Technical and Research Bulletin 3-51 - Amazon Web Services

Technical and Research Bulletin 3-51 - Amazon Web Services

Technical and Research Bulletin 3-51 - Amazon Web Services

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

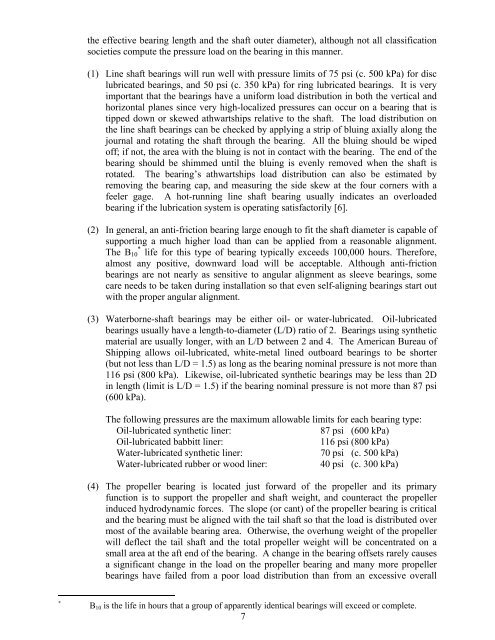

the effective bearing length <strong>and</strong> the shaft outer diameter), although not all classification<br />

societies compute the pressure load on the bearing in this manner.<br />

(1) Line shaft bearings will run well with pressure limits of 75 psi (c. 500 kPa) for disc<br />

lubricated bearings, <strong>and</strong> 50 psi (c. 350 kPa) for ring lubricated bearings. It is very<br />

important that the bearings have a uniform load distribution in both the vertical <strong>and</strong><br />

horizontal planes since very high-localized pressures can occur on a bearing that is<br />

tipped down or skewed athwartships relative to the shaft. The load distribution on<br />

the line shaft bearings can be checked by applying a strip of bluing axially along the<br />

journal <strong>and</strong> rotating the shaft through the bearing. All the bluing should be wiped<br />

off; if not, the area with the bluing is not in contact with the bearing. The end of the<br />

bearing should be shimmed until the bluing is evenly removed when the shaft is<br />

rotated. The bearing’s athwartships load distribution can also be estimated by<br />

removing the bearing cap, <strong>and</strong> measuring the side skew at the four corners with a<br />

feeler gage. A hot-running line shaft bearing usually indicates an overloaded<br />

bearing if the lubrication system is operating satisfactorily [6].<br />

(2) In general, an anti-friction bearing large enough to fit the shaft diameter is capable of<br />

supporting a much higher load than can be applied from a reasonable alignment.<br />

The B10 * life for this type of bearing typically exceeds 100,000 hours. Therefore,<br />

almost any positive, downward load will be acceptable. Although anti-friction<br />

bearings are not nearly as sensitive to angular alignment as sleeve bearings, some<br />

care needs to be taken during installation so that even self-aligning bearings start out<br />

with the proper angular alignment.<br />

(3) Waterborne-shaft bearings may be either oil- or water-lubricated. Oil-lubricated<br />

bearings usually have a length-to-diameter (L/D) ratio of 2. Bearings using synthetic<br />

material are usually longer, with an L/D between 2 <strong>and</strong> 4. The American Bureau of<br />

Shipping allows oil-lubricated, white-metal lined outboard bearings to be shorter<br />

(but not less than L/D = 1.5) as long as the bearing nominal pressure is not more than<br />

116 psi (800 kPa). Likewise, oil-lubricated synthetic bearings may be less than 2D<br />

in length (limit is L/D = 1.5) if the bearing nominal pressure is not more than 87 psi<br />

(600 kPa).<br />

The following pressures are the maximum allowable limits for each bearing type:<br />

Oil-lubricated synthetic liner: 87 psi (600 kPa)<br />

Oil-lubricated babbitt liner: 116 psi (800 kPa)<br />

Water-lubricated synthetic liner: 70 psi (c. 500 kPa)<br />

Water-lubricated rubber or wood liner: 40 psi (c. 300 kPa)<br />

(4) The propeller bearing is located just forward of the propeller <strong>and</strong> its primary<br />

function is to support the propeller <strong>and</strong> shaft weight, <strong>and</strong> counteract the propeller<br />

induced hydrodynamic forces. The slope (or cant) of the propeller bearing is critical<br />

<strong>and</strong> the bearing must be aligned with the tail shaft so that the load is distributed over<br />

most of the available bearing area. Otherwise, the overhung weight of the propeller<br />

will deflect the tail shaft <strong>and</strong> the total propeller weight will be concentrated on a<br />

small area at the aft end of the bearing. A change in the bearing offsets rarely causes<br />

a significant change in the load on the propeller bearing <strong>and</strong> many more propeller<br />

bearings have failed from a poor load distribution than from an excessive overall<br />

*<br />

B10 is the life in hours that a group of apparently identical bearings will exceed or complete.<br />

7