Paints and Coatings Auxiliaries for the coating of surfaces - Clariant

Paints and Coatings Auxiliaries for the coating of surfaces - Clariant

Paints and Coatings Auxiliaries for the coating of surfaces - Clariant

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Examples <strong>of</strong> <strong>for</strong>mulations<br />

<strong>for</strong> special applications<br />

Matting<br />

Nitrocellulose lacquers<br />

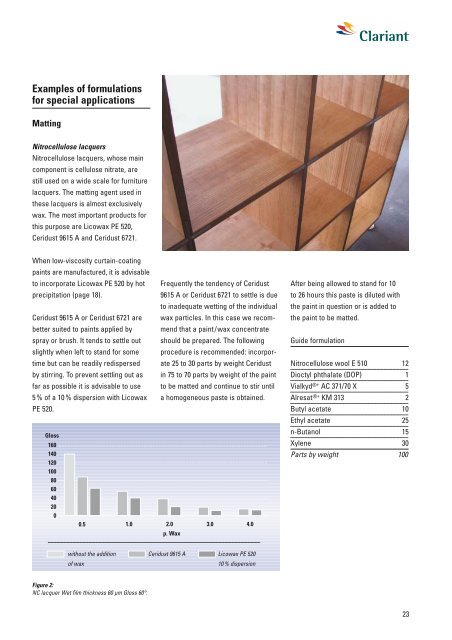

Nitrocellulose lacquers, whose main<br />

component is cellulose nitrate, are<br />

still used on a wide scale <strong>for</strong> furniture<br />

lacquers. The matting agent used in<br />

<strong>the</strong>se lacquers is almost exclusively<br />

wax. The most important products <strong>for</strong><br />

this purpose are Licowax PE 520,<br />

Ceridust 9615 A <strong>and</strong> Ceridust 6721.<br />

When low-viscosity curtain-<strong>coating</strong><br />

paints are manufactured, it is advisable<br />

to incorporate Licowax PE 520 by hot<br />

precipitation (page 18).<br />

Ceridust 9615 A or Ceridust 6721 are<br />

better suited to paints applied by<br />

spray or brush. It tends to settle out<br />

slightly when left to st<strong>and</strong> <strong>for</strong> some<br />

time but can be readily redispersed<br />

by stirring. To prevent settling out as<br />

far as possible it is advisable to use<br />

5 % <strong>of</strong> a 10 % dispersion with Licowax<br />

PE 520.<br />

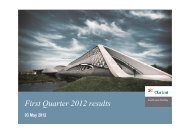

Gloss<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

0.5<br />

Frequently <strong>the</strong> tendency <strong>of</strong> Ceridust<br />

9615 A or Ceridust 6721 to settle is due<br />

to inadequate wetting <strong>of</strong> <strong>the</strong> individual<br />

wax particles. In this case we recommend<br />

that a paint /wax concentrate<br />

should be prepared. The following<br />

procedure is recommended: incorporate<br />

25 to 30 parts by weight Ceridust<br />

in 75 to 70 parts by weight <strong>of</strong> <strong>the</strong> paint<br />

to be matted <strong>and</strong> continue to stir until<br />

a homogeneous paste is obtained.<br />

1.0 2.0<br />

p. Wax<br />

3.0<br />

4.0<br />

without <strong>the</strong> addition Ceridust 9615 A Licowax PE 520<br />

<strong>of</strong> wax 10 % dispersion<br />

Figure 2:<br />

NC lacquer Wet film thickness 60 µm Gloss 60°.<br />

After being allowed to st<strong>and</strong> <strong>for</strong> 10<br />

to 26 hours this paste is diluted with<br />

<strong>the</strong> paint in question or is added to<br />

<strong>the</strong> paint to be matted.<br />

Guide <strong>for</strong>mulation<br />

Nitrocellulose wool E 510 12<br />

Dioctyl phthalate (DOP) 1<br />

Vialkyd ®+ AC 371/70 X 5<br />

Alresat ®+ KM 313 2<br />

Butyl acetate 10<br />

Ethyl acetate 25<br />

n-Butanol 15<br />

Xylene 30<br />

Parts by weight 100<br />

23