Sauer-Danfoss series S45 axial piston open circuit

Sauer-Danfoss series S45 axial piston open circuit

Sauer-Danfoss series S45 axial piston open circuit

- TAGS

- series

- axial

- piston

- circuit

- www.bibus.hu

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

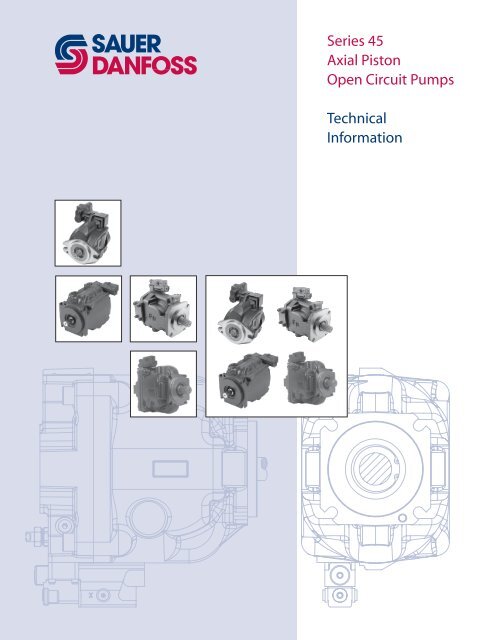

Series 45<br />

Axial Piston<br />

Open Circuit Pumps<br />

Technical<br />

Information

HistoRy of Revisions<br />

© 2009 <strong>Sauer</strong>-<strong>Danfoss</strong>. All rights reserved.<br />

2 520L0519 • Rev FN • July 2009<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

Revisions<br />

Table of Revisions<br />

Date Page Changed Rev.<br />

July 2009 34, 28 remove T2 shaft option from L and K Frames FN<br />

May 2009 various revise fitting depth warning to LS port X FM<br />

March 2009 various add fitting depth warning to LS port X FL<br />

October 2008 62, 65 add SAE-C two bolt housing FK<br />

September 2008 58-62 dimension changes for Frame J FJ<br />

June 2008 78, 93, 94, 95 various minor edits, removed S5 shaft from Frame E FI<br />

May 2008 32, 74, 75, 92 correction to schematics drawings FH<br />

April 2008 76 correction to S2 spline width (inch measurement only) FG<br />

April 2008 52, 53 correction to schematics drawings FG<br />

April 2008 27, 50, 72, 89 add Load sensing - RP and BP must be 20 bar FF<br />

April 2008 76 Correction to S2 shaft - Class 6 and 37.91 mm length FF<br />

March 2008 4 Correction to TOC FE<br />

February 2008 Various Add LS setting to specifications for each frame FD<br />

December 2007 Various Relocate F and E sections, add displacement limiter info. FC<br />

November 2007 50 Change load sensing setting - bar increments FB<br />

September 2007 Various Add Frame F, remove Frame G, and many edits FA<br />

November 2006 51, 52, 53 Revised schematics information E<br />

August 2005 - Removed Frame H, added Frame J D<br />

April 2003 Added Frame E C<br />

May 2001 - Added Frame H and Frame G B<br />

May 1999 - First printing A<br />

<strong>Sauer</strong>-<strong>Danfoss</strong> accepts no responsibility for possible errors in catalogs, brochures and<br />

other printed material. <strong>Sauer</strong> -<strong>Danfoss</strong> reserves the right to alter its products without<br />

prior notice. This also applies to products already ordered, provided that such alterations<br />

can be made without affecting agreed specifications. All trademarks in this material<br />

are properties of their respective owners. <strong>Sauer</strong>-<strong>Danfoss</strong>, the <strong>Sauer</strong>-<strong>Danfoss</strong> logotype,<br />

the <strong>Sauer</strong>-<strong>Danfoss</strong> S-icon, PLUS+1, What really matters is inside® and Know-How in<br />

Motion are trademarks of the <strong>Sauer</strong>-<strong>Danfoss</strong> Group.

GeneRaL infoRmation<br />

fRames L anD K<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

Contents<br />

Overview ........................................................................................................................................................... 6<br />

Design ................................................................................................................................................................ 6<br />

Typical applications ....................................................................................................................................... 6<br />

High performance .................................................................................................................................... 6<br />

Latest technology ..................................................................................................................................... 6<br />

Reliability ..................................................................................................................................................... 6<br />

The Series 45 product family ...................................................................................................................... 7<br />

Basic units .................................................................................................................................................... 7<br />

Load sensing <strong>open</strong> <strong>circuit</strong> system ............................................................................................................ 8<br />

Pressure compensated controls ................................................................................................................ 9<br />

Operation ..................................................................................................................................................... 9<br />

Pressure compensated system characteristics ............................................................................... 9<br />

Typical applications for pressure compensated systems ........................................................... 9<br />

Remote pressure compensated controls .............................................................................................10<br />

Remote pressure compensated system characteristics ............................................................10<br />

Typical applications for remote pressure compensated systems .........................................10<br />

Load sensing controls .................................................................................................................................11<br />

Operation ...................................................................................................................................................11<br />

Load sensing system characteristics ................................................................................................11<br />

Typical applications for load sensing systems..............................................................................11<br />

Electrical on/off pressure compensated controls .............................................................................12<br />

Operating parameters ................................................................................................................................13<br />

Fluids ...........................................................................................................................................................13<br />

Viscosity......................................................................................................................................................13<br />

Temperature .............................................................................................................................................13<br />

Inlet pressure ............................................................................................................................................13<br />

Case pressure ...........................................................................................................................................13<br />

Pressure ratings .......................................................................................................................................14<br />

Speed ratings ...........................................................................................................................................14<br />

Duty cycle and pump life .....................................................................................................................14<br />

Speed, flow, and inlet pressure ...........................................................................................................14<br />

Design parameters.......................................................................................................................................15<br />

Installation .................................................................................................................................................15<br />

Filtration .....................................................................................................................................................15<br />

Reservoir ....................................................................................................................................................15<br />

Fluid velocity ............................................................................................................................................16<br />

Shaft loads .................................................................................................................................................16<br />

Bearing life.................................................................................................................................................16<br />

Mounting flange loads ..........................................................................................................................17<br />

Auxiliary mounting pads ......................................................................................................................18<br />

Input shaft torque ratings ....................................................................................................................18<br />

Understanding and minimizing system noise .............................................................................19<br />

Sizing equations ...........................................................................................................................................20<br />

Design ..............................................................................................................................................................21<br />

Specifications .................................................................................................................................................22<br />

Performance L25C ........................................................................................................................................23<br />

Performance L30D .......................................................................................................................................24<br />

Performance K38C .......................................................................................................................................25<br />

Performance K45D .......................................................................................................................................26<br />

Order code ......................................................................................................................................................27<br />

520L0519 • Rev FN • July 2009<br />

3

fRames L anD K<br />

(continued)<br />

fRame J<br />

4 520L0519 • Rev FN • July 2009<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

Contents<br />

Controls ............................................................................................................................................................29<br />

Pressure compensated control (PC) .................................................................................................29<br />

Remote PC control (RP) .........................................................................................................................29<br />

Load sensing control (LS) .....................................................................................................................30<br />

Load sensing control with internal bleed orifice (LB) ................................................................30<br />

Normally closed on/off electric PC control (ED) .........................................................................31<br />

Normally <strong>open</strong> on/off electric PC control (AA) ............................................................................31<br />

Electric proportional control (EJ) (Normally closed) .................................................................32<br />

Input shafts .....................................................................................................................................................33<br />

Auxiliary mounting pads ...........................................................................................................................35<br />

SAE-A auxiliary mounting pad ...........................................................................................................35<br />

SAE-B auxiliary mounting pad ...........................................................................................................35<br />

SAE-A Auxilliary Pad ..............................................................................................................................36<br />

Mounting pads at 90 degrees ...........................................................................................................36<br />

Running cover ..........................................................................................................................................36<br />

Special SAE-A 11 tooth ........................................................................................................................36<br />

Displacement limiter ...................................................................................................................................37<br />

Installation drawings ...................................................................................................................................38<br />

Axial ported endcap ..............................................................................................................................38<br />

Radial ported endcap ............................................................................................................................40<br />

Electric on/off control............................................................................................................................42<br />

Design ..............................................................................................................................................................43<br />

Specifications .................................................................................................................................................44<br />

Performance J45B ........................................................................................................................................45<br />

Performance J51B ........................................................................................................................................46<br />

Performance J60B ........................................................................................................................................47<br />

Performance J65C ........................................................................................................................................48<br />

Performance J75C ........................................................................................................................................49<br />

Order code ......................................................................................................................................................50<br />

Controls ............................................................................................................................................................52<br />

Pressure compensated control (PC, BC) ..........................................................................................52<br />

Remote PC control (RP, BP) ..................................................................................................................52<br />

Load sensing control (LS, BS) ..............................................................................................................53<br />

Load sensing control with internal bleed orifice (LB, BB) .........................................................53<br />

Normally closed on/off electric PC control (AG) .........................................................................54<br />

Normally <strong>open</strong> on/off electric PC control (AF) ............................................................................54<br />

Input shafts .....................................................................................................................................................55<br />

Auxiliary mounting pads ...........................................................................................................................58<br />

SAE-A auxiliary mounting pad (non-integral) ..............................................................................58<br />

SAE-B auxiliary mounting pad ...........................................................................................................58<br />

Displacement limiter ...................................................................................................................................59<br />

SAE-C auxiliary mounting pad ...........................................................................................................60<br />

Running cover ..........................................................................................................................................60<br />

Installation drawings ...................................................................................................................................61<br />

Axial ported endcap ..............................................................................................................................61<br />

Radial ported endcap ............................................................................................................................64<br />

Electric on/off control/Radial endcap .............................................................................................66

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

Contents<br />

fRame f Design ..............................................................................................................................................................68<br />

Specifications .................................................................................................................................................69<br />

Performance F74B ........................................................................................................................................70<br />

Performance F90C ........................................................................................................................................71<br />

Order code ......................................................................................................................................................72<br />

Controls ............................................................................................................................................................74<br />

Pressure compensated control (PC) .................................................................................................74<br />

Remote PC Control (RP) ........................................................................................................................74<br />

Load sensing control with internal bleed orifice (LB) ................................................................75<br />

Load sensing control (LS) .....................................................................................................................75<br />

Input shafts .....................................................................................................................................................76<br />

Auxiliary mounting pads ...........................................................................................................................77<br />

SAE-A auxiliary mounting pad ...........................................................................................................77<br />

SAE-B auxiliary mounting pad ...........................................................................................................77<br />

Displacement limiter ...................................................................................................................................78<br />

SAE-C auxiliary mounting pad ...........................................................................................................78<br />

Adjustable displacement limiter and running cover .......................................................................79<br />

Axial ported endcap ....................................................................................................................................80<br />

Radial ported endcap .................................................................................................................................82<br />

fRame e<br />

Design ..............................................................................................................................................................84<br />

Specifications .................................................................................................................................................85<br />

Performance E100B .....................................................................................................................................86<br />

Performance E130B .....................................................................................................................................87<br />

Performance E147C .....................................................................................................................................88<br />

Order code ......................................................................................................................................................89<br />

Controls ............................................................................................................................................................91<br />

Pressure compensated control (PC) .................................................................................................91<br />

Remote PC control (RP) .........................................................................................................................91<br />

Load sensing control (LS) .....................................................................................................................92<br />

Load sensing control with internal bleed orifice (LB) ................................................................92<br />

Input shafts .....................................................................................................................................................93<br />

Auxiliary mounting pads ...........................................................................................................................95<br />

SAE-A auxiliary mounting pad ...........................................................................................................95<br />

SAE-B auxiliary mounting pad ...........................................................................................................95<br />

SAE-C auxiliary mounting pad ...........................................................................................................96<br />

Running cover ..........................................................................................................................................96<br />

Displacement limiters .................................................................................................................................97<br />

Installation drawings ...................................................................................................................................98<br />

Axial ported endcap, clockwise rotation ........................................................................................98<br />

Axial ported endcap, counterclockwise rotation ..................................................................... 100<br />

Radial ported endcap, clockwise rotation ................................................................................... 102<br />

Radial ported endcap, counterclockwise rotation ................................................................... 104<br />

520L0519 • Rev FN • July 2009<br />

5

6 520L0519 • Rev FN • July 2009<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

General information<br />

oveRview Series 45 is a complete family of variable displacement, <strong>axial</strong> <strong>piston</strong> pumps for <strong>open</strong><br />

<strong>circuit</strong> applications. Each frame within the Series 45 family is uniquely designed to<br />

optimize performance, size, and cost, matching the work function requirements of the<br />

demanding mobile equipment marketplace.<br />

DesiGn<br />

tyPiCaL aPPLiCations<br />

High performance<br />

• Displacements from 25 cm³ - 147 cm³ [1.53 - 8.97 in 3 /rev]<br />

• Speeds up to 3600 rpm<br />

• Pressures up to 310 bar [4495 psi] continuous, and 400 bar [5800 psi] peak<br />

• Variety of control system options including load sensing and pressure compensated<br />

• Through-drive capability for multi-<strong>circuit</strong> systems<br />

• Range of mounting flanges, shafts, and porting options for ease of installation<br />

Latest technology<br />

• Customer-driven using quality function deployment (QFD) and design for<br />

manufacturability (DFM) techniques<br />

• Optimized valve plates for maximum efficiency and quiet operation<br />

• Computer-modeled castings to optimize inlet conditions for maximum pump speed<br />

• Compact package size minimizing installation space requirements<br />

• Heavy-duty tapered roller bearings for long life<br />

• Single piece rigid housing to reduce noise and leak paths<br />

• Integrated controls for high speed response and system stability<br />

Reliability<br />

• Designed to rigorous standards<br />

• Proven in both laboratory and field<br />

• Manufactured to rigid quality standards<br />

• Long service life<br />

• Significantly fewer parts<br />

• No gasketed joints<br />

• Robust input shaft bearings to handle large external shaft loads<br />

• Integrated gauge ports for monitoring operating conditions<br />

• Cranes<br />

• Telescopic handlers<br />

• Forklift trucks<br />

• Wheel loaders<br />

• Sweepers<br />

• Backhoe loaders<br />

• Forestry and agricultural machinery<br />

• Fan drives<br />

• Other uses

tHe seRies 45 PRoDuCt<br />

famiLy<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

General information<br />

Basic units<br />

The <strong>series</strong> 45 family of <strong>open</strong> <strong>circuit</strong>, variable <strong>piston</strong> pumps, offers a range of<br />

displacements from 25 to 147 cm³/rev [1.53 to 8.97 in 3 /rev]. With maximum speeds up<br />

to 3600 rpm and continuous operating pressures up to 310 bar [4495 psi], you can tailor<br />

product selection to the flow and pressure requirements of your individual application.<br />

K/L Frame J Frame<br />

F Frame<br />

E Frame<br />

General performance specifications for the <strong>series</strong> 45 pump family<br />

Pump Displacement<br />

Continuous<br />

speed<br />

max. min.<br />

Pressure<br />

Continuous maximum<br />

theoretical flow<br />

(at rated speed)<br />

mounting<br />

Model cm3 in3 min-1 (rpm) min-1 (rpm) min-1 (rpm) bar psi bar psi US gal/min l/min Flange<br />

frame L See page 21<br />

L25C 25 1.53 3200 3600 500 260 3770 350 5075 21.0 80.0 SAE B - 2 bolt<br />

L30D 30 1.83 3200 3600 500 210 3045 300 4350 25.4 96.0 SAE B - 2 bolt<br />

frame K See page 21<br />

K38C 38 2.32 2650 2800 500 260 3770 350 5075 26.6 100.7 SAE B - 2 bolt<br />

K45D 45 2.75 2650 2800 500 210 3045 300 4350 31.5 119.3 SAE B - 2 bolt<br />

J45B 45 2.75 2800 3360 500 310 4495 400 5800 33.3 126.0<br />

J51B 51 3.11 2700 3240 500 310 4495 400 5800 36.4 137.7<br />

J60B 60 3.66 2600 3120 500 310 4495 400 5800 41.2 156.0<br />

520L0519 • Rev FN • July 2009<br />

See page 43<br />

SAE B 2-bolt<br />

SAE C 2 and 4-bolt<br />

SAE B 2-bolt<br />

SAE C 2 and 4-bolt<br />

SAE B 2-bolt<br />

SAE C 2 and 4-bolt<br />

J65C 65 3.97 2500 3000 500 260 3770 350 5075 42.9 162.6<br />

SAE B 2-bolt<br />

SAE C 2 and 4-bolt<br />

J75C 75 4.58 2400 2880 500 260 3770 350 5075 47.5 180.0<br />

SAE B 2-bolt<br />

SAE C 2 and 4-bolt<br />

frame f See page 68<br />

F74B 74 4.52 2400 2800 500 310 4495 400 5800 46.9 177.6 SAE B 2-bolt<br />

SAE C 4-bolt<br />

F90C 90 5.49 2200 2600 500 260 3770 350 5075 52.3 198 SAE B 2-bolt<br />

SAE C 4-bol<br />

frame e See page 84<br />

E100B 100 6.10 2450 2880 500 310 4495 400 5800 64.7 245.0 SAE C 4-bolt<br />

E130B 130 7.93 2200 2600 500 310 4495 400 5800 75.5 286.0 SAE C 4-bolt<br />

E147C 147 8.97 2100 2475 500 260 3770 350 5075 81.5 308.7 SAE C 4-bolt<br />

7

LoaD sensinG oPen<br />

CiRCuit system<br />

P101 658E<br />

Reservoir<br />

8 520L0519 • Rev FN • July 2009<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

General information<br />

The pump receives fluid directly from the reservoir through the inlet line. A screen in the<br />

inlet line protects the pump from large contaminants. The pump outlet feeds a PVG-32<br />

multi-section, load sensing, directional control valve. The PVG valve directs pump flow to<br />

the cylinder and gear motor. A heat exchanger cools the fluid returning from the valve. A<br />

filter cleans the fluid before it returns to the reservoir.<br />

Flow in the <strong>circuit</strong> determines the speed of the actuators. The position of the PVG valve<br />

determines the flow demand. A hydraulic pressure signal (LS signal) communicates<br />

demand to the pump control. The pump control monitors the pressure differential<br />

between pump outlet and the LS signal, and regulates servo pressure to control the<br />

swashplate angle. Swashplate angle determines pump flow.<br />

Actuator load determines system pressure. The pump control monitors system pressure<br />

and will decrease the swashplate angle to reduce flow if system pressure reaches the<br />

PC setting. A system relief valve in the PVG valve acts as a back-up to control system<br />

pressure.<br />

Pictorial <strong>circuit</strong> diagram<br />

Filter<br />

K/L Frame Series 45<br />

<strong>open</strong> <strong>circuit</strong> <strong>axial</strong><br />

<strong>piston</strong> pump with<br />

load sensing control<br />

Heat exchanger<br />

PVG 32<br />

mulit-section<br />

load<br />

sensing<br />

control<br />

valve<br />

Double-acting cylinder<br />

Bi-directional<br />

gear motor<br />

System pressure<br />

Servo pressure<br />

Actuator pressure<br />

Load sense pressure<br />

Actuator return<br />

Suction / case drain /<br />

system return

PRessuRe<br />

ComPensateD<br />

ContRoLs<br />

For additional system<br />

protection, install a relief<br />

valve in the pump outlet<br />

line.<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

General information<br />

operation<br />

The PC control maintains constant system pressure in the hydraulic <strong>circuit</strong> by varying<br />

the output flow of the pump. Used with a closed center control valve, the pump remains<br />

in high pressure standby mode at the PC setting with zero flow until the function is<br />

actuated. This condition is often called a dead head condition.<br />

Typical operating curve<br />

Q max<br />

Flow<br />

0<br />

0<br />

Pressure<br />

Once the closed center valve is <strong>open</strong>ed,<br />

the PC control senses the immediate<br />

drop in system pressure and increases<br />

pump flow by increasing the swashplate<br />

520L0519 • Rev FN • July 2009<br />

PC setting<br />

P101 166E<br />

Simple closed-center <strong>circuit</strong><br />

P101 965<br />

angle. The pump continues to increase flow until system pressure reaches the PC setting.<br />

If system pressure exceeds the PC setting, the PC control reduces the swashplate angle to<br />

maintain system pressure by reducing flow. The PC control continues to monitor system<br />

pressure and changes swashplate angle to match the output flow with the work function<br />

pressure requirements.<br />

If the demand for flow exceeds the capacity of the pump, the PC control directs the<br />

pump to maximum displacement. In this condition, actual system pressure depends on<br />

the actuator load.<br />

Each section includes control schematic diagrams, setting ranges, and response /<br />

recovery times for each control available. Response is the time (in milliseconds) for the<br />

pump to reach zero displacement when commanded by the control. Recovery is the<br />

time (in milliseconds) for the pump to reach full displacement when commanded by the<br />

control. Actual times can vary depending on application conditions.<br />

Pressure compensated system characteristics<br />

• Constant pressure and variable flow<br />

• High pressure standby mode when flow is not needed<br />

• System flow adjusts to meet system requirements<br />

• Single pump can provide flow to multiple work functions<br />

• Quick response to system flow and pressure requirements<br />

typical applications for pressure compensated systems<br />

• Constant force cylinders (bailers, compactors, refuse trucks)<br />

• On/off fan drives<br />

9

Remote PRessuRe<br />

ComPensateD<br />

ContRoLs<br />

10 520L0519 • Rev FN • July 2009<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

General information<br />

The remote PC control is a two-stage control that allows multiple PC settings. Remote<br />

PC controls are commonly used in applications requiring low and high pressure PC<br />

operation.<br />

Typical operating curve<br />

Q max<br />

Flow<br />

0<br />

0<br />

Remote PC setting<br />

Pressure<br />

PC setting<br />

P101 969E<br />

Closed center <strong>circuit</strong> with remote PC<br />

P101 966<br />

The remote PC control uses a pilot line connected to an external hydraulic valve. The<br />

external valve changes pressure in the pilot line, causing the PC control to operate at<br />

a lower pressure. When the pilot line is vented to reservoir, the pump maintains a low<br />

standby pressure of 15 to 20 bar [215 to 300 psi]. When pilot flow is blocked, the pump<br />

maintains pressure at the PC setting. An on-off solenoid valve can be used in the pilot<br />

line to create a low-pressure standby mode. A proportional solenoid valve, coupled with<br />

a microprocessor control, can produce an infinite range of operating pressures.<br />

Each section includes control schematic diagrams, setting ranges, and response /<br />

recovery times for each control available. Response is the time (in milliseconds) for the<br />

pump to reach zero displacement when commanded by the control. Recovery is the<br />

time (in milliseconds) for the pump to reach full displacement when commanded by the<br />

control. Actual times can vary depending on application conditions.<br />

Size the external valve and plumbing for a pilot flow of 3.8 l/min [1 US gal/min]. For<br />

additional system protection, install a relief valve in the pump outlet line.<br />

Remote pressure compensated system characteristics<br />

• Constant pressure and variable flow<br />

• High or low pressure standby mode when flow is not needed<br />

• System flow adjusts to meet system requirements<br />

• Single pump can provide flow to multiple work functions<br />

• Quick response to system flow and pressure requirements<br />

typical applications for remote pressure compensated systems<br />

• Modulating fan drives<br />

• Anti-stall control with engine speed feedback<br />

• Front wheel assist

LoaD sensinG<br />

ContRoLs<br />

For additional system<br />

protection, install a relief<br />

valve in the pump outlet<br />

line.<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

General information<br />

operation<br />

The LS control matches system requirements for both pressure and flow in the <strong>circuit</strong><br />

regardless of the working pressure. Used with a closed center control valve, the pump<br />

remains in low-pressure standby mode with zero flow until the valve is <strong>open</strong>ed. The LS<br />

setting determines standby pressure.<br />

Typical operating curve<br />

Q max<br />

Flow<br />

0<br />

0<br />

Pressure<br />

520L0519 • Rev FN • July 2009<br />

P101 968E<br />

Load sensing <strong>circuit</strong><br />

P101 967<br />

Most load sensing systems use parallel, closed center, control valves with special porting that<br />

allows the highest work function pressure (LS signal) to feed back to the LS control. margin<br />

pressure is the difference between system pressure and the LS signal pressure. The LS<br />

control monitors margin pressure to read system demand. A drop in margin pressure means<br />

the system needs more flow. A rise in margin pressure tells the LS control to decrease flow.<br />

LS control with bleed orifice<br />

The load sense signal line requires a bleed orifice to prevent high-pressure lockup of the<br />

pump control. Most load-sensing control valves include this orifice. An optional internal<br />

bleed orifice is available, if needed.<br />

Integral PC function<br />

The LS control also performs as a PC control, decreasing pump flow when system<br />

pressure reaches the PC setting. The pressure compensating function has priority over<br />

the load sensing function.<br />

Each section includes control schematic diagrams, setting ranges, and response /<br />

recovery times for each control available. Response is the time (in milliseconds) for the<br />

pump to reach zero displacement when commanded by the control. Recovery is the<br />

time (in milliseconds) for the pump to reach full displacement when commanded by the<br />

control. Actual times can vary depending on application conditions.<br />

Load sensing system characteristics<br />

• Variable pressure and flow<br />

• Low pressure standby mode when flow is not needed<br />

• System flow adjusted to meet system requirements<br />

• Single pump can supply flow and regulate pressure for multiple <strong>circuit</strong>s<br />

• Quick response to system flow and pressure requirements<br />

typical applications for load sensing systems<br />

• Priority steering<br />

• Load independent flow control for boom lift, tilt, and rotation<br />

PC setting<br />

11

eLeCtRiCaL on/<br />

off PRessuRe<br />

ComPensateD<br />

ContRoLs<br />

12 520L0519 • Rev FN • July 2009<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

General information<br />

The electrical on/off pressure<br />

compensated control allows the pump<br />

to operate as a PC type control under<br />

normal operating conditions. A solenoid<br />

valve overrides the PC control allowing<br />

the pump to operate in a low-pressure<br />

standby mode. This function provides<br />

reduced horsepower and torque loss in<br />

certain situations. It may be particularly<br />

useful to reduce loads on a system<br />

during engine start.<br />

ED schematic (normally closed)<br />

S When closed, the solenoid valve prevents<br />

L1<br />

P106 044<br />

flow across the LS spool gain orifice,<br />

defeating the LS spool. The pump then functions as a PC control pump. When <strong>open</strong>,<br />

the solenoid valve allows flow across the LS spool gain orifice to reservoir. This flow<br />

generates a pressure differential across the LS spool that shifts the spool and de-strokes<br />

the pump. The pump then operates in a low-pressure standby condition. The solenoid<br />

valve is available in a normally closed or normally <strong>open</strong> configuration.<br />

ED is the nomenclature for a normally closed on/off control for the L and K frame pumps.<br />

Other frame sizes and configurations have different order code designations.<br />

(ED) Electric control cross-section<br />

LS adjustment<br />

PC adjustment<br />

M2<br />

L2<br />

B<br />

Solenoid<br />

LS spool<br />

PC spool<br />

P106 183E<br />

X<br />

System pressure<br />

Servo pressure<br />

Pilot Pressure<br />

Drain

oPeRatinG<br />

PaRameteRs<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

General information<br />

fluids<br />

Ratings and performance data for Series 45 products are based on operating with<br />

premium hydraulic fluids containing oxidation, rust, and foam inhibitors. These<br />

include premium turbine oils, API CD engine oils per SAE J183, M2C33F or G automatic<br />

transmission fluids (ATF), Dexron II (ATF) meeting Allison C-3 or Caterpillar T0-2<br />

requirements, and certain specialty agricultural tractor fluids. For more information on<br />

hydraulic fluid selection, see <strong>Sauer</strong>-<strong>Danfoss</strong> publications 520L0463 Hydraulic Fluids and<br />

Lubricants, Technical Information, and 520L0465 Experience with Biodegradable Hydraulic<br />

Fluids, Technical Information.<br />

viscosity<br />

Maintain fluid viscosity within the<br />

recommended range for maximum<br />

efficiency and bearing life. minimum<br />

viscosity should only occur during<br />

brief occasions of maximum ambient<br />

temperature and severe duty cycle<br />

operation. maximum viscosity should<br />

only occur at cold start: Limit speeds<br />

until the system warms up.<br />

temperature<br />

Maintain fluid temperature within the<br />

limits shown in the table. minimum<br />

temperature relates to the physical<br />

properties of the component materials.<br />

Cold oil will not affect the durability<br />

of the pump components. However,<br />

520L0519 • Rev FN • July 2009<br />

Fluid viscosity limits<br />

Condition mm 2 /s (cst) sus<br />

ν min.<br />

ν max.<br />

continuous 9 58<br />

intermittent 6.4 47<br />

continuous 110 500<br />

intermittent<br />

(cold start)<br />

1000 4700<br />

Temperature limits<br />

minimum<br />

(intermittent, cold start)<br />

- 40° C [- 40° F]<br />

Continuous 82° C [180° F]<br />

maximum 104° C [220° F]<br />

it may affect the ability of the pump to provide flow and transmit power. maximum<br />

temperature is based on material properties. Don’t exceed it. Measure maximum<br />

temperature at the hottest point in the system. This is usually the case drain.<br />

Ensure fluid temperature and viscosity limits are concurrently satisfied.<br />

inlet pressure<br />

Maintain inlet pressure within the limits<br />

shown in the table. Low inlet pressure<br />

(vacuum) may limit maximum pump<br />

speed and cause cavitation. Refer to<br />

Inlet pressure vs. speed charts for each<br />

displacement.<br />

Case pressure<br />

Maintain case pressure within the limits<br />

shown in the table. The housing must<br />

always be filled with hydraulic fluid.<br />

Inlet pressure limits<br />

minimum<br />

(continuous)<br />

minimum<br />

(cold start)<br />

0.8 bar absolute [6.7 in. Hg vac.]<br />

(at reduced maximum speed)<br />

0.5 bar absolute [15.1 in. Hg vac.]<br />

Case pressure limits<br />

maximum 0.5 bar [7 psi] above inlet<br />

(continuous)<br />

intermittent 2 bar [29 psi] above inlet<br />

(cold start)<br />

C Caution<br />

Operating outside of inlet and case pressure limits will damage the pump. To minimize<br />

this risk, use full size inlet and case drain plumbing, and limit line lengths.<br />

13

oPeRatinG<br />

PaRameteRs<br />

(continued)<br />

14 520L0519 • Rev FN • July 2009<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

General information<br />

Pressure ratings<br />

The specification tables in each section give maximum and continuous pressure ratings<br />

for each displacement. Not all displacements within a given frame operate under the<br />

same pressure limits. Definitions of the operating pressure limits appear below.<br />

system pressure is the differential pressure between the outlet and inlet ports. It is the<br />

dominant operating variable affecting hydraulic unit life. High system pressure, which<br />

results from high load, reduces expected life. System pressure must remain at or below<br />

rated pressure during normal operation to achieve expected life.<br />

Continuous working pressure is the average, regularly occurring operating pressure.<br />

Operating at or below this pressure should yield satisfactory product life. For all<br />

applications, the load should move below this pressure.<br />

maximum (peak) working pressure is the highest intermittent pressure allowed.<br />

Maximum machine load should never exceed this pressure.<br />

speed ratings<br />

The specification tables in each section give minimum, maximum, and rated speeds for<br />

each displacement. Not all displacements within a given frame operate under the same<br />

speed limits. Definitions of these speed limits appear below.<br />

Rated speed is the maximum recommended operating speed at full displacement and<br />

1 bar abs. [0 in Hg vac] inlet pressure. Operating at or below this speed should yield<br />

satisfactory product life.<br />

maximum speed is the highest recommended operating speed at full power<br />

conditions. Operating at or beyond maximum speed requires positive inlet pressure<br />

and/or a reduction of pump outlet flow. Refer to Inlet pressure vs. speed charts for each<br />

displacement.<br />

minimum speed is the lowest operating speed allowed. Operating below this speed will<br />

not yield satisfactory performance.<br />

Duty cycle and pump life<br />

Knowing the operating conditions of your application is the best way to ensure proper<br />

pump selection. With accurate duty cycle information, your <strong>Sauer</strong>-<strong>Danfoss</strong> representative<br />

can assist in calculating expected pump life.<br />

speed, flow, and inlet pressure<br />

Inlet pressure vs. speed charts in each<br />

section show the relationship between<br />

speed, flow, and inlet pressure for each<br />

displacement. Use these charts to ensure<br />

your application operates within the<br />

prescribed range.<br />

The charts define the area of inlet<br />

pressures and speeds allowed for a<br />

given displacement. Operating at lower<br />

displacements allows greater speed or<br />

lower inlet pressure.<br />

Sample inlet pressure vs. speed chart<br />

Inlet Pressure (bar abs)<br />

1.6<br />

1.5<br />

1.4<br />

1.3<br />

1.2<br />

1.1<br />

1.0<br />

0.9<br />

0.8<br />

0.7<br />

Max. speed<br />

Rated speed<br />

100% 90% 80%<br />

0.6<br />

2800 3000 3200 3400 3600 3800 4000<br />

-1<br />

Shaft Speed min (rpm)<br />

8<br />

6<br />

4<br />

2<br />

0<br />

3<br />

6<br />

9<br />

(psi gauge)<br />

(in Hg vac)<br />

P101 972E<br />

Operating limit at 80% displacement<br />

Operating limit at 90% displacement<br />

Operating limit at 100% displacement

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

General information<br />

DesiGn PaRameteRs installation<br />

Series 45 pumps may be installed in any position. To optimize inlet conditions, we<br />

recommend installing the pump at an elevation below the minimum reservoir fluid<br />

level. Design inlet plumbing to maintain inlet pressure within prescribed limits (see Inlet<br />

pressure limits, page 13)<br />

Fill the pump housing and inlet line with clean fluid during installation. Connect the case<br />

drain line to the uppermost drain port (L1 or L2) to keep the housing full during operation.<br />

To allow unrestricted flow to the reservoir, use a dedicated drain line. Connect it below<br />

the minimum reservoir fluid level and as far away from the reservoir outlet as possible.<br />

Use plumbing adequate to maintain case pressure within prescribed limits (see Case<br />

pressure limits, page 13).<br />

filtration<br />

To prevent damage to the pump, including premature wear, fluid entering the pump<br />

inlet must be free of contaminants. Series 45 pumps require system filtration capable of<br />

maintaining fluid cleanliness at ISO 4406-1999 class 22/18/13 or better.<br />

<strong>Sauer</strong>-<strong>Danfoss</strong> does not recommend suction line filtration. Suction line filtration can<br />

cause high inlet vacuum, which limits pump operating speed. Instead we recommend<br />

a 125 µm (150 mesh) screen in the reservoir covering the pump inlet. This protects the<br />

pump from coarse particle ingestion.<br />

Return line filtration is the preferred method for <strong>open</strong> <strong>circuit</strong> systems. Consider these<br />

factors when selecting a system filter:<br />

• Cleanliness specifications<br />

• Contaminant ingression rates<br />

• Flow capacity<br />

• Desired maintenance interval<br />

Typically, a filter with a beta ratio of β 10 = 10 is adequate. However, because each system<br />

is unique, only a thorough testing and evaluation program can fully validate the<br />

filtration system. For more information, see <strong>Sauer</strong>-<strong>Danfoss</strong> publication 520L0467 Design<br />

Guidelines for Hydraulic Fluid Cleanliness.<br />

Reservoir<br />

The reservoir provides clean fluid, dissipates heat, and removes entrained air from the<br />

hydraulic fluid. It allows for fluid volume changes associated with fluid expansion and<br />

cylinder differential volumes. Minimum reservoir capacity depends on the volume<br />

needed to perform these functions. Typically, a capacity of one to three times the pump<br />

flow (per minute) is satisfactory.<br />

Locate the reservoir outlet (suction line) near the bottom, allowing clearance for settling<br />

foreign particles. Place the reservoir inlet (return lines) below the lowest expected fluid<br />

level, as far away from the outlet as possible.<br />

520L0519 • Rev FN • July 2009<br />

15

DesiGn PaRameteRs<br />

(continued)<br />

16 520L0519 • Rev FN • July 2009<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

General information<br />

fluid velocity<br />

Choose piping sizes and configurations<br />

sufficient to maintain optimum fluid<br />

velocity, and minimize pressure drops.<br />

This reduces noise, pressure drops, and<br />

overheating. It maximizes system life and<br />

performance.<br />

Velocity equations SI units<br />

US units<br />

Radial load formula<br />

Q = flow (l/min)<br />

A = area (mm²)<br />

Velocity = 16.67•Q (m/sec)<br />

A<br />

Recommended fluid velocities<br />

system lines 6 to 9 m/sec [20 to 30 ft/sec]<br />

suction line 1 to 2 m/sec [4 to 6 ft/sec]<br />

Case drain 3 to 5 m/sec [10 to 15 ft/sec]<br />

typical guidelines; obey all pressure ratings.<br />

Q = flow (US gal/min)<br />

A = area (in²)<br />

Velocity = 0.321•Q (ft/sec)<br />

A<br />

shaft loads<br />

Series 45 pumps have tapered roller bearings capable of accepting external radial and<br />

thrust loads. The external radial shaft load limits are a function of the load position,<br />

orientation, and the operating conditions of the pump.<br />

The maximum allowable radial load (R e) is based on the maximum external moment (M e)<br />

and the distance (L) from the mounting flange to the load. Compute radial loads using<br />

the formula below. Tables in each section give maximum external moment (M e) and<br />

thrust load (T in , T out) limits for each pump frame size and displacement.<br />

M e = R e•L<br />

Shaft load orientation<br />

0˚ Re<br />

90˚ Re 270˚ Re<br />

150˚<br />

180˚ Re<br />

210˚<br />

Tout<br />

L = Distance from mounting flange<br />

to point of load<br />

M e = Maximum external moment<br />

R e = Maximum radial side load<br />

P101 080E<br />

Bearing life<br />

All shaft loads affect bearing life. In applications where external shaft loads can not<br />

be avoided, maximize bearing life by orientating the load between the 150° and 210°<br />

positions, as shown. We recommend tapered input shafts or clamp-type couplings for<br />

applications with radial shaft loads. Tables in each section give B 10 bearing life for each<br />

pump frame size and displacement.<br />

Tin<br />

Axis of swashplate<br />

rotation<br />

Re<br />

L<br />

Mounting flange

DesiGn PaRameteRs<br />

(continued)<br />

Shock load formula<br />

Continuous load formula<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

General information<br />

mounting flange loads<br />

Adding auxiliary pumps and/or subjecting pumps to high shock loads may overload the<br />

pump mounting flange. Tables in each section give allowable continuous and shock load<br />

moments for each frame size. Applications with loads outside allowable limits require<br />

additional pump support.<br />

• shock load moment (M S) is the result of an instantaneous jolt to the system.<br />

• Continuous load moments (M c) are generated by the typical vibratory movement<br />

of the application.<br />

Estimating overhung load moments<br />

Use the equations below to estimate the overhung load moments for multiple pump<br />

mounting. See installation drawings in each section to find the distance from the<br />

mounting flange to the center of gravity for each frame size. Refer to the technical<br />

specifications in each section to find pump weight.<br />

Overhung load example<br />

mounting flange<br />

M s = G s•K•(W 1•L 1+W 2•L 2+...W n•L n)<br />

M c = G c•K•(W 1•L 1+W 2•L 2+...W n•L n)<br />

SI units<br />

M s = Shock load moment (N•m)<br />

M c = Continuous (vibratory) load<br />

moment (N•m)<br />

G s = Acceleration due to external<br />

shock (G’s)<br />

G c = Acceleration due to continuous<br />

vibration (G’s)<br />

K = Conversion factor = 0.00981<br />

W n = Mass of n th pump (kg)<br />

L n = Distance from mounting flange<br />

to n th pump CG (mm)<br />

520L0519 • Rev FN • July 2009<br />

L1<br />

Center of Gravity (CG)<br />

pump 1<br />

L2<br />

Center of Gravity (CG)<br />

pump 2<br />

P101 081E<br />

US units<br />

M s = Shock load moment (lbf•in)<br />

M c = Continuous (vibratory) load<br />

moment (lbf•in)<br />

G s = Acceleration due to external<br />

shock (G’s)<br />

G c = Acceleration due to continuous<br />

vibration (G’s)<br />

K = Conversion factor = 1<br />

W n = Weight of n th pump (lb)<br />

L n = Distance from mounting flange<br />

to n th pump CG (in)<br />

17

DesiGn PaRameteRs<br />

(continued)<br />

18 520L0519 • Rev FN • July 2009<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

General information<br />

auxiliary mounting pads<br />

Auxiliary mounting pads are available for all radial ported Series 45 pumps. Since the<br />

auxiliary pad operates under case pressure, use an O-ring to seal the auxiliary pump<br />

mounting flange to the pad. Oil from the main pump case lubricates the drive coupling.<br />

• All mounting pads meet SAE J744 Specifications.<br />

• The combination of auxiliary shaft torque and main pump torque must not<br />

exceed the maximum pump input shaft rating. Tables in each section give input<br />

shaft torque ratings for each frame size.<br />

• Applications subject to severe vibratory or shock loading may require additional<br />

support to prevent mounting flange damage. Tables in each section give allowable<br />

continuous and shock load moments for each frame size.<br />

• The drawing and table below give mating pump dimensions for each size mount.<br />

Refer to installation drawings in each section for auxiliary mounting pad dimensions.<br />

Mating pump specifications<br />

Mounting<br />

flange (ref)<br />

mm<br />

[in.]<br />

P101 079E<br />

Undercut<br />

spline<br />

Sled-runner<br />

spline<br />

B<br />

max.<br />

C<br />

max.<br />

D<br />

max.<br />

E<br />

max.<br />

Coupling<br />

F min. spline<br />

engagement<br />

for full torque<br />

rating<br />

P Ø<br />

+0 -0.05<br />

[+0 -0.002]<br />

Recommended<br />

cutter clearance<br />

2.3 [0.090]<br />

R 0.8 [0.03] max.<br />

Dimensions<br />

sae a sae B sae C<br />

P<br />

B<br />

C<br />

D<br />

e<br />

f<br />

82.55<br />

[3.250]<br />

6.35<br />

[0.250]<br />

12.70<br />

[0.500]<br />

58.20<br />

[2.290]<br />

15.00<br />

[0.590]<br />

13.50<br />

[0.530]<br />

101.60<br />

[4.000]<br />

9.65<br />

[0.380]<br />

15.20<br />

[0.600]<br />

53.10<br />

[2.090]<br />

17.50<br />

[0.690]<br />

14.20<br />

[0.560]<br />

127.00<br />

[5.000]<br />

12.70<br />

[0.500]<br />

23.37<br />

[0.920]<br />

55.60<br />

[2.190]<br />

30.50<br />

[1.200]<br />

18.30<br />

[0.720]<br />

input shaft torque ratings<br />

Input shaft tables in each section give maximum torque ratings for available input shafts.<br />

Ensure that your application respects these limits.<br />

maximum torque ratings are based on shaft strength. Do not exceed them.<br />

Coupling arrangements that are not oil-flooded provide a reduced torque rating. Contact<br />

your <strong>Sauer</strong>-<strong>Danfoss</strong> representative for proper torque ratings if your application involves<br />

non oil-flooded couplings.<br />

<strong>Sauer</strong>-<strong>Danfoss</strong> recommends mating splines adhere to ANSI B92.1-Class 5. <strong>Sauer</strong>-<strong>Danfoss</strong><br />

external splines are modified class 5 fillet root side fit. The external major diameter and<br />

circular tooth thickness dimensions are reduced to ensure a good clearance fit with the<br />

mating spline. Tables in each section give full spline dimensions and data.

DesiGn PaRameteRs<br />

(continued)<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

General information<br />

understanding and minimizing system noise<br />

Tables in each section give sound levels for each frame size and displacement. Sound<br />

level data are collected at various operating speeds and pressures in a semi-anechoic<br />

chamber. Many factors contribute to the overall noise level of any application. Here is<br />

some information to help understand the nature of noise in fluid power systems, and<br />

some suggestions to help minimize it.<br />

Noise is transmitted in fluid power systems in two ways: as fluid borne noise, and<br />

structure borne noise.<br />

fluid-borne noise (pressure ripple or pulsation) is created as pumping elements<br />

discharge oil into the pump outlet. It is affected by the compressibility of the oil, and<br />

the pump’s ability to transition pumping elements from high to low pressure. Pulsations<br />

travel through the hydraulic lines at the speed of sound (about 1400 m/s [4600 ft/sec]<br />

in oil) until there is a change (such as an elbow) in the line. Thus, amplitude varies with<br />

overall line length and position.<br />

structure-borne noise is transmitted wherever the pump casing connects to the rest<br />

of the system. The way system components respond to excitation depends on their size,<br />

form, material, and mounting.<br />

System lines and pump mounting can amplify pump noise. Follow these suggestions to<br />

help minimize noise in your application:<br />

• Use flexible hoses.<br />

• Limit system line length.<br />

• If possible, optimize system line position to minimize noise.<br />

• If you must use steel plumbing, clamp the lines.<br />

• If you add additional support, use rubber mounts.<br />

• Test for resonants in the operating range, if possible avoid them.<br />

520L0519 • Rev FN • July 2009<br />

19

sizinG equations<br />

Flow<br />

Torque<br />

Power<br />

Variables<br />

20 520L0519 • Rev FN • July 2009<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

General information<br />

Use these equations to help choose the right pump size and displacement for your<br />

application:<br />

Based on si units<br />

Vg • n • ηv Output flow Q = (l/min)<br />

1000<br />

Vg • ∆p<br />

Input torque M = (N•m)<br />

20 • π • ηm M • n • π Q • ∆p<br />

Input power P = = (kW)<br />

30 000 600 • ηt SI units [US units]<br />

Based on us units<br />

V g = Displacement per revolution cm 3 /rev [in 3 /rev]<br />

p O = Outlet pressure bar [psi]<br />

p i = Inlet pressure bar [psi]<br />

∆p = p O - p i (system pressure) bar [psi]<br />

n = Speed min -1 (rpm)<br />

η v = Volumetric efficiency<br />

η m = Mechanical efficiency<br />

η t = Overall efficiency (η v • η m)<br />

Vg • n • ηv Output flow Q = (US gal/min)<br />

231<br />

Vg • ∆p<br />

Input torque M = (lbf•in)<br />

2 • π • ηm M • n • π Q • ∆p<br />

Input power P = = (hp)<br />

198 000 1714 • ηt

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

Frames L and K<br />

DesiGn Series 45 Frame L and K pumps have a single servo <strong>piston</strong> design with a cradletype<br />

swashplate set in polymer-coated journal bearings. A bias spring and internal<br />

forces increase swashplate angle. The servo <strong>piston</strong> decreases swashplate angle. Nine<br />

reciprocating <strong>piston</strong>s displace fluid from the pump inlet to the pump outlet as the<br />

cylinder block rotates on the pump input shaft. The block spring holds the <strong>piston</strong><br />

slippers to the swashplate via the slipper retainer. The cylinder block rides on a bimetal<br />

valve plate optimized for high volumetric efficiency and low noise. Tapered roller<br />

bearings support the input shaft and a viton lip-seal protects against shaft leaks.<br />

An adjustable one spool (PC only, not shown) or two spool (LS and remote PC) control<br />

senses system pressure and load pressure (LS controls). The control ports system<br />

pressure to the servo <strong>piston</strong> to control pump output flow.<br />

Frame K/L cross section<br />

LS adjustment screw<br />

PC adjustment screw<br />

Endcap<br />

(<strong>axial</strong> ported)<br />

Servo <strong>piston</strong><br />

Valve plate<br />

Block spring<br />

Tapered roller bearing<br />

Cylinder block<br />

520L0519 • Rev FN • July 2009<br />

LS control<br />

(attached to endcap)<br />

Piston<br />

LS spool<br />

PC spool<br />

Swashplate<br />

Slipper retainer<br />

Bias spring<br />

Tapered roller<br />

bearing<br />

Input shaft<br />

Shaft seal<br />

Slipper<br />

P101 659E<br />

21

22 520L0519 • Rev FN • July 2009<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

Frames L and K<br />

sPeCifiCations Features and options model<br />

For general operating<br />

parameters, including fluid<br />

viscosity, temperature, and<br />

inlet and case pressures,<br />

see page 13. For system<br />

design parameters,<br />

including installation,<br />

filtration, reservoir, and line<br />

velocities, see page 15.<br />

For definitions of pressure<br />

and speed ratings,<br />

see page 14. For more<br />

information on external<br />

shaft loads, see page 16;<br />

mounting flange loads,<br />

see page 17.<br />

For more information on<br />

noise levels, see page 19.<br />

feature unit L25C L30D K38C K45D<br />

Maximum Displacement cm³ [in³] 25 [1.53] 30 [1.83] 38 [2.32] 45 [2.75]<br />

Flow at rated speed (theoretical) l/min<br />

[US gal/min]<br />

Input torque at maximum<br />

displacement (theoretical)<br />

Mass moment of inertia of internal<br />

rotating components<br />

N•m/bar<br />

[lbf•in/1000 psi]<br />

kg•m²<br />

[slug•ft²]<br />

80<br />

[21]<br />

0.398<br />

[243]<br />

0.00169<br />

[0.00125]<br />

96<br />

[25.4]<br />

0.477<br />

[291]<br />

0.00161<br />

[0.00119]<br />

100.7<br />

[26.6]<br />

0.605<br />

[369]<br />

0.00184<br />

[0.00135]<br />

Weight Axial ports kg [lb] 19 [42]<br />

Radial ports 24 [53]<br />

Rotation Clockwise, Counterclockwise<br />

Mounting SAE-B<br />

Auxiliary mounting (See page 35) SAE-A, SAE-B, SAE-BB<br />

System ports (type) SAE O-ring boss<br />

System ports (location) Axial, Radial<br />

119.3<br />

[31.5]<br />

0.716<br />

[438]<br />

0.00203<br />

[0.00150]<br />

Control types (See page 29) EP, ED, AA, PC, Remote PC, LS, LS with internal bleed<br />

Shafts (See page 33) Splined 13 tooth, 15 tooth<br />

Tapered Ø 25.4 mm [1 in], 1:8 taper<br />

Ø 22.23 mm [0.875 in], 1:8 taper<br />

Straight Ø 22.23 mm [0.875 in]<br />

(short)<br />

Displacement limiters (See page 37) Optional, adjustable<br />

Ø 22.23 mm [0.875 in]<br />

(long)<br />

Ratings<br />

model<br />

Rating units L25C L30D K38C K45D<br />

Input speed¹ minimum min -1 (rpm) 500 500 500 500<br />

continuous 3200 3200 2650 2650<br />

maximum 3600 3600 2800 2800<br />

Working pressure continuous bar [psi] 260 [3770] 210 [3045] 260 [3770] 210 [3045]<br />

External shaft<br />

loads<br />

maximum 350 [5075] 300 [4350] 350 [5075] 300 [4350]<br />

External moment (M e) N•m [lbf•in] 61 [540] 61 [540] 76 [673] 76 [673]<br />

Thrust in (T in), out (T out) N [lbf ] 1000 [225] 1000 [225] 1200 [270] 1200 [270]<br />

Bearing life at 140 bar [2030 psi] B 10 hours 49 100 24 600 35 300 19 600<br />

Mounting flange<br />

load moments<br />

at 210 bar [3045 psi] 14 100 7230 11 400 6200<br />

at 260 bar [3770 psi] 6590 — 5870 —<br />

Vibratory (continuous) N•m [lbf•in] 1005 [8895]<br />

Shock (max) 3550 [31 420]<br />

1. Input speeds are valid at 1 bar absolute [0 in Hg vac] inlet pressure. See Inlet pressure vs. speed charts.<br />

Sound levels²<br />

dB(a) 210 bar [3045 psi] 260 bar [3770 psi]<br />

Pump model 1800 min -1 (rpm) Rated speed 1800 min -1 (rpm) Rated speed<br />

L25C 65 69 66 70<br />

L30D 66 70 — —<br />

K38C 65 70 66 71<br />

K45D 66 71 — —<br />

2. Sound data was collected in a semi-anechoic chamber. Values have been adjusted (-3 dB) to reflect anechoic levels.

PeRfoRmanCe<br />

L25C<br />

Flow and power data valid<br />

at 49°C [120°F] and viscosity<br />

of 17.8 mm²/sec [88 SUS].<br />

The chart on the right<br />

shows allowable inlet<br />

pressure and speed at<br />

various displacements.<br />

Greater speeds and lower<br />

inlet pressures are possible<br />

at reduced displacement.<br />

Operating outside of<br />

acceptable limits reduces<br />

pump life.<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

Frames L and K<br />

Flow vs. speed<br />

Flow (l/min)<br />

Input power vs. speed<br />

Power (kW)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Inlet pressure vs. speed<br />

Inlet Pressure (bar abs)<br />

50<br />

40<br />

30<br />

20<br />

10<br />

520L0519 • Rev FN • July 2009<br />

0<br />

0<br />

1.6<br />

1.5<br />

1.4<br />

1.3<br />

1.2<br />

1.1<br />

1.0<br />

0.9<br />

0.8<br />

0.7<br />

0 500 1000 1500 2000 2500 3000 3500<br />

-1<br />

Speed min (rpm)<br />

260 bar [3770 psi]<br />

210 bar [3045 psi]<br />

140 bar [2030 psi]<br />

0 500 1000 1500 2000 2500 3000 3500<br />

-1<br />

Speed min (rpm)<br />

0.6<br />

2800 3000 3200 3400 3600 3800 4000<br />

-1<br />

Shaft Speed min (rpm)<br />

100% 90% 80%<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

P101 970E<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

P101 971E<br />

8<br />

6<br />

4<br />

2<br />

0<br />

3<br />

6<br />

9<br />

(psi gauge)<br />

(in Hg vac)<br />

P101 972E<br />

Flow (US gal/min)<br />

Power (hp)<br />

23

PeRfoRmanCe<br />

L30D<br />

Flow and power data valid<br />

at 49°C [120°F] and viscosity<br />

of 17.8 mm²/sec [88 SUS].<br />

The chart on the right<br />

shows allowable inlet<br />

pressure and speed at<br />

various displacements.<br />

Greater speeds and lower<br />

inlet pressures are possible<br />

at reduced displacement.<br />

Operating outside of<br />

acceptable limits reduces<br />

pump life.<br />

24 520L0519 • Rev FN • July 2009<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

Frames L and K<br />

Flow vs. speed<br />

Flow (l/min)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Input power vs. speed<br />

Power (kW)<br />

0<br />

0 500 1000 1500 2000 2500 3000<br />

-1<br />

Speed min (rpm)<br />

50<br />

40<br />

30<br />

20<br />

10<br />

Inlet pressure vs. speed<br />

Inlet Pressure (bar abs)<br />

1.6<br />

1.5<br />

1.4<br />

1.3<br />

1.2<br />

1.1<br />

1.0<br />

0.9<br />

0.8<br />

0.7<br />

210 bar [3045 psi]<br />

140 bar [2030 psi]<br />

0<br />

0 500 1000 1500 2000 2500 3000<br />

-1<br />

Speed min (rpm)<br />

0.6<br />

2800 3000 3200 3400 3600 3800 4000<br />

-1<br />

Shaft Speed min (rpm)<br />

100% 90% 80%<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

P101 973E<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

P101 974E<br />

8<br />

6<br />

4<br />

2<br />

0<br />

3<br />

6<br />

9<br />

(psi gauge)<br />

(in Hg vac)<br />

P101 972E<br />

Flow (US gal/min)<br />

Power (hp)

PeRfoRmanCe<br />

K38C<br />

Flow and power data valid<br />

at 49°C [120°F] and viscosity<br />

of 17.8 mm²/sec [88 SUS].<br />

The chart on the right<br />

shows allowable inlet<br />

pressure and speed at<br />

various displacements.<br />

Greater speeds and lower<br />

inlet pressures are possible<br />

at reduced displacement.<br />

Operating outside of<br />

acceptable limits reduces<br />

pump life.<br />

Series 45 Axial Piston Open Circuit Pumps<br />

Technical Information<br />

Frames L and K<br />

Flow vs. speed<br />

Flow (l/min)<br />

125<br />

100<br />

75<br />

50<br />

25<br />

Input power vs. speed<br />

Power (kW)<br />

520L0519 • Rev FN • July 2009<br />

0<br />

0 500 1000 1500 2000 2500<br />

-1<br />

Speed min (rpm)<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

Inlet pressure vs. speed<br />

Inlet Pressure (bar abs)<br />

1.6<br />

1.5<br />

1.4<br />

1.3<br />

1.2<br />

1.1<br />

1.0<br />

0.9<br />

0.8<br />

0.7<br />

260 bar [3770 psi]<br />

140 bar [2030 psi]<br />

0<br />

0 500 1000 1500 2000 2500<br />

-1<br />

Speed min (rpm)<br />

0.6<br />

2200 2400 2600 2800 3000<br />

-1<br />

Shaft Speed min (rpm)<br />

100% 90% 80%<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

P101 975E<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

P101 976E<br />

8<br />

6<br />

4<br />

2<br />

0<br />

3<br />

6<br />

9<br />

(psi gauge)<br />

(in Hg vac)<br />

P101 977E<br />

Flow (US gal/min)<br />

Power (hp)<br />

25