Baytec®MAX - BaySystems - customized polyurethanes - Bayer ...

Baytec®MAX - BaySystems - customized polyurethanes - Bayer ...

Baytec®MAX - BaySystems - customized polyurethanes - Bayer ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

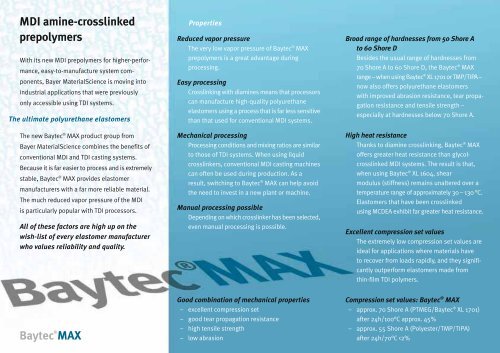

MDI amine-crosslinked<br />

prepolymers<br />

With its new MDI prepolymers for higher-performance,<br />

easy-to-manufacture system components,<br />

<strong>Bayer</strong> MaterialScience is moving into<br />

industrial applications that were previously<br />

only accessible using TDI systems.<br />

The ultimate polyurethane elastomers<br />

The new Baytec ® MAX product group from<br />

<strong>Bayer</strong> MaterialScience combines the benefits of<br />

conventional MDI and TDI casting systems.<br />

Because it is far easier to process and is extremely<br />

stable, Baytec ® MAX provides elastomer<br />

manufacturers with a far more reliable material.<br />

The much reduced vapor pressure of the MDI<br />

is particularly popular with TDI processors.<br />

All of these factors are high up on the<br />

wish-list of every elastomer manufacturer<br />

who values reliability and quality.<br />

Properties<br />

Reduced vapor pressure<br />

The very low vapor pressure of Baytec ® MAX<br />

prepolymers is a great advantage during<br />

processing.<br />

Easy processing<br />

Crosslinking with diamines means that processors<br />

can manufacture high-quality polyurethane<br />

elastomers using a process that is far less sensitive<br />

than that used for conventional MDI systems.<br />

Mechanical processing<br />

Processing conditions and mixing ratios are similar<br />

to those of TDI systems. When using liquid<br />

crosslinkers, conventional MDI casting machines<br />

can often be used during production. As a<br />

result, switching to Baytec ® MAX can help avoid<br />

the need to invest in a new plant or machine.<br />

Manual processing possible<br />

Depending on which crosslinker has been selected,<br />

even manual processing is possible.<br />

Good combination of mechanical properties<br />

– excellent compression set<br />

– good tear propagation resistance<br />

– high tensile strength<br />

– low abrasion<br />

Broad range of hardnesses from 50 Shore A<br />

to 60 Shore D<br />

Besides the usual range of hardnesses from<br />

70 Shore A to 60 Shore D, the Baytec ® MAX<br />

range – when using Baytec ® XL 1701 or TMP/TIPA –<br />

now also offers polyurethane elastomers<br />

with improved abrasion resistance, tear propagation<br />

resistance and tensile strength –<br />

especially at hardnesses below 70 Shore A.<br />

High heat resistance<br />

Thanks to diamine crosslinking, Baytec ® MAX<br />

offers greater heat resistance than glycolcrosslinked<br />

MDI systems. The result is that,<br />

when using Baytec ® XL 1604, shear<br />

modulus (stiffness) remains unaltered over a<br />

temperature range of approximately 30 – 130 °C.<br />

Elastomers that have been crosslinked<br />

using MCDEA exhibit far greater heat resistance.<br />

Excellent compression set values<br />

The extremely low compression set values are<br />

ideal for applications where materials have<br />

to recover from loads rapidly, and they significantly<br />

outperform elastomers made from<br />

thin-film TDI polymers.<br />

Compression set values: Baytec ® MAX<br />

– approx. 70 Shore A (PTMEG/Baytec ® XL 1701)<br />

after 24h/100°C approx. 45%<br />

– approx. 55 Shore A (Polyester/TMP/TIPA)<br />

after 24h/70°C