The magazine - Lafarge

The magazine - Lafarge

The magazine - Lafarge

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

AGGREGATES:<br />

PRESERVING RESSOURCES<br />

To provide its customers with more added<br />

value, <strong>Lafarge</strong> Aggregates is making<br />

improvements by focusing on river transport,<br />

the complementary nature of its offering and<br />

waste management. In several areas,<br />

<strong>Lafarge</strong> Aggregates decided to use an<br />

alternative mode of river transportation<br />

to deliver materials from the production site<br />

and collect excavated material from its<br />

customers’ premises. Customers find the<br />

excavated material collection service<br />

useful and it also benefits <strong>Lafarge</strong> as it<br />

recycles the material to redevelop or fill in<br />

quarries. Moreover, river transport is an<br />

environmentally-friendly, competitive,<br />

consistent and safe mode of transport.<br />

Certain <strong>Lafarge</strong> Aggregates sites already<br />

crush the concrete from demolished<br />

buildings then resell it to road builders<br />

who use this recycled material in the<br />

capping layer.<br />

In the United Kingdom and France, another<br />

service, developed at the initiative<br />

of <strong>Lafarge</strong> Aggregates, involves delivering<br />

aggregates in large heavy-duty sacks which<br />

are then used as waste sacks on site. ■<br />

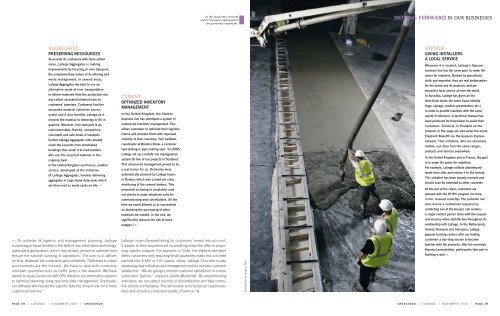

••• To optimize its logistics and management planning, <strong>Lafarge</strong><br />

is planning to boost its skills in the field of new information technology,<br />

particularly geolocation, which has already proven to optimize and<br />

ensure the smooth running of operations. <strong>The</strong> aim is to deliver<br />

on time, whatever the constraints and conditions. “Deliveries to urban<br />

environments are the trickiest. We have to deal with numerous<br />

unknown quantities such as traffic jams or the weather. We have<br />

started to equip our trucks with GPS linked to our information systems<br />

to optimize planning using real-time data management. Eventually,<br />

our software will include the specific features of each site for a more<br />

customized service."<br />

P A G E 2 8 | L A FA R G E | N O V E M B E R 2 0 0 7 | C R E S C E N D O<br />

CEMENT<br />

OPTIMIZED INVENTORY<br />

MANAGEMENT<br />

In the United Kingdom, the Cement<br />

business line has developed a system of<br />

outsourced inventory management. This<br />

allows customers to optimize their logistics<br />

chains and provides them with improved<br />

visibility of their inventory. Tom Caldwell,<br />

coordinator at Bredero Shaw, a customer<br />

specializing in pipe coating says: “In 2005,<br />

<strong>Lafarge</strong> set up a remote silo management<br />

system for two of our projects in Scotland.<br />

This outsourced management proved to be<br />

a real bonus for us. Deliveries were<br />

automatically planned by <strong>Lafarge</strong> teams<br />

in Dunbar, which also carried out close<br />

monitoring of the cement tankers. This<br />

prevented us having to constantly carry<br />

out checks or make telephone calls for<br />

commissioning and cancellations. All the<br />

time we saved allowed us to concentrate<br />

on planning the purchasing of other<br />

materials we needed. In the end, we<br />

significantly reduced the risk of stock<br />

outages." ■<br />

In the ready-mix concrete<br />

sector, transport and logistics<br />

are extremely important.<br />

<strong>Lafarge</strong> moves forward taking its customers’ needs into account.<br />

It adapts to their requirements by breaking down the offer or proposing<br />

specific support. For example, in Chile, the Valdivia site team<br />

offers customers only requiring small quantities ready-mix concrete<br />

packed into 0.5m 3 or 1m 3 plastic cases. <strong>Lafarge</strong> Concrete is also<br />

developing new indicators and management tools to increase customer<br />

satisfaction. “We are going to monitor customer satisfaction in a more<br />

systematic fashion,” explains Gaëlle Monteiller. By implementing<br />

indicators, we can detect sources of dissatisfaction and take corrective<br />

actions immediately. This will enable us to boost our responsiveness<br />

and ensure a consistent quality of service.” ■<br />

© Hamilton de Oliveira / REA<br />

MOVING FORWARD IN OUR BUSINESSES<br />

GYPSUM<br />

GIVING INSTALLERS<br />

A LOCAL SERVICE<br />

Wherever it is located, <strong>Lafarge</strong>’s Gypsum<br />

business line has the same goal: to make life<br />

easier for installers. Backed by specialized<br />

skills and expertise, they are real ambassadors<br />

for the brand and its products, and are<br />

ensured a local service all over the world.<br />

In Australia, <strong>Lafarge</strong> has given all the<br />

franchised stores the same visual identity<br />

(logo, signage, product presentation, etc.)<br />

in order to provide installers with the same<br />

points of reference. A technical manual has<br />

been produced for franchisees to assist their<br />

customers. Similarly, in Thailand all the<br />

products in the range are sold under the brand<br />

Elephant Board® via the Gypsum Express<br />

network. Thai installers, who are extremely<br />

mobile, can thus find the same ranges,<br />

products and services everywhere.<br />

In the United Kingdom and in France, the goal<br />

is to make life easier for installers.<br />

For example, <strong>Lafarge</strong> collects plasterboard<br />

waste from sites and returns it to the factory.<br />

This initiative has been warmly received and<br />

should soon be extended to other countries.<br />

At the end of the chain, customers are<br />

pleased with the OTIFIC program (on time,<br />

in full, invoiced correctly). <strong>The</strong> customer can<br />

also receive a customized response by<br />

contacting one of the Group’s call centers:<br />

a single contact person deals with the request<br />

and ensures entire statisfaction throughout its<br />

relationship with <strong>Lafarge</strong>. In the Netherlands,<br />

Ireland, Romania and Indonesia, <strong>Lafarge</strong><br />

gypsum training centers offer our trading<br />

customers a day-long session to become<br />

familiar with the products: after the morning’s<br />

theorical presentation, participants take part in<br />

building a wall. ■<br />

C R E S C E N D O | L A FA R G E | N O V E M B E R 2 0 0 7 | P A G E 2 9