➅<br />

➎➐<br />

➀➁➂➃➅<br />

Expander Diameter [mm]<br />

1,150 bar (16,700 psi)<br />

900 bar (13,000 psi)<br />

350 bar (5,100 psi)<br />

280 bar (4,100 psi)<br />

T<br />

20,000<br />

15,000<br />

10,000<br />

5,000<br />

Max. Allowable Working Pressure = Nominal Pressure<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

p [psi]

Pressure Performance MB 700<br />

Installation Requirements<br />

The working pressure specifications on the preceding page are obtainable under the following conditions.<br />

➀<br />

➁<br />

➂<br />

➃<br />

➎<br />

➅<br />

➐<br />

Base Material of the<br />

Installation<br />

High Strength St.<br />

ETG-100<br />

AISI 1144<br />

Free Machining Case<br />

Hard. Stl.<br />

C15 Pb<br />

DIN 1.0403<br />

Cast Iron<br />

GG-25<br />

DIN 1691<br />

Ductile Cast Iron<br />

GGG-50<br />

DIN 1693<br />

Aluminum Alloy<br />

Al Mg Si Pb<br />

DIN 3.0615<br />

AA6262<br />

Aluminum Alloy<br />

Al Cu Mg 2<br />

DIN 3.1354<br />

AA2024<br />

Cast Al Alloy<br />

G-Al Si 7 Mg<br />

3.2371<br />

AA356-T6<br />

Tensile Strength<br />

(avg.) [N/mm 2 ]<br />

Elongation (min.)<br />

[%]<br />

1000 6 865 280<br />

560 6 300 180<br />

250 – – 160<br />

500 7 320 170<br />

340 8 300 90<br />

480 8 380 120<br />

300 4 250 80<br />

• Equivalent working pressure capability can be obtained when using base materials with similar mechanical<br />

characteristics. However, the appropriate installation instructions must be followed.<br />

• Applications for other non-ferrous metals and non-metallic materials upon request.<br />

• Factors which may lower the working pressure capability are:<br />

- anchorage principle<br />

- bore roughness requirements<br />

- design guidelines<br />

Ultimate Strength<br />

(avg.) Rp 0.2 [N/mm 2 ]<br />

Hardness<br />

(min.) HB<br />

Drilled Hole<br />

T<br />

Tolerance [mm] Roughness R z [µm]<br />

• Anchorage between sleeve and base material is achieved when the sleeve is a minimum of HB=30 greater than<br />

the base material. If the hardness difference is less, hole roughness of 10 to 30 µm is needed to achieve<br />

indicated working pressures.<br />

Security Range<br />

The security range (the difference between working pressure and Test B pressure) allows for uncontrollable<br />

variations. For instance, dynamic loading at 1 million cycles and a frequency of 3-4Hz has shown that burst<br />

pressure Test A and Test B pressure are reduced about 20% after this point.<br />

+ 0.1<br />

0<br />

10 to 30<br />

anchorage<br />

in<br />

base metal<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

47

Pressure Performance MB 800<br />

Sleeve Material: Case Hardening Steel Tensile Strength Rm = 500 N/mm 2<br />

DIN 1.0403 Hardnesss H = 180<br />

p [bar]<br />

48<br />

1600<br />

1400<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

3<br />

1,100 bar (16,000 psi)<br />

1,000 bar (14,500 psi)<br />

350 bar (5,100 psi)<br />

320 bar (4,600 psi)<br />

4 5 6 7 8 9 10 12 14 16 18 20 22<br />

➀➁➂➃➅<br />

➎➐<br />

➎➐<br />

Proof Pressure Test B<br />

Base Material<br />

➎➐<br />

➀➁➂➃➅<br />

➀➁➂➃➅<br />

Expander Diameter [mm]<br />

900 bar (13,000 psi)<br />

800 bar (11,600 psi)<br />

280 bar (4,100 psi)<br />

250 bar (3,600 psi)<br />

T<br />

20,000<br />

15,000<br />

1,000<br />

5,000<br />

Max. Allowable Working Pressure = Nominal Pressure<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

p [psi]

Pressure Performance MB 800<br />

Installation Requirements<br />

The working pressure specifications on the preceding page are obtainable under the following conditions.<br />

➀<br />

➁<br />

➂<br />

➃<br />

➎<br />

➅<br />

➐<br />

Base Material of the<br />

Installation<br />

High Strength St.<br />

ETG-100<br />

AISI 1144<br />

Free Machining<br />

CasehHard. St.<br />

C15Pb<br />

DIN 1.0403<br />

Cast Iron<br />

GG-25<br />

DIN 1691<br />

Ductile Cast Iron<br />

GGG-50<br />

DIN 1693<br />

Aluminum Alloy<br />

Al Mg Si Pb<br />

DIN 3.0615<br />

AA6262<br />

Aluminum Alloy<br />

Al Cu Mg 2<br />

DIN 3.1354<br />

AA2024<br />

Cast Al Alloy<br />

G-Al Si 7 Mg<br />

DIN 3.2371<br />

AA356-T6<br />

Tensile Strength<br />

(avg.)<br />

Rm [N/mm 2 ]<br />

Elongation (min.)<br />

[%)<br />

1000 6 865 280<br />

560 6 300 180<br />

250 – – 160<br />

500 7 320 170<br />

340 8 300 90<br />

480 8 380 120<br />

300 4 250 80<br />

• Equivalent working pressure capability can be obtained when using base materials with similar mechanical<br />

characteristics. However, the appropriate installation instructions must be followed.<br />

• Applications for other non-ferrous metals and non-metallic materials upon request.<br />

• Factors which may lower the working pressure capability are:<br />

- anchorage principle<br />

- bore roughness requirements<br />

- design guidelines<br />

Ultimate Stength<br />

(avg.)<br />

Rp 0.2 [N/mm 2 ]<br />

T<br />

Hardness<br />

Drilled Hole<br />

(min.)<br />

HB Tolerance [mm] Roughness Rz [µm]<br />

• Anchorage between sleeve and base material is achieved when the sleeve is a minimum of HB=30 greater than<br />

the base material. If the hardness difference is less, hole roughness of 10 to 30 µm is needed to achieve<br />

indicated working pressures.<br />

Security Range<br />

The security range (the difference between working pressure and Test B pressure) allows for uncontrollable<br />

variations. For instance, dynamic loading at 1 million cycles and a frequency of 3-4Hz has shown that burst<br />

pressure Test A and Test B pressure are reduced about 20% after this point.<br />

+ 0.1<br />

0<br />

10 to 30<br />

anchorage<br />

in<br />

base metal<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

49

Pressure Performance Sidex-SK<br />

Sleeve Material : Case Hardening Steel Tensile Strength Rm = 500 N/mm 2<br />

DIN 1.0403 Hardness HB = 180<br />

50<br />

➀➁➂➃➅<br />

➎➐<br />

1800<br />

1600<br />

1400<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

4<br />

1,600 bar (23,200 psi)<br />

1,400 bar (20,300 psi)<br />

500 bar (7,200 psi)<br />

450 bar (6,500 psi)<br />

Proof Pressure Test B<br />

Base Material<br />

➀➁➂➃➅<br />

➎➐<br />

➀➁➂➃➅<br />

➎➐<br />

5 6 7 8 9 10<br />

Expander Diameter [mm]<br />

25,000<br />

20,000<br />

15,000<br />

10,000<br />

5,000<br />

p [psi]<br />

T<br />

Max. Allowable Working Pressure = Nominal Pressure<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Pressure Performance Sidex-SK<br />

Installation Requirements<br />

The working pressure specifications on the preceding page are obtainable under the following conditions.<br />

➀<br />

➁<br />

➂<br />

➃<br />

➎<br />

➅<br />

➐<br />

Base Material of the<br />

Installation<br />

High Strength St.<br />

ETG-100<br />

AISI 1144<br />

Free Machining Case<br />

Hard. Stl.<br />

C15 Pb<br />

DIN 1.0403<br />

Cast Iron<br />

GG-25<br />

DIN 1691<br />

Ductile Cast Iron<br />

GGG-50<br />

DIN 1693<br />

Aluminum Alloy<br />

Al Mg Si Pb<br />

DIN 3.0615<br />

AA6262<br />

Aluminum Alloy<br />

Al Cu Mg 2<br />

DIN 3.1354<br />

AA2024<br />

Cast Al Alloy<br />

G-Al Si 7 Mg<br />

3.2371<br />

AA356-T6<br />

Tensile Strength<br />

(avg.) [N/mm 2 ]<br />

Elongation (min.)<br />

[%]<br />

1000 6 865 280<br />

560 6 300 180<br />

250 – – 160<br />

500 7 320 170<br />

340 8 300 90<br />

480 8 380 120<br />

300 4 250 80<br />

• Equivalent working pressure capability can be obtained when using base materials with similar mechanical<br />

characteristics. However, the appropriate installation instructions must be followed.<br />

• Applications for other non-ferrous metals and non-metallic materials upon request.<br />

• Factors which may lower the working pressure capability are:<br />

- anchorage principle<br />

- bore roughness requirements<br />

- design guidelines<br />

Ultimate Strength<br />

(avg.) Rp 0.2 [N/mm 2 ]<br />

Hardness<br />

(min.) HB<br />

Drilled Hole<br />

T<br />

Tolerance [mm] Roughness R z [µm]<br />

+ 0.12<br />

0<br />

• If pressure is applied to both sides of the Sidex-SK plug, allowable working pressure on the insertion side is reduced<br />

by 50%.<br />

• Anchorage between sleeve and base material is achieved when the sleeve is a minimum of HB=30 greater than<br />

the base material. If the hardness difference is less, hole roughness of 10 to 30 µm is needed to achieve<br />

indicated working pressures.<br />

Security Range<br />

The security range (the difference between working pressure and Test B pressure) allows for uncontrollable<br />

variations. For instance, dynamic loading at 1 million cycles and a frequency of 3-4Hz has shown that burst<br />

pressure Test A and Test B pressure are reduced about 20% after this point.<br />

10 to 30<br />

anchorage<br />

in<br />

base metal<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

51

Pressure Performance HK 55<br />

Sleeve Material : Case Hardening Steel, soft annealed Tensile Strength Rm = 350 N/mm 2<br />

DIN 1.0403 Hardness HB = 100<br />

52<br />

p [bar]<br />

1600<br />

1400<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

3<br />

➀➁➂➃➅<br />

➎➐<br />

1,200 bar (17,400 psi)<br />

500 bar (7,200 psi)<br />

350 bar (5,100 psi)<br />

160 bar (2,300 psi)<br />

450 bar (6,500 psi)<br />

4 5 6 7 8 9 10<br />

Proof Pressure Test B<br />

Base Material<br />

➀➁➂➃<br />

➎➏➐<br />

➀➁➂➃<br />

➎➏➐<br />

Expander Diameter [mm]<br />

20,000<br />

15,000<br />

10,000<br />

5,000<br />

p [psi]<br />

T<br />

Max. Allowable Working Pressure = Nominal Pressure<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537

Pressure Performance HK 55<br />

Installation Requirements<br />

The working pressure specifications on the preceding page are obtainable under the following conditions.<br />

➀<br />

➁<br />

➂<br />

➃<br />

➎<br />

➏<br />

➐<br />

Base Material of the<br />

Installation<br />

High Strength St.<br />

ETG-100<br />

AISI 1144<br />

Free Machining Case<br />

Hard. Stl.<br />

C15 Pb<br />

DIN 1.0403<br />

Cast Iron<br />

GG-25<br />

DIN 1691<br />

Ductile Cast Iron<br />

GGG-50<br />

DIN 1693<br />

Aluminum Alloy<br />

Al Mg Si Pb<br />

DIN 3.0615<br />

AA6262<br />

Aluminum Alloy<br />

Al Cu Mg 2<br />

DIN 3.1354<br />

AA2024<br />

Cast Al Alloy<br />

G-Al Si 7 Mg<br />

3.2371<br />

AA356-T6<br />

Tensile Strength<br />

(avg.) [N/mm 2 ]<br />

Elongation (min.)<br />

[%]<br />

1000 6 865 280<br />

560 6 300 180<br />

250 – – 160<br />

500 7 320 170<br />

340 8 300 90<br />

480 8 380 120<br />

300 4 250 80<br />

• Equivalent working pressure capability can be obtained when using base materials with similar mechanical<br />

characteristics. However, the appropriate installation instructions must be followed.<br />

• Applications for other non-ferrous metals and non-metallic materials upon request.<br />

• Factors which may lower the working pressure capability are:<br />

- anchorage principle<br />

- bore roughness requirements<br />

- design guidelines<br />

Ultimate Strength<br />

(avg.) Rp 0.2 [N/mm 2 ]<br />

Hardness<br />

(min.) HB<br />

Drilled Hole<br />

T<br />

Tolerance [mm] Roughness R z [µm]<br />

• If HK plugs are used to keep channels separate, allowable working pressure on the insertion side is reduced by<br />

50%.<br />

• Anchorage between sleeve and base material is achieved when the sleeve is a minimum of HB=30 greater than<br />

the base material. If the hardness difference is less, hole roughness of 10 to 30 µm is needed to achieve<br />

indicated working pressures.<br />

Security Range<br />

The security range (the difference between working pressure and Test B pressure) allows for uncontrollable<br />

variations. For instance, dynamic loading at 1 million cycles and a frequency of 3-4Hz has shown that burst<br />

pressure Test A and Test B pressure are reduced about 20% after this point.<br />

+ 0.1<br />

0<br />

10 to 30<br />

roughness<br />

anchoring not<br />

effective<br />

*<br />

anchorage<br />

in<br />

base metal<br />

not possible<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />

SHEREX Industries Limited, 4180 Morris Drive, Burlington, Ontario, Canada L7L 5L6 Tel: (905) 639-7701 Fax: (905) 639-9537<br />

53

Pressure Performance LK 600<br />

54<br />

p [bar]<br />

200<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

➀➁➂➃➄➅➆<br />

Base Material<br />

4<br />

180 bar (2,600 psi)<br />

60 bar (870 psi)<br />

Proof Pressure Test B<br />

➀➁➂➃➄➅➆<br />

➀➁➂➃➄➅➆<br />

5 6 7 8 9 10<br />

Expander Diameter [mm]<br />

p [psi]<br />

T<br />

3,000<br />

2,500<br />

2,000<br />

1,500<br />

1,000<br />

Max. Allowable Working Pressure = Nominal Pressure<br />

➀➁➂➃➄ Temperature range for Proof Pressure Test B : -40ºC to +150ºC<br />

➅➆ Temperature range for Proof Pressure Test B : -40ºC to +100ºC<br />

SHEREX Industries Ltd., 1400 Commerce Parkway, Lancaster, NY U.S.A. 14086 Tel: (716) 681-6250 Fax: (716) 681-0270<br />