Cover-Story Knorr-Bremse in North America Location Joint Venture ...

Cover-Story Knorr-Bremse in North America Location Joint Venture ...

Cover-Story Knorr-Bremse in North America Location Joint Venture ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

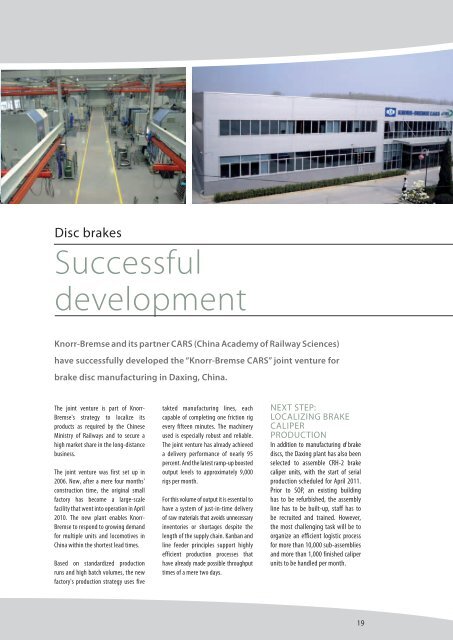

disc brakes<br />

Successful<br />

development<br />

<strong>Knorr</strong>-<strong>Bremse</strong> and its partner CARS (Ch<strong>in</strong>a Academy of Railway Sciences)<br />

have successfully developed the “<strong>Knorr</strong>-<strong>Bremse</strong> CARS” jo<strong>in</strong>t venture for<br />

brake disc manufactur<strong>in</strong>g <strong>in</strong> Dax<strong>in</strong>g, Ch<strong>in</strong>a.<br />

The jo<strong>in</strong>t venture is part of <strong>Knorr</strong>-<br />

<strong>Bremse</strong>'s strategy to localize its<br />

products as required by the Ch<strong>in</strong>ese<br />

M<strong>in</strong>istry of Railways and to secure a<br />

high market share <strong>in</strong> the long-distance<br />

bus<strong>in</strong>ess.<br />

The jo<strong>in</strong>t venture was first set up <strong>in</strong><br />

2006. Now, after a mere four months'<br />

construction time, the orig<strong>in</strong>al small<br />

factory has become a large-scale<br />

facility that went <strong>in</strong>to operation <strong>in</strong> April<br />

2010. The new plant enables <strong>Knorr</strong>-<br />

<strong>Bremse</strong> to respond to grow<strong>in</strong>g demand<br />

for multiple units and locomotives <strong>in</strong><br />

Ch<strong>in</strong>a with<strong>in</strong> the shortest lead times.<br />

Based on standardized production<br />

runs and high batch volumes, the new<br />

factory's production strategy uses five<br />

takted manufactur<strong>in</strong>g l<strong>in</strong>es, each<br />

capable of complet<strong>in</strong>g one friction rig<br />

every fifteen m<strong>in</strong>utes. The mach<strong>in</strong>ery<br />

used is especially robust and reliable.<br />

The jo<strong>in</strong>t venture has already achieved<br />

a delivery performance of nearly 95<br />

percent. And the latest ramp-up boosted<br />

output levels to approximately 9,000<br />

rigs per month.<br />

For this volume of output it is essential to<br />

have a system of just-<strong>in</strong>-time delivery<br />

of raw materials that avoids unnecessary<br />

<strong>in</strong>ventories or shortages despite the<br />

length of the supply cha<strong>in</strong>. Kanban and<br />

l<strong>in</strong>e feeder pr<strong>in</strong>ciples support highly<br />

efficient production processes that<br />

have already made possible throughput<br />

times of a mere two days.<br />

neXt step:<br />

locAlIzIng BRAKe<br />

cAlIpeR<br />

pRoductIon<br />

In addition to manufactur<strong>in</strong>g of brake<br />

discs, the Dax<strong>in</strong>g plant has also been<br />

selected to assemble CRH-2 brake<br />

caliper units, with the start of serial<br />

production scheduled for April 2011.<br />

Prior to SOP, an exist<strong>in</strong>g build<strong>in</strong>g<br />

has to be refurbished, the assembly<br />

l<strong>in</strong>e has to be built-up, staff has to<br />

be recruited and tra<strong>in</strong>ed. However,<br />

the most challeng<strong>in</strong>g task will be to<br />

organize an efficient logistic process<br />

for more than 10,000 sub-assemblies<br />

and more than 1,000 f<strong>in</strong>ished caliper<br />

units to be handled per month.<br />

19

![Geschäftsbericht 2010 [PDF, 23 MB] - Knorr-Bremse](https://img.yumpu.com/9723397/1/185x260/geschaftsbericht-2010-pdf-23-mb-knorr-bremse.jpg?quality=85)